Professional Documents

Culture Documents

Procurement & Preparation of Materials Batching of Concrete Mixture

Procurement & Preparation of Materials Batching of Concrete Mixture

Uploaded by

Queen OndeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procurement & Preparation of Materials Batching of Concrete Mixture

Procurement & Preparation of Materials Batching of Concrete Mixture

Uploaded by

Queen OndeCopyright:

Available Formats

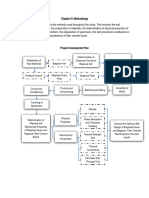

Procurement & Batching of Concrete

Preparation of Materials Mixture

Testing of Concrete Curing of Concrete

Specimens Specimens

Concrete Design Mix

(Cement, Aggregates, Water)

Control Setup Experimental Setup

0% Fiber 1.0% Fiber

0.5% Fiber 1.5% Fiber

T1 T3

T2 T4

Casting and Curing of Test Specimens

Test for Tensile Strength, Compressive

Strength & Flexural Strength

Data Analysis

Discussion and Conclusion

Preparation of Materials

Sea Rosemallow

Bast Fibers

Fine Aggregates Coarse Aggregates

Retting of Bast

Air-Drying of Fibers Cleaning and

Sand Washing of Gravel

Mechanical

Sieving of Sand Extraction of Bast Air-Drying of

Fibers Gravel

Preliminary Tests Alkaline Treatment Sieving of Gravel

before Adding to of Bast Fibers

the Concrete Mix

Preliminary Tests

Air-Drying of

before Adding to

Fibers

the Concrete Mix

Cutting of Fibers to

5 cm Length

Manual Separation

of Fibers

Preliminary Tests

before Adding to the

Concrete Mix

Concrete Design Mix

(Cement, Aggregates, Water)

Control Setup

Experimental Setup

with Sea Rosemallow bast fibers (by weight of cement)

0% Fiber

T1 0.5% Fiber T3 Fiber

1.0%

T2 T4

1.5% Fiber

Casting and Curing of Test Specimens

Test for Tensile Strength, Compressive

Strength & Flexural Strength

Data Analysis

Discussion and Conclusion

Type I Portland Cement Sand Gravel Water

Concrete Design Mix

Control Set-up Experimental Set-up

With Sea Rosemallow Bast Fibers

(by weight of cement)

0% 0.5% 1.0% 1.5%

T1 T2 T3 T4

Casting and Curing of Test Specimens

Test for Tensile Strength, Compressive

Strength & Flexural Strength

Data Analysis

Discussion and Conclusion

You might also like

- SisalDocument31 pagesSisalChaithra Shree100% (4)

- CB To Fill Up Items 1,2 & 4 and Col 3 of The Checklist NABCB AT To Fill The RestDocument75 pagesCB To Fill Up Items 1,2 & 4 and Col 3 of The Checklist NABCB AT To Fill The RestBS AnilKumarNo ratings yet

- Chapter III Methodology RecentDocument9 pagesChapter III Methodology RecentAnn Gabrielle SuarezNo ratings yet

- Civil and Construction: Strong Foundation Builds TrustDocument2 pagesCivil and Construction: Strong Foundation Builds TrustazhaniNo ratings yet

- Investigation of Properties of Fiber Reinforced Concrete Using RubberDocument5 pagesInvestigation of Properties of Fiber Reinforced Concrete Using RubberSumit Geete100% (1)

- Masjid Sahabat - Testing PlanDocument14 pagesMasjid Sahabat - Testing PlanDinn NsNo ratings yet

- Influence of Rice Husk Ash As Supplementary Material in Cement Paste and ConcreteDocument13 pagesInfluence of Rice Husk Ash As Supplementary Material in Cement Paste and ConcretemahmoodNo ratings yet

- ACMT Lec-11-FRP - SlidesDocument17 pagesACMT Lec-11-FRP - SlidesHamda GhaffarNo ratings yet

- 2761-Article Text-10878-1-10-20220104Document9 pages2761-Article Text-10878-1-10-20220104Fernando AcostaNo ratings yet

- TEAM BUNAL Experimental Flowchart1Document1 pageTEAM BUNAL Experimental Flowchart1Mark Angelo FloresNo ratings yet

- ﺔﻠﺠﻣ مﻮﻠﻌﻟا ﺔﺜﺤﺒﻟا و ﺔﻴﻘﻴﺒﻄﺘﻟا Estimation Compression Strength of Concrete Made from Local Material Using Non-destructive TestsDocument5 pagesﺔﻠﺠﻣ مﻮﻠﻌﻟا ﺔﺜﺤﺒﻟا و ﺔﻴﻘﻴﺒﻄﺘﻟا Estimation Compression Strength of Concrete Made from Local Material Using Non-destructive TestsAman SahadeoNo ratings yet

- Kandungan Semen Dan PasirDocument2 pagesKandungan Semen Dan Pasirtiursirait08No ratings yet

- Ijer 2014 106 PDFDocument5 pagesIjer 2014 106 PDFCva RajNo ratings yet

- Topic 4: Research Design / Methodology AssignmentDocument5 pagesTopic 4: Research Design / Methodology AssignmentHadi Iz'aanNo ratings yet

- 3M Product Data PDFDocument3 pages3M Product Data PDFmujahaddadNo ratings yet

- 9 SPJMRDocument10 pages9 SPJMRArsam HaqNo ratings yet

- Irjet V4i7178 PDFDocument4 pagesIrjet V4i7178 PDFAalaya Housing Private LimitedNo ratings yet

- Carbon Fiber Based Self Sensing Smart Concrete For Resistivity and ConductivityDocument35 pagesCarbon Fiber Based Self Sensing Smart Concrete For Resistivity and ConductivityHaaris RashidNo ratings yet

- "Strength and Analysis of Basalt Fibre in Concrete": Project Seminar OnDocument29 pages"Strength and Analysis of Basalt Fibre in Concrete": Project Seminar OnArsam Haq100% (1)

- Experimental Study On Flexural Behaviour of RC Beams With Graphene Oxide and Bottom AshDocument35 pagesExperimental Study On Flexural Behaviour of RC Beams With Graphene Oxide and Bottom AshPraveen RajNo ratings yet

- Asphalt Mix Design - Testing Plan - Matter LabDocument18 pagesAsphalt Mix Design - Testing Plan - Matter LabSOORAJ CHANDRA R SNo ratings yet

- Azerian PipeDocument3 pagesAzerian PipeHadad KarimiNo ratings yet

- Iabse2012 CairoDocument8 pagesIabse2012 Cairoomswarup meenaNo ratings yet

- Article FypDocument6 pagesArticle FypMuhammad ShaqeelNo ratings yet

- ServicesDocument2 pagesServicesSecretario SigmaNo ratings yet

- State of The Art Report On Moisture Damage Resistance of Asphalt Mixtures Using Surface Free Energy ApproachDocument2 pagesState of The Art Report On Moisture Damage Resistance of Asphalt Mixtures Using Surface Free Energy ApproachNikita BhagatNo ratings yet

- Chapter 3Document24 pagesChapter 3Md Ashiqur RahmanNo ratings yet

- Pojet PPT 1Document39 pagesPojet PPT 1Tushar JainNo ratings yet

- Degradation of Recycled PET Fibers in Portland Cement-Based MaterialsDocument6 pagesDegradation of Recycled PET Fibers in Portland Cement-Based MaterialsIrina RomanNo ratings yet

- CivilDocument2 pagesCivilShiyaNo ratings yet

- Wood Ash 6Document11 pagesWood Ash 6r;rNo ratings yet

- Pengaruh Variasi Komposisi Arang Kelapa Dan Kayu B PDFDocument5 pagesPengaruh Variasi Komposisi Arang Kelapa Dan Kayu B PDFDhinar CindarriyaniNo ratings yet

- Mini Project DocumentDocument22 pagesMini Project Document17-597 Sravani PanugantiNo ratings yet

- Strength of Concrete Containing Basalt Fibre: Parvez Imraan Ansari, Rajiv ChandakDocument5 pagesStrength of Concrete Containing Basalt Fibre: Parvez Imraan Ansari, Rajiv ChandakPathipati NarasimharaoNo ratings yet

- Influence of Marble Powder/granules in Concrete MixDocument8 pagesInfluence of Marble Powder/granules in Concrete Mixاسد راجNo ratings yet

- 703 - Aggregate (2012) PDFDocument19 pages703 - Aggregate (2012) PDFAron JoshuaNo ratings yet

- 10 1002@pen 25183Document10 pages10 1002@pen 25183Break LimsNo ratings yet

- Siddique 2003Document9 pagesSiddique 2003Claudia CarhuaniNo ratings yet

- Study On The Performance of Concrete Usi PDFDocument4 pagesStudy On The Performance of Concrete Usi PDFBenharzallah KrobbaNo ratings yet

- Chloride Diffusion CoefficientDocument7 pagesChloride Diffusion CoefficientAkhtar BahramNo ratings yet

- Comparison of Mechanical PropertiesDocument4 pagesComparison of Mechanical PropertiesFatima OudahNo ratings yet

- Experimental Investigations On Mechanical Properties of Coir/Zea Fiber Reinforced CompositesDocument25 pagesExperimental Investigations On Mechanical Properties of Coir/Zea Fiber Reinforced CompositesHemachandranNo ratings yet

- Properties of Steel Fibre Reinforced ConcreteDocument8 pagesProperties of Steel Fibre Reinforced ConcreteCuriosoNo ratings yet

- Study On Concrete With Replacement of Fi PDFDocument3 pagesStudy On Concrete With Replacement of Fi PDFBrine MutasaNo ratings yet

- 1 s2.0 S0950061806001784 MainDocument6 pages1 s2.0 S0950061806001784 MainN SHYAMANANDA SINGHNo ratings yet

- Plastic As Soil Stabilizer PDFDocument5 pagesPlastic As Soil Stabilizer PDFSagarKasarlaNo ratings yet

- Batch 1Document10 pagesBatch 120311a0135No ratings yet

- ITP FormatDocument5 pagesITP FormatCar ThickNo ratings yet

- GT9R6A1 - 1998 - Watertightness of Precast Concrete Lining Segments PDFDocument8 pagesGT9R6A1 - 1998 - Watertightness of Precast Concrete Lining Segments PDFOmar ElioNo ratings yet

- Influence of Marble Powder/granules in Concrete Mix: Research Article ISSN 0976 - 4399Document8 pagesInfluence of Marble Powder/granules in Concrete Mix: Research Article ISSN 0976 - 4399Yu Paing HanNo ratings yet

- Study On The Effect of Coir Fibre in The Bituminous Concrete MixDocument5 pagesStudy On The Effect of Coir Fibre in The Bituminous Concrete MixMD. NASIF HOSSAIN IMONNo ratings yet

- Experimental Studies On Effect of Alccofine in Workability and Mechanical Properties of Steel Fiber Reinforced ConcreteDocument6 pagesExperimental Studies On Effect of Alccofine in Workability and Mechanical Properties of Steel Fiber Reinforced ConcretevitusstructuresNo ratings yet

- Effect of Fiber Length On The Physical and Mechanical Properties of Tiger Grass Panicle Fiberboard Bonded by Polyester ResinDocument24 pagesEffect of Fiber Length On The Physical and Mechanical Properties of Tiger Grass Panicle Fiberboard Bonded by Polyester ResinJaycee CuarteroNo ratings yet

- Re 16Document4 pagesRe 16Alamgir kabirNo ratings yet

- Development of A Treatment Technique To Reduce The Water Absorption Capacity of Recycled AggregatesDocument6 pagesDevelopment of A Treatment Technique To Reduce The Water Absorption Capacity of Recycled AggregatespasinduNo ratings yet

- Experimental Investigation On Partially Replacement of Cement, Coarse Aggregate by Corn Cob Ash and Steel SlagDocument6 pagesExperimental Investigation On Partially Replacement of Cement, Coarse Aggregate by Corn Cob Ash and Steel SlagIJIRSTNo ratings yet

- A Study On Properties of Foamed Concrete With Fly Ash and Marble Sludge PowderDocument4 pagesA Study On Properties of Foamed Concrete With Fly Ash and Marble Sludge PowderAnuraagNo ratings yet

- Flow Behavior and Strength For y Ash Blended Cement Paste and MortarDocument8 pagesFlow Behavior and Strength For y Ash Blended Cement Paste and MortarZuhair NadeemNo ratings yet

- Materials Today: Proceedings: S. Sangeetha, N. Sakthieswaran, O. Ganesh BabuDocument5 pagesMaterials Today: Proceedings: S. Sangeetha, N. Sakthieswaran, O. Ganesh BabuShaik Abdul RaheemNo ratings yet

- An Anspiring Illonggo Visual Artist: Kristoffer George BraseliñoDocument14 pagesAn Anspiring Illonggo Visual Artist: Kristoffer George BraseliñoMarco Esco. CadungganNo ratings yet

- 2 Activity 1 TECHNODocument2 pages2 Activity 1 TECHNONoel SebongaNo ratings yet

- Geotextile BookDocument63 pagesGeotextile BookIsparmoNo ratings yet

- Vip 45.3Document17 pagesVip 45.3BūvfizikaNo ratings yet

- Rashomon - WikipediaDocument18 pagesRashomon - WikipediaShareena FarooqueNo ratings yet

- Fixed Drug EruptionsDocument5 pagesFixed Drug EruptionsShalu RjNo ratings yet

- Module 1: Authentic Assessment in The ClassroomDocument10 pagesModule 1: Authentic Assessment in The ClassroomSir Log100% (1)

- NDT Basics GuideDocument29 pagesNDT Basics Guideravindra_jivaniNo ratings yet

- Httpsrvce Edu Insitesdefaultfiles7 20EC20III202620IV PDFDocument51 pagesHttpsrvce Edu Insitesdefaultfiles7 20EC20III202620IV PDFNANDITA SNo ratings yet

- 1800 Mechanical Bender: Instruction ManualDocument42 pages1800 Mechanical Bender: Instruction ManualPato Loco Rateria100% (1)

- Biology, Ecology, and Management of The Pea Weevil, Bruchus Pisorum (Coleoptera: Chrysomelidae)Document12 pagesBiology, Ecology, and Management of The Pea Weevil, Bruchus Pisorum (Coleoptera: Chrysomelidae)Alexandra-Ana-Maria VulpeNo ratings yet

- Navyfield Full ManualDocument11 pagesNavyfield Full Manualmarti1125100% (2)

- Ibps RRB Clerk Prelims Model Paper PDF Set 9Document29 pagesIbps RRB Clerk Prelims Model Paper PDF Set 9Raj KNo ratings yet

- Surface To Air Missile SA-10 (S300)Document4 pagesSurface To Air Missile SA-10 (S300)Branislav LackovicNo ratings yet

- Geothermal Reservoir Simulation in Hot Sedimentary Aquifer System Using FeflowDocument1 pageGeothermal Reservoir Simulation in Hot Sedimentary Aquifer System Using FeflowImmanuel Lumban GaolNo ratings yet

- Onkyo tx-nr737 SM Parts Rev6Document110 pagesOnkyo tx-nr737 SM Parts Rev6MiroslavNo ratings yet

- Elan Gerzon Resume 2017Document3 pagesElan Gerzon Resume 2017api-352110674No ratings yet

- Sardar JokesDocument5 pagesSardar JokesblpsimhaNo ratings yet

- Cholistan Water Relief Project: Presented By: Zohaib Nishad Muhammad Mohsin Mansur Ahsan Zahid Ghazala Baraki Iqra AbidDocument11 pagesCholistan Water Relief Project: Presented By: Zohaib Nishad Muhammad Mohsin Mansur Ahsan Zahid Ghazala Baraki Iqra AbidMansoor SaeedNo ratings yet

- Dhaka University Affiliated Colleges: Third Year Syllabus Department of MathematicsDocument8 pagesDhaka University Affiliated Colleges: Third Year Syllabus Department of MathematicsHasibul Hassan ShantoNo ratings yet

- Exports Driven by Hallyu Increasing South Korea's Economic Growth - Cultural Diplomacy ApproachDocument17 pagesExports Driven by Hallyu Increasing South Korea's Economic Growth - Cultural Diplomacy ApproachAnastasya doriska MasliaNo ratings yet

- Detailed Lesson Plan in Numeracy For KindergartenDocument5 pagesDetailed Lesson Plan in Numeracy For KindergartenJan ArkNo ratings yet

- Family Biz BibleDocument26 pagesFamily Biz BibleFrank ParrNo ratings yet

- Pressform Refractory PRINT Brochure PDFDocument44 pagesPressform Refractory PRINT Brochure PDFravikumarangNo ratings yet

- Chalno Meaning v2Document1 pageChalno Meaning v2Roldan WilfridoNo ratings yet

- Graded Quesions Complete Book0Document344 pagesGraded Quesions Complete Book0Irimia Mihai Adrian100% (1)

- M Tech Dissertation Power SystemDocument7 pagesM Tech Dissertation Power SystemWriteMyStatisticsPaperAkron100% (1)

- CS Form No. 4 Certification of Assumption To Duty (Enteria)Document5 pagesCS Form No. 4 Certification of Assumption To Duty (Enteria)Concepcion MpsNo ratings yet

- Front End OperationsDocument21 pagesFront End OperationsDhwani DoshiNo ratings yet