Professional Documents

Culture Documents

Cu-ETP: C11000 Industrial Rolled

Cu-ETP: C11000 Industrial Rolled

Uploaded by

srsivaraman81Copyright:

Available Formats

You might also like

- Info Iec62271-209 (ed2.0.RLV) enDocument20 pagesInfo Iec62271-209 (ed2.0.RLV) enimtiaz_uddin_2No ratings yet

- Schneider Powerline PLUS M Brochure 2022Document12 pagesSchneider Powerline PLUS M Brochure 2022Hitachi100% (1)

- Tellus 2 - Assignment 5Document2 pagesTellus 2 - Assignment 5SusanaNo ratings yet

- BIOKMOR N01 3rd ExamDocument8 pagesBIOKMOR N01 3rd ExamMacy MarianNo ratings yet

- Catalogo Contatores MTDocument56 pagesCatalogo Contatores MTwillvinNo ratings yet

- Far East 07Bn8-F: Power Cables EN 50525-2-21Document7 pagesFar East 07Bn8-F: Power Cables EN 50525-2-21dachinicuNo ratings yet

- 2.9years Experience in Quality Department-Castings (Foundry) Sujith. DDocument3 pages2.9years Experience in Quality Department-Castings (Foundry) Sujith. Dsrsivaraman81No ratings yet

- Arteche CT Trafhv enDocument60 pagesArteche CT Trafhv enGenius DacpanoNo ratings yet

- Terzija-Koglin2001 Article ANewApproachToArcResistanceCalDocument6 pagesTerzija-Koglin2001 Article ANewApproachToArcResistanceCalAndres Vergara100% (1)

- Pa6 & Pa6g ComparisonDocument1 pagePa6 & Pa6g Comparisonsrsivaraman81No ratings yet

- CO2 and Lime Dosage Sea WaterDocument11 pagesCO2 and Lime Dosage Sea WaterNoureddine Merah100% (2)

- CFBC Refractory Dryout Along With Atmospheric Boilout FinalDocument7 pagesCFBC Refractory Dryout Along With Atmospheric Boilout FinalpurvgargNo ratings yet

- The Bogey BeastDocument5 pagesThe Bogey BeastBrayan ChiribogaNo ratings yet

- Aero-Z Reference ListDocument5 pagesAero-Z Reference ListPablo CondoriNo ratings yet

- Trip Circuit Supervision Relay - 7PA30 - Technical DataDocument2 pagesTrip Circuit Supervision Relay - 7PA30 - Technical DataJack Johnson0% (1)

- ET032 Ed.5 (OPGW) .Es - enDocument56 pagesET032 Ed.5 (OPGW) .Es - enfixer_007722No ratings yet

- Viewtenddoc PDFDocument68 pagesViewtenddoc PDFSundaresan SabanayagamNo ratings yet

- Industrial Training at Traco Cables Company Limited: Cochin University College of Engineering KUTTANADU-637215Document30 pagesIndustrial Training at Traco Cables Company Limited: Cochin University College of Engineering KUTTANADU-637215Zain MughalNo ratings yet

- TDS Fosroc Conbextra Cable Grout HS India3Document4 pagesTDS Fosroc Conbextra Cable Grout HS India3RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Aluminium AW 6101A T6 Busbar FlatDocument3 pagesAluminium AW 6101A T6 Busbar Flatdoshi78No ratings yet

- (3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2Document3 pages(3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2ErwinNo ratings yet

- Compact Conductor Calculation-1Document4 pagesCompact Conductor Calculation-1Gautama Chandra PradiptaNo ratings yet

- 1LE1503 3AB53 4AB4 Datasheet enDocument1 page1LE1503 3AB53 4AB4 Datasheet enilker subaşıNo ratings yet

- Protistor FusiblesDocument16 pagesProtistor FusiblesEdgar Sierra RodriguezNo ratings yet

- SK Product HandbookDocument110 pagesSK Product Handbooksupriyo110No ratings yet

- Ge MCBDocument20 pagesGe MCBHydrolectric Ltd.No ratings yet

- Olflex Power LV N 2xyry Pg87Document1 pageOlflex Power LV N 2xyry Pg87Hardy FerrysianNo ratings yet

- NA2XS FL 2Y RM 18 30 KV PDFDocument2 pagesNA2XS FL 2Y RM 18 30 KV PDFSid Ali RABEHINo ratings yet

- Isarc-P VeiDocument2 pagesIsarc-P Veiali_egemac100% (1)

- Catalogue-Simoprime en PDFDocument16 pagesCatalogue-Simoprime en PDFhizbi7No ratings yet

- Outdoor DisconnectorsDocument12 pagesOutdoor DisconnectorsengmswilamNo ratings yet

- Coelme CM113Document4 pagesCoelme CM113costelchelariuNo ratings yet

- Ojon4gb PDFDocument36 pagesOjon4gb PDFDimitar DimitrovNo ratings yet

- Caract Tecnicas Opgw Lsgs-11-Po0186 24sDocument4 pagesCaract Tecnicas Opgw Lsgs-11-Po0186 24sKamal ArreazaNo ratings yet

- MasterClad-Non-Arc-Resistant - NEMA Academy 2015Document61 pagesMasterClad-Non-Arc-Resistant - NEMA Academy 2015cachilet100% (1)

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.JayagurunathanNo ratings yet

- GraseDocument2 pagesGrasetony mejiaNo ratings yet

- PILC Cable Data Sheet PDFDocument2 pagesPILC Cable Data Sheet PDFbiglee82No ratings yet

- Routine Test Report: Tests Carried Out in Accordance With IEC 62271-102, IEC62271-1Document5 pagesRoutine Test Report: Tests Carried Out in Accordance With IEC 62271-102, IEC62271-1grigore mircea100% (1)

- Product Catalogue: Power CablesDocument54 pagesProduct Catalogue: Power CablesBrion Bara IndonesiaNo ratings yet

- TAQA Specs Update - SDocument56 pagesTAQA Specs Update - Safsar.erNo ratings yet

- AAAC 6201 Type A3 IEC61089Document1 pageAAAC 6201 Type A3 IEC61089Proteksitrans1 p3bsNo ratings yet

- HVX SelectionListDocument40 pagesHVX SelectionListkenlavie2100% (1)

- C2 E2 F1, Climatic Environmental and Fire With Stand Test On Dry Type TransformerDocument27 pagesC2 E2 F1, Climatic Environmental and Fire With Stand Test On Dry Type Transformerkrmurali2000No ratings yet

- 6 GFMF 150 DatasheetDocument2 pages6 GFMF 150 DatasheetHamad YousafaniNo ratings yet

- Industrial Low Voltage Cables: Acc. To CPR UE 305/11, EN 50575:2014 + A1:2016, Cca-S3, d1, A3Document3 pagesIndustrial Low Voltage Cables: Acc. To CPR UE 305/11, EN 50575:2014 + A1:2016, Cca-S3, d1, A3Yizhar Dwi GogaNo ratings yet

- Automatic Voltage ControlDocument32 pagesAutomatic Voltage ControlGolu KoliNo ratings yet

- AbbbDocument20 pagesAbbbMaz MoektiNo ratings yet

- Conductors Damage Curves CablesDocument4 pagesConductors Damage Curves CablesjonathanNo ratings yet

- 120mm2 Contact Wire Copper SilverDocument1 page120mm2 Contact Wire Copper SilverPablo MarajNo ratings yet

- Licensed by Information Handling ServicesDocument11 pagesLicensed by Information Handling ServicesCristian SnchezNo ratings yet

- Datasheet of STS 6000K H1 GCADocument1 pageDatasheet of STS 6000K H1 GCAHome AutomatingNo ratings yet

- Instructions Operation - Maintenance: Secondary Distribution SwitchgearDocument30 pagesInstructions Operation - Maintenance: Secondary Distribution SwitchgearMurtadha Kadhim100% (1)

- Zelio Timer Relays - RE7ML11BU PDFDocument19 pagesZelio Timer Relays - RE7ML11BU PDFAlex GonzalezNo ratings yet

- Technical Specification: Optical Ground WireDocument9 pagesTechnical Specification: Optical Ground WireMiftahul KhairNo ratings yet

- PSCAD Introduction PDFDocument72 pagesPSCAD Introduction PDFEnpak ArsalanNo ratings yet

- 2015 - Catalog - ABB Cable Accessories 145-170 KV - English - Cable Terminations CD - REV ADocument2 pages2015 - Catalog - ABB Cable Accessories 145-170 KV - English - Cable Terminations CD - REV ARomany AllamNo ratings yet

- Manual Contactor Lc1dfk Lc1dgk Lc1dpk Lc1dwk (Conde.)Document4 pagesManual Contactor Lc1dfk Lc1dgk Lc1dpk Lc1dwk (Conde.)joseNo ratings yet

- Tuboly-Astronic Product LeafletDocument12 pagesTuboly-Astronic Product LeafletClaude mekinaNo ratings yet

- Low Voltage NH Knife Blade Fuse LinksDocument10 pagesLow Voltage NH Knife Blade Fuse LinksAlan EduardoNo ratings yet

- TDDocument4 pagesTDJaime Arellano HuertaNo ratings yet

- Operation Manual: Metal-Clad SwitchgearDocument36 pagesOperation Manual: Metal-Clad Switchgearceti7No ratings yet

- Surge Arrester 3EP6: Operating ManualDocument17 pagesSurge Arrester 3EP6: Operating ManualLong TranNo ratings yet

- BJKBKDocument124 pagesBJKBKXero KrossingNo ratings yet

- Amted303030en (Web)Document2 pagesAmted303030en (Web)Andreas AndreassNo ratings yet

- Fuse Link CatalogDocument14 pagesFuse Link CatalogWayan dhani Saputra100% (1)

- Cu-HCP: C10300 Industrial RolledDocument7 pagesCu-HCP: C10300 Industrial RolledpierocarnelociNo ratings yet

- ImagesDocument1 pageImagessrsivaraman81No ratings yet

- TNPL Po192015006466Document1 pageTNPL Po192015006466srsivaraman81No ratings yet

- Annexure - Ii - Declaration SheetDocument1 pageAnnexure - Ii - Declaration Sheetsrsivaraman81No ratings yet

- Annexure Iii - Application SpecialistDocument2 pagesAnnexure Iii - Application Specialistsrsivaraman81No ratings yet

- PDFDocument127 pagesPDFsrsivaraman81No ratings yet

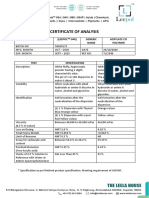

- Certificate of Analysis: Name of Product (Leepol - 940) Generic Name Acrylate Co PolymerDocument1 pageCertificate of Analysis: Name of Product (Leepol - 940) Generic Name Acrylate Co Polymerjuan felixNo ratings yet

- Sigmafast 278Document5 pagesSigmafast 278kaleshNo ratings yet

- Brechú-Franco (2016)Document4 pagesBrechú-Franco (2016)Rahul SharmaNo ratings yet

- Spectrum™ Xd3899 Microbiocide: The Industry Standard For Reducing Microbial Activity in PapermakingDocument4 pagesSpectrum™ Xd3899 Microbiocide: The Industry Standard For Reducing Microbial Activity in PapermakingUtibe EdemNo ratings yet

- Electrochimica ActaDocument6 pagesElectrochimica ActabecobeliNo ratings yet

- فيزياء كامل PDFDocument72 pagesفيزياء كامل PDFfdghhNo ratings yet

- (Lian - Zhuge, 2010) Optimum Mix Design of Enhanced Permeable Concrete - An Experimental InvestigationDocument8 pages(Lian - Zhuge, 2010) Optimum Mix Design of Enhanced Permeable Concrete - An Experimental InvestigationPSirotinNo ratings yet

- 8: Controlling Reactions 2 - Topic Questions: Year Series Paper NumberDocument11 pages8: Controlling Reactions 2 - Topic Questions: Year Series Paper NumberSumaira AliNo ratings yet

- Temperature and Effect On ConcreteDocument59 pagesTemperature and Effect On ConcreteBart KwanNo ratings yet

- Aw Hydraulic Oil: Applications Selection GuideDocument2 pagesAw Hydraulic Oil: Applications Selection GuideMassimiliano VolaNo ratings yet

- Mse Series Vrla Battery by C&D Technologies: For Standby ApplicationsDocument4 pagesMse Series Vrla Battery by C&D Technologies: For Standby Applicationsعلاء الدين ميرغنيNo ratings yet

- Bsc410s Sem 2 2021 Assignment 2Document10 pagesBsc410s Sem 2 2021 Assignment 2JustyNo ratings yet

- 1 s2.0 S0956053X19306579 MainDocument9 pages1 s2.0 S0956053X19306579 MainVanessa FerreiraNo ratings yet

- Nitoprime 25 TDS PDFDocument2 pagesNitoprime 25 TDS PDFgalih mahardikaNo ratings yet

- Science Paper 7 - SolvedDocument10 pagesScience Paper 7 - SolvedRavi KumarNo ratings yet

- Deco - POP Audit SheetDocument16 pagesDeco - POP Audit Sheetshivakumar ctNo ratings yet

- Laboratory Management: Princess Fatima Angela D. Mendoza BSMT 3-1Document4 pagesLaboratory Management: Princess Fatima Angela D. Mendoza BSMT 3-13pangalan 1taoNo ratings yet

- Guiding The Crude To chemicaGBPs compGBPex Towards A Net Zero FutureDocument2 pagesGuiding The Crude To chemicaGBPs compGBPex Towards A Net Zero FutureKemkengNo ratings yet

- Regulatory Requirements For Product ApprovalDocument13 pagesRegulatory Requirements For Product Approval50KMKDIVYA RAJPALNo ratings yet

- Desalination: Hasan Basri Senturk, Duygu Ozdes, Celal DuranDocument7 pagesDesalination: Hasan Basri Senturk, Duygu Ozdes, Celal DuranSeptian Perwira YudhaNo ratings yet

- Sika IgasolDocument2 pagesSika IgasolhaythamabdeldayemNo ratings yet

- CIHAN - Trouble Shooting CompressionDocument61 pagesCIHAN - Trouble Shooting CompressionHamidNo ratings yet

- An Experimental Investigationofthe Effective Parameterson Wet Washingof BiodieselpurificationDocument14 pagesAn Experimental Investigationofthe Effective Parameterson Wet Washingof BiodieselpurificationAdilla PratiwiNo ratings yet

- CLC International Brochure - EnglishDocument4 pagesCLC International Brochure - EnglishAishwarya KumarNo ratings yet

- Chemrobotics - Brochure 2.0Document1 pageChemrobotics - Brochure 2.0Vishwanath DasNo ratings yet

Cu-ETP: C11000 Industrial Rolled

Cu-ETP: C11000 Industrial Rolled

Uploaded by

srsivaraman81Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cu-ETP: C11000 Industrial Rolled

Cu-ETP: C11000 Industrial Rolled

Uploaded by

srsivaraman81Copyright:

Available Formats

C11000

Cu-ETP

Industrial Rolled

Alloy Designation Copper Rolled Products

EN Cu-ETP

(E-Cu, E-Cu58)

DIN CEN/TS 13388 CW004A

JIS C 1100

UNS C11000 We produce a vast assortment of copper rolled products with highest

purity in various in chemical compositions, sizes and formats, all suited to

many types of final processing.

Chemical Composition Characteristics

Weight percentage

Cu-ETP is an oxygen containing copper which has a very high electrical and

Cu ≥ 99.90 % thermal conductivity. It has excellent forming properties. Due to its

oxygen content soldering and welding properties are limited.

O 0.005 .. 0.040 %

This alloy is in accordance with RoHS

2002/96/CE for electric & electronic equip-

ments and 2002/53/CE for automotive industry

Main Applications

Automotive Radiators, Gaskets

Builders Hardware Cotter Pins, Butts, Ball Floats, Nails, Tacks, Soldering Copper, Rivets

Consumer Christmas Ornaments

Electrical Transformer Coils, Switches, Terminals, Contacts, Radio Parts, Busbars, Terminal Connectors, Conductors, Stranded

Conductors, Cable Strip

Fasteners Fasteners

Industrial Printed circuit boards, Stamped parts, Pressure Vessels, Chemical Process Equipment, Chlorine Cells, Chimney Cap Screens,

Heat Exchangers, Printing Rolls, Anodes, Rotating Bands, Kettles, Pans, Vats, Heat sinks

Preferred Applications

Transformer Fuse; Relay Box; Cable Strip Current Carrying

Punshed Screen Capacity

xx xx xx xx

x = well suited xx = particularly well suited

Physical Properties

Typical values in annealed temper at 20 °C

Density 8.93 g/cm³

Thermal expansion coefficient -191 .. 16 °C 14.1 10-6/K

0 .. 300 °C 17.7 10-6/K

Specific heat capacity 0.386 J/(g·K)

Thermal conductivity 394 W/(m·K)

Electrical conductivity (1 MS/m = 1 m/(Ω mm²) ≥ 58 MS/m

Electrical conductivity (IACS) 100 %

Thermal coefficient of electrical resistance (0 .. 200 °C) 3.7 10-3/K

Modulus of elasticity ( 1 GPa = 1 kN/mm²) cold formed 130 GPa

annealed 110 GPa

©KME Germany GmbH & Co. KG - www.kme.com - info-germany@kme.com

Page 1

C11000

Cu-ETP

Industrial Rolled

Mechanical Properties (EN 1652)

Temper Tensile Yield Strength Elongation Hardness

Strength Minimum

Rm Rp0.2 A50mm HV *

MPa MPa % HV

R200 annealed 200 .. 250 ≤ 100* (≥ 2,5 mm) 42 40 .. 65

R220 annealed 220 .. 260 < 140* 33 40 .. 65

R240 240 .. 300 ≥ 180 8 65 .. 95

R290 290 .. 360 ≥ 250 4 90 .. 110

R360 ≥ 360 ≥ 320 2 ≥ 110

* only for information

Electrical Conductivity

60

Electrical conductivity is strongly influenced by

chemical composition. A high level of cold

E. Conductivity [MS/m]

59 deformation and small grain size decrease the

electrical conductivity moderately. Minimum

conductivity level can be specified.

58

57

56

55

R200 / R220 R240 R290 R360

Temper

Fabrication Properties* Corrosion Resistance*

Cold Forming Properties Excellent Resistant to:

Atmospheric corrosion: formation of the a greenish

Hot Forming Properties Good protective patina due to the formation of copper basic salts

at 750 .. 950°C (such sulphates, chlorides in marine environment, nitrates

Machinability (Rating 20) Less suitable and carbonates). Cu-ETP is showing a good resistance in in

natural atmosphere.

Electroplating Properties Excellent Industrial and drinking water, aqueous and alkaline solutions

Hot Tinning Properties Excellent (excluding aqaueous solutions containing cyanides, halgens,

ammonia), pure water vapour (steam), non oxidizing acids

Soft soldering Excellent (without oxygen in solution), neutral saline solutions.

Material can be heat-treated in reducing atmosphere.

Resistance Welding Less suitable

Gas Shielded Arc Welding Less suitable Practically resistant against stress corrosion cracking

Laser Welding Less suitable Not resistant to:

Oxidising acids, solutions containing cyanides, ammonia or

Soft Annealing 250 .. 500°C halogens, hydrosulfide, seawater.

Stress Relieving Annealing 150 .. 200°C * For more details call our technical service

During heating in reducing atmosphere hydrogen can penetrate

inside the copper and react with Cu-Oxide to water vapour. Its

pressure can cause embrittlement.

©KME Germany GmbH & Co. KG - www.kme.com - info-germany@kme.com

Page 2

C11000

Cu-ETP

Industrial Rolled

Bending Properties Thickness: ≤ 0.5 mm

6 Bending test according to EN ISO 7438 is done

bending edge transvers to rolling direction

relative Bending Radius R/T

with 10 mm wide samples. Smaller samples in

5 general – as well as lower thickness – allow a

bending edge in rolling direction lower bending radius without cracks. If needed

4 we supply bending optimized temper classes that

90° Bending far exceed standard quality.

3 Please take care when comparing with ASTM E

290 results, there the bend definition direction is

contradictory.

2

1

Bending Definition

0

Transverse = good way

R200 / R220 R240 R290 R360

Parallel = bad way

Temper

6 180° Parallel

bending edge transvers to rolling direction

relative Bending Radius R/T

5

bending edge in rolling direction

4

180° Bending

3 90° Transverse

2 90° Parallel 180° Transverse

1

Minimum Bending Radius Calculation

0 To find out the minimum possible bending

R200 / R220 R240 R290 R360 radius take the R/T value from the list.

Example: R/T = 0.5 and thickness 0.3 mm

Minimum radius = (R/T) x thickness

Temper

= 0.5 x 0.3 mm = 0.15 mm

Bending Properties*

Temper Thickness Bending Bending

Range 90° 180°

Trans- Parallel Trans- Parallel

vers vers

mm R/T R/T R/T R/T

R220 ≤ 0.5 0 0 0 0

R240 ≤ 0.5 0 0 0 0

R290 ≤ 0.5 0 0.5 0.5 1

R360 ≤ 0.5 1 2 1.5 2.5

* Measured at sample width 10 mm according to EN 1654

Possible bending radius = (R/T) x thickness

©KME Germany GmbH & Co. KG - www.kme.com - info-germany@kme.com

Page 3

C11000

Cu-ETP

Industrial Rolled

Softening Resistance

200 After short time heat treatment

180 Vickers Hardness is measured.

R360 at 300°C

Vickers Hardness HV

The diagram shows typical

160 R360 at 250°C values.

140

120

100

80

60

40

20

0

0 10 30 60 180 300 1800 3600

Time [s]

Bend Fatigue (at room temperature)

The fatigue strength gives an indication about the resistance to variations in applied tension. It is measured under

symmetrical alternating load. The maximum bending load for 107 load cycles without crack is measured. Dependent on the

temper class it is approximately 1/3 of the tensile strength Rm.

Standards for copper and copper alloys

EN 1652 Plate, sheet, strip and circles for general purposes

EN 1654 Strip for springs and connectors

EN 1758 Strip for lead frames

Cu-ETP_15_08_2017

EN 13148 Hot-dip tinned strip

EN 13599 Copper plate, sheet and strip for electrical purposes

EN 14436 Electrolytically tinned strip

©KME Germany GmbH & Co. KG - www.kme.com - info-germany@kme.com

Page 4

You might also like

- Info Iec62271-209 (ed2.0.RLV) enDocument20 pagesInfo Iec62271-209 (ed2.0.RLV) enimtiaz_uddin_2No ratings yet

- Schneider Powerline PLUS M Brochure 2022Document12 pagesSchneider Powerline PLUS M Brochure 2022Hitachi100% (1)

- Tellus 2 - Assignment 5Document2 pagesTellus 2 - Assignment 5SusanaNo ratings yet

- BIOKMOR N01 3rd ExamDocument8 pagesBIOKMOR N01 3rd ExamMacy MarianNo ratings yet

- Catalogo Contatores MTDocument56 pagesCatalogo Contatores MTwillvinNo ratings yet

- Far East 07Bn8-F: Power Cables EN 50525-2-21Document7 pagesFar East 07Bn8-F: Power Cables EN 50525-2-21dachinicuNo ratings yet

- 2.9years Experience in Quality Department-Castings (Foundry) Sujith. DDocument3 pages2.9years Experience in Quality Department-Castings (Foundry) Sujith. Dsrsivaraman81No ratings yet

- Arteche CT Trafhv enDocument60 pagesArteche CT Trafhv enGenius DacpanoNo ratings yet

- Terzija-Koglin2001 Article ANewApproachToArcResistanceCalDocument6 pagesTerzija-Koglin2001 Article ANewApproachToArcResistanceCalAndres Vergara100% (1)

- Pa6 & Pa6g ComparisonDocument1 pagePa6 & Pa6g Comparisonsrsivaraman81No ratings yet

- CO2 and Lime Dosage Sea WaterDocument11 pagesCO2 and Lime Dosage Sea WaterNoureddine Merah100% (2)

- CFBC Refractory Dryout Along With Atmospheric Boilout FinalDocument7 pagesCFBC Refractory Dryout Along With Atmospheric Boilout FinalpurvgargNo ratings yet

- The Bogey BeastDocument5 pagesThe Bogey BeastBrayan ChiribogaNo ratings yet

- Aero-Z Reference ListDocument5 pagesAero-Z Reference ListPablo CondoriNo ratings yet

- Trip Circuit Supervision Relay - 7PA30 - Technical DataDocument2 pagesTrip Circuit Supervision Relay - 7PA30 - Technical DataJack Johnson0% (1)

- ET032 Ed.5 (OPGW) .Es - enDocument56 pagesET032 Ed.5 (OPGW) .Es - enfixer_007722No ratings yet

- Viewtenddoc PDFDocument68 pagesViewtenddoc PDFSundaresan SabanayagamNo ratings yet

- Industrial Training at Traco Cables Company Limited: Cochin University College of Engineering KUTTANADU-637215Document30 pagesIndustrial Training at Traco Cables Company Limited: Cochin University College of Engineering KUTTANADU-637215Zain MughalNo ratings yet

- TDS Fosroc Conbextra Cable Grout HS India3Document4 pagesTDS Fosroc Conbextra Cable Grout HS India3RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Aluminium AW 6101A T6 Busbar FlatDocument3 pagesAluminium AW 6101A T6 Busbar Flatdoshi78No ratings yet

- (3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2Document3 pages(3.6/6 KV 18/30 KV) Cu/XLPE/CTS/SWA/PVC (N2XSEYRY) : SNI IEC 60502-2 / IEC 60502-2ErwinNo ratings yet

- Compact Conductor Calculation-1Document4 pagesCompact Conductor Calculation-1Gautama Chandra PradiptaNo ratings yet

- 1LE1503 3AB53 4AB4 Datasheet enDocument1 page1LE1503 3AB53 4AB4 Datasheet enilker subaşıNo ratings yet

- Protistor FusiblesDocument16 pagesProtistor FusiblesEdgar Sierra RodriguezNo ratings yet

- SK Product HandbookDocument110 pagesSK Product Handbooksupriyo110No ratings yet

- Ge MCBDocument20 pagesGe MCBHydrolectric Ltd.No ratings yet

- Olflex Power LV N 2xyry Pg87Document1 pageOlflex Power LV N 2xyry Pg87Hardy FerrysianNo ratings yet

- NA2XS FL 2Y RM 18 30 KV PDFDocument2 pagesNA2XS FL 2Y RM 18 30 KV PDFSid Ali RABEHINo ratings yet

- Isarc-P VeiDocument2 pagesIsarc-P Veiali_egemac100% (1)

- Catalogue-Simoprime en PDFDocument16 pagesCatalogue-Simoprime en PDFhizbi7No ratings yet

- Outdoor DisconnectorsDocument12 pagesOutdoor DisconnectorsengmswilamNo ratings yet

- Coelme CM113Document4 pagesCoelme CM113costelchelariuNo ratings yet

- Ojon4gb PDFDocument36 pagesOjon4gb PDFDimitar DimitrovNo ratings yet

- Caract Tecnicas Opgw Lsgs-11-Po0186 24sDocument4 pagesCaract Tecnicas Opgw Lsgs-11-Po0186 24sKamal ArreazaNo ratings yet

- MasterClad-Non-Arc-Resistant - NEMA Academy 2015Document61 pagesMasterClad-Non-Arc-Resistant - NEMA Academy 2015cachilet100% (1)

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.JayagurunathanNo ratings yet

- GraseDocument2 pagesGrasetony mejiaNo ratings yet

- PILC Cable Data Sheet PDFDocument2 pagesPILC Cable Data Sheet PDFbiglee82No ratings yet

- Routine Test Report: Tests Carried Out in Accordance With IEC 62271-102, IEC62271-1Document5 pagesRoutine Test Report: Tests Carried Out in Accordance With IEC 62271-102, IEC62271-1grigore mircea100% (1)

- Product Catalogue: Power CablesDocument54 pagesProduct Catalogue: Power CablesBrion Bara IndonesiaNo ratings yet

- TAQA Specs Update - SDocument56 pagesTAQA Specs Update - Safsar.erNo ratings yet

- AAAC 6201 Type A3 IEC61089Document1 pageAAAC 6201 Type A3 IEC61089Proteksitrans1 p3bsNo ratings yet

- HVX SelectionListDocument40 pagesHVX SelectionListkenlavie2100% (1)

- C2 E2 F1, Climatic Environmental and Fire With Stand Test On Dry Type TransformerDocument27 pagesC2 E2 F1, Climatic Environmental and Fire With Stand Test On Dry Type Transformerkrmurali2000No ratings yet

- 6 GFMF 150 DatasheetDocument2 pages6 GFMF 150 DatasheetHamad YousafaniNo ratings yet

- Industrial Low Voltage Cables: Acc. To CPR UE 305/11, EN 50575:2014 + A1:2016, Cca-S3, d1, A3Document3 pagesIndustrial Low Voltage Cables: Acc. To CPR UE 305/11, EN 50575:2014 + A1:2016, Cca-S3, d1, A3Yizhar Dwi GogaNo ratings yet

- Automatic Voltage ControlDocument32 pagesAutomatic Voltage ControlGolu KoliNo ratings yet

- AbbbDocument20 pagesAbbbMaz MoektiNo ratings yet

- Conductors Damage Curves CablesDocument4 pagesConductors Damage Curves CablesjonathanNo ratings yet

- 120mm2 Contact Wire Copper SilverDocument1 page120mm2 Contact Wire Copper SilverPablo MarajNo ratings yet

- Licensed by Information Handling ServicesDocument11 pagesLicensed by Information Handling ServicesCristian SnchezNo ratings yet

- Datasheet of STS 6000K H1 GCADocument1 pageDatasheet of STS 6000K H1 GCAHome AutomatingNo ratings yet

- Instructions Operation - Maintenance: Secondary Distribution SwitchgearDocument30 pagesInstructions Operation - Maintenance: Secondary Distribution SwitchgearMurtadha Kadhim100% (1)

- Zelio Timer Relays - RE7ML11BU PDFDocument19 pagesZelio Timer Relays - RE7ML11BU PDFAlex GonzalezNo ratings yet

- Technical Specification: Optical Ground WireDocument9 pagesTechnical Specification: Optical Ground WireMiftahul KhairNo ratings yet

- PSCAD Introduction PDFDocument72 pagesPSCAD Introduction PDFEnpak ArsalanNo ratings yet

- 2015 - Catalog - ABB Cable Accessories 145-170 KV - English - Cable Terminations CD - REV ADocument2 pages2015 - Catalog - ABB Cable Accessories 145-170 KV - English - Cable Terminations CD - REV ARomany AllamNo ratings yet

- Manual Contactor Lc1dfk Lc1dgk Lc1dpk Lc1dwk (Conde.)Document4 pagesManual Contactor Lc1dfk Lc1dgk Lc1dpk Lc1dwk (Conde.)joseNo ratings yet

- Tuboly-Astronic Product LeafletDocument12 pagesTuboly-Astronic Product LeafletClaude mekinaNo ratings yet

- Low Voltage NH Knife Blade Fuse LinksDocument10 pagesLow Voltage NH Knife Blade Fuse LinksAlan EduardoNo ratings yet

- TDDocument4 pagesTDJaime Arellano HuertaNo ratings yet

- Operation Manual: Metal-Clad SwitchgearDocument36 pagesOperation Manual: Metal-Clad Switchgearceti7No ratings yet

- Surge Arrester 3EP6: Operating ManualDocument17 pagesSurge Arrester 3EP6: Operating ManualLong TranNo ratings yet

- BJKBKDocument124 pagesBJKBKXero KrossingNo ratings yet

- Amted303030en (Web)Document2 pagesAmted303030en (Web)Andreas AndreassNo ratings yet

- Fuse Link CatalogDocument14 pagesFuse Link CatalogWayan dhani Saputra100% (1)

- Cu-HCP: C10300 Industrial RolledDocument7 pagesCu-HCP: C10300 Industrial RolledpierocarnelociNo ratings yet

- ImagesDocument1 pageImagessrsivaraman81No ratings yet

- TNPL Po192015006466Document1 pageTNPL Po192015006466srsivaraman81No ratings yet

- Annexure - Ii - Declaration SheetDocument1 pageAnnexure - Ii - Declaration Sheetsrsivaraman81No ratings yet

- Annexure Iii - Application SpecialistDocument2 pagesAnnexure Iii - Application Specialistsrsivaraman81No ratings yet

- PDFDocument127 pagesPDFsrsivaraman81No ratings yet

- Certificate of Analysis: Name of Product (Leepol - 940) Generic Name Acrylate Co PolymerDocument1 pageCertificate of Analysis: Name of Product (Leepol - 940) Generic Name Acrylate Co Polymerjuan felixNo ratings yet

- Sigmafast 278Document5 pagesSigmafast 278kaleshNo ratings yet

- Brechú-Franco (2016)Document4 pagesBrechú-Franco (2016)Rahul SharmaNo ratings yet

- Spectrum™ Xd3899 Microbiocide: The Industry Standard For Reducing Microbial Activity in PapermakingDocument4 pagesSpectrum™ Xd3899 Microbiocide: The Industry Standard For Reducing Microbial Activity in PapermakingUtibe EdemNo ratings yet

- Electrochimica ActaDocument6 pagesElectrochimica ActabecobeliNo ratings yet

- فيزياء كامل PDFDocument72 pagesفيزياء كامل PDFfdghhNo ratings yet

- (Lian - Zhuge, 2010) Optimum Mix Design of Enhanced Permeable Concrete - An Experimental InvestigationDocument8 pages(Lian - Zhuge, 2010) Optimum Mix Design of Enhanced Permeable Concrete - An Experimental InvestigationPSirotinNo ratings yet

- 8: Controlling Reactions 2 - Topic Questions: Year Series Paper NumberDocument11 pages8: Controlling Reactions 2 - Topic Questions: Year Series Paper NumberSumaira AliNo ratings yet

- Temperature and Effect On ConcreteDocument59 pagesTemperature and Effect On ConcreteBart KwanNo ratings yet

- Aw Hydraulic Oil: Applications Selection GuideDocument2 pagesAw Hydraulic Oil: Applications Selection GuideMassimiliano VolaNo ratings yet

- Mse Series Vrla Battery by C&D Technologies: For Standby ApplicationsDocument4 pagesMse Series Vrla Battery by C&D Technologies: For Standby Applicationsعلاء الدين ميرغنيNo ratings yet

- Bsc410s Sem 2 2021 Assignment 2Document10 pagesBsc410s Sem 2 2021 Assignment 2JustyNo ratings yet

- 1 s2.0 S0956053X19306579 MainDocument9 pages1 s2.0 S0956053X19306579 MainVanessa FerreiraNo ratings yet

- Nitoprime 25 TDS PDFDocument2 pagesNitoprime 25 TDS PDFgalih mahardikaNo ratings yet

- Science Paper 7 - SolvedDocument10 pagesScience Paper 7 - SolvedRavi KumarNo ratings yet

- Deco - POP Audit SheetDocument16 pagesDeco - POP Audit Sheetshivakumar ctNo ratings yet

- Laboratory Management: Princess Fatima Angela D. Mendoza BSMT 3-1Document4 pagesLaboratory Management: Princess Fatima Angela D. Mendoza BSMT 3-13pangalan 1taoNo ratings yet

- Guiding The Crude To chemicaGBPs compGBPex Towards A Net Zero FutureDocument2 pagesGuiding The Crude To chemicaGBPs compGBPex Towards A Net Zero FutureKemkengNo ratings yet

- Regulatory Requirements For Product ApprovalDocument13 pagesRegulatory Requirements For Product Approval50KMKDIVYA RAJPALNo ratings yet

- Desalination: Hasan Basri Senturk, Duygu Ozdes, Celal DuranDocument7 pagesDesalination: Hasan Basri Senturk, Duygu Ozdes, Celal DuranSeptian Perwira YudhaNo ratings yet

- Sika IgasolDocument2 pagesSika IgasolhaythamabdeldayemNo ratings yet

- CIHAN - Trouble Shooting CompressionDocument61 pagesCIHAN - Trouble Shooting CompressionHamidNo ratings yet

- An Experimental Investigationofthe Effective Parameterson Wet Washingof BiodieselpurificationDocument14 pagesAn Experimental Investigationofthe Effective Parameterson Wet Washingof BiodieselpurificationAdilla PratiwiNo ratings yet

- CLC International Brochure - EnglishDocument4 pagesCLC International Brochure - EnglishAishwarya KumarNo ratings yet

- Chemrobotics - Brochure 2.0Document1 pageChemrobotics - Brochure 2.0Vishwanath DasNo ratings yet