Professional Documents

Culture Documents

Odor Threshold Determinations of 53 Odorant Chemicals

Odor Threshold Determinations of 53 Odorant Chemicals

Uploaded by

T. LimCopyright:

Available Formats

You might also like

- Organic Chemistry Board Exam QuestionsDocument10 pagesOrganic Chemistry Board Exam QuestionsRiza Joie Versales100% (1)

- DS48A - (1978) Compilation of Odor and Taste Threshold Values DataDocument510 pagesDS48A - (1978) Compilation of Odor and Taste Threshold Values DataJacques BlueqNo ratings yet

- The Chemistry of FragranceDocument1 pageThe Chemistry of FragrancePatricia de LeonNo ratings yet

- Rum Ether Burnside - ErinDocument60 pagesRum Ether Burnside - ErinRichardClayre100% (1)

- Electronic NoseDocument28 pagesElectronic Nosevivek gangwar0% (1)

- Odour PollutionDocument25 pagesOdour PollutionDhananjay ShimpiNo ratings yet

- On The Unpredictability of OdorDocument8 pagesOn The Unpredictability of OdorFuckYouNo ratings yet

- Odor LawsDocument27 pagesOdor LawsΔημητρηςΣαρακυρουNo ratings yet

- Sensation and Perception: The Chemical Senses: Perceiving Odor and TasteDocument38 pagesSensation and Perception: The Chemical Senses: Perceiving Odor and TasteQuan TranNo ratings yet

- Is 2284 1988Document10 pagesIs 2284 1988TruptiNo ratings yet

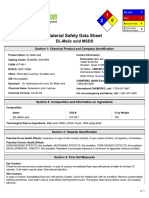

- Material Safety Data Sheet: 1. Identification of Substance/Preparation & CompanyDocument4 pagesMaterial Safety Data Sheet: 1. Identification of Substance/Preparation & CompanyCarlos ThomasNo ratings yet

- Is 3025 05 1983-Odour PDFDocument5 pagesIs 3025 05 1983-Odour PDFKrishna ReddyNo ratings yet

- PatchouliDocument38 pagesPatchouliBashir AnastasNo ratings yet

- Neuroscience6e ch15 Chemical SensesDocument34 pagesNeuroscience6e ch15 Chemical Sensesapi-438756405No ratings yet

- Perfumery Presentation ChemaromeDocument38 pagesPerfumery Presentation ChemaromeHamidah LutfianaNo ratings yet

- Odor PollutionDocument5 pagesOdor PollutionArafat IslamNo ratings yet

- The Perception of Fragrance Mixtures: A Comparison of Odor Intensity Models - Teixeira (2010)Document17 pagesThe Perception of Fragrance Mixtures: A Comparison of Odor Intensity Models - Teixeira (2010)Carloyos HoyosNo ratings yet

- Is.5126.1996-Sensory Analysis VocabularyDocument16 pagesIs.5126.1996-Sensory Analysis VocabularyTruptiNo ratings yet

- Article WJPR 1438667348Document40 pagesArticle WJPR 1438667348Ida NeniNo ratings yet

- Molecules: Perfume and Flavor Engineering: A Chemical Engineering PerspectiveDocument22 pagesMolecules: Perfume and Flavor Engineering: A Chemical Engineering PerspectiveAzamuddin JasrelNo ratings yet

- Lychee FlavourDocument58 pagesLychee FlavourshishirchemNo ratings yet

- PerfumeDocument21 pagesPerfumeoscar allen briosoNo ratings yet

- Solutions - Solutions or ProblemsDocument3 pagesSolutions - Solutions or ProblemsMorneNo ratings yet

- Organic Chemistry NotesDocument12 pagesOrganic Chemistry NotesZaina ImamNo ratings yet

- Submitted By: Kiran Naz O7-Arid-64 FT 6 SemesterDocument42 pagesSubmitted By: Kiran Naz O7-Arid-64 FT 6 SemesterKiran NiaziNo ratings yet

- Basic Flavour Systems 2014Document3 pagesBasic Flavour Systems 2014Shishir Kumar SinghNo ratings yet

- MSDS Europe Flavor - QL37106Document5 pagesMSDS Europe Flavor - QL37106Francisca SofiaNo ratings yet

- c06Document8 pagesc06Felipe SousaNo ratings yet

- Perfumes Brief TemplateDocument6 pagesPerfumes Brief TemplateRanNo ratings yet

- Perfume Making Equipment Guide 1Document18 pagesPerfume Making Equipment Guide 1omaralsaadi92No ratings yet

- VIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFDocument83 pagesVIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFOsamaAliMoussaNo ratings yet

- Diagnostics and Control of Odours-General PresentationDocument36 pagesDiagnostics and Control of Odours-General PresentationwaxsswaxNo ratings yet

- 1976 FixationDocument9 pages1976 FixationMark EvansNo ratings yet

- A04 - 475 Perfume IndustryDocument14 pagesA04 - 475 Perfume IndustryHectorNo ratings yet

- Philip Kraft, Karl A. D. Swift - Perspectives in Flavor and Fragrance Research-Wiley-VCH (2005)Document240 pagesPhilip Kraft, Karl A. D. Swift - Perspectives in Flavor and Fragrance Research-Wiley-VCH (2005)puneeth.darkNo ratings yet

- Firmenich - Collaborative Supply Chain StrategyDocument16 pagesFirmenich - Collaborative Supply Chain Strategyedwinwong81No ratings yet

- Firmenich Booklet Si2023Document23 pagesFirmenich Booklet Si2023Renee BarrettNo ratings yet

- SM2016 - 32. 2150 Odor (1997)Document5 pagesSM2016 - 32. 2150 Odor (1997)David AmayaNo ratings yet

- PROJECT Herbal HennaDocument209 pagesPROJECT Herbal HennaAkhil BijarniaNo ratings yet

- Measurement Values: Absolute Color Scales (Available When Display Type Is Absolute)Document26 pagesMeasurement Values: Absolute Color Scales (Available When Display Type Is Absolute)rafael_dvgNo ratings yet

- Odor ControlDocument9 pagesOdor ControlSabrina Dorado VinsonNo ratings yet

- A Method of Creation PerfumeryDocument32 pagesA Method of Creation PerfumeryAntwan NounehNo ratings yet

- Odor MapsDocument23 pagesOdor MapsMarcelo Teixeira RossiNo ratings yet

- Jean Claude Ellena Is Starting To Stand Out Among The Superstar Perfumers of Our TimeDocument6 pagesJean Claude Ellena Is Starting To Stand Out Among The Superstar Perfumers of Our Timemanasdev83No ratings yet

- Hydrodistillation: Myroxylon Balsamum, Storax, MyrrhDocument9 pagesHydrodistillation: Myroxylon Balsamum, Storax, MyrrhPatricia de LeonNo ratings yet

- VENTÓS Catalog 2012Document68 pagesVENTÓS Catalog 2012ernestoventosNo ratings yet

- Know Your Perfume: Fragrance Classification and CategoriesDocument11 pagesKnow Your Perfume: Fragrance Classification and CategoriesGretchen ReigNo ratings yet

- The Search For New Amber IngredientsDocument10 pagesThe Search For New Amber IngredientsOctavian CoifanNo ratings yet

- Additional Resources and SuppliersDocument9 pagesAdditional Resources and SuppliersErik NguyenNo ratings yet

- A Fragrant Introduction To Terpenoid Chemistry 3Document2 pagesA Fragrant Introduction To Terpenoid Chemistry 3Dele AwosileNo ratings yet

- Allergen Components (Found In) 1. Nickel Sulphate: Product Ordering About T.R.U.E. Test® Find A Distributor Contact UsDocument11 pagesAllergen Components (Found In) 1. Nickel Sulphate: Product Ordering About T.R.U.E. Test® Find A Distributor Contact UsLuqman HadiNo ratings yet

- Vanilin KirkDocument13 pagesVanilin KirkputrikurniawatiNo ratings yet

- Natural Pigment Betacyanin As Tracking Dye For Gel ElectrophoresisDocument4 pagesNatural Pigment Betacyanin As Tracking Dye For Gel ElectrophoresisWidya Isti AriantiNo ratings yet

- Symrise AR08Document156 pagesSymrise AR08María Margarita RodríguezNo ratings yet

- WRF Taste and Odor 1995Document400 pagesWRF Taste and Odor 1995aditiNo ratings yet

- Fragrances: Jeanne Duus Johansen and Jean-Pierre LepoittevinDocument21 pagesFragrances: Jeanne Duus Johansen and Jean-Pierre LepoittevinJuanManuelAmaroLuisNo ratings yet

- Carles1 PDFDocument11 pagesCarles1 PDFAnil KumarNo ratings yet

- By William Ilk. Curby and Vincent F. Lisanti : Methods FOR Evaluation of Products Designed FOR Oral Odor ControlDocument12 pagesBy William Ilk. Curby and Vincent F. Lisanti : Methods FOR Evaluation of Products Designed FOR Oral Odor ControlShobha KunduNo ratings yet

- Odor Thresholds and Irritation Levels of Several Chemical SubstancesDocument10 pagesOdor Thresholds and Irritation Levels of Several Chemical SubstancesIgnacio Quero EcheverriaNo ratings yet

- Boiling Range Distribution of Petroleum Fractions by Gas ChromatographyDocument20 pagesBoiling Range Distribution of Petroleum Fractions by Gas ChromatographyT. LimNo ratings yet

- Characterization and Properties of Petroleum Fractions ExcerptsDocument34 pagesCharacterization and Properties of Petroleum Fractions ExcerptsT. LimNo ratings yet

- Enclosed Ground Flares: Zero Smoke, Low Noise and No Visible FlameDocument4 pagesEnclosed Ground Flares: Zero Smoke, Low Noise and No Visible FlameT. LimNo ratings yet

- Char Siu (叉燒) - Chinese BBQ Pork - Made With LauDocument3 pagesChar Siu (叉燒) - Chinese BBQ Pork - Made With LauT. LimNo ratings yet

- On Sale On Sale On Sale On SaleDocument6 pagesOn Sale On Sale On Sale On SaleT. LimNo ratings yet

- Selection and Use of Firefighting Foams: Information BulletinDocument24 pagesSelection and Use of Firefighting Foams: Information BulletinT. LimNo ratings yet

- The Selection of The International Port Design StaDocument12 pagesThe Selection of The International Port Design StaT. LimNo ratings yet

- Air-Assisted Flares: Wide Range of Operation, Low Noise & Long Service LifeDocument4 pagesAir-Assisted Flares: Wide Range of Operation, Low Noise & Long Service LifeT. LimNo ratings yet

- Cafhi JettyDocument1 pageCafhi JettyT. LimNo ratings yet

- Planning Waste Cooking Oil Collection SyDocument13 pagesPlanning Waste Cooking Oil Collection SyT. LimNo ratings yet

- Wanner Control Freak ManualDocument28 pagesWanner Control Freak ManualT. LimNo ratings yet

- API 521 2020 Extract Hydraulic ReliefDocument6 pagesAPI 521 2020 Extract Hydraulic ReliefT. LimNo ratings yet

- DL Malic Acid SDSDocument5 pagesDL Malic Acid SDST. LimNo ratings yet

- AGI National Acid Sulfate Soils Guidance Identification-Laboratory-MethodsDocument105 pagesAGI National Acid Sulfate Soils Guidance Identification-Laboratory-MethodsT. LimNo ratings yet

- AGI NAtional Acid Sulfate Soils Guidance Sampling-Identification-MethodsDocument67 pagesAGI NAtional Acid Sulfate Soils Guidance Sampling-Identification-MethodsT. LimNo ratings yet

- Fumaric Acid MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pagesFumaric Acid MSDS: Section 1: Chemical Product and Company IdentificationT. LimNo ratings yet

- AGI National Acid Sulfate Soils Guidance Dewatering-Acid-Sulfate-SoilsDocument113 pagesAGI National Acid Sulfate Soils Guidance Dewatering-Acid-Sulfate-SoilsT. LimNo ratings yet

- Malic Acid - Food Grade: Thirumalai Chemicals LTDDocument2 pagesMalic Acid - Food Grade: Thirumalai Chemicals LTDT. LimNo ratings yet

- VEL2164-CAT-Filter-Separator-for-Aviation-Fuel-Handling ExcerptDocument1 pageVEL2164-CAT-Filter-Separator-for-Aviation-Fuel-Handling ExcerptT. LimNo ratings yet

- Gamma-Butyrolactone: Technical InformationDocument2 pagesGamma-Butyrolactone: Technical InformationT. LimNo ratings yet

- Product Stewardship Summary: Maleic AnhydrideDocument6 pagesProduct Stewardship Summary: Maleic AnhydrideT. LimNo ratings yet

- Fumaric Acid - Food Grade: Thirumalai Chemicals LTDDocument2 pagesFumaric Acid - Food Grade: Thirumalai Chemicals LTDT. LimNo ratings yet

- Tanks and Terminals - Summer 2019Document77 pagesTanks and Terminals - Summer 2019T. Lim100% (1)

- Process Measurement & Control Solutions: Dewatering of Storage Tanks, Automatic Draw Water Control, & Manual Tank GaugingDocument3 pagesProcess Measurement & Control Solutions: Dewatering of Storage Tanks, Automatic Draw Water Control, & Manual Tank GaugingT. LimNo ratings yet

- Organic Chemistry: Section A: Straight Objective TypeDocument26 pagesOrganic Chemistry: Section A: Straight Objective TypeAmarNo ratings yet

- PIEAS 02 Past Paper PakLearningSpotDocument7 pagesPIEAS 02 Past Paper PakLearningSpotFahad NawabNo ratings yet

- Chemistry Part 2 - Previous Board QuestionDocument13 pagesChemistry Part 2 - Previous Board QuestionSay2LearnNo ratings yet

- Hydrocarbon-04 Solved ProblemsDocument14 pagesHydrocarbon-04 Solved ProblemsRaju SinghNo ratings yet

- Narayana GT 1 Sol PDFDocument9 pagesNarayana GT 1 Sol PDFgyandattNo ratings yet

- Organic Agricultural Chemistry (1916) - J Chamberlain PDFDocument356 pagesOrganic Agricultural Chemistry (1916) - J Chamberlain PDFbabithy100% (1)

- Liquid Hand Dishwashing Detergent CompositionDocument38 pagesLiquid Hand Dishwashing Detergent CompositionEdgardo Ed RamirezNo ratings yet

- Dimethylsulfate Dupont Bulletin-Ahg-240913Document36 pagesDimethylsulfate Dupont Bulletin-Ahg-240913Dhiren PatelNo ratings yet

- SP Carey - Parte BDocument260 pagesSP Carey - Parte BLeanne SilvaNo ratings yet

- Reaction MechanismDocument13 pagesReaction MechanismMUHAMMAD YASEENNo ratings yet

- Carbon and Hydrogen Isotope Systematics of Bacterial Formation and Oxidation of Methane PDFDocument24 pagesCarbon and Hydrogen Isotope Systematics of Bacterial Formation and Oxidation of Methane PDFxocitlaNo ratings yet

- Chemistry-Xii (Chapter-06) - 2Document9 pagesChemistry-Xii (Chapter-06) - 2kanayalal184No ratings yet

- Valve Chemical - Compatibility - ChartDocument24 pagesValve Chemical - Compatibility - ChartElzeftawyNo ratings yet

- Acidicity Basicity & H - Bonding Tautomerism (Q.B.) 13thDocument16 pagesAcidicity Basicity & H - Bonding Tautomerism (Q.B.) 13thRaju SinghNo ratings yet

- Organic Vapour List PDFDocument1 pageOrganic Vapour List PDFDrGurkirpal Singh MarwahNo ratings yet

- SynthsisDocument30 pagesSynthsisGhost9350% (2)

- Alcohols-Structure and Synthesis 2Document82 pagesAlcohols-Structure and Synthesis 2Ali Issa OthmanNo ratings yet

- Goc TestDocument10 pagesGoc TestbalramsharmaNo ratings yet

- Fundamental Organic ChemistryDocument42 pagesFundamental Organic ChemistryShivam GuptaNo ratings yet

- Hsslive-Xi-Chem-Prvs-Qn-12. Organic Chemistry Some Basic PrinciplesDocument7 pagesHsslive-Xi-Chem-Prvs-Qn-12. Organic Chemistry Some Basic PrinciplesLayanNo ratings yet

- 3164 PDFDocument133 pages3164 PDFnoelNo ratings yet

- Organic Molecules React in Predictable Ways: Functional GroupsDocument21 pagesOrganic Molecules React in Predictable Ways: Functional GroupsNia Rakhmayanti NurdinNo ratings yet

- Monomethylation of Amphetamines - (WWW - Rhodium.ws)Document4 pagesMonomethylation of Amphetamines - (WWW - Rhodium.ws)Adam BruhNo ratings yet

- Key HW 2 Reson Acids&BasesDocument18 pagesKey HW 2 Reson Acids&BasesZES ProductionNo ratings yet

- Isododecane and Ldpe ProductionDocument6 pagesIsododecane and Ldpe ProductionjaveddilberNo ratings yet

- Listado Inertes EPADocument77 pagesListado Inertes EPAToSTADA RoyonNo ratings yet

- 12th Chemistry 1mark TestDocument6 pages12th Chemistry 1mark TestPons RathiNo ratings yet

- 15 Organic SynthesisDocument30 pages15 Organic SynthesisJulia MaramatNo ratings yet

- Design and Optimization of Dimethyl Oxalate (DMO) Hydrogenation Process To Produce Ethylene Glycol (EG)Document18 pagesDesign and Optimization of Dimethyl Oxalate (DMO) Hydrogenation Process To Produce Ethylene Glycol (EG)BryanJian100% (1)

Odor Threshold Determinations of 53 Odorant Chemicals

Odor Threshold Determinations of 53 Odorant Chemicals

Uploaded by

T. LimOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Odor Threshold Determinations of 53 Odorant Chemicals

Odor Threshold Determinations of 53 Odorant Chemicals

Uploaded by

T. LimCopyright:

Available Formats

Journal of the Air Pollution Control Association

ISSN: 0002-2470 (Print) (Online) Journal homepage: https://www.tandfonline.com/loi/uawm16

Odor Threshold Determinations of 53 Odorant

Chemicals

Gregory Leonardos , David Kendall & Nancy Barnard

To cite this article: Gregory Leonardos , David Kendall & Nancy Barnard (1969) Odor Threshold

Determinations of 53 Odorant Chemicals, Journal of the Air Pollution Control Association, 19:2,

91-95, DOI: 10.1080/00022470.1969.10466465

To link to this article: https://doi.org/10.1080/00022470.1969.10466465

Published online: 16 Mar 2012.

Submit your article to this journal

Article views: 43324

View related articles

Citing articles: 30 View citing articles

Full Terms & Conditions of access and use can be found at

https://www.tandfonline.com/action/journalInformation?journalCode=uawm20

Gregory Leonardos, David Odor Threshold Determinations

Kendall and Nancy Barnard

Arthur D. Little, Inc. Of 53 Odorant Chemicals

In order to assist in assessing potential odor problems arising from chemical manufacturing operations, the

odor thresholds of 53 commercially important odorant chemicals have been determined using a standardized

and defined procedure. The odor threshold data previously available have shown wide variation reflect-

ing the diversity of procedures and techniques used. Factors that may affect the odor threshold measure-

ment include the mode of presentation of the stimulus to the observer, the influence of extraneous odorants

in the presentation system, the type of observer used, the definition of the odor response, the treatment of

the data obtained, and the chemical purity of the odorant. The experimental approach used has mini-

mized these variations. The odoranfs were presented to a trained odor panel in a static air system utiliz-

ing a low odor background air as the dilution medium. The odor threshold is defined as the first concen-

tration at which all panel members can recognize the odor. The effect of chemical purity has been deter-

mined by measuring the odor threshold of materials representing different modes of manufacture or after

purification by gas chromatographic procedures. The threshold concentrations range over six orders of

magnitude. Trimethylamine exhibited the lowest threshold (0.00021 ppm volume); methylene chloride

was not recognizable below 214 ppm. Of the 53 chemicals, sulfur bearing compounds exhibit low thres-

hold values on the order of parts per billion. Aside from the sulfides, it is not possible to anticipate the

odor threshold of a material based on its chemical structure or functionality.

Odor thresholds for 53 commercially affect the odor threshold measurement The experimental procedure used

important odorant chemicals have been include the mode of presentation of the minimizes variation in the factors affect-

determined under controlled laboratory stimulus to the observer, the influence ing the odor threshold by utilizing the

conditions to permit comparison of their of extraneous odorants in the presenta- best available technology and proce-

absolute odor strengths. The odor tion system, the type of observer used, dures for measuring odor. We recog-

threshold data previously available the definition of the odor response, the nize the effect of chemical purity on the

have shown wide variation reflecting treatment of the data obtained, and the odor threshold and have studied this, on

the diversity of procedures and tech- chemical purity of the odorant. a limited basis, by evaluating the odor

niques used. Factors that may affect The experimental procedures used in threshold of the same chemical produced

the odor threshold measurement include determining the odor thresholds include from different starting materials,

the mode of presentation of the stimulus an odor test room offixedvolume (static method of production, or the addition of

to the observer, the influence of extrane- system) and low background odor for stabilizers. Selected chemicals were

ous odorants in the presentation system, presenting the stimulus to the observer. purified by gas liquid chromatographic

the type of observer used, the definition Trained odor analysts, who are capable procedures to note the effect of chemical

of the odor response, the treatment of of describing the character and intensity purity of the material on the odor

the data obtained, and the chemical of odor, were used throughout the study. threshold.

purity of the odorant. The experi- The odor response was defined rigor-

mental approach used has minimized ously by requiring each panel member Odor and the Odor Threshold

these variations. Laboratory deter- to describe the odor quality. By Before describing the techniques used

mination of recognition threshold con- minimizing the variation in procedure, and the results obtained, it is important

centrations is only one type of data re- sample presentation, and panelist, it is to have an understanding of the odor

quired to establish meaningful air possible to use a smaller number of re- sense, what it is, how and what is mea-

quality criteria. sponses. The odor threshold has been sured, and the significance of the odor

In 1967 the Manufacturing Chemists' defined as the first concentration at threshold. At the present time or in

Association asked Arthur D. Little, which all the panel members have been the foreseeable future, there are no

Inc., to determine the odor thresholds of •able to recognize the odor sensation instruments available for measuring

53 odorant chemicals using a standard- that is characteristic of the chemical odor other than the human and his nose.

ized and defined procedure to permit a and have been consistent in their re- The human nose has a well-deserved

comparison of their relative odor im- sponse at all higher test concentrations, reputation as a detector with high sensi-

portance. even when these are presented in a ran- tivity to certain chemicals at extremely

Odor thresholds in the past have been dom fashion to minimize sample order low concentrations. At the present

determined by a variety of methods. bias. time, instruments are available with

This may in part account for the varia- The experimental approach, then, sufficient sensitivity to detect concen-

tion in the reported data.1 Factors that was to determine the odor thresholds of trations of some odorant chemicals (such

a wide variety of chemicals of com- as methanol) that are below the odor

mercial importance using the standard- threshold. An odor measuring instru-

ized and defined procedure. The odor ment must not only parallel the sensi-

Mr. Leonardos, Mr. Kendall and tivity of the human nose but, more

Miss Barnard are Staff Chemists thresholds determined in this study are

with Arthur D. Little, Incorporated, internally consistent and on this basis important its response must parallel the

Acorn Park, Cambridge, Massachu- should find wide use in assessing poten- response of the biological system.

setts 02140. tial odor problems. Odor can be defined as sensations re-

February 1969 Volume 19, No. 2 91

suiting from the interaction of volatile center that just produces a response. liable nor reproducible. It may be

chemical species inhaled through the Concentrations of odorant chemical be- affected by subtle changes in back-

nose, making contact with the olfactory low this point will be judged not odor- ground odor, and by its very nature, is a

area and registering in the brain. Not ous. The concept of threshold, to be poorly defined odor response. Interest

all chemical compounds impinging on effective, requires a rigorously defined on the part of odor research workers has

the olfactorium produce the odor sensa- response. In the odor literature, there switched to the recognition threshold

tion. Odor may be considered as hav- are essentially two thresholds. Some concept which affords a better definition

ing at least two parameters—quality investigators have defined threshold as of the odor change. The statement,

and intensity. Both of these pa- the point where there is a detectable "We feel comfortable with the known,"

rameters are of importance in the odor difference from background. Another could be extended to "and the recogniz-

threshold measurement. The qualita- definition of threshold is the minimum able" when applied to measuring odor

tive aspect of the odor sensation may be identifiable odor (MIO) or recognition thresholds.

described in associative terms (odor threshold. Both may be properly con- The odor thresholds determined in

character notes) or broadly as hedonics, sidered odor thresholds. However, it this study are derived under near-ideal

i.e., "like-dislike." The lay observer has been our experience that the detec- conditions of low background odor. It

has a tendency to give a "like-dislike" tion threshold (first change from back- is not known what the effect on the odor

response. Through training, experi- ground) is less reliable and difficult to threshold is as a result of the interaction

ence, and attitude, the odor analyst will reproduce as it relies on a poorly defined of other odor contributing materials in

describe the odor sensation in terms of judgment of the observer. Often there the environment. In the real situation,

familiar qualitative experiences like is confusion as to the definition of the a high background odor partly through

fatty, sour, sweet, which are termed first change as well as changes that can the mechanism of adaptation becomes

odor character notes. occur in the background odor. The the reference point against which

Food flavors which are largely aromas recognition threshold, on the other changes are perceived.

are comprised of complex mixtures of hand, utilizing trained observers, al- It is likely that the odor thresholds

hundreds of chemicals which act as lows for a rigorous definition of the odor determined in this study may be lower

stimuli to the human sensor}^ organs. response. The recognition odor thresh- than those determined under environ-

Some of the chemicals are directly old can be defined as the first concentra- mental background conditions in view

identifiable, but most are either buried tion at which an observer can positively of their being determined under near-

in a complex blend or are read by the identify the odor quality of the odorant ideal conditions. However, we would

human system in combination as a char- chemical and is consistent in his re- like to point out the possible influence

acter note. These principles have sponse at all higher concentration levels. on odor threshold of varying back-

evolved into a method of measuring Some experimental work3 carried out ground odors to which the lay popula-

flavor and odor—The Flavor Profile previously at ADL suggests, that for a tion is subjected. The human reacts to

Method2—that has been successfully limited number of odorants over a change, and odor problems occur as a

used for solving flavor and odor prob- range of concentrations, it is possible to discernible change. At the present

lems for some 25 years. Odor char- distinguish by triangulation a difference time, the degree of this discernible

acter notes may be attributed to the in intensity produced by an increase of change is not known. This study

odor of a single chemical or an inte- concentration of approximately 60 per- should give some indication as to the

grated response to a mixture of chem- cent. Thus, there are 25-30 just-notice- extent of potential odor problems as a

icals. Reference to these chemicals or able differences (JND). The JND is de- result of chemical manufacturing opera-

mixtures of chemicals allows for the de- fined as the minimum change in con- tions.

velopment of a common terminology in centration which can be recognized

describing odor. "Single" chemical statistically as a difference in odor in-

Experimental

compounds may be described with one tensity. In practice, most organoleptic

or more character notes, depending on methods of flavor and odor analysis rely The chemicals obtained represent the

the nature of the chemical and the pres- on a seven to nine point intensity scale. highest purity commercially available

ence of impurities. The use of trained The threshold intensity is regarded as a from large scale production. Addi-

analysts who describe the odor response fixed concentration with other intensity tional samples of carbon tetrachloride

allows for increased confidence in assess- ratings representing a range or spread of and toluene representing different modes

ing data obtained for determining odor concentrations. Based on our observa- of production or starting material were

thresholds. In most threshold studies, tions in this work, it is probable that the evaluated. Samples of styrene with

emphasis has been placed on the in- odor threshold for an individual observer and without inhibitor were evaluated to

tensity of the odor response and not for a chemical may show some variation. note any effect on the odor threshold of

enough on the quality of the odor re- However, it is not likely that such the inhibitor. In addition, two samples

sponse. variation will be significantly greater of hydrogen sulfide were evaluated.

The second parameter of the odor re- than an order of magnitude. In this

sponse is the intensity (strength of re- study, concentrations evaluated occur Test Room

sponse). Although there is consider- in equal logarithmic steps somewhat The odor test room offers the conve-

able argument, intensity is generally greater than two JND's. nience of presenting the odor stimulus

accepted to be a logarithmic function of The detection threshold has been re- simultaneously to a group of analysts

the concentration of the chemical species lied upon to a great extent in the past. in a low odor background. The test

(as expressed by the Weber-Fechner This has been defined as that concentra- room consists of two chambers — an

Law). The Weber-Fechner Law has tion of odorant which produces the first antechamber and the test room — with

found wide application in the senses of change in odor over background. It is supporting equipment such as fans,

sound and sight and appears to be possible that much of the literature data ducts, and activated carbon filters for

applicable to the sense of smell. As although reported as detection thresh- removing odorized air and introducing a

with all biological systems, the response olds are in reality recognition thresholds controllable "odor-free background"

to odorants is not elicited at all concen- due to misinterpretation of the odor that serves as a dilution system.4 The

trations. Threshold is defined as the response. It has been our experience test room and antechamber are lined

degree of stimulation of a nerve or nerve that the detection threshold is not re- with polished aluminum that has been

92 Journal of the Air Pollution Control Association

shown to be relatively nonabsorptive to solvents used were other liquid mate- be present for all the odor examinations

odorant materials. Influent air that is rials whose odor properties had been scheduled for the day, as a different con-

used to purge the room is passed through studied within the program. Usually centration was evaluated at each ses-

a bank of activated carbon filters, cir- ethanol or mcthanol were used. The sion. The panel members were not in-

culated through the antechamber and dilutions were made in such a manner formed of the concentration of the

test room by five electric fans, and ex- that the amount of solvent present in chemical in the test room. A concen-

pelled through an exhaust port in the the test room was considerably below tration range was selected that was

ceiling. The test room has a volume of threshold. thought to include the threshold con-

approximately 500 cubic feet (13,200 Solid materials used to odorize the centration. The order of presentation

liters). test room were introduced in two ways —• of concentrations was on a random

The antechamber serves as a buffer injection of a solution containing the basis. The panel members did not

between the test room and the external dissolved solid or by volatilizing a make continuous observations; each

environment and serves to acclimate weighed amount with a flow of hot air. observation was separated by a mini-

the panel members to the relatively As an example, phenol was dissolved in mum of 25 minutes which was the time

odor-free conditions prior to each test odor-free water, and the appropriate necessary to purge the room and intro-

exposure. volume of the phenol solution was in- duce a new concentration of material

The chemical to be studied is intro- jected into the test room. Other solids into the test room. Olfactory fatigue

duced quantitatively at the appropriate were weighed into a suitable receptacle is thus no factor in the observations.

concentration level into the test room by which was placed in the test room, and The concentration levels examined

a variety of methods depending on its volatilized by a flow of warm air pro- for each chemical are increased in equal

physical properties. Three electric fans vided by a hot air fan. Usually five logarithmic steps. It is presumed that

circulate the odorant for five minutes, minutes was sufficient to volatilize the odor is a logarithmic function of con-

after which time the fans are shut down solid material. centration. The concentrations ex-

and the air in the test room is allowed to Gases were diluted with odor-free air amined were multiples by ten of 1, 2.1,

come to rest. The panel members enter in a dilution apparatus outside the test and 4.6 ppm (by volume). The large

the test room from the antechamber and room. The apparatus consisted of incremental steps in concentration were

make their individual odor observations three glass dilution bulbs which could selected so as to make the odor changes

describing the odor character and the be evacuated to as low as 0.01 mm Hg more evident and minimize the effects of

intensity of each odor character note by a mercury diffusion pump coupled individual variation.

that may be present. Upon completion to a liquid nitrogen trap. The three The results obtained from each pan-

of the analysis, the test room and ante- glass bulbs were used to prepare inter- elist were examined separately. A posi-

chamber are purged with the carbon- mediate dilutions of the gas. A 1.3 tive response is indicated for each con-

treated air for twenty minutes. In liter glass bulb was attached to the centration at which the panelist de-

only a few instances was the twenty- apparatus, evacuated, and then charged scribed the odor of the chemical. As

minute purge period inadequate for with a precisely calculated pressure the concentration level was varied at

odor removal. In these cases, purging from one of the three dilution bulbs. random, the threshold concentration

was continued until the room was odor The charged 1.3 liter bomb was then for each subject was determined by

free or a complete wash-down of the brought to atmospheric pressure with noting the positive responses as a func-

room was required. odor-free air. The contents of the 1.3 tion of the concentration. The thresh-

liter bomb were then swept into the test old was taken as the lowest concentra-

Odorization of the Test Room room with compressed air. tion at which the panelist could define

The chemicals evaluated included the odor and that which could be con-

liquids, gases, and solids. The air in Odor Panel sistently recognized at higher concen-

the test room (volume of 13,200 liters) A trained panel of four staff members trations.

served as the dilution medium. Liq- of the Food and Flavor Section of The threshold concentration for each

uids were injected into the test room Arthur D. Little, Inc. was used for chemical is compiled in this manner for

using Hamilton (Gas Tight) micro- determining the odor threshold of each each panel member. The odor thresh-

syringes. The syringes can accurately chemical. Panel members were selected old reported is the concentration at

deliver as little as 0.1 ul of material and from a pool of approximately fifteen which all four panel members could

are used extensively in gas chromatog- observers with more than one year of positively recognize the odor of the

raphy. To obtain the desired concen- analytical odor work. Only one chem- chemical.

tration of odorant chemical in the test ical was observed per day. Prior to the Three chemicals were selected for

room, the "Conversion Tables for Gases test room observations, the panel study to note the effects of the purity of

and Vapors" (Handbook of Physics and examined the odor over water at various the chemical on the odor threshold.

Chemistry, 44th edition, 1962, p. 2288) dilutions to become acquainted with the Toluene, styrene, and tolylene diiso-

were used to convert from ppm volume odor type and to develop a common cyanate were purified on a gas chro-

to milligrams of chemical per liter of air. terminology for describing the odor. matographic column (20' x 3/8" 50%

The total milligrams of material re- Each chemical was examined at a SE-30 on 80/100 Chromport XXX,

quired for the test room were calculated minimum offivedifferent concentrations preparative) under isothermal condi-

by multiplying the mg/liter by test in the odor test room. The first odor tions. The chromatographic column

room volume. The specific gravity as observation of the day for the odor effects a high plate efficiency distilla-

supplied by the manufacturer was then panel was a determination of the back- tion. Nitrogen was used as a carrier

used to calculate the volume of liquid ground level of the test room. These gas at a flow rate of 110 ml per minute.

odorant chemical to be injected into the sessions were included to ensure that the A number of repeated injections and

test room. As little as 0.1 jul of liquid room was not contaminated and also to collections were made to amass sufficient

odorant could be directly injected into acquaint the panel members with any quantities of purified material for the

the test room. Liquids whose threshold background odors that are inherent to odor test room study.

concentration was such that an injection the room. The background odor was Results

of less than 0.1 n\ was required were usually described as very slightly musty. The odor threshold reported for each

diluted in an appropriate solvent. The Each panel member was required to chemical is the concentration at which

February 1969 Volume 19, No. 2 93

Table I. Odor thresholds in air (ppm volume). all panelists recognize the odor. All

11

concentrations are calculated as parts

. Chemical Odor Threshold Odor Description per million by volume. The minimum

0.21 Green sweet,

threshold observed was with trimethyl

Acetaldehyde

Acetic acid 1.0 Sour amine at 0.00021 ppm (0.21 ppb).

Acetone 100.0 Chemical sweet, pungent Methylene chloride was not described

Acrolein 0.21 Burnt sweet, pungent below a concentration of 214 ppm. The

Acrylonitrile 21.4 Onion-garlic-pungency 53 compounds studied represent a range

Allyl chloride 0.47 Garlic-onion pungency.'green of six orders of magnitude in threshold

Amine, dimethyl 0.047 Fishy concentrations (Table I). Odor de-

Amine, monomethyl 0.021 Fishy, pungent scriptions (other than chemical name)

Amine, trimethyl 0.00021 Fishy, pungent used to describe the odor quality of the

Ammonia 46.8 Pungent

odorant chemical are included in Table

Aniline 1.0 Pungent

4.68 Solvent

I.

Benzene

Benzyl chloride 0.047 Solvent Sulfur Containing Compounds

Benzyl sulfide 0.0021 Sulfidy

As a group, compounds with the sulfur

Bromine 0.047 Bleach, pungent

0.001 Sour

atom in their structure have the lowest

Butyric acid

Carbon disulfide 0.21 Vegetable sulfide

thresholds of the compounds evaluated

Carbon tetrachloride (chlorination of CS2) 21.4 Sweet, pungent (Table II). All the sulfides with the

Carbon tetrachloride (chlorination of CH4) 100.0 exception of carbon disulfide and sulfur

Chloral 0.047 Sweet dioxide have threshold concentrations at

Chlorine 0.314 Bleach, pungent the parts per billion level.

Dimethylacetamide 46.8 Amine, burnt, oily Hydrogen sulfide gas from a cylinder

Dimethylformamide 100.0 Fishy, pungent exhibited a lower threshold than hy-

Dimethyl sulfide 0.001 Vegetable sulfide drogen sulfide gas produced by acidify-

Diphenyl ether (perfume grade) 0.1

Burnt rubbery

ing sodium sulfide. The discrepancy in

Diphenyl sulfide 0.0047

Ethanol (synthetic) 10.0 Sweet

the determined odor threshold for the

Ethyl acrylate 0.00047 Hot plastic, earthy two hydrogen sulfide samples may be

Ethyl mercaptan 0.001 Earthy, sulfidy due to impurities that are present in the

Formaldehyde 1.0 Hay/straw-like, pungent samples used; further studies are being

Hydrochloric acid gas 10.0 Pungent pursued to determine the factors ac-

Hydrogen sulfide (from Na2S) 0.0047 Eggy sulfide counting for this discrepancy between

Hydrogen sulfide gas 0.00047 samples. It is of interest that carbon

Methanol 100.0 Sweet disulfide, sulfur dichloride, and sulfur

Methyl chloride (above 10 ppm) dioxide affect the other chemical senses

Methylene chloride 214.0 (taste and feel) as well as having odorous

Methyl ethyl ketone 10.0 Sweet

Methyl isobutyl ketone 0.47 Sweet

effects.

Methyl mercaptan 0.0021 Sulfidy, pungent Nitrogen-Containing Compounds

Methyl methacrylate 0.21 Pungent, sulfidy Of the 53 odorant chemicals eval-

Monochlorobenzene 0.21 Chlorinated, moth'balls

Nitrobenzene

uated, trimethyl amine exhibited the

0.0047 Shoe polish, pungent

Paracresol 0.001 Tar-like, pungent

lowest threshold (0.00021 ppm). Di-

Paraxylene 0.47 Sweet methyl formamide is recognizable at

Perchloroethylene 4.68 Chlorinated solvent 100 ppm. The nitrogen-containing

Phenol 0.047 Medicinal compounds indicate the wide range of

Phosgene 1.0 Hay-like threshold concentrations that can occur

Phosphine 0.021 Oniony, mustard (Table III).

Pyridine 0.021 Burnt, pungent, diamine

Styrene (inhibited) 0.1 Solventy, rubbery Oxygenated Compounds

Styrene (uninhibited) 0.047 Solventy, rubbery, plasticy Table IV lists the odor thresholds of

Sulfur dichloride 0.001 Sulfidy oxygenated compounds according to

Sulfur dioxide 0.47 chemical class. Extent of oxidation of

Toluene (from coke) 4.68 Floral, pungent, solventy the ethanol series (ethanol, acetalde-

Toluene (from petroleum) 2.14 Moth balls, rubbery hyde, acetic acid) does not appear to

Tolylene diisocyanate 2.14 Medicated bandage, pungent

Trichloroethylene

have an affect on the odor threshold

21.4 Solventy

trend. One might expect a lower

a threshold as the oxidation state is in-

Other than chemical name

creased. Chloral (trichlorinated analog

of acetaldehyde) does have a substan-

tially lower threshold (0.047 ppm) than

Table II. Odor thresholds — sulfur Table III. Odor thresholds —nitrogenous

acetaldehyde. Considering other chlo-

pounds (ppm volume). compounds (ppm volume). rine-containing compounds studied, it is

not possible to make a generalization as

Hydrogen sulfide (cylinder) 0.00047 Trimethyl amine 0.00021 to the effect of chlorination on the odor

Dimethyl sulfide 0.0010 Nitrobenzene 0.0047 threshold.

Ethyl mercaptan 0.0010 Monomethyl amine 0.021

Sulfur dichloride 0.0010 Pyridine 0.021 Unsaturated Compounds

Benzyl sulfide 0.0021 Dimethyl amine 0.047 The presence of unsaturation in an

Methyl mercaptan 0.0021 Aniline 1.0 odorant chemical is not associated with

Hydrogen sulfide (Na2S) 0.0047 Acrylonitrile 21.4

Diphenyl sulfide 0.0047 Ammonia 46.8

low threshold concentrations (Table V).

Carbon disulfide 0.21 Dimethyl acetamide 46.8

Ethyl acrylate and methyl methacrylate

Sulfur dioxide 0.47 Dimethyl formamide 100.0 are isomeric, however, the threshold

concentrations are quite different. The

94 Journal of the Air Pollution Control Association

Table IV. Odor thresholds — oxygenated odor descriptions do differ (see Table I).

compounds (ppm volume). odor response provide consistent and

This disparity points up the difficulty of internally comparable data for one

Carbonyls making extended generalizations per- parameter of odor. These recognition

Chloral 0.047 taining to the odor threshold based on threshold concentrations demonstrate

Acetaldehyde 0.21 similar chemical structures. the broad range in sensitivity of human

Acrolein 0.21 olfaction to various chemical structures

Methyl isobutyl 1ketone 0.47 Benzenoid Compounds

under ideal test conditions.

Phosgene 1.0 The effect of substitution on the It should be noted that, in addition

Formaldehyde 1.0 benzene ring also produces a wide varia-

Methyl ethyl ketone 10.0 to the threshold concentration for a

tion in odor thresholds Table VI. given chemical compound, there are at

Acetone 100.0

A single methylation of the benzene least three sensory attributes and two

Esters ring (toluene) lowers the threshold one

Ethyl acrylate 0.00047 psychological parameters to be con-

concentration step. Further methyla- sidered in evaluating its contribution to

Methyl methacrylate 0.21

tion (p-xylene) succeeds in lowering the odor problems. The three sensory

Carboxylic Acids

odor threshold by an order of magnitude. attributes are: (1) the change in intensity

Butyric acid 0.001

Acetic acid 1.0

The —CH2CI group (benzyl chloride) (odor strength) with concentration;

produces an odor threshold that is 100 (2) the qualitative character of the

Alcohols

p-Cresol

times lower than benzene. The only odor; and (3) the type and degree of

0.001

Phenol 0.047

generalization possible with benzenoid- interaction with other odorants. Psy-

Ethanol 10.0 type materials is that substitution on chologically, people react either posi-

Methanol 100.0 the ring reduces the odor threshold by tively or negatively to odor types —

as much as a thousandfold depending on they like or dislike them. A problem is

the nature of the group added. usually associated with those that

Purity of the Chemical people dislike. Secondly, people react

Table V. Odor thresholds —variously Odor thresholds of samples purified more strongly to things that are differ-

substituted ethylenic compounds ( p p m

by gas liquid chromatography show ent and, therefore, what is normal or

volume).

slight differences, if any, from the start- expected is frequently accepted be it

Odor ing material. With tolylene diiso- good or bad.

Thresh- cyanate, the prime effect of the purifica- The work discussed in this paper is a

Chemical R Group(s) olds

tion appears to eliminate or reduce sub- first step in providing basic informa-

Ethyl acrylate -C:OOC2H6 0.00047 sidiary odor character notes and leaves tion on a number of chemicals which

Styrene —CeHs 0.047 a sharper odor impression of the prime are industrially important. The recog-

Acrolein —HC:O 0.21 odor character note. In this case, nition odor thresholds reported in this

Methyl meth- —CHs, 0.21 purification did not affect the recogni- study were developed under ideal lab-

acrylate —C:OOCH 3 oratory conditions and are not recom-

Allyl chloride —CH2CI

tion threshold. Table VII lists the

0.47

Tetrachloroethylene —CI(4X) 4.68

odor thresholds of chemicals before and mended for air quality criteria and

Trichloroethylene —CI(3X) 21.4 after purification. standards since no effort was made to

Acrylonitrile —C=N 21.4 Toluene (from coke) purified chroma- define the degree of objectionability of

tographically has a slighly lower odor the odorant chemicals. Future phases

threshold; styrene, however, on purifica- of this program will attempt to provide

tion showed a higher odor threshold. data on the other aspects of the problem,

Samples of carbon tetrachloride and such as the method of sample presenta-

Table VI. Odor thresholds'—variously

substituted benzenoid compounds (ppm toluene representing different modes of tion, the use of untrained observers, the

volume). manufacture do show variation in the change in intensity (and quality) with

odor threshold concentration (Table I). concentration, and the odor interactions

Odor with typical impurities.

Thresh- Carbon tetrachloride manufactured by

Chemical R Group(s) old the chlorination of carbon disulfide has a Studies are presently being conducted

lower threshold (21.4 ppm) than carbon to determine and compare the odor

Paracresol —OH, —CH 3 0.0010 tetrachloride produced by the chlorina- thresholds of selected chemicals ob-

Nitrobenzene —NO2 0.0047

Phenol —OH 0.0470

tion of methane (100 ppm). Toluene tained from various methods of odor

Benzyl Chloride —CH2CI 0.0470

produced from coke has a slightly higher presentation. These include the syringe

Styrene —CH:CH 2 0.0470 threshold concentration (4.68 ppm) dilution method and a dynamic (odor

Monochlorobenzene —Cl 0.21 than toluene produced from petroleum hood) method of odor presentation.

p-Xylene —CHs, —CH 3 0.47 (2.14 ppm). The odor character notes In addition, the effect of varying types

Aniline —NH 2 1.0 (Table I) used to describe the two sam- and levels of background odor on the

Toluene —CH 3 2.14 ples reflect the difference in mode of recognition odor threshold are being

Benzene 4.68 manufacture. The purity of the chem- evaluated.

ical can affect the odor quality as well as

the odor threshold. Thus it is difficult References

to predict with any certainty the role 1. Adams, E. M., "Air Pollution Abate-

Table VII. Odor thresholds of chemicals that impurities present in the compound ment Manual—Physiological Effects,"

purified by GLC. may play in affecting the odor threshold. Gosline, ed., 22-26, Ch. 5, Manual

Sheet p. 6, Manufacturing Chemists'

t o l y l e n e diisocyanate 2.14 ppm Conclusions

Assoc, Washington (1951)

Tolylene diisocyanate* 2.14 ppm

2. Sjostrom, L. B., Cairncross, S. E., and

Recognition odor thresholds have Caul, J. F., "Methodology of the flavor

Toluene (coke) 4.68 ppm

been determined in the laboratory by an profile," Food Tech. XI, 20, (1957)

Toluene (coke) a 2.14 ppm 3. Hainer, R. M., Emslie, A. G., and

Toluene (petroleum) 2.14 ppm

expert panel for 53 commercially im- Jacobson, A., "An information theory

portant chemicals. By standardizing of olfaction," Annals N.Y. Acad. of

Styrene (inhibited) 0.10 ppm

the method of sample presentation and Sci. 58, 158-173 (1954)

Styrene (inhibited) 3 0.21 ppm 4. Deininger, N., and McKinley, R. W.,

Styrene (uninhibited) 0.047 ppm minimizing extraneous sensory inter-

"The design, construction, and use of an

ference, the concentrations determined odor test room," ASTM, Sp. Tech.

«• Purified by GLC proceedures as producing the minimum identifiable Publ. No. 164 (1954)';

February 1969 Volume 19, No. 2 95

You might also like

- Organic Chemistry Board Exam QuestionsDocument10 pagesOrganic Chemistry Board Exam QuestionsRiza Joie Versales100% (1)

- DS48A - (1978) Compilation of Odor and Taste Threshold Values DataDocument510 pagesDS48A - (1978) Compilation of Odor and Taste Threshold Values DataJacques BlueqNo ratings yet

- The Chemistry of FragranceDocument1 pageThe Chemistry of FragrancePatricia de LeonNo ratings yet

- Rum Ether Burnside - ErinDocument60 pagesRum Ether Burnside - ErinRichardClayre100% (1)

- Electronic NoseDocument28 pagesElectronic Nosevivek gangwar0% (1)

- Odour PollutionDocument25 pagesOdour PollutionDhananjay ShimpiNo ratings yet

- On The Unpredictability of OdorDocument8 pagesOn The Unpredictability of OdorFuckYouNo ratings yet

- Odor LawsDocument27 pagesOdor LawsΔημητρηςΣαρακυρουNo ratings yet

- Sensation and Perception: The Chemical Senses: Perceiving Odor and TasteDocument38 pagesSensation and Perception: The Chemical Senses: Perceiving Odor and TasteQuan TranNo ratings yet

- Is 2284 1988Document10 pagesIs 2284 1988TruptiNo ratings yet

- Material Safety Data Sheet: 1. Identification of Substance/Preparation & CompanyDocument4 pagesMaterial Safety Data Sheet: 1. Identification of Substance/Preparation & CompanyCarlos ThomasNo ratings yet

- Is 3025 05 1983-Odour PDFDocument5 pagesIs 3025 05 1983-Odour PDFKrishna ReddyNo ratings yet

- PatchouliDocument38 pagesPatchouliBashir AnastasNo ratings yet

- Neuroscience6e ch15 Chemical SensesDocument34 pagesNeuroscience6e ch15 Chemical Sensesapi-438756405No ratings yet

- Perfumery Presentation ChemaromeDocument38 pagesPerfumery Presentation ChemaromeHamidah LutfianaNo ratings yet

- Odor PollutionDocument5 pagesOdor PollutionArafat IslamNo ratings yet

- The Perception of Fragrance Mixtures: A Comparison of Odor Intensity Models - Teixeira (2010)Document17 pagesThe Perception of Fragrance Mixtures: A Comparison of Odor Intensity Models - Teixeira (2010)Carloyos HoyosNo ratings yet

- Is.5126.1996-Sensory Analysis VocabularyDocument16 pagesIs.5126.1996-Sensory Analysis VocabularyTruptiNo ratings yet

- Article WJPR 1438667348Document40 pagesArticle WJPR 1438667348Ida NeniNo ratings yet

- Molecules: Perfume and Flavor Engineering: A Chemical Engineering PerspectiveDocument22 pagesMolecules: Perfume and Flavor Engineering: A Chemical Engineering PerspectiveAzamuddin JasrelNo ratings yet

- Lychee FlavourDocument58 pagesLychee FlavourshishirchemNo ratings yet

- PerfumeDocument21 pagesPerfumeoscar allen briosoNo ratings yet

- Solutions - Solutions or ProblemsDocument3 pagesSolutions - Solutions or ProblemsMorneNo ratings yet

- Organic Chemistry NotesDocument12 pagesOrganic Chemistry NotesZaina ImamNo ratings yet

- Submitted By: Kiran Naz O7-Arid-64 FT 6 SemesterDocument42 pagesSubmitted By: Kiran Naz O7-Arid-64 FT 6 SemesterKiran NiaziNo ratings yet

- Basic Flavour Systems 2014Document3 pagesBasic Flavour Systems 2014Shishir Kumar SinghNo ratings yet

- MSDS Europe Flavor - QL37106Document5 pagesMSDS Europe Flavor - QL37106Francisca SofiaNo ratings yet

- c06Document8 pagesc06Felipe SousaNo ratings yet

- Perfumes Brief TemplateDocument6 pagesPerfumes Brief TemplateRanNo ratings yet

- Perfume Making Equipment Guide 1Document18 pagesPerfume Making Equipment Guide 1omaralsaadi92No ratings yet

- VIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFDocument83 pagesVIETNAM. PROCESSING OF AROMA CHEMICALS AND FRAGRANCE MATERIALS. TECHNICAL REPORT - AROMA CHEMICALS AND PERFUME BLENDING (20598.en) PDFOsamaAliMoussaNo ratings yet

- Diagnostics and Control of Odours-General PresentationDocument36 pagesDiagnostics and Control of Odours-General PresentationwaxsswaxNo ratings yet

- 1976 FixationDocument9 pages1976 FixationMark EvansNo ratings yet

- A04 - 475 Perfume IndustryDocument14 pagesA04 - 475 Perfume IndustryHectorNo ratings yet

- Philip Kraft, Karl A. D. Swift - Perspectives in Flavor and Fragrance Research-Wiley-VCH (2005)Document240 pagesPhilip Kraft, Karl A. D. Swift - Perspectives in Flavor and Fragrance Research-Wiley-VCH (2005)puneeth.darkNo ratings yet

- Firmenich - Collaborative Supply Chain StrategyDocument16 pagesFirmenich - Collaborative Supply Chain Strategyedwinwong81No ratings yet

- Firmenich Booklet Si2023Document23 pagesFirmenich Booklet Si2023Renee BarrettNo ratings yet

- SM2016 - 32. 2150 Odor (1997)Document5 pagesSM2016 - 32. 2150 Odor (1997)David AmayaNo ratings yet

- PROJECT Herbal HennaDocument209 pagesPROJECT Herbal HennaAkhil BijarniaNo ratings yet

- Measurement Values: Absolute Color Scales (Available When Display Type Is Absolute)Document26 pagesMeasurement Values: Absolute Color Scales (Available When Display Type Is Absolute)rafael_dvgNo ratings yet

- Odor ControlDocument9 pagesOdor ControlSabrina Dorado VinsonNo ratings yet

- A Method of Creation PerfumeryDocument32 pagesA Method of Creation PerfumeryAntwan NounehNo ratings yet

- Odor MapsDocument23 pagesOdor MapsMarcelo Teixeira RossiNo ratings yet

- Jean Claude Ellena Is Starting To Stand Out Among The Superstar Perfumers of Our TimeDocument6 pagesJean Claude Ellena Is Starting To Stand Out Among The Superstar Perfumers of Our Timemanasdev83No ratings yet

- Hydrodistillation: Myroxylon Balsamum, Storax, MyrrhDocument9 pagesHydrodistillation: Myroxylon Balsamum, Storax, MyrrhPatricia de LeonNo ratings yet

- VENTÓS Catalog 2012Document68 pagesVENTÓS Catalog 2012ernestoventosNo ratings yet

- Know Your Perfume: Fragrance Classification and CategoriesDocument11 pagesKnow Your Perfume: Fragrance Classification and CategoriesGretchen ReigNo ratings yet

- The Search For New Amber IngredientsDocument10 pagesThe Search For New Amber IngredientsOctavian CoifanNo ratings yet

- Additional Resources and SuppliersDocument9 pagesAdditional Resources and SuppliersErik NguyenNo ratings yet

- A Fragrant Introduction To Terpenoid Chemistry 3Document2 pagesA Fragrant Introduction To Terpenoid Chemistry 3Dele AwosileNo ratings yet

- Allergen Components (Found In) 1. Nickel Sulphate: Product Ordering About T.R.U.E. Test® Find A Distributor Contact UsDocument11 pagesAllergen Components (Found In) 1. Nickel Sulphate: Product Ordering About T.R.U.E. Test® Find A Distributor Contact UsLuqman HadiNo ratings yet

- Vanilin KirkDocument13 pagesVanilin KirkputrikurniawatiNo ratings yet

- Natural Pigment Betacyanin As Tracking Dye For Gel ElectrophoresisDocument4 pagesNatural Pigment Betacyanin As Tracking Dye For Gel ElectrophoresisWidya Isti AriantiNo ratings yet

- Symrise AR08Document156 pagesSymrise AR08María Margarita RodríguezNo ratings yet

- WRF Taste and Odor 1995Document400 pagesWRF Taste and Odor 1995aditiNo ratings yet

- Fragrances: Jeanne Duus Johansen and Jean-Pierre LepoittevinDocument21 pagesFragrances: Jeanne Duus Johansen and Jean-Pierre LepoittevinJuanManuelAmaroLuisNo ratings yet

- Carles1 PDFDocument11 pagesCarles1 PDFAnil KumarNo ratings yet

- By William Ilk. Curby and Vincent F. Lisanti : Methods FOR Evaluation of Products Designed FOR Oral Odor ControlDocument12 pagesBy William Ilk. Curby and Vincent F. Lisanti : Methods FOR Evaluation of Products Designed FOR Oral Odor ControlShobha KunduNo ratings yet

- Odor Thresholds and Irritation Levels of Several Chemical SubstancesDocument10 pagesOdor Thresholds and Irritation Levels of Several Chemical SubstancesIgnacio Quero EcheverriaNo ratings yet

- Boiling Range Distribution of Petroleum Fractions by Gas ChromatographyDocument20 pagesBoiling Range Distribution of Petroleum Fractions by Gas ChromatographyT. LimNo ratings yet

- Characterization and Properties of Petroleum Fractions ExcerptsDocument34 pagesCharacterization and Properties of Petroleum Fractions ExcerptsT. LimNo ratings yet

- Enclosed Ground Flares: Zero Smoke, Low Noise and No Visible FlameDocument4 pagesEnclosed Ground Flares: Zero Smoke, Low Noise and No Visible FlameT. LimNo ratings yet

- Char Siu (叉燒) - Chinese BBQ Pork - Made With LauDocument3 pagesChar Siu (叉燒) - Chinese BBQ Pork - Made With LauT. LimNo ratings yet

- On Sale On Sale On Sale On SaleDocument6 pagesOn Sale On Sale On Sale On SaleT. LimNo ratings yet

- Selection and Use of Firefighting Foams: Information BulletinDocument24 pagesSelection and Use of Firefighting Foams: Information BulletinT. LimNo ratings yet

- The Selection of The International Port Design StaDocument12 pagesThe Selection of The International Port Design StaT. LimNo ratings yet

- Air-Assisted Flares: Wide Range of Operation, Low Noise & Long Service LifeDocument4 pagesAir-Assisted Flares: Wide Range of Operation, Low Noise & Long Service LifeT. LimNo ratings yet

- Cafhi JettyDocument1 pageCafhi JettyT. LimNo ratings yet

- Planning Waste Cooking Oil Collection SyDocument13 pagesPlanning Waste Cooking Oil Collection SyT. LimNo ratings yet

- Wanner Control Freak ManualDocument28 pagesWanner Control Freak ManualT. LimNo ratings yet

- API 521 2020 Extract Hydraulic ReliefDocument6 pagesAPI 521 2020 Extract Hydraulic ReliefT. LimNo ratings yet

- DL Malic Acid SDSDocument5 pagesDL Malic Acid SDST. LimNo ratings yet

- AGI National Acid Sulfate Soils Guidance Identification-Laboratory-MethodsDocument105 pagesAGI National Acid Sulfate Soils Guidance Identification-Laboratory-MethodsT. LimNo ratings yet

- AGI NAtional Acid Sulfate Soils Guidance Sampling-Identification-MethodsDocument67 pagesAGI NAtional Acid Sulfate Soils Guidance Sampling-Identification-MethodsT. LimNo ratings yet

- Fumaric Acid MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pagesFumaric Acid MSDS: Section 1: Chemical Product and Company IdentificationT. LimNo ratings yet

- AGI National Acid Sulfate Soils Guidance Dewatering-Acid-Sulfate-SoilsDocument113 pagesAGI National Acid Sulfate Soils Guidance Dewatering-Acid-Sulfate-SoilsT. LimNo ratings yet

- Malic Acid - Food Grade: Thirumalai Chemicals LTDDocument2 pagesMalic Acid - Food Grade: Thirumalai Chemicals LTDT. LimNo ratings yet

- VEL2164-CAT-Filter-Separator-for-Aviation-Fuel-Handling ExcerptDocument1 pageVEL2164-CAT-Filter-Separator-for-Aviation-Fuel-Handling ExcerptT. LimNo ratings yet

- Gamma-Butyrolactone: Technical InformationDocument2 pagesGamma-Butyrolactone: Technical InformationT. LimNo ratings yet

- Product Stewardship Summary: Maleic AnhydrideDocument6 pagesProduct Stewardship Summary: Maleic AnhydrideT. LimNo ratings yet

- Fumaric Acid - Food Grade: Thirumalai Chemicals LTDDocument2 pagesFumaric Acid - Food Grade: Thirumalai Chemicals LTDT. LimNo ratings yet

- Tanks and Terminals - Summer 2019Document77 pagesTanks and Terminals - Summer 2019T. Lim100% (1)

- Process Measurement & Control Solutions: Dewatering of Storage Tanks, Automatic Draw Water Control, & Manual Tank GaugingDocument3 pagesProcess Measurement & Control Solutions: Dewatering of Storage Tanks, Automatic Draw Water Control, & Manual Tank GaugingT. LimNo ratings yet

- Organic Chemistry: Section A: Straight Objective TypeDocument26 pagesOrganic Chemistry: Section A: Straight Objective TypeAmarNo ratings yet

- PIEAS 02 Past Paper PakLearningSpotDocument7 pagesPIEAS 02 Past Paper PakLearningSpotFahad NawabNo ratings yet

- Chemistry Part 2 - Previous Board QuestionDocument13 pagesChemistry Part 2 - Previous Board QuestionSay2LearnNo ratings yet

- Hydrocarbon-04 Solved ProblemsDocument14 pagesHydrocarbon-04 Solved ProblemsRaju SinghNo ratings yet

- Narayana GT 1 Sol PDFDocument9 pagesNarayana GT 1 Sol PDFgyandattNo ratings yet

- Organic Agricultural Chemistry (1916) - J Chamberlain PDFDocument356 pagesOrganic Agricultural Chemistry (1916) - J Chamberlain PDFbabithy100% (1)

- Liquid Hand Dishwashing Detergent CompositionDocument38 pagesLiquid Hand Dishwashing Detergent CompositionEdgardo Ed RamirezNo ratings yet

- Dimethylsulfate Dupont Bulletin-Ahg-240913Document36 pagesDimethylsulfate Dupont Bulletin-Ahg-240913Dhiren PatelNo ratings yet

- SP Carey - Parte BDocument260 pagesSP Carey - Parte BLeanne SilvaNo ratings yet

- Reaction MechanismDocument13 pagesReaction MechanismMUHAMMAD YASEENNo ratings yet

- Carbon and Hydrogen Isotope Systematics of Bacterial Formation and Oxidation of Methane PDFDocument24 pagesCarbon and Hydrogen Isotope Systematics of Bacterial Formation and Oxidation of Methane PDFxocitlaNo ratings yet

- Chemistry-Xii (Chapter-06) - 2Document9 pagesChemistry-Xii (Chapter-06) - 2kanayalal184No ratings yet

- Valve Chemical - Compatibility - ChartDocument24 pagesValve Chemical - Compatibility - ChartElzeftawyNo ratings yet

- Acidicity Basicity & H - Bonding Tautomerism (Q.B.) 13thDocument16 pagesAcidicity Basicity & H - Bonding Tautomerism (Q.B.) 13thRaju SinghNo ratings yet

- Organic Vapour List PDFDocument1 pageOrganic Vapour List PDFDrGurkirpal Singh MarwahNo ratings yet

- SynthsisDocument30 pagesSynthsisGhost9350% (2)

- Alcohols-Structure and Synthesis 2Document82 pagesAlcohols-Structure and Synthesis 2Ali Issa OthmanNo ratings yet

- Goc TestDocument10 pagesGoc TestbalramsharmaNo ratings yet

- Fundamental Organic ChemistryDocument42 pagesFundamental Organic ChemistryShivam GuptaNo ratings yet

- Hsslive-Xi-Chem-Prvs-Qn-12. Organic Chemistry Some Basic PrinciplesDocument7 pagesHsslive-Xi-Chem-Prvs-Qn-12. Organic Chemistry Some Basic PrinciplesLayanNo ratings yet

- 3164 PDFDocument133 pages3164 PDFnoelNo ratings yet

- Organic Molecules React in Predictable Ways: Functional GroupsDocument21 pagesOrganic Molecules React in Predictable Ways: Functional GroupsNia Rakhmayanti NurdinNo ratings yet

- Monomethylation of Amphetamines - (WWW - Rhodium.ws)Document4 pagesMonomethylation of Amphetamines - (WWW - Rhodium.ws)Adam BruhNo ratings yet

- Key HW 2 Reson Acids&BasesDocument18 pagesKey HW 2 Reson Acids&BasesZES ProductionNo ratings yet

- Isododecane and Ldpe ProductionDocument6 pagesIsododecane and Ldpe ProductionjaveddilberNo ratings yet

- Listado Inertes EPADocument77 pagesListado Inertes EPAToSTADA RoyonNo ratings yet

- 12th Chemistry 1mark TestDocument6 pages12th Chemistry 1mark TestPons RathiNo ratings yet

- 15 Organic SynthesisDocument30 pages15 Organic SynthesisJulia MaramatNo ratings yet

- Design and Optimization of Dimethyl Oxalate (DMO) Hydrogenation Process To Produce Ethylene Glycol (EG)Document18 pagesDesign and Optimization of Dimethyl Oxalate (DMO) Hydrogenation Process To Produce Ethylene Glycol (EG)BryanJian100% (1)