Professional Documents

Culture Documents

Excavation and Backfill

Excavation and Backfill

Uploaded by

Amanda CervantesCopyright:

Available Formats

You might also like

- C902Document3 pagesC902Rufo CascoNo ratings yet

- Astm C1491Document3 pagesAstm C1491BeymerBustamanteMejíaNo ratings yet

- An Introduction To Rigid Pavement DesignDocument24 pagesAn Introduction To Rigid Pavement DesignSheikh Nouman Mohsin Ramzi100% (1)

- Saudi Aramco Civil CBT Inspector Qualification Test: Excavation and BackfillingDocument17 pagesSaudi Aramco Civil CBT Inspector Qualification Test: Excavation and BackfillingUSMAN NAGTHAN100% (2)

- Aptransco 220kV & 132kV Lines & SS QAP FormatDocument89 pagesAptransco 220kV & 132kV Lines & SS QAP FormatArogya Raju Pudhota100% (1)

- FHWA-HI-99-025 Drilled Shafts Construction Procedures and Design MethodsDocument784 pagesFHWA-HI-99-025 Drilled Shafts Construction Procedures and Design Methodssean_dibartolo3668No ratings yet

- Analysis of Single Piles Under Lateral LoadingDocument181 pagesAnalysis of Single Piles Under Lateral LoadingAmanda CervantesNo ratings yet

- Decentralization, Corruption & Social Capital - Sten Widmalm - 2007 PDFDocument232 pagesDecentralization, Corruption & Social Capital - Sten Widmalm - 2007 PDFAji DeniNo ratings yet

- Kumpulan Mesin PancangDocument48 pagesKumpulan Mesin PancangFajrin M. NatsirNo ratings yet

- Pre Exam Review 21 653 TanksDocument6 pagesPre Exam Review 21 653 TanksBassam AbdelazeemNo ratings yet

- Raft Foundations Bearing Capacity and Settlement Report PDFDocument9 pagesRaft Foundations Bearing Capacity and Settlement Report PDFixynnuddoNo ratings yet

- Sti p3 InstallationDocument6 pagesSti p3 InstallationnjkasdncjkdNo ratings yet

- Installing Factory-Made Corrugated Aluminum Culverts and Storm Sewer PipeDocument6 pagesInstalling Factory-Made Corrugated Aluminum Culverts and Storm Sewer PipeROHITNo ratings yet

- Traduccion Apendice B API 650Document22 pagesTraduccion Apendice B API 650Miguel Felipe PovedaNo ratings yet

- Plate Load Soil Test ReportDocument5 pagesPlate Load Soil Test ReportJoseph Cloyd L. LamberteNo ratings yet

- Sti R912Document4 pagesSti R912Mauricio AdameNo ratings yet

- Api 650Document16 pagesApi 650cfpc10459No ratings yet

- Api Asphalt TankDocument18 pagesApi Asphalt Tankgen_lethal100% (1)

- AssignmentDocument32 pagesAssignmentsyedNo ratings yet

- HCL Fuel Tank SpecsDocument62 pagesHCL Fuel Tank SpecsM.Sreeram SanjayNo ratings yet

- Exam July 2021Document16 pagesExam July 202101280724321 Helmy100% (1)

- Tech Spec 2 ConstructionDocument8 pagesTech Spec 2 ConstructionHuascar Medrano LazarteNo ratings yet

- Choice of Foundation For BrigdesDocument15 pagesChoice of Foundation For BrigdesSamuel AntobamNo ratings yet

- Compliance SheetDocument4 pagesCompliance Sheetمحمد عبدالرحيمNo ratings yet

- Is.2911.1.2.2010 Part3Document6 pagesIs.2911.1.2.2010 Part3Dixit JariwalaNo ratings yet

- Tank Foundation 650 554Document16 pagesTank Foundation 650 554Mayuresh Kudve100% (1)

- Field Compaction ControlDocument2 pagesField Compaction ControlEftikarNo ratings yet

- TANK FoundationDocument6 pagesTANK FoundationUsama AhmedNo ratings yet

- Pages From (BS en 14015 - 2004) Specification For The Design and Manufacture of Site Built - DecryptedDocument8 pagesPages From (BS en 14015 - 2004) Specification For The Design and Manufacture of Site Built - Decryptedali niknamiNo ratings yet

- IRS - Well Pile Foundation Code PDFDocument17 pagesIRS - Well Pile Foundation Code PDFtipsypigNo ratings yet

- IS2911 (Part1sec2) 2005draft PDFDocument35 pagesIS2911 (Part1sec2) 2005draft PDFkanagarajodishaNo ratings yet

- UL-142 R912 Installation InstructionsDocument4 pagesUL-142 R912 Installation InstructionsRodrigoNo ratings yet

- Crib WallDocument11 pagesCrib Walltanyt123No ratings yet

- TDI41 Tank Inspection Repair & Alteration API 653 Sec 9Document13 pagesTDI41 Tank Inspection Repair & Alteration API 653 Sec 9Faizal Sattu100% (2)

- Quality Assurance PlanDocument89 pagesQuality Assurance PlanSai KumarNo ratings yet

- Outlet ProtectionDocument6 pagesOutlet ProtectionalikoleiniNo ratings yet

- Trench Cuts and Restorations Across Roadways: Flexible Pavement Cut Rigid Pavement CutDocument3 pagesTrench Cuts and Restorations Across Roadways: Flexible Pavement Cut Rigid Pavement CutIqueline JacqelineNo ratings yet

- Cement Stabilized Base CourseDocument6 pagesCement Stabilized Base CourseAmosNo ratings yet

- 2-1-9 - The Processing of High Strength Prestressed Spun ConcreteDocument5 pages2-1-9 - The Processing of High Strength Prestressed Spun ConcreteChan Kin CheungNo ratings yet

- Cablemate Installation GuideDocument16 pagesCablemate Installation Guideawaisnazir11No ratings yet

- C1568 08 (2013)Document6 pagesC1568 08 (2013)diego rodriguez100% (2)

- Astm C12Document7 pagesAstm C12omarguillermogarzon100% (1)

- Aptransco 220.132kV Lines-SS QAP & FormatDocument89 pagesAptransco 220.132kV Lines-SS QAP & Formatbharat_ravulapalli75% (4)

- 6.1 Pavement: 6.1.1 Materials - Base Course, Sub-Base, Subgrade, and Select FillDocument8 pages6.1 Pavement: 6.1.1 Materials - Base Course, Sub-Base, Subgrade, and Select FillEma WeismanNo ratings yet

- Abandonment Standards: Special CasesDocument6 pagesAbandonment Standards: Special CasesAntonio DiabanzaNo ratings yet

- KjfkjeDocument24 pagesKjfkjeaefNo ratings yet

- Chapter 62C-27 Conservation of Oil and Gas: DrillingDocument4 pagesChapter 62C-27 Conservation of Oil and Gas: DrillingAry RachmanNo ratings yet

- Astm C845 PDFDocument3 pagesAstm C845 PDFJohn Richard NelsonNo ratings yet

- Well Pile Foundation PDFDocument17 pagesWell Pile Foundation PDFlingamkumarNo ratings yet

- C1479Document8 pagesC1479Jesús Ernesto Flores RamírezNo ratings yet

- SA Standard NotesDocument22 pagesSA Standard Notesatiq0592No ratings yet

- Installing Vitrified Clay Pipe Lines: Standard Practice ForDocument9 pagesInstalling Vitrified Clay Pipe Lines: Standard Practice Formhamed1No ratings yet

- Exercise 4 Check Dam PDFDocument5 pagesExercise 4 Check Dam PDFBimleshKumarNo ratings yet

- IS218.02B - Suggested Specification For Concrete Parking AreasDocument2 pagesIS218.02B - Suggested Specification For Concrete Parking AreasfarhanNo ratings yet

- Sodium Hypo FRP SpecDocument6 pagesSodium Hypo FRP SpecZeroRecoNo ratings yet

- C125 PDFDocument4 pagesC125 PDFAntu IsabelNo ratings yet

- MOS - Flexible Pavement RehabilitationDocument6 pagesMOS - Flexible Pavement RehabilitationcdipcinNo ratings yet

- Dewatering Revised Oct 98Document11 pagesDewatering Revised Oct 98Mahmoud BreamaNo ratings yet

- 1999Spr GeblerDocument5 pages1999Spr Geblerwagzarus14No ratings yet

- Installation of Precast Reinforced Concrete Monolithic Box Sections For Culverts, Storm Drains, and SewersDocument4 pagesInstallation of Precast Reinforced Concrete Monolithic Box Sections For Culverts, Storm Drains, and SewersEligio Antonio CerdaNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Levee Safety Update: Jamie Mcvicker Named Usace Civilian of The YearDocument6 pagesLevee Safety Update: Jamie Mcvicker Named Usace Civilian of The YearAmanda CervantesNo ratings yet

- Model 640 With Night SightsDocument1 pageModel 640 With Night SightsAmanda CervantesNo ratings yet

- Levee Portfolio Report: U.S. Army Corps of EngineersDocument136 pagesLevee Portfolio Report: U.S. Army Corps of EngineersAmanda CervantesNo ratings yet

- Levee Safety Update: A Warm Welcome To Phoebe Percell, P.E., Chief Dam and Levee Safety Engineering BranchDocument9 pagesLevee Safety Update: A Warm Welcome To Phoebe Percell, P.E., Chief Dam and Levee Safety Engineering BranchAmanda CervantesNo ratings yet

- Seismic Design of Bridges With Seat-Type Abutments Considering The Participation of The Abutments During Earthquake ExcitationDocument10 pagesSeismic Design of Bridges With Seat-Type Abutments Considering The Participation of The Abutments During Earthquake ExcitationAmanda CervantesNo ratings yet

- DRAFT TM Design Criteria Considerations March 2012Document56 pagesDRAFT TM Design Criteria Considerations March 2012Amanda CervantesNo ratings yet

- Foreword: No Policy or Substantive Changes Have Been Incorporated in EP 1110-2-18Document44 pagesForeword: No Policy or Substantive Changes Have Been Incorporated in EP 1110-2-18Amanda CervantesNo ratings yet

- Levee Safety Update: National Levee Inventory & Review EffortDocument8 pagesLevee Safety Update: National Levee Inventory & Review EffortAmanda CervantesNo ratings yet

- Construction Dewatering and Groundwater ControlDocument2 pagesConstruction Dewatering and Groundwater ControlAmanda CervantesNo ratings yet

- Levee S!Fety Upd!Te: US!E Levee Portfolio ReportDocument6 pagesLevee S!Fety Upd!Te: US!E Levee Portfolio ReportAmanda CervantesNo ratings yet

- Nhi16009 v3Document299 pagesNhi16009 v3Amanda CervantesNo ratings yet

- Design and Construction of Driven Pile Foundations - Volume 1 (Nhi16009 - v1)Document559 pagesDesign and Construction of Driven Pile Foundations - Volume 1 (Nhi16009 - v1)Amanda Cervantes100% (1)

- Design and Construction of Driven Pile Foundations - Volume 1 (Nhi16009 - v1)Document559 pagesDesign and Construction of Driven Pile Foundations - Volume 1 (Nhi16009 - v1)Amanda Cervantes100% (1)

- NCHRP REPORT 611 Seismic Analysis and Design of Retaining Walls Buried Structures Slopes and EmbankmentsDocument311 pagesNCHRP REPORT 611 Seismic Analysis and Design of Retaining Walls Buried Structures Slopes and EmbankmentsQuangNguyenVanNo ratings yet

- Guidelines For Earthwork Construction Control Testing of Gravelly SoilsDocument27 pagesGuidelines For Earthwork Construction Control Testing of Gravelly SoilsAmanda CervantesNo ratings yet

- Transient Analyses of Interceptor TrenchDocument9 pagesTransient Analyses of Interceptor TrenchAmanda CervantesNo ratings yet

- Soil Nailing Field Inspectors Manual FHWA SA 93 068Document124 pagesSoil Nailing Field Inspectors Manual FHWA SA 93 068Amanda CervantesNo ratings yet

- FHWA Guidelines For Preparing Engineer's Estimate Bid Reviews and Evaluation (2004)Document18 pagesFHWA Guidelines For Preparing Engineer's Estimate Bid Reviews and Evaluation (2004)Amanda CervantesNo ratings yet

- 2009 Impoundment Design ManualDocument869 pages2009 Impoundment Design ManualAmanda CervantesNo ratings yet

- BoaDocument90 pagesBoadoxedwatsonNo ratings yet

- The Position of The Bioeconomy in The NetherlandsDocument8 pagesThe Position of The Bioeconomy in The NetherlandsMaryam AsdNo ratings yet

- All About Zookeeper and ClickHouse KeeperDocument45 pagesAll About Zookeeper and ClickHouse KeeperomyeudaihiepNo ratings yet

- Identifikasi Miskonsepsi Materi IPA Kelas VII SMP N 1 Gunung Sugih Lampung TengahDocument12 pagesIdentifikasi Miskonsepsi Materi IPA Kelas VII SMP N 1 Gunung Sugih Lampung TengahMawarniwati Waruwu Undiksha 2019No ratings yet

- Rfa Ar04Document5 pagesRfa Ar04cuanicochorielynjuviNo ratings yet

- Practical Tools For Attackers and Defenders: 6.1 Steps To Launch An AttackDocument42 pagesPractical Tools For Attackers and Defenders: 6.1 Steps To Launch An AttackRaghu Vamsi PNo ratings yet

- 56ef945cea29b 1312621 SampleDocument16 pages56ef945cea29b 1312621 SamplepanditrulesNo ratings yet

- Capitol Lagoon Complex: Existing Hard DataDocument6 pagesCapitol Lagoon Complex: Existing Hard DataNeanderthalNo ratings yet

- Indian ClimateDocument7 pagesIndian ClimatePrakash Kumar Kumar100% (1)

- Lva1 App6892Document146 pagesLva1 App6892Adam Shahabuddin Abdul RazakNo ratings yet

- Irp Test-1 (07!12!17) (Solution) (Jee Mains) Code-AbDocument20 pagesIrp Test-1 (07!12!17) (Solution) (Jee Mains) Code-Abvejoshi21699No ratings yet

- GU 0009. Leisegang Colposcope Directions ForUseDocument44 pagesGU 0009. Leisegang Colposcope Directions ForUseGabriela Ponce GuerrerpNo ratings yet

- Anime and MangaDocument14 pagesAnime and Mangapuspo agungNo ratings yet

- Body Repairs General Body RepairsDocument87 pagesBody Repairs General Body RepairsergdegNo ratings yet

- Huff ManDocument4 pagesHuff Mangopal_svsemails8998No ratings yet

- SIKA Marine 2016Document164 pagesSIKA Marine 2016pcatruongNo ratings yet

- "134-S" Series: Optional Gasket KitDocument45 pages"134-S" Series: Optional Gasket KitginoNo ratings yet

- Improving Machine Translation With Conditional Sequence Generative Adversarial NetsDocument10 pagesImproving Machine Translation With Conditional Sequence Generative Adversarial Netsmihai ilieNo ratings yet

- BNPL and Store CardsDocument13 pagesBNPL and Store CardsTrader CatNo ratings yet

- Pratik ResumeDocument2 pagesPratik ResumeHarshada lawaleNo ratings yet

- Lesson 2 - Victimology and VictimDocument19 pagesLesson 2 - Victimology and VictimHernandez JairineNo ratings yet

- Overview of Extended RealityDocument7 pagesOverview of Extended RealityAkul DevtaNo ratings yet

- 2exam LogisticsDocument6 pages2exam LogisticsJessica LaguatanNo ratings yet

- Exoglove Research PaperDocument8 pagesExoglove Research Papersanket jainNo ratings yet

- Set 6: Knowledge Representation: The Propositional Calculus: Chapter 7 R&NDocument85 pagesSet 6: Knowledge Representation: The Propositional Calculus: Chapter 7 R&NQaisar HussainNo ratings yet

- Integrated Budget & Accounting System (iBAS++)Document46 pagesIntegrated Budget & Accounting System (iBAS++)Hamanta RoyNo ratings yet

- SshaDocument13 pagesSshaFitahiana Mickaël RANDRIANARIMALALANo ratings yet

- Choice of Therapy in PrimaryDocument19 pagesChoice of Therapy in PrimaryThiago SartiNo ratings yet

- List of Doctors Clinics HospitalsDocument6 pagesList of Doctors Clinics HospitalsAjay Kaushik50% (2)

Excavation and Backfill

Excavation and Backfill

Uploaded by

Amanda CervantesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Excavation and Backfill

Excavation and Backfill

Uploaded by

Amanda CervantesCopyright:

Available Formats

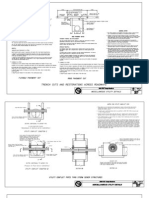

EXCAVATION AND BACKFILL

1. General. Excavation and backfill in the critical area of a flood control project could have

a direct impact on the stability of the flood control project. Improper excavation in the levee

embankment or in the critical area can create unstable slopes and slope failures, which damage

the levee embankment and weaken the flood protection structure. Additional damages to the

levee embankment or flood protection structure can also be caused by underseepage conditions

associated with piping and heave. This removal of material from the flood control structure

foundation (piping) can ultimately produce collapse of a levee embankment or floodwall. All

excavation and backfill activities within the critical area are to be reviewed and approved by the

COE and the local sponsor before construction begins.

2. Underseepage. Excavation stability may be influenced by underseepage. Underseepage

considerations include methods of determining of the hydraulic grade line through the levee and

through the foundation material, which are used for uplift calculations of proposed structures and

for stability analysis for excavations and temporary flood control. Underseepage analysis should

conform to the recommendations and method summarized in the topic UNDERSEEPAGE.

3. Excavation Requirements. All excavations must meet Federal, State and local criteria,

COE safety manual and OSHA criteria. Supplementary requirements for the excavation and

backfill in the critical area are as follows:

3.1. Excavation in levee embankments below the freeboard zone must be analyzed to

determine the stability of the embankment. The analysis should include the assumptions used,

basis for selection of soil parameters, and the failure surfaces and associated factors of safety.

Stability of the levee embankment must be maintained at all times. Vertical or unsupported

over-steepened side slopes in or through the foundation or embankment will not be permitted.

Excavations within the freeboard area should be sloped no steeper than 1V on 1.5H.

3.2. Excavation adjacent to the levees within the limits of the levee-projected slopes should be

sloping no steeper than 1V on 1.5H from the bottom of the excavation. Stability analysis may be

required for the deep excavations or problem foundations.

3.3. Excavations beyond the projected levee slopes but still within the critical area, should

meet Federal, State and local criteria, COE safety manual and OSHA criteria.

3.4. Excavation utilizing sheeting and bracing in lieu of open cut, requires a design analysis

for the excavation support system. In the event that the sheeting and bracing method of

excavation are used in the critical area, the sheeting and bracing must be removed as the backfill

is brought up. In no event shall the bracing or sheeting be left in place permanently. Materials

in areas outside of the sheeting and bracing showing evidence of distress will need to be

removed, backfilled, and recompacted. The sheeting and bracing should be designed conform to

requirements described in TM 5-818-1 and EM 1110-2-2504: Design of Sheet Pile Walls.

Trench boxes are allowed outside the levee-projected slope only.

EXCAVATION AND BACKFILL - 1

3.5 Dewatering: Dewatering control should conform to the topic DEWATERING.

3.6. Temporary Flood Control should conform to requirements shown in the topic INTERIM

FLOOD PROTECTION AND CONTINGENCY PLAN. Stability of the temporary flood

control projects, as ring levees, should conform to the topic STABILITY ANALYSIS.

3.7. Excavation in the critical area shall not be performed between flooding season of any

year. The flooding season is shown in the INTERIM FLOOD PROTECTION AND

CONTINGENCY PLAN. Waivers to this restriction may be obtained from the Corps of

Engineers for periods not to exceed 30 days, provided antecedent conditions and potential river

stages are favorable. A waiver request should include a contingency plan for high river stages.

The contingency plan should conform to requirements shown in the topic INTERIM FLOOD

PROTECTION AND CONTINGENCY PLAN. Any work, which potentially weakens a flood

protection structure, shall be performed in an expedited manner to minimize the length of time

that the structure is weakened. Complete backfill of the excavated area and bulkheading of any

drainage structures or other outfalls, will be required within 24 hours if flood stages are forecast.

Major excavations in or near mainstream levees are treated on a "case-by-case" basis and further

restrictions may be required.

3.8. Slope stability. Slope stability considerations include the determination of appropriate

soil shear strengths to perform stability analyses. Excavations into a levee embankment or berm

or on channel banks must be evaluated. Slope stability analyses must conform to

recommendations and methods discussed in the topic SLOPE STABILITY.

4. Backfill and compaction requirements.

4.1. Crushed rock or other pervious materials will not be permitted within the critical area. An

exception can be made for pervious zones existing in the foundation.

4.2. Care shall be taken to replace the natural foundation stratification and embankment

zoning. In lieu of selective stockpiling and zoned backfill, impervious materials from an

approved borrow may be used.

4.3. Frozen material shall not be used nor shall any fill be placed on frozen surfaces.

4.4. No foundation or embankment backfill shall be placed in standing or running water.

Should a quick condition develop, dewatering by well points or other methods, which will nullify

the excess gradient, shall be used. Sump pumping will not be permitted.

4.5. Impervious materials such as silts, clays (ML, CL and CH) or semi-impervious materials

placed as backfill within the levee embankment, and within the projected embankment slopes,

must be placed in loose lifts thicknesses not to exceed 8 inches and compacted to a minimum 95

percent Standard Proctor density determined at optimum moisture content according to ASTM

D-698. Moisture control limits are to be within -1% to +3% of optimum.

4.6 Compaction of impervious and semi-impervious materials outside the projected levee

EXCAVATION AND BACKFILL - 2

slopes, within the critical area of the flood control project, should be compacted to a minimum of

90 percent of maximum Standard Proctor dry density determined at optimum moisture content

according to ASTM D-698, unless otherwise directed. Moisture control limits are to be within -

1% to +3% of optimum.

4.7 Compaction requirements of pervious materials. Pervious materials are usually defined

as free-draining, cohesionless sand and/or gravel, containing less than approximately 5% passing

US Standard 200 screen. Where zoning of the levee or stratification of the foundation permits

the use of pervious material, it shall be placed in 6-inch layers in a manner that will prevent

segregation. Compaction shall be performed to a minimum of 70% relative density according to

ASTM Test D-2049.

4.8 All disturbed areas shall be completely restored to the original condition. This restoration

shall include but is not limited to, sodding, seeding, surfacing, slope protection, and bedding

restoration.

4.9 Flowable fill used for trench backfill. If flowable fill is used for trench backfill it should

conform to the following requirements:

4.9.1 Flowable fill mix:

Fill Mix (batch

Material weights per cubic Remarks

yard)

ASTM C 150 meeting low alkali requirements.

Portland

Alternately, Ground Granulated Blast Furnace Slag

Cement, Type I at least 100

(GGBFS) cement conforming to ASTM C 989

or II (lbs)

Grade 100 or 120 is acceptable.

ASTM C 618, Class N, C, or F. (Class C shall not

be used with Missouri River Sand, or other

Fly Ash (lbs) at least 275

aggregate, which exhibits alkali-aggregate

reactivity potential).

ASTM C 33, concrete fine aggregate. Projects

requiring 200 cubic yards or more of flowable fill

shall be tested for alkali-aggregate reactivity in

Sand, SSD (lbs) 2795

accordance with ASTM C 1260. Test results shall

indicate measured expansion of less than 0.10% at

16 days after casting.

Total Water

no more than 370 Potable source.

(lbs)

Air Entraining

at least 2 ASTM C 260.

Agent, oz.

As Required to

Water Reducing

produce a cohesive ASTM C 494, Type A or F. See Para. 4.9.3.

Admixture

flowable mixture.

EXCAVATION AND BACKFILL - 3

4.9.2 Flowable fill strength - The mixture shall have a compressive strength of 100 psi at 28

days age.

4.9.3 Flowable fill consistency - The fresh mixture shall not be thin and watery, but shall have

a consistency similar to that of batter. It shall be tested by filling an open-ended 3-inch diameter,

6-inch high cylinder to the top with the mixture and immediately pulling the cylinder straight up.

The correct consistency will produce an approximate 8-inch diameter circular-type spread with

no segregation.

5. Criteria for borrow areas in the critical area of flood control projects.

5.1 Borrow from historical riverside scour holes is not recommended, since these areas

generally consist of soft river sediment deposits. Also, they have probably been backfilled in

previous repair efforts to provide for underseepage protection. Scour holes located close to the

levee toes were typically filled with a layer of impervious fill to minimize underseepage. Both

existing borrow areas and scour holes backfilled by the river should be investigated and

underseepage analyses performed before being recommended for borrow sites.

5.2 Although site subsurface investigation and underseepage analysis may indicate that the

borrow area does not reduce the safety factor for underseepage below minimum requirements,

the minimum suggested distance for locating a borrow area from the levee toe is 100 feet both

riverside and landside.

5.3 A minimum 2 foot thick impervious layer should be left on the bottom of the borrow

areas in the critical areas of the flood control project, unless underseepage analysis supports a

lesser thickness. Also the vertical elevation limits at the bottom of the borrow areas located

along the Missouri River should stay 5 feet above the construction reference plane as required in

Corps of Engineers Guidance Construction Reference Plane, dated March 1990.

6. Recommended references. The following references contain details regarding the COE

requirements for excavation and backfill in levee embankments and within the critical area.

6.1 EM 1110-2-1913, DESIGN AND CONSTRUCTION OF LEVEES, includes the

following:

a. Necessary subsurface investigations and laboratory testing to define the foundation of

the proposed construction and adjacent levee and to obtain the geotechnical properties for

underseepage and stability analyses.

b. Seepage control, including foundation underseepage and seepage through

embankments

. c. The topic B “Mathematical Analysis of Underseepage and Substratum Pressure”

establishes the method of underseepage analysis, the assumptions and the determination of

factors involved in the analysis for different cases.

6.2 EM-1110-2-1901, SEEPAGE ANALYSIS AND CONTROL FOR DAMS, includes the

following:

EXCAVATION AND BACKFILL - 4

a. Necessary subsurface investigations for determination of soil parameters for

groundwater analysis.

b. Determination of permeability of soils in the foundation.

c. Seepage principles, including seepage forces, hydraulic gradients and uplift pressure.

d. Seepage conditions in the presence of relief wells, including well design.

e. Seepage control in earth foundations adjacent to structures, and remedial seepage

control.

f. Monitoring of ground water and seepage control features.

g. Seepage control using relief or dewatering wells.

6.3 EM 1110-1-1804, GEOTECHNICAL INVESTIGATIONS, includes the following:

a. Field investigation for determination of the foundation soils parameters for new

construction, or temporary flood control projects (geophysical explorations, drilling methods,

exploratory excavations, groundwater studies, and in situ testing).

b. Empirical correlations for determination of soil parameters.

c. Laboratory testing necessary.

d. Backfilling of boreholes and exploratory excavations.

6.4 EM 1110-2-1906, LABORATORY SOIL TESTING, describes laboratory testing

procedures for obtaining the necessary soil parameters to be used in the design of flood control

features.

6.5 EM 1110-1-1906, SOIL SAMPLING, describes the methods and equipment for drilling

and sampling of undisturbed or disturbed soil samples from boreholes and exploratory test pits or

trenches.

6.6 EM 1110-2-2504: Design of Sheet Pile Walls, includes requirements for sheeting and

bracing design.

6.7 TM 5-818-4, AFM 88-5, Chap.5: BACKFILL FOR SUBSURFACE STRUCTURES

describes the following.

a. Excavations for structures to accommodate backfill operations.

b. Excavation and preparation for foundation.

c. Backfill operations such as placement, instrumentation, preconstruction distress.

d. Construction control such as excavation control techniques, foundation preparation and

control techniques, backfill quality control.

6.8 TM 5-818-1, AFM 88-3, Chap. 7, SOILS AND GEOLOGY PROCEDURES FOR

FOUNDATION DESIGN OF BUILDINGS AND OTHER STRUCTURES (EXCEPT

HYDRAULIC STRUCTURES), includes information regarding dewatering, ground water

control, and excavation support systems (including sheeting and bracing).

EXCAVATION AND BACKFILL - 5

You might also like

- C902Document3 pagesC902Rufo CascoNo ratings yet

- Astm C1491Document3 pagesAstm C1491BeymerBustamanteMejíaNo ratings yet

- An Introduction To Rigid Pavement DesignDocument24 pagesAn Introduction To Rigid Pavement DesignSheikh Nouman Mohsin Ramzi100% (1)

- Saudi Aramco Civil CBT Inspector Qualification Test: Excavation and BackfillingDocument17 pagesSaudi Aramco Civil CBT Inspector Qualification Test: Excavation and BackfillingUSMAN NAGTHAN100% (2)

- Aptransco 220kV & 132kV Lines & SS QAP FormatDocument89 pagesAptransco 220kV & 132kV Lines & SS QAP FormatArogya Raju Pudhota100% (1)

- FHWA-HI-99-025 Drilled Shafts Construction Procedures and Design MethodsDocument784 pagesFHWA-HI-99-025 Drilled Shafts Construction Procedures and Design Methodssean_dibartolo3668No ratings yet

- Analysis of Single Piles Under Lateral LoadingDocument181 pagesAnalysis of Single Piles Under Lateral LoadingAmanda CervantesNo ratings yet

- Decentralization, Corruption & Social Capital - Sten Widmalm - 2007 PDFDocument232 pagesDecentralization, Corruption & Social Capital - Sten Widmalm - 2007 PDFAji DeniNo ratings yet

- Kumpulan Mesin PancangDocument48 pagesKumpulan Mesin PancangFajrin M. NatsirNo ratings yet

- Pre Exam Review 21 653 TanksDocument6 pagesPre Exam Review 21 653 TanksBassam AbdelazeemNo ratings yet

- Raft Foundations Bearing Capacity and Settlement Report PDFDocument9 pagesRaft Foundations Bearing Capacity and Settlement Report PDFixynnuddoNo ratings yet

- Sti p3 InstallationDocument6 pagesSti p3 InstallationnjkasdncjkdNo ratings yet

- Installing Factory-Made Corrugated Aluminum Culverts and Storm Sewer PipeDocument6 pagesInstalling Factory-Made Corrugated Aluminum Culverts and Storm Sewer PipeROHITNo ratings yet

- Traduccion Apendice B API 650Document22 pagesTraduccion Apendice B API 650Miguel Felipe PovedaNo ratings yet

- Plate Load Soil Test ReportDocument5 pagesPlate Load Soil Test ReportJoseph Cloyd L. LamberteNo ratings yet

- Sti R912Document4 pagesSti R912Mauricio AdameNo ratings yet

- Api 650Document16 pagesApi 650cfpc10459No ratings yet

- Api Asphalt TankDocument18 pagesApi Asphalt Tankgen_lethal100% (1)

- AssignmentDocument32 pagesAssignmentsyedNo ratings yet

- HCL Fuel Tank SpecsDocument62 pagesHCL Fuel Tank SpecsM.Sreeram SanjayNo ratings yet

- Exam July 2021Document16 pagesExam July 202101280724321 Helmy100% (1)

- Tech Spec 2 ConstructionDocument8 pagesTech Spec 2 ConstructionHuascar Medrano LazarteNo ratings yet

- Choice of Foundation For BrigdesDocument15 pagesChoice of Foundation For BrigdesSamuel AntobamNo ratings yet

- Compliance SheetDocument4 pagesCompliance Sheetمحمد عبدالرحيمNo ratings yet

- Is.2911.1.2.2010 Part3Document6 pagesIs.2911.1.2.2010 Part3Dixit JariwalaNo ratings yet

- Tank Foundation 650 554Document16 pagesTank Foundation 650 554Mayuresh Kudve100% (1)

- Field Compaction ControlDocument2 pagesField Compaction ControlEftikarNo ratings yet

- TANK FoundationDocument6 pagesTANK FoundationUsama AhmedNo ratings yet

- Pages From (BS en 14015 - 2004) Specification For The Design and Manufacture of Site Built - DecryptedDocument8 pagesPages From (BS en 14015 - 2004) Specification For The Design and Manufacture of Site Built - Decryptedali niknamiNo ratings yet

- IRS - Well Pile Foundation Code PDFDocument17 pagesIRS - Well Pile Foundation Code PDFtipsypigNo ratings yet

- IS2911 (Part1sec2) 2005draft PDFDocument35 pagesIS2911 (Part1sec2) 2005draft PDFkanagarajodishaNo ratings yet

- UL-142 R912 Installation InstructionsDocument4 pagesUL-142 R912 Installation InstructionsRodrigoNo ratings yet

- Crib WallDocument11 pagesCrib Walltanyt123No ratings yet

- TDI41 Tank Inspection Repair & Alteration API 653 Sec 9Document13 pagesTDI41 Tank Inspection Repair & Alteration API 653 Sec 9Faizal Sattu100% (2)

- Quality Assurance PlanDocument89 pagesQuality Assurance PlanSai KumarNo ratings yet

- Outlet ProtectionDocument6 pagesOutlet ProtectionalikoleiniNo ratings yet

- Trench Cuts and Restorations Across Roadways: Flexible Pavement Cut Rigid Pavement CutDocument3 pagesTrench Cuts and Restorations Across Roadways: Flexible Pavement Cut Rigid Pavement CutIqueline JacqelineNo ratings yet

- Cement Stabilized Base CourseDocument6 pagesCement Stabilized Base CourseAmosNo ratings yet

- 2-1-9 - The Processing of High Strength Prestressed Spun ConcreteDocument5 pages2-1-9 - The Processing of High Strength Prestressed Spun ConcreteChan Kin CheungNo ratings yet

- Cablemate Installation GuideDocument16 pagesCablemate Installation Guideawaisnazir11No ratings yet

- C1568 08 (2013)Document6 pagesC1568 08 (2013)diego rodriguez100% (2)

- Astm C12Document7 pagesAstm C12omarguillermogarzon100% (1)

- Aptransco 220.132kV Lines-SS QAP & FormatDocument89 pagesAptransco 220.132kV Lines-SS QAP & Formatbharat_ravulapalli75% (4)

- 6.1 Pavement: 6.1.1 Materials - Base Course, Sub-Base, Subgrade, and Select FillDocument8 pages6.1 Pavement: 6.1.1 Materials - Base Course, Sub-Base, Subgrade, and Select FillEma WeismanNo ratings yet

- Abandonment Standards: Special CasesDocument6 pagesAbandonment Standards: Special CasesAntonio DiabanzaNo ratings yet

- KjfkjeDocument24 pagesKjfkjeaefNo ratings yet

- Chapter 62C-27 Conservation of Oil and Gas: DrillingDocument4 pagesChapter 62C-27 Conservation of Oil and Gas: DrillingAry RachmanNo ratings yet

- Astm C845 PDFDocument3 pagesAstm C845 PDFJohn Richard NelsonNo ratings yet

- Well Pile Foundation PDFDocument17 pagesWell Pile Foundation PDFlingamkumarNo ratings yet

- C1479Document8 pagesC1479Jesús Ernesto Flores RamírezNo ratings yet

- SA Standard NotesDocument22 pagesSA Standard Notesatiq0592No ratings yet

- Installing Vitrified Clay Pipe Lines: Standard Practice ForDocument9 pagesInstalling Vitrified Clay Pipe Lines: Standard Practice Formhamed1No ratings yet

- Exercise 4 Check Dam PDFDocument5 pagesExercise 4 Check Dam PDFBimleshKumarNo ratings yet

- IS218.02B - Suggested Specification For Concrete Parking AreasDocument2 pagesIS218.02B - Suggested Specification For Concrete Parking AreasfarhanNo ratings yet

- Sodium Hypo FRP SpecDocument6 pagesSodium Hypo FRP SpecZeroRecoNo ratings yet

- C125 PDFDocument4 pagesC125 PDFAntu IsabelNo ratings yet

- MOS - Flexible Pavement RehabilitationDocument6 pagesMOS - Flexible Pavement RehabilitationcdipcinNo ratings yet

- Dewatering Revised Oct 98Document11 pagesDewatering Revised Oct 98Mahmoud BreamaNo ratings yet

- 1999Spr GeblerDocument5 pages1999Spr Geblerwagzarus14No ratings yet

- Installation of Precast Reinforced Concrete Monolithic Box Sections For Culverts, Storm Drains, and SewersDocument4 pagesInstallation of Precast Reinforced Concrete Monolithic Box Sections For Culverts, Storm Drains, and SewersEligio Antonio CerdaNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Levee Safety Update: Jamie Mcvicker Named Usace Civilian of The YearDocument6 pagesLevee Safety Update: Jamie Mcvicker Named Usace Civilian of The YearAmanda CervantesNo ratings yet

- Model 640 With Night SightsDocument1 pageModel 640 With Night SightsAmanda CervantesNo ratings yet

- Levee Portfolio Report: U.S. Army Corps of EngineersDocument136 pagesLevee Portfolio Report: U.S. Army Corps of EngineersAmanda CervantesNo ratings yet

- Levee Safety Update: A Warm Welcome To Phoebe Percell, P.E., Chief Dam and Levee Safety Engineering BranchDocument9 pagesLevee Safety Update: A Warm Welcome To Phoebe Percell, P.E., Chief Dam and Levee Safety Engineering BranchAmanda CervantesNo ratings yet

- Seismic Design of Bridges With Seat-Type Abutments Considering The Participation of The Abutments During Earthquake ExcitationDocument10 pagesSeismic Design of Bridges With Seat-Type Abutments Considering The Participation of The Abutments During Earthquake ExcitationAmanda CervantesNo ratings yet

- DRAFT TM Design Criteria Considerations March 2012Document56 pagesDRAFT TM Design Criteria Considerations March 2012Amanda CervantesNo ratings yet

- Foreword: No Policy or Substantive Changes Have Been Incorporated in EP 1110-2-18Document44 pagesForeword: No Policy or Substantive Changes Have Been Incorporated in EP 1110-2-18Amanda CervantesNo ratings yet

- Levee Safety Update: National Levee Inventory & Review EffortDocument8 pagesLevee Safety Update: National Levee Inventory & Review EffortAmanda CervantesNo ratings yet

- Construction Dewatering and Groundwater ControlDocument2 pagesConstruction Dewatering and Groundwater ControlAmanda CervantesNo ratings yet

- Levee S!Fety Upd!Te: US!E Levee Portfolio ReportDocument6 pagesLevee S!Fety Upd!Te: US!E Levee Portfolio ReportAmanda CervantesNo ratings yet

- Nhi16009 v3Document299 pagesNhi16009 v3Amanda CervantesNo ratings yet

- Design and Construction of Driven Pile Foundations - Volume 1 (Nhi16009 - v1)Document559 pagesDesign and Construction of Driven Pile Foundations - Volume 1 (Nhi16009 - v1)Amanda Cervantes100% (1)

- Design and Construction of Driven Pile Foundations - Volume 1 (Nhi16009 - v1)Document559 pagesDesign and Construction of Driven Pile Foundations - Volume 1 (Nhi16009 - v1)Amanda Cervantes100% (1)

- NCHRP REPORT 611 Seismic Analysis and Design of Retaining Walls Buried Structures Slopes and EmbankmentsDocument311 pagesNCHRP REPORT 611 Seismic Analysis and Design of Retaining Walls Buried Structures Slopes and EmbankmentsQuangNguyenVanNo ratings yet

- Guidelines For Earthwork Construction Control Testing of Gravelly SoilsDocument27 pagesGuidelines For Earthwork Construction Control Testing of Gravelly SoilsAmanda CervantesNo ratings yet

- Transient Analyses of Interceptor TrenchDocument9 pagesTransient Analyses of Interceptor TrenchAmanda CervantesNo ratings yet

- Soil Nailing Field Inspectors Manual FHWA SA 93 068Document124 pagesSoil Nailing Field Inspectors Manual FHWA SA 93 068Amanda CervantesNo ratings yet

- FHWA Guidelines For Preparing Engineer's Estimate Bid Reviews and Evaluation (2004)Document18 pagesFHWA Guidelines For Preparing Engineer's Estimate Bid Reviews and Evaluation (2004)Amanda CervantesNo ratings yet

- 2009 Impoundment Design ManualDocument869 pages2009 Impoundment Design ManualAmanda CervantesNo ratings yet

- BoaDocument90 pagesBoadoxedwatsonNo ratings yet

- The Position of The Bioeconomy in The NetherlandsDocument8 pagesThe Position of The Bioeconomy in The NetherlandsMaryam AsdNo ratings yet

- All About Zookeeper and ClickHouse KeeperDocument45 pagesAll About Zookeeper and ClickHouse KeeperomyeudaihiepNo ratings yet

- Identifikasi Miskonsepsi Materi IPA Kelas VII SMP N 1 Gunung Sugih Lampung TengahDocument12 pagesIdentifikasi Miskonsepsi Materi IPA Kelas VII SMP N 1 Gunung Sugih Lampung TengahMawarniwati Waruwu Undiksha 2019No ratings yet

- Rfa Ar04Document5 pagesRfa Ar04cuanicochorielynjuviNo ratings yet

- Practical Tools For Attackers and Defenders: 6.1 Steps To Launch An AttackDocument42 pagesPractical Tools For Attackers and Defenders: 6.1 Steps To Launch An AttackRaghu Vamsi PNo ratings yet

- 56ef945cea29b 1312621 SampleDocument16 pages56ef945cea29b 1312621 SamplepanditrulesNo ratings yet

- Capitol Lagoon Complex: Existing Hard DataDocument6 pagesCapitol Lagoon Complex: Existing Hard DataNeanderthalNo ratings yet

- Indian ClimateDocument7 pagesIndian ClimatePrakash Kumar Kumar100% (1)

- Lva1 App6892Document146 pagesLva1 App6892Adam Shahabuddin Abdul RazakNo ratings yet

- Irp Test-1 (07!12!17) (Solution) (Jee Mains) Code-AbDocument20 pagesIrp Test-1 (07!12!17) (Solution) (Jee Mains) Code-Abvejoshi21699No ratings yet

- GU 0009. Leisegang Colposcope Directions ForUseDocument44 pagesGU 0009. Leisegang Colposcope Directions ForUseGabriela Ponce GuerrerpNo ratings yet

- Anime and MangaDocument14 pagesAnime and Mangapuspo agungNo ratings yet

- Body Repairs General Body RepairsDocument87 pagesBody Repairs General Body RepairsergdegNo ratings yet

- Huff ManDocument4 pagesHuff Mangopal_svsemails8998No ratings yet

- SIKA Marine 2016Document164 pagesSIKA Marine 2016pcatruongNo ratings yet

- "134-S" Series: Optional Gasket KitDocument45 pages"134-S" Series: Optional Gasket KitginoNo ratings yet

- Improving Machine Translation With Conditional Sequence Generative Adversarial NetsDocument10 pagesImproving Machine Translation With Conditional Sequence Generative Adversarial Netsmihai ilieNo ratings yet

- BNPL and Store CardsDocument13 pagesBNPL and Store CardsTrader CatNo ratings yet

- Pratik ResumeDocument2 pagesPratik ResumeHarshada lawaleNo ratings yet

- Lesson 2 - Victimology and VictimDocument19 pagesLesson 2 - Victimology and VictimHernandez JairineNo ratings yet

- Overview of Extended RealityDocument7 pagesOverview of Extended RealityAkul DevtaNo ratings yet

- 2exam LogisticsDocument6 pages2exam LogisticsJessica LaguatanNo ratings yet

- Exoglove Research PaperDocument8 pagesExoglove Research Papersanket jainNo ratings yet

- Set 6: Knowledge Representation: The Propositional Calculus: Chapter 7 R&NDocument85 pagesSet 6: Knowledge Representation: The Propositional Calculus: Chapter 7 R&NQaisar HussainNo ratings yet

- Integrated Budget & Accounting System (iBAS++)Document46 pagesIntegrated Budget & Accounting System (iBAS++)Hamanta RoyNo ratings yet

- SshaDocument13 pagesSshaFitahiana Mickaël RANDRIANARIMALALANo ratings yet

- Choice of Therapy in PrimaryDocument19 pagesChoice of Therapy in PrimaryThiago SartiNo ratings yet

- List of Doctors Clinics HospitalsDocument6 pagesList of Doctors Clinics HospitalsAjay Kaushik50% (2)