Professional Documents

Culture Documents

Comparacion FVD Vs FDD

Comparacion FVD Vs FDD

Uploaded by

Bernardo Diaz SuarezCopyright:

Available Formats

You might also like

- Instruction Manual: For Installation, Operation & MaintenanceDocument40 pagesInstruction Manual: For Installation, Operation & MaintenanceAvinash GamitNo ratings yet

- 102 103 Differential Pressure Switches Cat388Document16 pages102 103 Differential Pressure Switches Cat388contato.tiagogatodesouzaNo ratings yet

- 102 103 Differential Pressure Switches Cat388Document16 pages102 103 Differential Pressure Switches Cat388Fake AccountNo ratings yet

- Fluid Viscous DamperDocument3 pagesFluid Viscous DamperShikhar KothariNo ratings yet

- Copeland VFDDocument4 pagesCopeland VFDluigi schiavoneNo ratings yet

- High Voltage Breai (Ers, IncDocument9 pagesHigh Voltage Breai (Ers, IncAnonymous u0wETydFNo ratings yet

- Choosing The Right Cable For Your Variable Frequency Drive (VFD) SystemDocument7 pagesChoosing The Right Cable For Your Variable Frequency Drive (VFD) SystemAhmedNo ratings yet

- WATTS New Premium ContentDocument32 pagesWATTS New Premium ContentbaoHVLABNo ratings yet

- CT PDFDocument63 pagesCT PDFGobi Kannan S.100% (3)

- Turn Green With Variable-Frequency Drives: Hydraulic PressesDocument3 pagesTurn Green With Variable-Frequency Drives: Hydraulic PressesabhisdestinyNo ratings yet

- The Best Applications For VFDS: Home Technical ArticlesDocument4 pagesThe Best Applications For VFDS: Home Technical ArticlesjnikkoNo ratings yet

- Xylem Guide To BlowersDocument11 pagesXylem Guide To BlowersAmal KaNo ratings yet

- Product Catalog Copeland Scroll ZBKQ Compressor For Refrigeration Applications en SG 6631804Document80 pagesProduct Catalog Copeland Scroll ZBKQ Compressor For Refrigeration Applications en SG 6631804Muhammad Zhakri Muhammad KamalNo ratings yet

- V, HV, HVRS Series & Hypac: Rotary Vane Air CompressorsDocument12 pagesV, HV, HVRS Series & Hypac: Rotary Vane Air CompressorsCelso FernandesNo ratings yet

- Advanced Efficiency, Precision Cooling: Design An HVAC System Like No OtherDocument6 pagesAdvanced Efficiency, Precision Cooling: Design An HVAC System Like No Other12345laurNo ratings yet

- NIDECDocument18 pagesNIDECroyert8No ratings yet

- Fluid Damper (FD)Document20 pagesFluid Damper (FD)monalisa estherNo ratings yet

- Variable Effort SupportsDocument29 pagesVariable Effort SupportssanmukhaNo ratings yet

- Inverter Duty MotorDocument6 pagesInverter Duty Motorseshubabu_999No ratings yet

- Understanding Variable Speed Drives: Basic VFD TheoryDocument7 pagesUnderstanding Variable Speed Drives: Basic VFD TheorynikecerreroNo ratings yet

- DA102-13 Damper Torque PDFDocument3 pagesDA102-13 Damper Torque PDFNguyễn LinhNo ratings yet

- Damper TorqueDocument3 pagesDamper TorqueNguyễn LinhNo ratings yet

- Coupling Design and SelectionDocument11 pagesCoupling Design and SelectionVivek RathodNo ratings yet

- Trane Jan2006Document8 pagesTrane Jan2006TomLinNo ratings yet

- Protection of VSD TransformersDocument12 pagesProtection of VSD TransformersGetssy PrathibaNo ratings yet

- VFD For Centrifugal PumpsDocument11 pagesVFD For Centrifugal PumpsChem.EnggNo ratings yet

- Variable Frequency DrivesDocument46 pagesVariable Frequency DrivesCubix AutomationNo ratings yet

- EN53000 Einsatzbedingungen Ventile PDFDocument1 pageEN53000 Einsatzbedingungen Ventile PDFPritesh KoratNo ratings yet

- EN53000 Einsatzbedingungen Ventile PDFDocument1 pageEN53000 Einsatzbedingungen Ventile PDFPritesh KoratNo ratings yet

- Conditions and Instructions For ValvesDocument1 pageConditions and Instructions For ValveshelderfgmNo ratings yet

- Yonis Hussain ReportDocument9 pagesYonis Hussain ReportENG.YONIS HUSSAINNo ratings yet

- Centaflex DDocument7 pagesCentaflex DInu Muh NuurNo ratings yet

- KVT High Pressure Large Bore Valves PDFDocument16 pagesKVT High Pressure Large Bore Valves PDFkamal arabNo ratings yet

- Refrigeration and Air ConditioningDocument4 pagesRefrigeration and Air ConditioningAleksandar Sasa SeferovicNo ratings yet

- Variable Frequency DriveDocument11 pagesVariable Frequency DriveNAYEEM100% (5)

- Operation and Application of Variable Frequency Drive (VFD) TechnologyDocument11 pagesOperation and Application of Variable Frequency Drive (VFD) TechnologyFryjo FrancisNo ratings yet

- Produkte PowerStromteiler Datenbl EnglDocument16 pagesProdukte PowerStromteiler Datenbl EnglCarlos Augusto100% (1)

- Comparisonbetweenvrv Vrfbrandssuppliersuaemarket May2016 Bygetco 160430182626Document128 pagesComparisonbetweenvrv Vrfbrandssuppliersuaemarket May2016 Bygetco 160430182626phuongnhsfc100% (1)

- FITformerWINDflyer-pdf - Original FileDocument3 pagesFITformerWINDflyer-pdf - Original Filef.dimarinoNo ratings yet

- Frecuencias Críticas para Motor USDocument2 pagesFrecuencias Críticas para Motor USInstalaciones ElectromecánicasNo ratings yet

- Choosing The Right Cable For Your Variable Frequency Drive (VFD) SystemDocument8 pagesChoosing The Right Cable For Your Variable Frequency Drive (VFD) SystemroyclhorNo ratings yet

- Significant Nonlinearities Due To Force-Deflection Hysteresis and DueDocument16 pagesSignificant Nonlinearities Due To Force-Deflection Hysteresis and Duekosarayu2007No ratings yet

- Korfund Spring MountsDocument50 pagesKorfund Spring Mountsuamiranda3518No ratings yet

- Variable Frequency Drives For Centrifugal PumpsDocument11 pagesVariable Frequency Drives For Centrifugal PumpsOzkr_sgNo ratings yet

- DESCH Complete Press DriveDocument8 pagesDESCH Complete Press DriveSerdar FildisNo ratings yet

- The Rotary Screw Compressor: Ashrae JournalDocument3 pagesThe Rotary Screw Compressor: Ashrae JournalAkhli RahmatullohNo ratings yet

- 2010 23 Supercond SC Tech Superconductur Transformer 0953 2048 23-1-014025Document6 pages2010 23 Supercond SC Tech Superconductur Transformer 0953 2048 23-1-014025Sandra ZitzNo ratings yet

- MD SeriesDocument91 pagesMD Seriesebraheem ElbrinsNo ratings yet

- Unit 6Document40 pagesUnit 6mott macNo ratings yet

- Wcee2012 2922 PDFDocument10 pagesWcee2012 2922 PDFponjoveNo ratings yet

- DJ1E2DM VFD SuitablilyDocument2 pagesDJ1E2DM VFD Suitablilysahendra4673No ratings yet

- TMC AdustableSpeedDrive WP PDFDocument2 pagesTMC AdustableSpeedDrive WP PDFTandin WangChukNo ratings yet

- Info Penting Ahli Struktur GempaDocument337 pagesInfo Penting Ahli Struktur Gempadicky1969No ratings yet

- Taylor Devices, Inc. Building Today For Tomorrow Since 1955Document28 pagesTaylor Devices, Inc. Building Today For Tomorrow Since 1955rosciiNo ratings yet

- 1 1061GBDocument8 pages1 1061GBPatricio RojasNo ratings yet

- TransformersDocument77 pagesTransformersAshwani Dogra100% (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- High Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorFrom EverandHigh Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorNo ratings yet

- A New Approach To System Identi Fication and Damage Detection of High-Rise BuildingsDocument25 pagesA New Approach To System Identi Fication and Damage Detection of High-Rise BuildingsBernardo Diaz SuarezNo ratings yet

- Memoria de Calculo EstructuralDocument160 pagesMemoria de Calculo EstructuralBernardo Diaz SuarezNo ratings yet

- Review Paper: Fundamentals of System Identification in Structural DynamicsDocument12 pagesReview Paper: Fundamentals of System Identification in Structural DynamicsBernardo Diaz SuarezNo ratings yet

- Analysis and Estimation of Stochastic Mechanical Systems 1988 PDFDocument352 pagesAnalysis and Estimation of Stochastic Mechanical Systems 1988 PDFBernardo Diaz SuarezNo ratings yet

- Operational Modal Identification in The Presence of Harmonic ExcitationDocument9 pagesOperational Modal Identification in The Presence of Harmonic ExcitationBernardo Diaz SuarezNo ratings yet

- Data FusionDocument35 pagesData FusionBernardo Diaz SuarezNo ratings yet

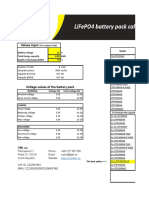

- The Best Suitable Lifepo4 Cells Values Input: (Fill in Yellow Fields)Document2 pagesThe Best Suitable Lifepo4 Cells Values Input: (Fill in Yellow Fields)HirenNo ratings yet

- Genzeb 2 On TaxDocument15 pagesGenzeb 2 On TaxAbu DadiNo ratings yet

- Radar and Sonar ProblemsDocument5 pagesRadar and Sonar ProblemsShiela Monique FajardoNo ratings yet

- ICICI Bank by Anant Jain)Document128 pagesICICI Bank by Anant Jain)Anant JainNo ratings yet

- Informe Semana 11Document4 pagesInforme Semana 11LILI JHOVANITA SALDAÑA MANOSALVANo ratings yet

- People Vs SendaydiegoDocument22 pagesPeople Vs SendaydiegoryuseiNo ratings yet

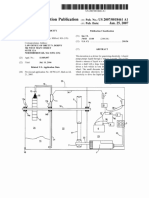

- United States: (12) Patent Application Publication (10) Pub. No.: US 2007/0018461 A1Document6 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2007/0018461 A1Andrzej JurczyńskiNo ratings yet

- Mean, Median and Mode of Ungrouped DataDocument36 pagesMean, Median and Mode of Ungrouped Dataafz100% (2)

- Ariesogeo BR Nse Ae - 0Document2 pagesAriesogeo BR Nse Ae - 0Martine OneNo ratings yet

- 8&9-High Voltage KitDocument7 pages8&9-High Voltage KitMinh VienNo ratings yet

- Lesson 1 FRANCHISING Introduction Converted 1Document32 pagesLesson 1 FRANCHISING Introduction Converted 1arzeljoyvillanueva3No ratings yet

- Abdominal Ultrasound For Pediatric Blunt Trauma FAST Is Not Always BetterDocument3 pagesAbdominal Ultrasound For Pediatric Blunt Trauma FAST Is Not Always BetterInryuu ZenNo ratings yet

- Dfe Brochure Osd Def Web-1Document6 pagesDfe Brochure Osd Def Web-1jessica febeNo ratings yet

- Cluster Coordinators Csos Contact ListDocument1 pageCluster Coordinators Csos Contact ListAbdishakur Mohamud HassanNo ratings yet

- Fundamentals of Information Systems PDFDocument164 pagesFundamentals of Information Systems PDFharshithaNo ratings yet

- Destinations For International English StudentsDocument5 pagesDestinations For International English StudentsNGUYÊN PHẠM NGỌC KHÔINo ratings yet

- IMC 2014 Brochure JB 1Document16 pagesIMC 2014 Brochure JB 1tristanmaharajNo ratings yet

- 2.2 Smaller Version of The Complete Personal Finance DashboardDocument823 pages2.2 Smaller Version of The Complete Personal Finance DashboardVijay YadavNo ratings yet

- Tikz TutorialDocument34 pagesTikz Tutorialmz_haq100% (1)

- App I Section 03050 Fill CreteDocument2 pagesApp I Section 03050 Fill CreteAnonymous M4BGwOkIpNo ratings yet

- Stok InverterDocument8 pagesStok Inverterad01 kinNo ratings yet

- Mercedes Benz Brocure Mb900Document16 pagesMercedes Benz Brocure Mb900ramsi17No ratings yet

- NUST Business School: ECO 215 Fundamentals of Econometrics Assignment 2Document11 pagesNUST Business School: ECO 215 Fundamentals of Econometrics Assignment 2Asadullah SherNo ratings yet

- Freeze Dry ParametersDocument9 pagesFreeze Dry ParametersAndres PeñaNo ratings yet

- Preliminary Full KrisDocument59 pagesPreliminary Full KrisKris Antonnete DaleonNo ratings yet

- C5G Tech Specs enDocument65 pagesC5G Tech Specs enСања БанковићNo ratings yet

- Involute Gear Gear NomenclatureDocument9 pagesInvolute Gear Gear NomenclatureGraham MutumaNo ratings yet

- WSS M4D924 B11.Document8 pagesWSS M4D924 B11.JOSENo ratings yet

- MAD Lab ManualDocument60 pagesMAD Lab Manualarun kumarNo ratings yet

- Engine Performance Data at 1500 RPM: B3.9 1 Cummins IncDocument4 pagesEngine Performance Data at 1500 RPM: B3.9 1 Cummins IncJosé CarlosNo ratings yet

Comparacion FVD Vs FDD

Comparacion FVD Vs FDD

Uploaded by

Bernardo Diaz SuarezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparacion FVD Vs FDD

Comparacion FVD Vs FDD

Uploaded by

Bernardo Diaz SuarezCopyright:

Available Formats

Comparison between Fluid Viscous Dampers and Friction Damper Devices

Fluid Viscous Dampers (FVD) Friction Damper Device (FDD)

Working principle: Working principle:

FVD is a central piston strokes through a flu- The friction damper device consists of several

id-filled chamber. As the piston moves it steel plates rotating against each other in

pushes fluid through orifices around and opposite directions. The steel plates are sep-

through the piston head. Fluid velocity is very arated by shims of high tech friction pad ma-

high in this region so the upstream pressure terial producing friction with the steel plates.

energy converts almost entirely to kinetic en- When the external forces become large

ergy. When the fluid subsequently expands enough the steel plates of the dampers start

into the full volume on the other side of the to rotate and mechanical energy is converted

piston head it slows down and loses its kinet- into heat in the friction layer between friction

ic energy into turbulence. There is very little pads and the steel plates.

pressure on the downstream side of the pis-

ton head compared with the full pressure on When the applied forces are reversed, the

the upstream side of the piston head. This plates will rotate in opposite way and the

difference in pressures produces a large damper continues to convert mechanical en-

force that resists the motion of the damper. ergy into heat and thus reducing the vibration

The following elements form a typical viscous of the structure.

damper: Piston rod, cylinder, fluid, seal, pis-

ton head

FVD Hysteresis Loop FDD Hysteresis Loop

1 6-006 FVD vs FDD 2013

Comparison between Fluid Viscous Dampers and Friction Damper Devices

Fluid Viscous Dampers (FVD) Friction Damper Device (FDD)

Performance with different temperatures Performance with different temperatures

FVDs can be very sensitive to temperature Damper performance is reliable and Inde-

variation and you will get different damper pendent on temperature.

performances for varying temperatures.

The possibility of leakage:

The possibility of leakage:

Friction Damper Devices can not possibly

There is always the possibility of Fluid Vis- leak as there are no fluids in a Friction

cous dampers leaking: Damper Device

Reason 1:

Dampers often sit for long periods without

use. It is very difficult for the seal to not exhib-

it long-term sticking or to avoid fluid seepage

during these long periods.

Reason 2:

When the damper is activated the internal

pressure of the cylinder is very large, some-

times up to 100 MPa (in comparison the

pressure of a High-pressure boiler is 50

MPa).

2 6-006 FVD vs FDD 2013

Comparison between Fluid Viscous Dampers and Friction Damper Devices

Fluid Viscous Dampers (FVD) Friction Damper Device (FDD)

Combination: Combination:

FVDs with different capacity and stroke FDDs can be combined in many different

length are basically the same damper with ways and exist with many different

different dimensions. geometries and shapes:

This means that the possibility of having dif-

ferent models with different geometries and

shape is impossible

The FVDs can ONLY work in one direction

and the number of configurations they can be

used in are therefore limited

Installation types:

Can just be used in a few traditional types of

installation: Diagonal bracings, V-shape Brac-

ings, Toggle Bracings

FDDs can work in two directions which

means that they are much more flexible than

FVDs.

Installation types:

Based on traditional installation types, there

are many installation models and ideas:

3 6-006 FVD vs FDD 2013

Comparison between Fluid Viscous Dampers and Friction Damper Devices

Fluid Viscous Dampers Friction Damper Device

(FVD) (FDD)

Relation between velocity and FVDs are velocity depend- The Damper force is inde-

damper force ent which means that the pendent of velocity and will

damper will exert different exert a constant force in all

forces in different earth- future earthquakes.

quakes. This makes it easier and more

The forces exerted in the economical to design connec-

Maximum Credi- tions and bracings as the

ble Earthquake (MCE) are damper force is fixed.

much higher than for other

earthquakes

Supply time Manufacturing process is Manufacturing process is

complex and needs a long simple and does not take a

time. Usually it takes 5-6 long time, usually around 2-3

months, except for FVDs of months.

bad quality.

The ability of large number of If the damper is used for Due to the high tech friction

cycles many cycles (for wind or pads all FDDs can be used

tuned mass dampers) the for 10 000 cycles or more and

quality of the damper mate- the damper performance

rials has to be very high. does not decline more than 2-

The damper in this case 5%. The damper materials

will be very expensive. are the same so the price of

the damper is the same too.

Adjustment after production The force capacity can not The force capacity can easily

be adjusted after produc- be adjusted after production

tion by simply adjusting the tight-

ness of the bolts

Repair / Replace The whole damper needs Just needs removal of a part

to be shipped back to the of the damper and does not

factory need to be shipped back to

the factory.

There is no one single case

with damage or problem.

4 6-006 FVD vs FDD 2013

Comparison between Fluid Viscous Dampers and Friction Damper Devices

Velocity:

FDD’s force is velocity independent. The force of FVDs depends on the velocity, and is determined

by the formula F=CVα, where C and α are damper constants.

Velocity

Energy Dissipation

Friction damper devices have a rectangular hysteresis loop compared to the elliptical shaped hys-

teresis loop of the fluid viscous dampers with α=1.

For a given force the area of the hysteresis loop of the friction damper devices considerably larger

than for the fluid viscous damper with α=1. The energy dissipation of the friction dampers is there-

fore considerably larger than the energy dissipation of fluid viscous dampers with α=1.

Displacement

5 6-006 FVD vs FDD 2013

Comparison between Fluid Viscous Dampers and Friction Damper Devices

Different performance with different cases

1 Wind/small earthquake

FDD will be a lock up device, it will be like fixed connection on the building.

FVD is a velocity devices, it will be flexible connection on the building. The comfortable degree should be

checked.

2 Medium size earthquake.

Both FDD & FVD will start dissipate energy, but the force of FVD will be smaller than FDD. Because FVD is a

velocity device, the force is only has relationship with velocity, if the design force of damper is 1000 kN, the

force of FVD just around 500 kN when medium size earthquake, but the force of FDD will be 1000 kN.

Therefore FDD will be more effective than FVD.

6 6-006 FVD vs FDD 2013

Comparison between Fluid Viscous Dampers and Friction Damper Devices

3 Large Earthquake.

Usually the damper max force is set for this case.

If the capacity of both dampers is the same, FDD will dissipate more energy than FVD.

4 Very Large Earthquake

When very large earthquake hit, FVD will be broken and lose effectiveness, the building will have serious

damages or may be collapse, which is very serious situation. But FDD will not be broken (the output force

will be same) . The FDD can also be a stopper at very large displacement.

NOTE;

At large displacements the FDD resisting force can be increase because the lever arm get smaller.

Such increase in damper force will be good to have.

7 6-006 FVD vs FDD 2013

You might also like

- Instruction Manual: For Installation, Operation & MaintenanceDocument40 pagesInstruction Manual: For Installation, Operation & MaintenanceAvinash GamitNo ratings yet

- 102 103 Differential Pressure Switches Cat388Document16 pages102 103 Differential Pressure Switches Cat388contato.tiagogatodesouzaNo ratings yet

- 102 103 Differential Pressure Switches Cat388Document16 pages102 103 Differential Pressure Switches Cat388Fake AccountNo ratings yet

- Fluid Viscous DamperDocument3 pagesFluid Viscous DamperShikhar KothariNo ratings yet

- Copeland VFDDocument4 pagesCopeland VFDluigi schiavoneNo ratings yet

- High Voltage Breai (Ers, IncDocument9 pagesHigh Voltage Breai (Ers, IncAnonymous u0wETydFNo ratings yet

- Choosing The Right Cable For Your Variable Frequency Drive (VFD) SystemDocument7 pagesChoosing The Right Cable For Your Variable Frequency Drive (VFD) SystemAhmedNo ratings yet

- WATTS New Premium ContentDocument32 pagesWATTS New Premium ContentbaoHVLABNo ratings yet

- CT PDFDocument63 pagesCT PDFGobi Kannan S.100% (3)

- Turn Green With Variable-Frequency Drives: Hydraulic PressesDocument3 pagesTurn Green With Variable-Frequency Drives: Hydraulic PressesabhisdestinyNo ratings yet

- The Best Applications For VFDS: Home Technical ArticlesDocument4 pagesThe Best Applications For VFDS: Home Technical ArticlesjnikkoNo ratings yet

- Xylem Guide To BlowersDocument11 pagesXylem Guide To BlowersAmal KaNo ratings yet

- Product Catalog Copeland Scroll ZBKQ Compressor For Refrigeration Applications en SG 6631804Document80 pagesProduct Catalog Copeland Scroll ZBKQ Compressor For Refrigeration Applications en SG 6631804Muhammad Zhakri Muhammad KamalNo ratings yet

- V, HV, HVRS Series & Hypac: Rotary Vane Air CompressorsDocument12 pagesV, HV, HVRS Series & Hypac: Rotary Vane Air CompressorsCelso FernandesNo ratings yet

- Advanced Efficiency, Precision Cooling: Design An HVAC System Like No OtherDocument6 pagesAdvanced Efficiency, Precision Cooling: Design An HVAC System Like No Other12345laurNo ratings yet

- NIDECDocument18 pagesNIDECroyert8No ratings yet

- Fluid Damper (FD)Document20 pagesFluid Damper (FD)monalisa estherNo ratings yet

- Variable Effort SupportsDocument29 pagesVariable Effort SupportssanmukhaNo ratings yet

- Inverter Duty MotorDocument6 pagesInverter Duty Motorseshubabu_999No ratings yet

- Understanding Variable Speed Drives: Basic VFD TheoryDocument7 pagesUnderstanding Variable Speed Drives: Basic VFD TheorynikecerreroNo ratings yet

- DA102-13 Damper Torque PDFDocument3 pagesDA102-13 Damper Torque PDFNguyễn LinhNo ratings yet

- Damper TorqueDocument3 pagesDamper TorqueNguyễn LinhNo ratings yet

- Coupling Design and SelectionDocument11 pagesCoupling Design and SelectionVivek RathodNo ratings yet

- Trane Jan2006Document8 pagesTrane Jan2006TomLinNo ratings yet

- Protection of VSD TransformersDocument12 pagesProtection of VSD TransformersGetssy PrathibaNo ratings yet

- VFD For Centrifugal PumpsDocument11 pagesVFD For Centrifugal PumpsChem.EnggNo ratings yet

- Variable Frequency DrivesDocument46 pagesVariable Frequency DrivesCubix AutomationNo ratings yet

- EN53000 Einsatzbedingungen Ventile PDFDocument1 pageEN53000 Einsatzbedingungen Ventile PDFPritesh KoratNo ratings yet

- EN53000 Einsatzbedingungen Ventile PDFDocument1 pageEN53000 Einsatzbedingungen Ventile PDFPritesh KoratNo ratings yet

- Conditions and Instructions For ValvesDocument1 pageConditions and Instructions For ValveshelderfgmNo ratings yet

- Yonis Hussain ReportDocument9 pagesYonis Hussain ReportENG.YONIS HUSSAINNo ratings yet

- Centaflex DDocument7 pagesCentaflex DInu Muh NuurNo ratings yet

- KVT High Pressure Large Bore Valves PDFDocument16 pagesKVT High Pressure Large Bore Valves PDFkamal arabNo ratings yet

- Refrigeration and Air ConditioningDocument4 pagesRefrigeration and Air ConditioningAleksandar Sasa SeferovicNo ratings yet

- Variable Frequency DriveDocument11 pagesVariable Frequency DriveNAYEEM100% (5)

- Operation and Application of Variable Frequency Drive (VFD) TechnologyDocument11 pagesOperation and Application of Variable Frequency Drive (VFD) TechnologyFryjo FrancisNo ratings yet

- Produkte PowerStromteiler Datenbl EnglDocument16 pagesProdukte PowerStromteiler Datenbl EnglCarlos Augusto100% (1)

- Comparisonbetweenvrv Vrfbrandssuppliersuaemarket May2016 Bygetco 160430182626Document128 pagesComparisonbetweenvrv Vrfbrandssuppliersuaemarket May2016 Bygetco 160430182626phuongnhsfc100% (1)

- FITformerWINDflyer-pdf - Original FileDocument3 pagesFITformerWINDflyer-pdf - Original Filef.dimarinoNo ratings yet

- Frecuencias Críticas para Motor USDocument2 pagesFrecuencias Críticas para Motor USInstalaciones ElectromecánicasNo ratings yet

- Choosing The Right Cable For Your Variable Frequency Drive (VFD) SystemDocument8 pagesChoosing The Right Cable For Your Variable Frequency Drive (VFD) SystemroyclhorNo ratings yet

- Significant Nonlinearities Due To Force-Deflection Hysteresis and DueDocument16 pagesSignificant Nonlinearities Due To Force-Deflection Hysteresis and Duekosarayu2007No ratings yet

- Korfund Spring MountsDocument50 pagesKorfund Spring Mountsuamiranda3518No ratings yet

- Variable Frequency Drives For Centrifugal PumpsDocument11 pagesVariable Frequency Drives For Centrifugal PumpsOzkr_sgNo ratings yet

- DESCH Complete Press DriveDocument8 pagesDESCH Complete Press DriveSerdar FildisNo ratings yet

- The Rotary Screw Compressor: Ashrae JournalDocument3 pagesThe Rotary Screw Compressor: Ashrae JournalAkhli RahmatullohNo ratings yet

- 2010 23 Supercond SC Tech Superconductur Transformer 0953 2048 23-1-014025Document6 pages2010 23 Supercond SC Tech Superconductur Transformer 0953 2048 23-1-014025Sandra ZitzNo ratings yet

- MD SeriesDocument91 pagesMD Seriesebraheem ElbrinsNo ratings yet

- Unit 6Document40 pagesUnit 6mott macNo ratings yet

- Wcee2012 2922 PDFDocument10 pagesWcee2012 2922 PDFponjoveNo ratings yet

- DJ1E2DM VFD SuitablilyDocument2 pagesDJ1E2DM VFD Suitablilysahendra4673No ratings yet

- TMC AdustableSpeedDrive WP PDFDocument2 pagesTMC AdustableSpeedDrive WP PDFTandin WangChukNo ratings yet

- Info Penting Ahli Struktur GempaDocument337 pagesInfo Penting Ahli Struktur Gempadicky1969No ratings yet

- Taylor Devices, Inc. Building Today For Tomorrow Since 1955Document28 pagesTaylor Devices, Inc. Building Today For Tomorrow Since 1955rosciiNo ratings yet

- 1 1061GBDocument8 pages1 1061GBPatricio RojasNo ratings yet

- TransformersDocument77 pagesTransformersAshwani Dogra100% (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- High Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorFrom EverandHigh Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorNo ratings yet

- A New Approach To System Identi Fication and Damage Detection of High-Rise BuildingsDocument25 pagesA New Approach To System Identi Fication and Damage Detection of High-Rise BuildingsBernardo Diaz SuarezNo ratings yet

- Memoria de Calculo EstructuralDocument160 pagesMemoria de Calculo EstructuralBernardo Diaz SuarezNo ratings yet

- Review Paper: Fundamentals of System Identification in Structural DynamicsDocument12 pagesReview Paper: Fundamentals of System Identification in Structural DynamicsBernardo Diaz SuarezNo ratings yet

- Analysis and Estimation of Stochastic Mechanical Systems 1988 PDFDocument352 pagesAnalysis and Estimation of Stochastic Mechanical Systems 1988 PDFBernardo Diaz SuarezNo ratings yet

- Operational Modal Identification in The Presence of Harmonic ExcitationDocument9 pagesOperational Modal Identification in The Presence of Harmonic ExcitationBernardo Diaz SuarezNo ratings yet

- Data FusionDocument35 pagesData FusionBernardo Diaz SuarezNo ratings yet

- The Best Suitable Lifepo4 Cells Values Input: (Fill in Yellow Fields)Document2 pagesThe Best Suitable Lifepo4 Cells Values Input: (Fill in Yellow Fields)HirenNo ratings yet

- Genzeb 2 On TaxDocument15 pagesGenzeb 2 On TaxAbu DadiNo ratings yet

- Radar and Sonar ProblemsDocument5 pagesRadar and Sonar ProblemsShiela Monique FajardoNo ratings yet

- ICICI Bank by Anant Jain)Document128 pagesICICI Bank by Anant Jain)Anant JainNo ratings yet

- Informe Semana 11Document4 pagesInforme Semana 11LILI JHOVANITA SALDAÑA MANOSALVANo ratings yet

- People Vs SendaydiegoDocument22 pagesPeople Vs SendaydiegoryuseiNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2007/0018461 A1Document6 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2007/0018461 A1Andrzej JurczyńskiNo ratings yet

- Mean, Median and Mode of Ungrouped DataDocument36 pagesMean, Median and Mode of Ungrouped Dataafz100% (2)

- Ariesogeo BR Nse Ae - 0Document2 pagesAriesogeo BR Nse Ae - 0Martine OneNo ratings yet

- 8&9-High Voltage KitDocument7 pages8&9-High Voltage KitMinh VienNo ratings yet

- Lesson 1 FRANCHISING Introduction Converted 1Document32 pagesLesson 1 FRANCHISING Introduction Converted 1arzeljoyvillanueva3No ratings yet

- Abdominal Ultrasound For Pediatric Blunt Trauma FAST Is Not Always BetterDocument3 pagesAbdominal Ultrasound For Pediatric Blunt Trauma FAST Is Not Always BetterInryuu ZenNo ratings yet

- Dfe Brochure Osd Def Web-1Document6 pagesDfe Brochure Osd Def Web-1jessica febeNo ratings yet

- Cluster Coordinators Csos Contact ListDocument1 pageCluster Coordinators Csos Contact ListAbdishakur Mohamud HassanNo ratings yet

- Fundamentals of Information Systems PDFDocument164 pagesFundamentals of Information Systems PDFharshithaNo ratings yet

- Destinations For International English StudentsDocument5 pagesDestinations For International English StudentsNGUYÊN PHẠM NGỌC KHÔINo ratings yet

- IMC 2014 Brochure JB 1Document16 pagesIMC 2014 Brochure JB 1tristanmaharajNo ratings yet

- 2.2 Smaller Version of The Complete Personal Finance DashboardDocument823 pages2.2 Smaller Version of The Complete Personal Finance DashboardVijay YadavNo ratings yet

- Tikz TutorialDocument34 pagesTikz Tutorialmz_haq100% (1)

- App I Section 03050 Fill CreteDocument2 pagesApp I Section 03050 Fill CreteAnonymous M4BGwOkIpNo ratings yet

- Stok InverterDocument8 pagesStok Inverterad01 kinNo ratings yet

- Mercedes Benz Brocure Mb900Document16 pagesMercedes Benz Brocure Mb900ramsi17No ratings yet

- NUST Business School: ECO 215 Fundamentals of Econometrics Assignment 2Document11 pagesNUST Business School: ECO 215 Fundamentals of Econometrics Assignment 2Asadullah SherNo ratings yet

- Freeze Dry ParametersDocument9 pagesFreeze Dry ParametersAndres PeñaNo ratings yet

- Preliminary Full KrisDocument59 pagesPreliminary Full KrisKris Antonnete DaleonNo ratings yet

- C5G Tech Specs enDocument65 pagesC5G Tech Specs enСања БанковићNo ratings yet

- Involute Gear Gear NomenclatureDocument9 pagesInvolute Gear Gear NomenclatureGraham MutumaNo ratings yet

- WSS M4D924 B11.Document8 pagesWSS M4D924 B11.JOSENo ratings yet

- MAD Lab ManualDocument60 pagesMAD Lab Manualarun kumarNo ratings yet

- Engine Performance Data at 1500 RPM: B3.9 1 Cummins IncDocument4 pagesEngine Performance Data at 1500 RPM: B3.9 1 Cummins IncJosé CarlosNo ratings yet