Professional Documents

Culture Documents

Wrapidcoat PVC: Superior Mechanical Protection

Wrapidcoat PVC: Superior Mechanical Protection

Uploaded by

cocoaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wrapidcoat PVC: Superior Mechanical Protection

Wrapidcoat PVC: Superior Mechanical Protection

Uploaded by

cocoaCopyright:

Available Formats

WrapidCoat® PVC

Superior Mechanical Protection

WrapidCoat® PVC is a tough, polyvinyl chloride based tape with

special high tack adhesive formulated as the outer wrap for

WrapidBond® viscoelastic coated pipe. The high tack adhesive and

tough backing provides effective mechanical protection and aids

as a barrier to water and oxygen which provides effective corrosion

protection and soil stress resistance.

Chemical Resistance

• Combined with WrapidBond®, the system is resistant to corrosive

salt water, soil acids, alkalies and salts, common chemicals,

Applications

chemical vapors, and short term exposure to outdoor weathering

and sunlight.

Oil & Gas

Flexibility & Adhesion

• Highly conformable, 0.50 mm (20 mil) thick tape

designed for application over a wide temperature range. Repair & Rehab

• Very easy to apply at high or low temperatures it provides

excellent adhesion and shear resistance.

Corrosion Coating

Long Term Corrosion Protection

• In combination with WrapidBond®, the composition of both

products is such that they provide an effective barrier to water Girth-Weld Joints

and oxygen which enhances corrosion protection and soil stress

resistance.

Fittings & Bends

WrapidBond™ inner wrap WrapidCoat™ PVC outer wrap

PRODUCT DATA SHEET canusacps.com

The product information

® shown here is intended as a guide

WrapidCoat PVC for standard products.

Consult your Canusa

Superior Mechanical Protection representative for specific

projects or unique applications.

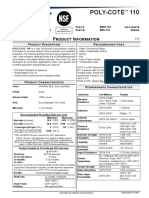

Typical Product Properties Test Method Typical Value

Color Black

Thickness 0.50 mm (20 mils)

Elongation @ Break ASTM D1000 200%

Tensile Strength ASTM D1000 70.0 N/cm (40 pli)

Impact Strength ASTM G14 15 J

Adhesion to Steel @ 12°C (54°F ) ASTM D1000 3.3 N/cm (1.9 pli)

Adhesion to Steel @ 23°C (74°F) ASTM D1000 2.2 N/cm (1.3 pli)

Roll Unwind @ 12°C (54°F) ASTM D1000 1.75 N/cm (1.0 pli)

Roll Unwind @ 23°C (74°F ) ASTM D1000 1.75 N/cm (1.0 pli) Canusa-CPS

A division of Shawcor Ltd.

Water Vapor Transmission Rate

ASTM D3833 1.0 Head Office

@ g/645 cm²/24 hrs.

25 Bethridge Road

Moisture Absorption ASTM D570 .35% Toronto, ON, Canada M9W 1M7

Tel: +1 416 743 7111

Dielectric Strength ASTM D1000 20 kv Fax: +1 416 743 5927

Canada

Normal Application -12°C to 70°C Dome Tower St. 2200, 333-7th Avenue SW

Calgary, AB, Canada T2P 2Z1

Temperature Range (+10°F to 158°F) Tel: +1 403 218 8207

Fax: +1 403 264 3649

Normal Service -48°C to 85°C

Americas

Temperature Range (-55°F to 185°F) 5875 N. Sam Houston Pkwy W., Suite 200

Houston, TX, USA 77086

* This data is not to be used for specification. Values listed are for typical properties and should not be considered minimum or maximum. Tel: +1 281 886 2350

Fax: +1 281 886 2353

Middle East

Plot # 37-WR43, Sector no.: ICAD III

Musaffah South, PO Box 2621

Abu Dhabi, The United Arab Emirates

Tel: +971 2 204 9800

Europe, Africa & Russia

Dellaertweg 9-E, Gebouw “Le Carrefour”

2316 WZ Leiden, The Netherlands (NL)

Tel: +31 71 80 802 70

Fax: +31 71 80 802 71

Asia-Pacific

101 Thomson Road, #11-03 United Square

307591 Singapore

Tel: +65 6749 8918

Fax: +65 6749 8919

Quality Management system

registered to ISO 9001

Canusa warrants that the product conforms to its

chemical and physical description and is appropriate

for the use stated on the product data sheet when

used in compliance with Canusa’s written instructions.

Since many installation factors are beyond our control,

the user shall determine the suitability of the products

for the intended use and assume all risks and liabilities

in connection therewith. Canusa’s liability is stated

in the standard terms and conditions of sale. Canusa

makes no other warranty either expressed or implied.

Since 1967, Canusa-CPS has been a leading developer and manufacturer of specialty pipeline coatings All information contained in this data sheet is to be

used as a guide and is subject to change without

for the sealing and corrosion protection of pipeline joints and other substrates. Canusa-CPS high notice. This data sheet supersedes all previous data

sheets on this product. E&OE

performance products are manufactured to the highest quality standards and are available in a number

of configurations to accommodate many specific project applications. PDS_Wrapid Coat PVC_rev021

You might also like

- Cathodic Protection For Steel Water Storage TanksDocument47 pagesCathodic Protection For Steel Water Storage TanksAhmed shaban100% (1)

- Airbnb House Manual TemplateDocument5 pagesAirbnb House Manual TemplatecocoaNo ratings yet

- Titanium Heat ExchangersDocument13 pagesTitanium Heat Exchangersxo123456789No ratings yet

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 pagesWrapidcoat PVC: Superior Mechanical ProtectionsenthilkumarNo ratings yet

- Wrapidcoat PVC: Superior Mechanical ProtectionDocument2 pagesWrapidcoat PVC: Superior Mechanical ProtectionHendra AwanNo ratings yet

- Wrapidtape: Primerless Crosslinked Protective TapeDocument2 pagesWrapidtape: Primerless Crosslinked Protective TapeHendra AwanNo ratings yet

- CANUSA Wrapid TapeDocument2 pagesCANUSA Wrapid TapeHalimNo ratings yet

- Wrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionDocument2 pagesWrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionHendra AwanNo ratings yet

- Wrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionDocument2 pagesWrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionHendra AwanNo ratings yet

- PDS - Na - Klon-KlnnDocument2 pagesPDS - Na - Klon-Klnndemi bajakanNo ratings yet

- Scar Guard EnglishDocument2 pagesScar Guard EnglishVismael SantosNo ratings yet

- Canusa GTS 80Document2 pagesCanusa GTS 80ZainudinNo ratings yet

- Pds Na Gts65Document2 pagesPds Na Gts65Yan FerizalNo ratings yet

- Parche CRP 65 - Ficha Técnica - en InglesDocument2 pagesParche CRP 65 - Ficha Técnica - en IngleserwinvillarNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Hbe-Os: High Build Epoxy Coating For Offshore Corrosion ProtectionDocument2 pagesHbe-Os: High Build Epoxy Coating For Offshore Corrosion Protectionsamkarthik47No ratings yet

- High Build Epoxy Coating For Pipelines: Product Data SheetDocument2 pagesHigh Build Epoxy Coating For Pipelines: Product Data Sheetdemi bajakanNo ratings yet

- PDS - NA - PRP Repair Data SheetDocument2 pagesPDS - NA - PRP Repair Data SheetHendra AwanNo ratings yet

- GRI-GM30: Weld Easier. Install Faster. Contain BetterDocument2 pagesGRI-GM30: Weld Easier. Install Faster. Contain BetterAndreas Erdian WijayaNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- Technical Brief Galal Make SleevesDocument1 pageTechnical Brief Galal Make SleevesSELVAGANAPATHINo ratings yet

- Wrapidbond™ FST: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionDocument2 pagesWrapidbond™ FST: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionDinesh PillaiNo ratings yet

- Pds Na Hbeht HssDocument2 pagesPds Na Hbeht HssdakidofdaboomNo ratings yet

- HSS Canusa PDFDocument2 pagesHSS Canusa PDFresp-ectNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Hbe-Cw: High Build Liquid Coating For Low Temperature ApplicationsDocument2 pagesHbe-Cw: High Build Liquid Coating For Low Temperature ApplicationsMohammad Mehdi JafariNo ratings yet

- High Build Epoxy Coating For Pipelines: Product Data SheetDocument2 pagesHigh Build Epoxy Coating For Pipelines: Product Data SheetChegg ChemNo ratings yet

- Poly-Cote 110 (Aug'22)Document4 pagesPoly-Cote 110 (Aug'22)David cNo ratings yet

- Elite NG 5401BDocument3 pagesElite NG 5401BAbdo WalidNo ratings yet

- Mariseal 400 Aqua Version18Document2 pagesMariseal 400 Aqua Version18Chetal BholeNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- Manta Canusa - GTS65 - en InglesDocument2 pagesManta Canusa - GTS65 - en IngleserwinvillarNo ratings yet

- Hoja Tecnica PEAD PE-100 Tipo P600Document1 pageHoja Tecnica PEAD PE-100 Tipo P600Manuel Agustin TeneNo ratings yet

- DoW LDPE 2685GDocument4 pagesDoW LDPE 2685Gtariquekhan143No ratings yet

- Estane Skythane S185A TPU: TypeDocument1 pageEstane Skythane S185A TPU: Typejuliushasan2No ratings yet

- Epofine 556 FR/ FInehard 951Document3 pagesEpofine 556 FR/ FInehard 951Karishma Prabhu100% (1)

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetEdwin Bustamante Cabrera100% (1)

- Canusa Flanş Izolasyonu Için Isı Ile Büzüşen Levha Çözümü PDS - NA - HSDocument2 pagesCanusa Flanş Izolasyonu Için Isı Ile Büzüşen Levha Çözümü PDS - NA - HSozcanNo ratings yet

- Lotte Titanpro PM903 Product DataDocument1 pageLotte Titanpro PM903 Product DataJoni Sie MssNo ratings yet

- Exceed™ S 9333 Series: Performance PolymerDocument2 pagesExceed™ S 9333 Series: Performance PolymerMaram YasserNo ratings yet

- 3M Heavy Wall Heat Shrink Tubing ITCSNDocument4 pages3M Heavy Wall Heat Shrink Tubing ITCSNmuahdibNo ratings yet

- DOWLEX™ 2038.68G: Polyethylene ResinDocument3 pagesDOWLEX™ 2038.68G: Polyethylene ResinJosé PalmaNo ratings yet

- NA9800000Document2 pagesNA9800000Noe floresNo ratings yet

- PVC Insulating Tape PREMIUMDocument1 pagePVC Insulating Tape PREMIUMengman2121No ratings yet

- VISCOWRAP-HT Product Data Sheet EnglishDocument2 pagesVISCOWRAP-HT Product Data Sheet EnglishJA BustosNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonatepuvitta sudeshilaNo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateROHIT SHARMANo ratings yet

- PolycarbonateDocument2 pagesPolycarbonateAdnan KhanNo ratings yet

- HDPE-100 Catalogue PDFDocument9 pagesHDPE-100 Catalogue PDFkumar sandeepNo ratings yet

- tds12 19 2019 - 10 49 12Document1 pagetds12 19 2019 - 10 49 12Camilo DazaNo ratings yet

- K-Resin BK10: Styrene Butadiene Copolymer (SBC)Document2 pagesK-Resin BK10: Styrene Butadiene Copolymer (SBC)Manikanta Sai KumarNo ratings yet

- Futong Ism Tds SCG Hdpe h2001wc 20jul20Document3 pagesFutong Ism Tds SCG Hdpe h2001wc 20jul20Aung Thein OoNo ratings yet

- 21.00078 Classic - TDS - CA - v6Document2 pages21.00078 Classic - TDS - CA - v6beattiecNo ratings yet

- Sikadur-42 MP Normal HCDocument6 pagesSikadur-42 MP Normal HCDidiet PuteraNo ratings yet

- EcoSonic VpCI 125 ESD HP UVDocument3 pagesEcoSonic VpCI 125 ESD HP UVcongnghiephoachat01No ratings yet

- Ajedium Films (Solvay)Document3 pagesAjedium Films (Solvay)hyper meshNo ratings yet

- Datasheet - r680s - Randompp - e 3Document2 pagesDatasheet - r680s - Randompp - e 3Gulzar HossainNo ratings yet

- Product Data Sheet PP 200Document1 pageProduct Data Sheet PP 200AlonsoNo ratings yet

- SCGC LSP L2420J Technical Datasheet ProvisionalDocument3 pagesSCGC LSP L2420J Technical Datasheet Provisionalakankshas06No ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- What Do Guests Value Most in Airbnb Accommodations - An Application of The Hedonic Pricing Approach - Dogru PekinDocument14 pagesWhat Do Guests Value Most in Airbnb Accommodations - An Application of The Hedonic Pricing Approach - Dogru PekincocoaNo ratings yet

- Perceptual Map of Online Fashion Store: Journal of Business and ManagementDocument8 pagesPerceptual Map of Online Fashion Store: Journal of Business and ManagementcocoaNo ratings yet

- Aihw Aus 232Document76 pagesAihw Aus 232cocoaNo ratings yet

- 1.9.1.2-10T - Aluminum BronzeDocument4 pages1.9.1.2-10T - Aluminum BronzechonubobbyNo ratings yet

- Ice Melt Buyer'S Guide Ice Melt Buyer'S GuideDocument7 pagesIce Melt Buyer'S Guide Ice Melt Buyer'S GuidelyndondrNo ratings yet

- NALCO Corrosionmanual PDFDocument126 pagesNALCO Corrosionmanual PDFhoannhu100% (2)

- Application of Coating - PT BadakDocument29 pagesApplication of Coating - PT BadakDimas PratamaNo ratings yet

- Inspection and Inspection Above Ground FRP LiningDocument8 pagesInspection and Inspection Above Ground FRP LiningKamatchi NathanNo ratings yet

- A2 - Topic 3 - Intan Sri Maharani - E1b120010Document6 pagesA2 - Topic 3 - Intan Sri Maharani - E1b120010Intan Maharani0% (1)

- ACDelco Brochure PDFDocument64 pagesACDelco Brochure PDFEljhal CastleNo ratings yet

- MercruiserDocument268 pagesMercruiserJoe Pudlak100% (1)

- Failure Analysis of Bend Tube Preheater On Heat Recovery Steam GeneratorDocument6 pagesFailure Analysis of Bend Tube Preheater On Heat Recovery Steam GeneratorarifbogNo ratings yet

- Surface Preparation and Marking of Metallic Surgical ImplantsDocument3 pagesSurface Preparation and Marking of Metallic Surgical ImplantsEssam Eldin Metwally AhmedNo ratings yet

- SORDocument110 pagesSORChandan GautamNo ratings yet

- Trim Number Chart API ValveDocument2 pagesTrim Number Chart API ValveVelu .cNo ratings yet

- Halox SZP-391: Technical DataDocument1 pageHalox SZP-391: Technical DataArturo BarjauNo ratings yet

- IS 10569 - 2005 - Reff2021Document7 pagesIS 10569 - 2005 - Reff2021k27571No ratings yet

- Civil Engineering Materials MaterialsDocument19 pagesCivil Engineering Materials MaterialsTabi RamseyNo ratings yet

- Chapter 2Document5 pagesChapter 2wsrfcvNo ratings yet

- Electromagnetic Compatibility: Unit-1: Introduction To EmcDocument28 pagesElectromagnetic Compatibility: Unit-1: Introduction To EmcShiva Prasad M100% (1)

- NopanDocument3 pagesNopanM.Dwi CahyaNo ratings yet

- Epoxy Coating of Steel ReinforcementDocument2 pagesEpoxy Coating of Steel ReinforcementSam WanneNo ratings yet

- Guia Linear Bosch RexrothDocument232 pagesGuia Linear Bosch RexrothmarcioNo ratings yet

- Principles of Cathodic ProtectionDocument8 pagesPrinciples of Cathodic Protectionskumar_krishnan100% (1)

- Amalgam PresentationDocument11 pagesAmalgam Presentationkr2001_2001No ratings yet

- 2007gates Hyd Cat10-10-07Document598 pages2007gates Hyd Cat10-10-07jaysx5No ratings yet

- Appendix 4 Worked Example: Type C Strategy: Esr-In-Confidence HOIS-G-103 Issue 1Document8 pagesAppendix 4 Worked Example: Type C Strategy: Esr-In-Confidence HOIS-G-103 Issue 1Mo BlackNo ratings yet

- Technical Process Bulletin: Alumiprep® 33Document3 pagesTechnical Process Bulletin: Alumiprep® 33JUAN PABLO VASQUEZ VASQUEZNo ratings yet

- Civil Engineering Kerala SyllabusDocument120 pagesCivil Engineering Kerala SyllabusJinu MadhavanNo ratings yet

- It Syllabus For Kuk BtechDocument130 pagesIt Syllabus For Kuk Btechjigaro7150% (2)

- Inspection of HDG.Document71 pagesInspection of HDG.Mritunjay100% (1)