Professional Documents

Culture Documents

Propec® 5S Audit Checklist: Work Area Completed by Date

Propec® 5S Audit Checklist: Work Area Completed by Date

Uploaded by

Pratik SharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Propec® 5S Audit Checklist: Work Area Completed by Date

Propec® 5S Audit Checklist: Work Area Completed by Date

Uploaded by

Pratik SharmaCopyright:

Available Formats

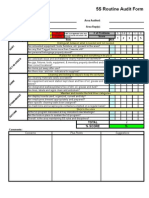

ProPeC® 5s Audit Checklist

Work area

Completed by

Date 0 1 2 3 4 Actions

All unnecessary items have been removed from the area?

Tools and equipment are located in the most convenient place

Sort Machinery is laid out in the best way

Shelves, cabinets and other storage solutions only contain what is needed

There are no unnecessary obstacles in the way impeding operatives

Storage areas including shelves, cupboards etc. are clearly labelled and the footprint marked

Safety equipment is present, clearly marked and up to date

Set in Order Shadow boards are present for all appropriate tooling and equipment

Tools and equipment are where they should be i.e. on shadow boards, marked areas etc.

Walk areas are clearly marked and unobstructed?

Floors are clean and tidy and well maintained

Machines are clean and well maintained without damage or leaking oil

Shine Tools and other equipment are well maintained and clean

Bins are clearly marked, emptied regularly, used appropriately and segregated according to waste type

Individuals are accountable for the tidiness of their work area

There are established and understood standards in place for the first 3S's

Picture standards are in place and used

Standardise There is an understood process for routine inspection and maintenance

There is an understood process for everyone to raise issues and suggest improvement

There is an understood improvement process to deal with issues raised

Over the last month routine inspection and maintenance has been carried out according to the standard

Over the last month the required amount of audits have been carried out

Sustain Checklists are available and being used

A 5S board is being used and is up to date

The workforce and managers are appropriately trained and knowledgeable in 5s

Key

0 = No compliance, 1 = very little compliance, 2 = some compliance, 3 = significant compliance, 4 = total compliance

General notes and observations

You might also like

- 5S Audit ChecksheetDocument1 page5S Audit ChecksheetIB Ismady70% (20)

- 5S Audit Check Sheet: Department: - Completed By: - Supervisor: - DateDocument1 page5S Audit Check Sheet: Department: - Completed By: - Supervisor: - DateP K Senthil Kumar50% (4)

- 5s Audit Check SheetDocument2 pages5s Audit Check SheetElizabethMayMendiolaSabando100% (2)

- 5S Audit Checklist PDFDocument4 pages5S Audit Checklist PDFAjay Krishnan100% (3)

- A Critical Review of Manufacturing Processes Used in Regenerated Cellulosic Fibers Viscose Cellulose Acetate Cuprammonium EtcDocument28 pagesA Critical Review of Manufacturing Processes Used in Regenerated Cellulosic Fibers Viscose Cellulose Acetate Cuprammonium EtcMoqeet AwanNo ratings yet

- Laboratory Quality/Management: A Workbook with an Eye on AccreditationFrom EverandLaboratory Quality/Management: A Workbook with an Eye on AccreditationRating: 5 out of 5 stars5/5 (1)

- 5 S ChecklistsDocument11 pages5 S Checklistsjahazi2No ratings yet

- 5S Classroom Review Checklist PDFDocument1 page5S Classroom Review Checklist PDFTJOSNo ratings yet

- 5 S Presentation Basic TrainingDocument82 pages5 S Presentation Basic TrainingEmman Bosito100% (2)

- 5S Safety AuditDocument9 pages5S Safety Auditmuthuswamy77No ratings yet

- 5S Technique DataDocument9 pages5S Technique DataMuhammad Luqman FarooquiNo ratings yet

- Seiri Audit ChecklistDocument4 pagesSeiri Audit Checklistthephaiduong100% (1)

- Lear 145 5S ChecklistsDocument10 pagesLear 145 5S ChecklistsEfrain PerezNo ratings yet

- 5S Audit FormDocument2 pages5S Audit Formsigmasundar100% (1)

- Module 5: Practice Problems: Answer: 3 Grams (G)Document11 pagesModule 5: Practice Problems: Answer: 3 Grams (G)Katrina Tiempo Miquiabas0% (1)

- 5s Audit Check SheetDocument4 pages5s Audit Check SheetLAI WEI SINGNo ratings yet

- 5S Audit FormDocument2 pages5S Audit Formmounirs719883No ratings yet

- 5S Audit FormDocument2 pages5S Audit FormNavnath Tamhane100% (2)

- 5S Audit FormDocument2 pages5S Audit FormWaqar DarNo ratings yet

- 5S Classroom Review ChecklistDocument1 page5S Classroom Review ChecklistAtul Sharma100% (1)

- 5S Classroom Review Checklist PDFDocument1 page5S Classroom Review Checklist PDFradhajaladiNo ratings yet

- 5S Classroom Review ChecklistDocument1 page5S Classroom Review ChecklistIan MardiansyahNo ratings yet

- 5S Audit MudaMastersDocument1 page5S Audit MudaMastersManoj ShahNo ratings yet

- BF Area - 5S Check ListDocument30 pagesBF Area - 5S Check ListVi KraNo ratings yet

- Audit 5 SDocument6 pagesAudit 5 SGleone KaiserinNo ratings yet

- 5S ChecklistsDocument5 pages5S ChecklistsRheneir MoraNo ratings yet

- Category Criteria Audit Period Scoring System: PLS Office 5S + Safety Audit Form - DraftDocument109 pagesCategory Criteria Audit Period Scoring System: PLS Office 5S + Safety Audit Form - DraftblitzkrigNo ratings yet

- 5s Audit Checklist NewDocument2 pages5s Audit Checklist NewdrkefyalewtayeNo ratings yet

- 6S Audit Report No.4Document13 pages6S Audit Report No.4Rachel FloresNo ratings yet

- 5s Evaluation ChecklistDocument4 pages5s Evaluation ChecklistTessa DejesusNo ratings yet

- 5 S Checklist - Workplace Evaluation: 5 or More 0 3 To 4 1 2 2 1 3 None 4Document6 pages5 S Checklist - Workplace Evaluation: 5 or More 0 3 To 4 1 2 2 1 3 None 4Dian PeshevNo ratings yet

- Group Number 1: Renu Kapoor Peu Banerjee Swati Ritu Vishwakarma Ashwin HazariDocument36 pagesGroup Number 1: Renu Kapoor Peu Banerjee Swati Ritu Vishwakarma Ashwin HazariPeu BanerjeeNo ratings yet

- 5S Audit SheetDocument4 pages5S Audit SheetJohn Robert StoneNo ratings yet

- 5s ChecklistDocument4 pages5s ChecklistedeceNo ratings yet

- CHP 6 FRSI 2043 5SDocument36 pagesCHP 6 FRSI 2043 5SSamuel MergaNo ratings yet

- 5s As A Tool and Strategy For Improvising The Work PlaceDocument3 pages5s As A Tool and Strategy For Improvising The Work PlaceOscar PedrozaNo ratings yet

- New Note On Apply 5s ProcedureDocument9 pagesNew Note On Apply 5s ProcedureTeamir Legese100% (1)

- 5S AuditDocument7 pages5S Auditjorge.kemelNo ratings yet

- 5s ChecklistDocument8 pages5s ChecklistMohini MaratheNo ratings yet

- 5S (Japanese Safety Models)Document1 page5S (Japanese Safety Models)Rathish RagooNo ratings yet

- Lean Overview For OrientationDocument14 pagesLean Overview For OrientationFabio GonzalezNo ratings yet

- 5SDocument56 pages5SInderpreet Singh AhujaNo ratings yet

- SIMSA Warehouse 5S Audit ChecklistDocument7 pagesSIMSA Warehouse 5S Audit ChecklistAshish MendirattaNo ratings yet

- 5S CFT Audit Checklist-FY 2014-15Document2 pages5S CFT Audit Checklist-FY 2014-15arunbiswal100% (1)

- 5S Audit TemplateDocument1 page5S Audit Templateashblack160No ratings yet

- 5 S WayDocument11 pages5 S WayYasser BadrNo ratings yet

- Stangerweb 5S Audit QuestionnaireDocument4 pagesStangerweb 5S Audit QuestionnaireambicaNo ratings yet

- Welcome: Workplace Organization & Housekeeping 101Document70 pagesWelcome: Workplace Organization & Housekeeping 101Pedro SousaNo ratings yet

- 5s in Quality ManagementDocument10 pages5s in Quality Managementعزالدين الحسينيNo ratings yet

- 5s Housekeeping Observations Checklist: Sort Distinguished Between What Is Needed and What Is Not NeededDocument2 pages5s Housekeeping Observations Checklist: Sort Distinguished Between What Is Needed and What Is Not Neededsaeed ahmedNo ratings yet

- 5S Audit Form PCI MasterDocument2 pages5S Audit Form PCI MasterTengku SmyNo ratings yet

- 6S ChecklistDocument2 pages6S Checklistabbiejune_363739No ratings yet

- 5S Training and Its Implementation PDFDocument66 pages5S Training and Its Implementation PDFdlishNo ratings yet

- 5S ImplementationDocument37 pages5S ImplementationPakshal Shah0% (1)

- 5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsFrom Everand5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Guidelines to make your own SOP (Standard Operating Procedure)): 1, #1From EverandGuidelines to make your own SOP (Standard Operating Procedure)): 1, #1No ratings yet

- HarishDocument4 pagesHarishVivek PaulNo ratings yet

- Detecting Gross Leaks in Medical Packaging by Internal Pressurization (Bubble Test)Document5 pagesDetecting Gross Leaks in Medical Packaging by Internal Pressurization (Bubble Test)Hernan MartNo ratings yet

- Sanskrit Participles - Overview - Sanskrit Studio PDFDocument14 pagesSanskrit Participles - Overview - Sanskrit Studio PDFRskrsk RskNo ratings yet

- Chemistry-Ch 3 - Chemical BondingDocument8 pagesChemistry-Ch 3 - Chemical BondingHassan RiazNo ratings yet

- Fantasy Foundry (10032611)Document8 pagesFantasy Foundry (10032611)Oscar Chacon100% (1)

- Leica Absolute Interferometer White Paper enDocument4 pagesLeica Absolute Interferometer White Paper entheflamebearerNo ratings yet

- Diagnosa Prolanis (Seluruhnya)Document6 pagesDiagnosa Prolanis (Seluruhnya)Rasjid tabanalNo ratings yet

- BSSPAR1: Chapter 5 Measurement Processing: 1 © Nokia Siemens NetworksDocument27 pagesBSSPAR1: Chapter 5 Measurement Processing: 1 © Nokia Siemens NetworksJunaidNo ratings yet

- The Cumulative Frequency Graph Shows The Amount of Time in Minutes, 200 Students Spend Waiting For Their Train On A Particular MorningDocument8 pagesThe Cumulative Frequency Graph Shows The Amount of Time in Minutes, 200 Students Spend Waiting For Their Train On A Particular MorningJonathanNo ratings yet

- English 361 - 7 Pre A2 Starters Authentic Examination Papers 3 2019Document3 pagesEnglish 361 - 7 Pre A2 Starters Authentic Examination Papers 3 2019addraubay100% (1)

- Luxeon 7070Document22 pagesLuxeon 7070guciNo ratings yet

- Basic C ProgramDocument1 pageBasic C ProgramPallab DattaNo ratings yet

- Anita KalafatiDocument3 pagesAnita KalafatiTarun ThadaniNo ratings yet

- Random Dice Deck Database - SearchDocument36 pagesRandom Dice Deck Database - SearchGiovanni PalomboNo ratings yet

- Neonatal JaundiceDocument15 pagesNeonatal JaundiceSharan SekhonNo ratings yet

- Decs Ece DeceDocument58 pagesDecs Ece Decesailolla30No ratings yet

- VaricoceleDocument4 pagesVaricoceleRahajeng Ainiken PutririmasariNo ratings yet

- Carbocation - Wikipedia, The Free EncyclopediaDocument5 pagesCarbocation - Wikipedia, The Free EncyclopediaBenni WewokNo ratings yet

- Bridge Course Unit 1 AssignmentDocument2 pagesBridge Course Unit 1 AssignmentSrinidhi SrinivasanNo ratings yet

- Security Dilemma vs. US Policy Towards ChinaDocument10 pagesSecurity Dilemma vs. US Policy Towards ChinaAfri AfrimadonaNo ratings yet

- Custom Reference 26 of 2010 With 7 Connected PDFDocument39 pagesCustom Reference 26 of 2010 With 7 Connected PDFA8nanbaigNo ratings yet

- CH1104 Chapter 11Document59 pagesCH1104 Chapter 11Chuah Chong YangNo ratings yet

- Lec 1-Vapor Liquid Equilibrium-Part 1Document30 pagesLec 1-Vapor Liquid Equilibrium-Part 1DianaNo ratings yet

- Crim 1 BDocument1 pageCrim 1 BJose Antonio Peralta Achaval Jr.No ratings yet

- ADSP2106x PDFDocument698 pagesADSP2106x PDFShiv Ram ChNo ratings yet

- Биология. Общие Закономерности Жизни 9 КлассDocument129 pagesБиология. Общие Закономерности Жизни 9 КлассHell boyNo ratings yet

- 15CV64 Dec18-Jan19 PDFDocument2 pages15CV64 Dec18-Jan19 PDFkarthikNo ratings yet

- NadiahBamadhaj DescentDocument24 pagesNadiahBamadhaj DescentAbu WafaNo ratings yet