Professional Documents

Culture Documents

Safety Risk Managment Plan (Lahor Project)

Safety Risk Managment Plan (Lahor Project)

Uploaded by

rao sajjadOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Safety Risk Managment Plan (Lahor Project)

Safety Risk Managment Plan (Lahor Project)

Uploaded by

rao sajjadCopyright:

Available Formats

Safety Risk Management Plan

(Project Name)

Document Control # Revision # 00

Issue Date Revision Date -

Introduction of Project

Purpose and Scope of Plan

Project Team Name List

Shan Foods (Pvt) Ltd. Page 1 of 14

Safety Risk Management Plan

(Project Name)

Document Control # Revision # 00

Issue Date Revision Date -

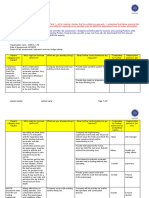

Sr. No. Hazard category Who might be harmed and Risk What controls/actions are required?

Timescale Responsible

and hazard how? Impact

(Low, Medium, s (Actions to be person’s

completed)

High)

. 1. Enclosed area to be set up for

Hazardous All workers or visitors in sanding/grinding/mixing operations

1 Substances construction site. including that will include a suitable

local exhaust ventilation system

Concrete Due to the construction

Formwork 2. Use water to reduce the dust

activity, High concentrations of

Concrete Mixing frequently and isolate the area of

Concrete Pouring- process dust, cement, and

dust to protect the workers/visitors

high concentrations other solid particles are always

in site and outside public.

of process dust, present from the routine and

Paint Work frequent activities being

3. Provide personal protective Admin Manager &

carried out. Workers breath in

hazardous dust which can Medium equipment to the workers (face Project Engineer

mask). Immediately

cause anything from short-

term irritation to long-term

4. Housekeeping will be improving and

serious health conditions.

perform frequently.

5. Awareness session will be

Can also get the irritant dust on conducted to all workers for control

their skin (which can cause the dust particles in the atmosphere.

dermatitis), in their eyes

(causing eye irritation and 6. General hygiene education for those

damage) or even accidentally workers undertaking these activities

swallow it

e.g., dust ingestion or inhaled from

hand to mouth contact.

Workers exposed of paint mist

could develop occupational

asthma. 7. Improved welfare arrangements and

PPE.

Slip, Trip and All workers and 1. Provision of proper housekeeping

2 Falling Hazard visitors in construction site.

Shan Foods (Pvt) Ltd. Page 2 of 14

Safety Risk Management Plan

(Project Name)

Document Control # Revision # 00

Issue Date Revision Date -

Sr. No. Hazard category Who might be harmed and Risk What controls/actions are required?

Timescale Responsible

and hazard how? Impact

(Low, Medium, s (Actions to be person’s

completed)

High)

2. Safety signs.

Working Platform, Working platform was not

obstructed properly clean due to that oil on 3. Training of workers about good

walkways, the surface of the platform it can housekeeping practices and

Spillages of oil in cause different types of slipping cleaning of workplace. 2 Weeks

motor, wire of hazards. Medium

Admin Manager &

Driller trialing on 4. Proper maintenance of machine. Project Engineer

the pedestrian There were no Toe boards

walkway, around the platform it may

Installation of 5. Additional electrical sockets could

cause the falling of object

drainpipes etc. hazards. be installed to prevent as many

trailing cables.

There was the wire of Driller

trialling on the pedestrian 6. Drain channels to be covered in the

walkway this may cause the area. Regular Maintenance of

Tripping hazard. pedestrian pathways to be done.

Cuts, bruises, muscle 7. Signage to be pasted at the area

strains/sprains, broken bones

from tripping over cables or

tools/equipment left in

walkways, or on wet surfaces

(including oil/fuel spills) etc.

Open drain channel without the

proper marking & arrangements

of movement were found that

can cause fall in the area

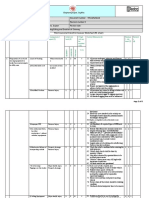

3 Fire All workers and visitors 1. Proper maintenance must be

in construction site could either provided to the generator.

Smoking, suffer burns/death.

Emergency Exits, 2. Generator must be away from the 3 Weeks Project Engineer

Shan Foods (Pvt) Ltd. Page 3 of 14

Safety Risk Management Plan

(Project Name)

Document Control # Revision # 00

Issue Date Revision Date -

Sr. No. Hazard category Who might be harmed and Risk What controls/actions are required?

Timescale Responsible

and hazard how? Impact

(Low, Medium, s (Actions to be person’s

completed)

High)

Fire Detector, Oil spillage from the generator. working area.

Welding (Hot And the Generator produces

Work), Oil Spillage spark when it gets start this may 3. Introduce Permit to work.

cause Fire. High

4. Safety Warning Sign (No Smoking)

Welding activities were carrying

out without the area barrigation. 5. Provide Fire Extinguisher into the

site in sufficient numbers.

Worker smoking near to oil tank it

may cause the fire. 6. Provide training to employees that

how to operate the Fire Extinguisher

and How to react at the time of fire.

7. Provide Emergency Exits.

8. Allocate the Assembly points.

4 Transport and All workers and visitors in 1. Provide good maintenance to the

Vehicles construction site. vehicles and record of maintenance

must be maintained.

Oil leakage, High

Speed, Moving Lube oil was dropping out from 2. Prepare vehicles pre-use inspection Admin Manager

Vehicles, Reversing the engine. It my causes of oil Checklist.

spillage and spill hazard. Low

operation,

Shan Foods (Pvt) Ltd. Page 4 of 14

Safety Risk Management Plan

(Project Name)

Document Control # Revision # 00

Issue Date Revision Date -

Sr. No. Hazard category Who might be harmed and Risk What controls/actions are required?

Timescale Responsible

and hazard how? Impact

(Low, Medium, s (Actions to be person’s

completed)

High)

3. Install the reversing alarm in

Vehicle have no reversing alarm vehicles. 2 Weeks

during reversing process to notify

others for reversing operation. It 4. Provide the proper way of vehicles

my causes personal injury and and pedestrian.

damage to assets.

5. Provide the speed limits at 5mph in

The driver of truck was driving too the workplace

fast in the workplace which can

causes accidents.

5 Working at Anyone worker working at height 1. Platform must have the guard rail of

Height in construction site. 3 feet.

Overhead electric 2. Permit to work system is required to 3 Weeks Project Engineer

wires, Roof do such kind of activities.

Insulation, Working at height without wearing

Installation Window safety harness. It may causes

falling, fractures or more serious Medium 3. Provide personal protective

and door,

Shan Foods (Pvt) Ltd. Page 5 of 14

Safety Risk Management Plan

(Project Name)

Document Control # Revision # 00

Issue Date Revision Date -

Sr. No. Hazard category Who might be harmed and Risk What controls/actions are required?

Timescale Responsible

and hazard how? Impact

(Low, Medium, s (Actions to be person’s

completed)

High)

Temporary injuries e.g. head, internal equipment and isolate the area.

Platform/Scaffolding, injuries, and even death.

Crane, 4. Provide training and instructions to

Working near Overhead electric workers.

at height. It can cause the serious

electric shock to the workers. 5. Isolate people from the area.

6. Use of banksman for the crane

No use of barricades for the operation.

working operation of crane. No

barricading around the working 7. Toolbox talk about safe operation of

area. It may cause of injury by crane.

falling objects or load

6 Permit to Any workers are working in 1. Introduce the work permit system in

Work construction site the construction site.

2 Weeks

Hot work (Welding, 2. Provide the training information and Project Engineer

grinding), Work at instruction about the PTW.

Working in confined space is very

Height, Confined

dangerous for workers without Medium 3. Provide the safe system of work, to

Space

permit to work. work in confined space.

Workers were working welding

4. Provide proper personal protective

Shan Foods (Pvt) Ltd. Page 6 of 14

Safety Risk Management Plan

(Project Name)

Document Control # Revision # 00

Issue Date Revision Date -

Sr. No. Hazard category Who might be harmed and Risk What controls/actions are required?

Timescale Responsible

and hazard how? Impact

(Low, Medium, s (Actions to be person’s

completed)

High)

and grinding without permit. It can equipment.

cause fire.

Working on a construction site

without permit can create

complexity and causes many

accidents.

7 Noise All workers and visitors in 1. Provide the good maintenance of

construction site. carne, generator, and trucks.

Excessive noise

from truck and 2. Isolate the source of noise 2 Weeks Admin Manager &

In the construction site, there was Low

generator at generation. Project Engineer

constructions site lot of noise. Due to combine

operation of carne, generator, 3. Noise test carried out by 3rd party

and trucks, this may cause frequently.

damage the hearing sense.

4. Provide the ear plugs and mufflers

Continuous working in high noise to the workers.

area may cause the stress in

workers and can causes 5. Provide frequent breaks.

accidents.

Shan Foods (Pvt) Ltd. Page 7 of 14

Safety Risk Management Plan

(Project Name)

Document Control # Revision # 00

Issue Date Revision Date -

Sr. No. Hazard category Who might be harmed and Risk What controls/actions are required?

Timescale Responsible

and hazard how? Impact

(Low, Medium, s (Actions to be person’s

completed)

High)

8 Vibration Workers in the construction site 1. Inspection plan will be revised and

perform daily basis. Ongoing

Sanding, drilling,

and grinding Excessive use of faulty hand-held 2. Provide personal protective Admin Manager &

activities tools such as disc cutters, equipment’s. Project Engineer

sanders and grinders could lead Medium

to hand- arm-vibration and 3. Introduce job rotation methods. And

damage the nerves and bones of update duty roaster.

workers.

Shan Foods (Pvt) Ltd. Page 8 of 14

Safety Risk Management Plan

(Project Name)

Document Control # Revision # 00

Issue Date Revision Date -

Sr. No. Hazard category Who might be harmed and Risk What controls/actions are required?

Timescale Responsible

and hazard how? Impact

(Low, Medium, s (Actions to be person’s

completed)

High)

9 Health, All Workers in the construction

Welfare, and site 1. Provide good area for resting,

eating, and drinking water.

work

environment 2 Weeks Admin Manager

No good welfare facilities in the 2. Provide shelter having good

construction site like resting,

Low ventilating system and sitting plan.

Working on extreme eating, drinking it may cause ill-

temperature health conditions. 3. Frequent Breaks.

4. Medical test will be carried out.

5. Provide Medical dispensary in site.

6. Provide First Aid box in all sites.

7. Provide ambulance vehicles for

carry workers in case of critical

emergency.

Shan Foods (Pvt) Ltd. Page 9 of 14

Safety Risk Management Plan

(Project Name)

Document Control # Revision # 00

Issue Date Revision Date -

Sr. No. Hazard category Who might be harmed and Risk What controls/actions are required?

Timescale Responsible

and hazard how? Impact

(Low, Medium, s (Actions to be person’s

completed)

High)

Sr. No. Hazard category Who might be harmed and Risk What controls/actions are required?

Timescale Responsible

and hazard how? Impact

(Low, Medium, s (Actions to be person’s

completed)

High)

.

10 Electricity All workers or visitors in 1. Prepared Electrical installation

construction site. Inspection plan and will be

performed frequently and all

Portable electrical Any worker using faulty checks are carried out on all 240V

equipment, equipment or electrical equipment by a certified

equipment in the installation on site eg, electrician.

Workshop and plugging in equipment in

general electric faulty socket. 2. Do not use electrical equipment in

installation for wet conditions.

whole site. The harm most likely to be Admin Manager &

caused are issues resulting from High Project Engineer

electric shock such as burns, 3. The mains switchboard will be a Immediately

and fibrillation. Worst case build in residual current device.

scenario is fatality

(electrocution). 4. Some low voltage tools will be

purchased and will used where

Electrical equipment used in possible e.g., low voltage hand

wet and damped conditions. lamps.

It may cause shocks and

burns. 5. Trained first aiders are available

who can deal with minor electric

shock victims.

Shan Foods (Pvt) Ltd. Page 10 of 14

Safety Risk Management Plan

(Project Name)

Document Control # Revision # 00

Issue Date Revision Date -

Sr. No. Hazard category Who might be harmed and Risk What controls/actions are required?

Timescale Responsible

and hazard how? Impact

(Low, Medium, s (Actions to be person’s

completed)

High)

6. All workers aware of emergency

arrangements for electricity related

incidents.

Shan Foods (Pvt) Ltd. Page 11 of 14

Safety Risk Management Plan

(Project Name)

Document Control # Revision # 00

Issue Date Revision Date -

Sr. No. Hazard category Who might be harmed and Risk What controls/actions are required?

Timescale Responsible

and hazard how? Impact

(Low, Medium, s (Actions to be person’s

completed)

High)

Manual Workers in the construction site. 1. Use manual handling aids such as

11 Handling/Lifting trollies and lifts. Project Engineer

Workers lifting blocks of Medium Ongoing

Lifting Concrete concrete, bricks and plaster at 2. Reduce height by using

above shoulders and support or appropriate

Blocks, Brick and bending/stooping can be a major shelves.

Plaster cause of muscle pain, back

injury,

3. Provide training of manual handling.

Shan Foods (Pvt) Ltd. Page 12 of 14

Safety Risk Management Plan

(Project Name)

Document Control # Revision # 00

Issue Date Revision Date -

Sr. No. Hazard category Who might be harmed and Risk What controls/actions are required?

Timescale Responsible

and hazard how? Impact

(Low, Medium, s (Actions to be person’s

completed)

High)

12 Working at Workers in the construction site.

Confined 1. If the excavation is more than 2 m Project Engineer

space deep, a substantial barrier

Materials falling on workers in the consisting of guardrails and toe Ongoing

Excavation, excavation. It may cause personal Medium boards should be provided around

Trenches, Soil injury. the surface of the workings.

backfilling

Hazardous substances, Workers 2. The workers should wear hard hats.

exposed could develop

occupational asthma.

3. Vehicles should be kept away as far

During excavation fumes, lack of as possible using warning signs and

oxygen and other health hazards. barriers.

4. Safe access by ladders is essential.

Shan Foods (Pvt) Ltd. Page 13 of 14

Shan Foods (Pvt) Ltd. Page 14 of 14

You might also like

- Postural Restoration Institute2023Document4 pagesPostural Restoration Institute2023Aryan KarkiNo ratings yet

- Health and Safety Management Manual With Procedures ExampleDocument13 pagesHealth and Safety Management Manual With Procedures ExampleVepxvia NadiradzeNo ratings yet

- Fes TBT Housekeeping PDFDocument1 pageFes TBT Housekeeping PDFsalem enwaijiNo ratings yet

- Congenital Hip DislocationDocument2 pagesCongenital Hip DislocationKenNo ratings yet

- 13 Emergency Response: Project Employer Engineer ContractorDocument9 pages13 Emergency Response: Project Employer Engineer ContractorcenkunalNo ratings yet

- Health and Safety Audit ToolsDocument4 pagesHealth and Safety Audit ToolsAbdur Rashid KhanNo ratings yet

- RA Arc, Welding 150310Document4 pagesRA Arc, Welding 150310Mohd FikryNo ratings yet

- Toolboxtalk2 Housekeeping PDFDocument2 pagesToolboxtalk2 Housekeeping PDFSajid HussainNo ratings yet

- Procedure For Hazard Identification, Risk Assessment, and Determining ControlsDocument8 pagesProcedure For Hazard Identification, Risk Assessment, and Determining Controlsdhir.ankur100% (1)

- Hazard Identification and Risk Assessment LiftingDocument2 pagesHazard Identification and Risk Assessment LiftingHariharan Muthukrishanan100% (1)

- Risk Assessmenygfyt Control Form 5 Hazards You Have Identified in Your SITE INSPECTION ASSESSMENT YODocument5 pagesRisk Assessmenygfyt Control Form 5 Hazards You Have Identified in Your SITE INSPECTION ASSESSMENT YOHarry PotarNo ratings yet

- 9.0 - Workplace Wellness v3.0 EnglishDocument10 pages9.0 - Workplace Wellness v3.0 EnglishVi VekNo ratings yet

- HSE-P-04 Periodic Evaluation of Legal Compliance Issue 2.1Document3 pagesHSE-P-04 Periodic Evaluation of Legal Compliance Issue 2.1eng20072007No ratings yet

- Loading and Offloading MaterialDocument3 pagesLoading and Offloading MaterialThabani NkomoNo ratings yet

- OHSMS DOC 10.3 - Continual Improvement ProcedureDocument2 pagesOHSMS DOC 10.3 - Continual Improvement ProcedureTuan AnhNo ratings yet

- Chemical and Biological HazardsDocument3 pagesChemical and Biological HazardsLeo Agustin HadeNo ratings yet

- Mechanism 8 0 - AD EHS Practitioner Registration - Ver 2.2 (March 2014)Document48 pagesMechanism 8 0 - AD EHS Practitioner Registration - Ver 2.2 (March 2014)prabhu_amtNo ratings yet

- Risk / Impact Assessment Control Sheet: MatrixDocument4 pagesRisk / Impact Assessment Control Sheet: MatrixSaim AliNo ratings yet

- Health, Safety AND Environmental PlanDocument63 pagesHealth, Safety AND Environmental Planm.umarNo ratings yet

- PRO410 Traffic ManagementDocument15 pagesPRO410 Traffic ManagementviniNo ratings yet

- NEW CL - JLA Steel Hand Tool - SWPDocument3 pagesNEW CL - JLA Steel Hand Tool - SWPAbdul Rafiq100% (1)

- Arc Welder Risk MG T FormDocument9 pagesArc Welder Risk MG T FormMohd FikryNo ratings yet

- Incident Investigation Report Format No: HSE Format - 03 Rev. E Page 1 of 2Document2 pagesIncident Investigation Report Format No: HSE Format - 03 Rev. E Page 1 of 2NibhaNo ratings yet

- General Requirements For Construction Health and Safety For Lusail Development ProjectDocument35 pagesGeneral Requirements For Construction Health and Safety For Lusail Development ProjectAnthony PapadopoulosNo ratings yet

- Cebe JSS Audit 2 Report 08.12.2017Document14 pagesCebe JSS Audit 2 Report 08.12.2017mthokozisishangase6No ratings yet

- Construction-Safety-Management-Plan For Hydro Power PlantDocument73 pagesConstruction-Safety-Management-Plan For Hydro Power PlantRaza Muhammad SoomroNo ratings yet

- Essay Writing Sample AssignmentDocument4 pagesEssay Writing Sample AssignmentJane AustinNo ratings yet

- HSE Procedure For Garbage DisposalDocument4 pagesHSE Procedure For Garbage DisposalKhuda BukshNo ratings yet

- HSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0Document15 pagesHSE-RA-063 Erecting and Dismantling of Placing Boom - Rev 0عمروNo ratings yet

- Al-Harthyh Contracting: Hse Management PlanDocument30 pagesAl-Harthyh Contracting: Hse Management PlanAhmed GamalNo ratings yet

- Job Safety Analysis: S.No Activities Hazard Risk Control MeasuresDocument2 pagesJob Safety Analysis: S.No Activities Hazard Risk Control Measureskhaja asifuddin100% (1)

- SWMS Mobilisation of Blocks For MLT TEST RKDocument14 pagesSWMS Mobilisation of Blocks For MLT TEST RKrakeshkhanna78100% (1)

- Emc Faqs Learner v5Document8 pagesEmc Faqs Learner v5Raz BiophyNo ratings yet

- Food Safety Level 2Document1 pageFood Safety Level 2sampathdtNo ratings yet

- Health & Safety: Noise Hazard Identification FormDocument1 pageHealth & Safety: Noise Hazard Identification FormAhmad Anas Nagoor GunnyNo ratings yet

- FSC Learner Guide v3Document12 pagesFSC Learner Guide v3Simon KNo ratings yet

- BEMS-MP-06 OHS Monitoring and Measurement PlanDocument13 pagesBEMS-MP-06 OHS Monitoring and Measurement PlanrememberNo ratings yet

- Heat Stress Risk Assessment FormDocument3 pagesHeat Stress Risk Assessment Formum erNo ratings yet

- HSE KPI'sDocument8 pagesHSE KPI'sMahir ShihabNo ratings yet

- EP06Document5 pagesEP06Chrome PicassoNo ratings yet

- 4-Final RA For Installation of Instalation Precast PDFDocument2 pages4-Final RA For Installation of Instalation Precast PDFeng mohamad husamNo ratings yet

- 083 11 542.pdfp03782 PDFDocument67 pages083 11 542.pdfp03782 PDFSultana LaboniNo ratings yet

- ENGY-EnG3-MOS-20210603-002 - Method of Statement For Concrete Pavement WorksDocument21 pagesENGY-EnG3-MOS-20210603-002 - Method of Statement For Concrete Pavement WorksTemur LomidzeNo ratings yet

- 02-009 Smoking PolicyDocument6 pages02-009 Smoking PolicyJoachimNo ratings yet

- KOC HE 027 - Heat Stress Management ProcedureDocument44 pagesKOC HE 027 - Heat Stress Management ProcedureGeorge LameyNo ratings yet

- ISO-14001-2015 EA And-Procedure-SampleDocument7 pagesISO-14001-2015 EA And-Procedure-SampleFaisal0% (1)

- Objectives and TargetsDocument2 pagesObjectives and TargetsZohaib TahirNo ratings yet

- Health, Safty & Environment SheduleDocument21 pagesHealth, Safty & Environment SheduleEmmanuel ThomasNo ratings yet

- Schedule For Inspection Sept 19Document1 pageSchedule For Inspection Sept 19Siddharth RanaNo ratings yet

- SRP-Waste Management Plan-G225IEX-SRP-R-PLN-003Document10 pagesSRP-Waste Management Plan-G225IEX-SRP-R-PLN-003Ows AnishNo ratings yet

- Form N - OHS Practitioner Resume Template-V3.0 EnglishDocument5 pagesForm N - OHS Practitioner Resume Template-V3.0 EnglishfaizalpsNo ratings yet

- VII 2 GEN - Health Safety Plan Guidelines Rev01Document34 pagesVII 2 GEN - Health Safety Plan Guidelines Rev01lampardbkNo ratings yet

- 021 - Energy Isolation, Lockout and Tagout ProcedureDocument22 pages021 - Energy Isolation, Lockout and Tagout ProcedureemmyNo ratings yet

- SHEQ01: Safety, Health, Environmental and Quality PolicyDocument30 pagesSHEQ01: Safety, Health, Environmental and Quality PolicyASEPNo ratings yet

- RA - 14 - For Waterproofing Membrane ApplicationDocument13 pagesRA - 14 - For Waterproofing Membrane ApplicationIbrahim EsmatNo ratings yet

- QUU Contractor WHS Management SOP PRO586Document23 pagesQUU Contractor WHS Management SOP PRO586Travis BakerNo ratings yet

- Evaluation Criteria Table 1: Description of Likelihood (Probability)Document2 pagesEvaluation Criteria Table 1: Description of Likelihood (Probability)Rafee PieNo ratings yet

- Fire Protection Plan 1Document11 pagesFire Protection Plan 1Muhammad TariqNo ratings yet

- 22-RA-Paint WorkDocument2 pages22-RA-Paint Workravindra100% (1)

- STFC Objectives and Targets SHE PlanDocument2 pagesSTFC Objectives and Targets SHE PlanThato KebuangNo ratings yet

- Ig2 Example 1 v1Document16 pagesIg2 Example 1 v1asim zeeshanNo ratings yet

- Part 2 Correct OneDocument8 pagesPart 2 Correct OneMock ProjectNo ratings yet

- Hope12 q1 Mod5 ObservespersonalsafetyprotocolpdfDocument15 pagesHope12 q1 Mod5 Observespersonalsafetyprotocolpdfjessamaegaamil33No ratings yet

- 2 - Risk AssessmentDocument4 pages2 - Risk AssessmentNangyal KhanNo ratings yet

- Ra-20 Lifting and Errection of ChimneyDocument8 pagesRa-20 Lifting and Errection of Chimneyalla malikNo ratings yet

- Price Needs Updating, Should We Call The Police?: C M Bleakley, P Glasgow, D C MacauleyDocument2 pagesPrice Needs Updating, Should We Call The Police?: C M Bleakley, P Glasgow, D C MacauleyAna BelchiorNo ratings yet

- Circular Saw - Ryobi CSB125Document48 pagesCircular Saw - Ryobi CSB125BmackieNo ratings yet

- Full Body Cool Down Static StretchingDocument8 pagesFull Body Cool Down Static StretchingOrestisNo ratings yet

- Basic Knee Arthroscopy Part 2Document2 pagesBasic Knee Arthroscopy Part 2Diego BellingNo ratings yet

- Head and Neck IndebirDocument544 pagesHead and Neck Indebirdr.mumtaz09No ratings yet

- Hilot: Filipino Ancient TherapyDocument6 pagesHilot: Filipino Ancient Therapychristos koutsotasiosNo ratings yet

- Wound Infection & OsteomyelitisDocument33 pagesWound Infection & OsteomyelitisMoiz AzizNo ratings yet

- Medico Legal Aspect of Stab Wound - Dilraj Singh ChouhanDocument16 pagesMedico Legal Aspect of Stab Wound - Dilraj Singh ChouhanDilraj Singh Th Det100% (2)

- Problem Nursing Diagnosis Outcome Plan Intervention Evaluation Subjective Short Term IndependentDocument1 pageProblem Nursing Diagnosis Outcome Plan Intervention Evaluation Subjective Short Term IndependentkyawNo ratings yet

- StrokeDocument9 pagesStrokeezar Al barraqNo ratings yet

- Effects of Neuromuscular Training On Children andDocument11 pagesEffects of Neuromuscular Training On Children andJussie PereiraNo ratings yet

- A Hero Like YouDocument26 pagesA Hero Like YoukikiNo ratings yet

- Jurnal InggrisDocument15 pagesJurnal InggrisDICKY PANDUWINATANo ratings yet

- HemothoraxDocument13 pagesHemothoraxسما كركوكليNo ratings yet

- Emr Cheat Sheet: Frontline First Aid & Emergency Training 250-470-0205Document15 pagesEmr Cheat Sheet: Frontline First Aid & Emergency Training 250-470-0205Sarah-kate Paterson100% (2)

- Amputation: Sites of Amputation: UEDocument6 pagesAmputation: Sites of Amputation: UEChristine PilarNo ratings yet

- Basic Medico Legal Duties of Medical OfficersDocument47 pagesBasic Medico Legal Duties of Medical OfficersTikiri Bandara Gunethilake75% (4)

- John F Kennedy Memorial Hospital Tubman National Institute of Medical Art (TNIMA)Document7 pagesJohn F Kennedy Memorial Hospital Tubman National Institute of Medical Art (TNIMA)Widimongar W. JarqueNo ratings yet

- Ankle Syndesmosis InjuriesDocument16 pagesAnkle Syndesmosis InjuriesRin MaghfirahNo ratings yet

- Module 4 - PathFitDocument3 pagesModule 4 - PathFitBrody Shag100% (4)

- Accident Report FormDocument2 pagesAccident Report Formengineermoelci1No ratings yet

- 6 Series - Notes Need To WriteDocument9 pages6 Series - Notes Need To WriteVijay UNo ratings yet

- Somatosensory SystemDocument34 pagesSomatosensory SystemMicko Martha ThamrinNo ratings yet

- Management of Acute Spinal Cord Injury - A Summary of The Evidence Pertaining To The Acute Management, Operative and Non-Operative ManagementDocument12 pagesManagement of Acute Spinal Cord Injury - A Summary of The Evidence Pertaining To The Acute Management, Operative and Non-Operative Managementzee zeeNo ratings yet

- 2018 May The Point - ReducedDocument42 pages2018 May The Point - ReducedConstanza RuizNo ratings yet