Professional Documents

Culture Documents

Lincoln Auto Lubrication System: Maintenance Procedure List

Lincoln Auto Lubrication System: Maintenance Procedure List

Uploaded by

Nova kurniawan 34Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lincoln Auto Lubrication System: Maintenance Procedure List

Lincoln Auto Lubrication System: Maintenance Procedure List

Uploaded by

Nova kurniawan 34Copyright:

Available Formats

LINCOLN AUTO LUBRICATION SYSTEM

MAINTENANCE PROCEDURE LIST

SERVICE " A "

ITEM T A S K

1 Visual check all grease points, ensure all points are wet from grease.

2 Clean up grease point area, ensure adapter and fitting are tight.

3 Visual check all grease hoses for leaks or damage, put in clamp and cable ties

if necessery to make lines tidy.

4 Take off injector nipple caps (p/n 90471) for ensure the injector can supply grease.

5 Ensure grease tank has enough grease.

6 Test grease pump working with manual button or with air compressed

if main switch is lock out.

7 Check grease injectors are working at nipple (p/n 90471), if we find any grease point

dry, loosen fitting from adapter grease point and ensure grease comes out from fitting.

To ensure adapter grease points not blocked, manual grease this point with grease

gun from service bay. And if point is still blocked, report to mechanic foreman.

8 If system uses Lincoln timer (p/n 84015), open cover and setting adjuster to 2,5 second

to ensure automatic timer is functional.

9 Ensure grease tank, grease pump bracket and the other components in pump assy are

tight not loose or broken.

10 Open grease pump head cover (p/n 236286) and put in some grease to lubricate

moving parts.

11 Clean up grease tank area and refill grease tank if grease less or empty.

12 Check grease injectors assy are tight or not leaking and clean up the area.

You might also like

- Kubota BX 2200 Operators ManualDocument64 pagesKubota BX 2200 Operators ManualMark Dubravec63% (16)

- 2 - Canrig Top Drive Rig Crew TrainingDocument104 pages2 - Canrig Top Drive Rig Crew TrainingDiego Fabian Ruiz Vacaflor89% (9)

- Diagnostic Code List: TroubleshootingDocument17 pagesDiagnostic Code List: TroubleshootingNova kurniawan 34No ratings yet

- Operators Manual Hydraulic Crane PK10000Document219 pagesOperators Manual Hydraulic Crane PK10000Nova kurniawan 34100% (4)

- Nor30p Serv ManDocument187 pagesNor30p Serv Manjason_meyer_14100% (2)

- Adjusting Fuel TimingDocument3 pagesAdjusting Fuel TimingSanjay MadakaNo ratings yet

- Cummins Confidential: 146797638.xls - Ms - Office, Tab: Wiring Diagram Page 1 of 2Document2 pagesCummins Confidential: 146797638.xls - Ms - Office, Tab: Wiring Diagram Page 1 of 2Nova kurniawan 34100% (2)

- NimcoDocument5 pagesNimcoomarvicoNo ratings yet

- Lubricating Oil Filter Bypass ValveDocument7 pagesLubricating Oil Filter Bypass ValveJulio GámezNo ratings yet

- Checking Lubricant For Water: CautionDocument1 pageChecking Lubricant For Water: Cautionbetabet GeorgeNo ratings yet

- Guidelines For Lubrication ProceduresDocument6 pagesGuidelines For Lubrication Proceduresdanielch123No ratings yet

- Atc70 73-84Document106 pagesAtc70 73-84saragood781100% (1)

- Caterpillar Crawler Operators Manual CT o d9Document7 pagesCaterpillar Crawler Operators Manual CT o d9Tommy JunNo ratings yet

- Fitting Steering Pump SpidDocument15 pagesFitting Steering Pump SpidJuan GarcNo ratings yet

- Installation Instruction: Lubricating Oil Filter Bypass ValveDocument6 pagesInstallation Instruction: Lubricating Oil Filter Bypass ValveSean DuncanNo ratings yet

- Service Information: October/04 II 25 01/04Document3 pagesService Information: October/04 II 25 01/04Marcelo GiussaniNo ratings yet

- Rcrit 14V647 9581Document43 pagesRcrit 14V647 9581Eko PurwantoNo ratings yet

- NissanDocument24 pagesNissanUbaldo SanchezNo ratings yet

- TM 120 Daily and Weekly Inspection and Maintenance TasksDocument23 pagesTM 120 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoNo ratings yet

- Warning: Section 5 Maintenance & LubricationDocument2 pagesWarning: Section 5 Maintenance & LubricationJuan Reynaga CoronadoNo ratings yet

- Drill Head Inspectionand Oil LevelsDocument6 pagesDrill Head Inspectionand Oil LevelsSipa1109No ratings yet

- HI-KALIBRE ActuatorDocument22 pagesHI-KALIBRE ActuatorProyectil De ProyectoNo ratings yet

- Atc70-125 1985 and Earlier Servicemanual OcrDocument32 pagesAtc70-125 1985 and Earlier Servicemanual Ocr80sDweebNo ratings yet

- PM Kelompok 4Document21 pagesPM Kelompok 4hakimNo ratings yet

- TM 80 Daily and Weekly Inspection and Maintenance TasksDocument25 pagesTM 80 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoNo ratings yet

- Geareducer Model 32.2: UsermanualDocument8 pagesGeareducer Model 32.2: UsermanualR BhattacharyaNo ratings yet

- MRP-004 - Brake Bleed - S08-001 v6.1Document4 pagesMRP-004 - Brake Bleed - S08-001 v6.1Matt CrossanNo ratings yet

- Attention: 62TE Installation GuideDocument2 pagesAttention: 62TE Installation Guideiriana2009No ratings yet

- Automatic Lubrication System Air - PurgeDocument2 pagesAutomatic Lubrication System Air - PurgeFernando Pérez SarriaNo ratings yet

- TM 5-3805-254-14P-2 Part 5 Ihc F-5070 Dump TruckDocument140 pagesTM 5-3805-254-14P-2 Part 5 Ihc F-5070 Dump TruckAdvocateNo ratings yet

- Intervalos de ManutençãoDocument3 pagesIntervalos de ManutençãoOzan MedeirosNo ratings yet

- E ServiceDocument2 pagesE Servicecatuheise2No ratings yet

- V40232 Clark C270 Torque ConverterDocument44 pagesV40232 Clark C270 Torque ConverterRemHenry100% (4)

- Service Instruction: LycomingDocument4 pagesService Instruction: LycomingGANo ratings yet

- E4nb71 - 300ZXDocument99 pagesE4nb71 - 300ZXbricasco100% (1)

- Section 5 - LubricationDocument7 pagesSection 5 - LubricationJulio Chapilliquen SandovalNo ratings yet

- SEBU6965-06 Before StartDocument6 pagesSEBU6965-06 Before StartLUIZ GUSTAVONo ratings yet

- RNM-12 400Document18 pagesRNM-12 400Matija ŠobanNo ratings yet

- j05 Maintenance 02Document57 pagesj05 Maintenance 02Asvedin SalihovicNo ratings yet

- Oil Change Service - Petrol A: HaynesDocument4 pagesOil Change Service - Petrol A: HaynesArizona RonnNo ratings yet

- Lubrication PDFDocument22 pagesLubrication PDFAndrey GladyshevNo ratings yet

- CS76 Before OperationDocument4 pagesCS76 Before OperationJosé Carlos CarvalhoNo ratings yet

- Instruct For OperationDocument1 pageInstruct For OperationAriel Martinez NNo ratings yet

- LC50ZB60-4 9C、LC80ZB30-4 9C+Owner's+ManuakDocument29 pagesLC50ZB60-4 9C、LC80ZB30-4 9C+Owner's+ManuakCarloss CastroNo ratings yet

- 2011 Maintenance Manual of Zoomlion Mixer(中英文)Document16 pages2011 Maintenance Manual of Zoomlion Mixer(中英文)Freddy AndresNo ratings yet

- 6D105 Series O&M ManualDocument49 pages6D105 Series O&M Manualjobin joyNo ratings yet

- Maintenance and Repair InstructionsDocument12 pagesMaintenance and Repair InstructionsDhananjay NilkuteNo ratings yet

- Oil Change Service - Petrol A: Renewal FDocument4 pagesOil Change Service - Petrol A: Renewal FArizona RonnNo ratings yet

- Onshore Rig Inspection ChecklistDocument113 pagesOnshore Rig Inspection ChecklistGregorio Otero Sosa100% (2)

- CAT CS533E Engine Part 4Document6 pagesCAT CS533E Engine Part 4Oecox Cah DjadoelNo ratings yet

- Hyundai Exel 89 1.5l.mantenimientoDocument18 pagesHyundai Exel 89 1.5l.mantenimientoAlexander cesar neyra sotoNo ratings yet

- Automatic Transmission NAG1 - Fluid and FilterDocument4 pagesAutomatic Transmission NAG1 - Fluid and FilterKrivega88No ratings yet

- Geareducer Model 32.2: UsermanualDocument8 pagesGeareducer Model 32.2: UsermanualR BhattacharyaNo ratings yet

- Kbu KBZ1Document4 pagesKbu KBZ1Andrew VNo ratings yet

- A-4000 OElindikator GBDocument4 pagesA-4000 OElindikator GBmadiNo ratings yet

- Oil Filter Wrench 1: IB - 69171 - PAWO12A1 - LB7 22.08.2011 12:36 Uhr Seite 1Document8 pagesOil Filter Wrench 1: IB - 69171 - PAWO12A1 - LB7 22.08.2011 12:36 Uhr Seite 1Dragan CristianNo ratings yet

- Motion Pro Leak Test 2TDocument1 pageMotion Pro Leak Test 2TLeandro CaraccioliNo ratings yet

- 6.0L Oil Change GuideDocument2 pages6.0L Oil Change GuidejegoodNo ratings yet

- Motorcraft 6 0L Diesel Oil Chage Reference SheetDocument2 pagesMotorcraft 6 0L Diesel Oil Chage Reference SheetivanNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- 7192 DR5021Document328 pages7192 DR5021Nova kurniawan 34No ratings yet

- 740 Vs Volvo A40D (TEJB8012)Document28 pages740 Vs Volvo A40D (TEJB8012)Nova kurniawan 34100% (1)

- Emergency Stop & Idle Timer System Liebh 9400Document2 pagesEmergency Stop & Idle Timer System Liebh 9400Nova kurniawan 34No ratings yet

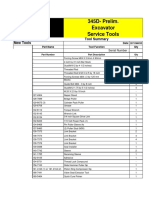

- 345D-Prelim. Excavator Service Tools: Tool Summary New ToolsDocument6 pages345D-Prelim. Excavator Service Tools: Tool Summary New ToolsNova kurniawan 34No ratings yet

- Product Manual: Idle Timer Etr Controller 12/24 VDocument20 pagesProduct Manual: Idle Timer Etr Controller 12/24 VNova kurniawan 34100% (2)

- 345D HEX Dealer Recommended Parts Stocking ListDocument3 pages345D HEX Dealer Recommended Parts Stocking ListNova kurniawan 34No ratings yet

- Diagnostic Flash Codes For CAT C13 Engines: Troubleshooting. Contact Your Local Cat Dealer For More InformationDocument3 pagesDiagnostic Flash Codes For CAT C13 Engines: Troubleshooting. Contact Your Local Cat Dealer For More InformationNova kurniawan 34100% (1)

- PA No: 19/08 For GCN1, GCN2, Asia & India OnlyDocument8 pagesPA No: 19/08 For GCN1, GCN2, Asia & India OnlyNova kurniawan 34No ratings yet

- Engine: Technical TrainingDocument70 pagesEngine: Technical TrainingNova kurniawan 34No ratings yet

- Electrical Component LocationDocument5 pagesElectrical Component LocationNova kurniawan 34No ratings yet