Professional Documents

Culture Documents

Operation Manual Book MT1740SLT

Operation Manual Book MT1740SLT

Uploaded by

Nova kurniawan 340 ratings0% found this document useful (0 votes)

15 views140 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

15 views140 pagesOperation Manual Book MT1740SLT

Operation Manual Book MT1740SLT

Uploaded by

Nova kurniawan 34Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 140

1 - OPERATING

_ AND SAFETY

INSTRUCTIONS |

we 14

GLa ae ee ee

oC

co

INSTRUCTIONS TO THE COMPANY MANAGER 4-4

‘THE OPERATOR a4

‘TE LIFT TRUCK 4-4

‘A= THE LIFT TRUCKS SUITABILITY FOR THE JOB ‘ 14

5 - ADAPTATION OF THE LIFT TRUCK TO STANDARD ENVIRONMENTAL CONDITIONS: 44

1-4

1-5

a8

aioe

Cc

(C- MODIFICATION OF THE LIFT TRUCK

‘THE INSTRUCTIONS

THE MAINTENANCE

INSTRUCTIONS FOR THE OPERATOR

ao

PREAMBULE

GENERAL INSTRUCTIONS

‘A. OPERATOR'S MANUAL.

'B - AUTHORIZATION FOR USE IN FRANCE

(or see current legisiation in other counties)

(© MAINTENANCE

tr 1D MODIFICATION OF THE Lier TRUCK

E“UFTING PEOPLE

OPERATING INSTRUCTIONS UNLADEN AND LADEN

Es ‘A~ BEFORE STARTING THE LIFT TRUCK

B - DRIVER'S OPERATING INSTRUCTIONS

U (G- ENVIRONMENT

O- VISIBILITY

5 E- STARTING THE LIFT TRUCK

DRIVING THE LIFT TRUCK.

L STOPPING THE LIFT TRUCK .

H.- DRIVING THE LIFT TRUGK ON THE PUBLIC. HIGHWAY

INSTRUCTIONS FOR HANDLING A LOAD

‘A- CHOICE OF ATTACHMENTS

{3 MASS OF LOAD AND CENTRE OF GRAVITY

- LONGITUDINAL STABILITY ALARM,

- TRANSVERSE ATTITUDE OF THE Lier TRUCK

“TAKING UP A LORD ON THE GROUND

F.- TAKING UP AND LAYING A HIGH LOAD ON TYRES

G.- TAKING UP AND LAYING A HIGH LOAD ON STABILIZERS

(OPERATING INSTRUCTIONS THE PLATFORM

'A~ DISPOSITION tN THE PLATFORM

18 - OPERATING THE PLATFORM

©. ENVIRONWENT

INSTRUCTIONS FOR USING THE RADIO-CONTROL

aaaa

BEBE Beene ee ee eee fhe

bb o0adaved

RS888E5RRR5EE5R

oc

1

Beep BEER BE

MMAWrenaNce INSTRUCTIONS OF THE LIFT TRUCK

8

GENERAL INSTRUCTIONS

= MAINTENANCE

‘LUBRICANT AND FUEL LEVELS

1 HYDRAULIC.

ELECTRICITY

4 WELDING

Uj ‘WASHING THE LIFT TRUCK

pepeein [he

SERBBBB

BEREE |p

U ‘Te THE LIFT TRUCK IS NOT TO BE USED FOR A LONG TIME

INTRODUCTION

4 PREPARING THE LIFT TRUCK

PROTECTING THE I.C. ENGINE,

u PROTECTING THE LIFT TRUCK

BRINGING THE LIFT TRUCK BACK INTO SERVICE

beeee |B

eee eee

Tue OPERATOR

Only qualified, authorized personnel can use the tit ruck This authorization is gven In wring by the appropriate person in the

establishment with respect to the use of lift trucks and must be carried permanently by the operator.

Ly 2hite bast of oeece, tee ae a rmber of posal stanton I wh oertig the I ck contrat Such fore

sevable abmormal wses the man ones belng std below are sity fiden.

«The foreseeable anormal Behaviour resulting tom ordinary neglect, but doesnot result rm ay wish to put te machinery to

any improper us0.

~The eilex reactors of a person nthe event ofa alintion indent fal ote. during operation othe Ht tuck.

+ Behaviour esting fom appt ofthe “pcp of eat action” when porfoning a task.

= For certain machines, te oresceabe bokavor of sch persons as peroties, teenager, hondleapped persons trainees

tempted to drive a litt truck, operator tempted to operate a truck to win 2 bet, in competition or for thelr own personal experience...

‘The person in charge of the equipment must take these eer ito account when assessing whether oot 2 porsoa wil make a

sultabie vee

The wer TRUCK

(THE LIFT TRUGK’S SUITABILITY FOR THE JOB

‘MANITOU has ensured that this fift truck is suitable for use under the standard opereting conditions defined in this operator's

‘manual, with a STATIC test cocfficient of 4.38 and a DYNAMIC test coefficient of 4, as spectied In harmonised norm EN 2459

for variable range trucks. :

+ Before commissioning, the company manager must make sure thatthe lift truck Is sppropriste for the work to be done, end per-

‘orm certain tests (in accordance with current legislation).

'B- ADAPTATION OF THE LIFT TRUCK TO STANDARD ENVIRONMENTAL CONDITIONS :

“In adaition to series equipment mounted on your ift truck, many options are avaliable, cuch 2 : road lighting, stop lights, fo-

shing light, reverse lights, reverse buzzer olor, front light, reer fight, light at the jis head, etc.

~The operator trust toke into account the opeteting conditions to define the lift truck's signalling and lighting equlpment. Contact

your dealer,

+ Take Into eccount cltic and atmospheric conditions of the site of utilisation.

« Protection against fost (see : 3- MAINTENANCE : LUBRIOANTS AND FUEL).

+ Adaptation of lubricants (ask your dealer for information).

{1G engine fitration (see : 3 MAINTENANCE : FICTERS CARTRIDGES AND BELTS).

For operation under average matic conditions, Le, between -15 °C and + 85 °C, comect levels of bricants i al tho citeuits aro

‘Ohecked in production, For operation under more severe climatic conditions, before stating up, Its nocessary to drain all tho circuits,

thon ensure comet levels of lbricants using lubricants propedy suite to the relevant amblent temperatares, It isthe same fer the

ool Baud.

* _-f truck operating in an area without fire extingilshing equipment must be equipped with an Inchidal extinguisher. There are

olstions, consult your dealer.

SA Yur it truck Is deslgned for outdoor use under nora atmosphere conditions anid Indoor use In suitably aerated and ventiated pro-

mises. tf protiited to use the Wit truck i areas where there is ask of fie or wich are potentially explosive (e.g. Refineries, fuel

or gas depots, store ofinammable products). For use In these areas, spelfo equipment fx avaliable (ask your denior fr Informa-

tion).

‘© MODIFICATION OF THE LIFT TRUCK

“For your safety and that of others, you must not change the structure and settings of the various components used In your lft

‘ruck (hycraulle pressure, calibrating limiters, .C. engine speed, dation of extra equipment, addition of counterweight, unap-

proved and unauthorised attachments, alarm systems, ets.) yourself. In this event, the manufacturer cannot be held responsible.

eae

eee aD eae ce epee Pc

Stel

WHENEVER YOU SEE THIS SYMBOL IT MEANS :

A

WARNING I BE CAREFUL 1 YOUR SAFETY OR THE SAFETY OF THE LIFT TRUCK IS AT RISK.

Dy Tes of peste wt ute, seiing or opting your it tuck can be reseed Wt you foto the safety instructors an satty

measures detalled In these instruction.

Only the operations and manczuvres described in these operator's manual must be performed, The manufacturer cannot predict

all possible risky situations. Consequentty, the safety Instructions given In the operator's manual and on the if truck itself ere

‘ot exhaustive,

At eny time, 2s an operator, you must envisage, within reason, the possible ick to yours, to others or to the lit truck Keel

when you use it.

Dy Dio esse te satety an operating iestettons or he instructions fo tepaliagoSrc yar Mt ack may lat sos,

even fatal accident.

~~ Gevenan nsteverions

‘A OPERATOR'S MANUAL

Reed the operator's manual carefully.

The operator's manual must ahveys be in good condition and inthe place provided for ton the If truck.

+ Yoit must report any plates and stickers which are no longer legible or which are demaged.

AUTHORIZATION FOR USE IN FRANCE

{ot see current logistation in other counttles)

+ Only qualified, euthorized personnel! may use the it truck. This authorization Is gven In writing by the appropriate person in the

‘company, in charge of using the lift truck, and must be permanently carried by the operator.

~The operator Is not competent to authorise the criving ofthe lft truck by another person.

(C- MAINTENANCE 7

~The operator must immediately acvise his superior if hs ft truck Is not In good working order or does not comply withthe sate

ty notice.

+ The operetor fe protibted from carrying out any repalrs or adjustments himself, unless he hes been trained for this purpose. He

must keep the lift truck property cleaned if this Is among his responsibiities.

~The operator must cerry out day maintenance (see : 3~ MAINTENANCE : A DAILY OR EVERY 40 HOURS SERVICE).

+The operator must ensure tyres are adapted to the nature ofthe ground {see area ofthe contact surface of the tyres inthe chap-

(> fer 2- DESCRIPTION : CHARACTERISTICS), There ere optional eolwons, eansut your desler.

CO) = SAND tyes.

LAND res.

Snow chains.

Do not use the fit track if tho tyres are Incorrectly Inflated, damaged or excessively wom, because this could put your own safety or

that of others at isk or cause damage to the lit truck itself. The fitting of foam inflated tyres fs prabibited and is not guaranteed by

the manofacterer, excepting sor authorisation,

D- MODIFICATION OF THE LIFT TRUCK.

For your safety end that of others, you must not change the structure end settings of the various components used In your lit

truck (hydraulic pressure, calibrating limiters, LC. engine speed, addition of extra equloment, adeitfon of counterweight, unap

Proved and unauthorised attachments, alarm systems, etc) yourself. In this event, the manufacturer cannot be held responsiblo.

eee

E- LIFTING PEOPLE

G ~The use of working equipment and load lifting attachments to lift people

Is:

* either forbidden

+ of authorized exceptionally and under certain conditions (see

current regulations In the country in which the lift truck is

used),

~The pictogram posted at the operator station reminds you that :

* Lefthend oolurmn

itis forbidden to lit people, with any kind of attache

tent, using @ non ORH Eft truek.

+ Righehend column

With an ORH lift truck, people cen only be lifted using

Platforms designed by MANITOU for the purpose.

* MANITOU setis equipment specifically designed for iting poople (OPTION

ORH tit truck, contect your dealer).

Ieee Ree tee

}

a

OPERATING INSTRUCTIONS UNLADEN AND LADEN

‘A BEFORE STARTING THE LIFT TRUCK

Carry out daily maintenance (see : 3 - MAINTENANCE : A~ DAILY OR EVERY 10 HOURS SERVICE).

Make sure the lights, indlestors and windscreen wipers are working properly.

= Make sure the feer view mirars are in good condition, clean and propery adjusted,

Make sura the horn works.

B- DRIVER'S OPERATING INSTRUCTIONS :

= Whetovar his exprience, the operator le ecvised to fernlrize himself wth the postion and opertion of al the controls end ins-

‘ruments before operating the lit truck,

Weer clothes sufted for civng the it truck, avoid loose clothes.

Make sure you have the appropriate protective equipment forthe job to be done.

~ Prolonged exposure to high noise levels may cause heerng problems. It's recommended to wear ear muffs to protect against

excessive noise.

Always face the Ii truck when getting into and (eeving the criving seat and use the hendlo(e) provided for this purpose. Do not

Jump out ofthe seat to get down.

~ Aways pay attention when using the lt tuck, Do not listen tothe radio or musle using headphones or earphones.

Never operate the it tuck when hands or fost aro wet or sciled with greasy substances,

~ For inoreaced comfort, adjust the seat to yourroqurements and adopt the correct pesition in the civer's cab,

Eon

Byer to ctemsences mii set east wie thet tack mov

“~ carefully when epproaching the authorized load limit (see : 2 - DESCRIPTION : INSTRU-

(Co ments ano controts),

+ Always watch this device during handling operations.

When the device Is in alert made, it is forbidden_to perform so-called *AGGRAVATING™

movements, these being :

‘A- Extending the fb.

B.- Loworing the jib.

Perform movements to relieve aggravation In the following order (ig. ©): if necessary,

raise the jib (1), retract the [lb 8s far as possible (2) and lower the Jb (8) to release the

toad.

cy

tou pea Oa

‘The Instrument roading may be erroneous when the steering ie atts maximum Hint or the

rear axle oscilated to Its limit. Before Hting a load, make sure that the lift truck Is aot in

‘ither of these situations.

tI

eee Ieee

ca

D - TRANSVERSE ATTITUDE OF THE LIFT TRUCK

(depending onto loft tru)

Oo

‘The transverse attitude is the transverse slope of the chassis with respect to the horizan-

tal.

{| Raising the jib reduces the lift truck's iateral stability. The transverse attitude must be set,

with the jb in down position as follows: -

{] sur mune iro comeston use on nas

“Foston the ition athe ao nthe le! Deen th ws (00: 2-

Desens NSTRUMENTS Ais coNTPOCS,

eee

“are h lopo ving be hyalicontl navn re htorallyva the ee The

{[] bubble tn the level must be bebveen tho two lines (see: 2- DESCRIPTION : INSTRU

(] Mens conan

= LIFT TRUCK USED ON STABILZERS

= Set the two stabilizers on the ground and raise the two front wheels of the lift truck (fc.

D4).

"orrect the slope using the stabilizers (ig. 02) and make sure the truck is horizontal by

hecking the level, Te bubble of the level must be between the two lines (see : 2- DES-

CRIPTION : INSTRUMENTS AND CONTROLS). In this position, the two front wheels must

be off the ground.

co

TAKING UP A LOAD ON THE GROUND

~ Approsch the it truck perpentioular to the load, with theb retracted and the forks In 2

[7] horizontal position ig. E1).

LJ. ~Acust the tork spread and osrtertng In connection with the oad (g. E2) (optional solu

tions exist, consut your deaien.

Never lit @ Toad with a single fork,

LT dtl etree za Uo ete ec ace

~ Move the Iift truck forward slowly (1) and bring the forks to stop In front of the load (fig.

{] - 3), trnecessary, sighty tft the jb (2) while taking up the toad.

Lette tea io eanportbaakon

+ Tilt the load fer enough backwards to ensure stability (loss of load on braking or going

downhill).

ero

"Satine ug fowatdeend me te It ck son forwards (2) Inert the fork

Torts et oe tod Wncessan :

= Continue to move the lift truck forwards (2) tilting the carriage (3) (fig, £4) backwards to

postion the ood onto fra and check load lengua enter abt

ca

ie

ee

ie

{isan}

®

g

U8

co

oO

O

co

Da

F- TAKING UP AND LAYING A HIGH LOAD ON TYRES

You most not raise the Jib Ifyou heve not checked the transverse attitude of the fit truck

{seo INSTRUCTIONS FOR HANDLING A LOAD: D > TRANSVERSE ATTITUDE OF THE LIFT

TRUCK).

REMINDER : Make sure that the following operations can be performed with good visibi-

ty (gee : OPERATIONS INSTRUCTIONS UNLADEN AND LADEN : D- VISIBILITY).

‘TAKING UP A HIGH LOAD ON TYRES.

~ Ensure thet the forks wil easily pass under the load.

“Lift and extend the jb (1) (2) until the forks are level with the load, moving the lft truck

(G) forward if necessary (ig. Fa), moving very siowly anc carefully.

~ Always think about Keeping the distance necessary to fit the forks under the load, bet-

‘ween the pile and the lift truck (fig. F4) end use the shortest possible length of Jb.

+ Stop the forks in front of the load by alternately extending and retracting the jb (1) or, if

Necessary, moving the lit truck forward (2) (fg, F2). Put the handbrake on and set the

reverse gear to neutral.

+ Slightly it the load (4) and inctine the carriage (2) backwards to stablize the loed (Rg.

FS),

Tithe toad sufficiently backwards to ensure its stability,

+ Watch the longitudinal stability alarm (see ; INSTRUCTIONS FOR HANDLING A LOAD : C=

LONGITUDINAL STABILITY ALARM). If I's overloaded, répiace the Toad In the place from

‘whit it was taken,

If possible lower the load without shifting the lit truck. Lift the jib (4) to release the load,

(C xt2st 2) end tower thoi () to tring the lod rt the transport poston (eg FA.

if this Is not possible, back up the lift truck (1), manoeuvring very gently and oarefully to.

release the load, Retract (2) and lower the jis (8) to bring the load into the traneport pos!

ton (fig. F3).

[mas

[onan te FT oes

ani |

coe

Tc

oe

ot

TTC

ca ta cS

cy

ITI

Cre

en a a a es)

laa

co po

eee eee

LING A HIGH LOAD ON TYRES

Approach the load in the transport position infront of the plo (fig. F8).

~ Put the handbrake on and set the reversing lever to neutral.

~ Lift and extend the jo (4) (2) until the load Is ebove the pile, while Keeping an eye on the

fongitucinel stabilty elarm (see : INSTRUCTIONS FOR HANDLING A LOAD : C.- LONGITU-

DINAL STABILITY ALARM). If necessary, move the lift truck (8) forward (fig. FZ), cing

vory slowly and carefully.

~ Plate the load in a horizontal position and tay it down on the pile hy lowering and retrac-

‘ing the jib (1) (2) n order to position the load correctly (ig. F8).

+ If possible, release the fork by alternately retracting and raising the lb (4) (ig. F9). Then

‘et the forks into transport position.

“If this ts not possible, reverse the lift truck (1) very slowly and carefully to release the

forks (ig. £10). Then set them into transport poston.

@- TAKING UP AND LAYING A HIGH LOAD ON STABILIZERS

{@openogo the mote fi trae)

You must not raise the ib Ifyou have not chocked the transverse attftude of the lift truck (see : INSTRUCTIONS FOR HANDLING A

LOAD:: D- TRANSVERSE ATTITUDE OF THE LIFT TRUCK).

REMINDER : Make sure that the following operations can be performed with good visibility (see : OPERATIONS INSTRUCTIONS

UNLADEN AND LADEN :

~ViSIBILITY).

USING THE STABILZERS

‘The stabllzers are used to optimise the lit truck's liting perfarmances (see : 2- DESCRIPTION : INSTRUMENTS AND CONTROLS).

POSITION THE STABILIZERS WIT THE FORKS I TRANSPORT POSITION (UNLADEN AND LADEN)

+ Set the forks In transport position In front of the elevation.

+ Stay far enough away to have room forthe jb to be raised.

+ Puton the porking brake and set the gear reverser lever to neutral.

+ Set the two stabilizers on the ground and ff the two front wheels of the lift truck (fig.

Gi), while maintaining its transverse stability.

RIE THE STABLIZERS WIT THE FORKS IN TRANSPORT POSTON (LADEN AND LADEN)

+ Raise both stabilizers fuly and at the same time.

(Cree sous 1 onan ao EN

Bi tis conten aut exc! and prome wth gost ca.

Raise the Jb-and retract the telescopes completely.

Set the lfttruckin position infront ofthe elevation (fiz. G2) moving very slowly and care-

fully.

Put on the patking brake and sot the goar reversor lever to neutral.

“Move the stabilizers very slowly end gracualy as soon es they are close to the ground or

In contact with it.

- Lower the two stabilizers and lift the two front wheels ofthe fft truck (fig, 63). During this

‘operation, transverse altitude must be permanently maintained : the bubble inthe level

must be kept between the two tines.

‘SING THE STABILIZERS WITH THE 13 UP (UNLADEN AND LADEN)

Bi tite coton st bo expt! ond pred th oat oe,

- Koop the Jib up and retract the telescopes completely (fig. G3). i

Move the stabilizers very slowly and gradually 2s soon as they are in contact with the

‘ground and when they leave the ground. Duting this operation, the transverse atlitude

(>) ust be permanently maintained: the bubble Inthe level must be Kept between the two

~~ tines.

+ Rolse both stablizers completely.

+ Release the parking brake and reverse the it truck (1) very slowly and carefully, to releze

'e it and lower the forks (2) into transport position (Rg. G4).

ot

Cy

{iat

eee ee

ee

ecvcr

q

u

TAKING UP A HIGH LOAD ON STABILIZERS

(7) -Make sure the forks wil ft easily under the toed.

LI -check the position of the lft ruck with respect tothe load and make a test run, i neces-

sary, witout taking the foad.

+ Raise and extend th jb (2) (2) until the forks are atthe level ofthe load tg. 05).

g ~ Black the forks tn front of the load by alternately using the controls to extend and lower

‘theo (1) tz. G6).

“Lift the load sight (4) and tt the cariage (2) baclovard to etablize the foad (fe. G7).

(7. “Monitor th iongitusinet stably alarm (eb0: INSTRUCTIONS FOR HANDLING A LOAD :

LL

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Diagnostic Code List: TroubleshootingDocument17 pagesDiagnostic Code List: TroubleshootingNova kurniawan 34No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cummins Confidential: 146797638.xls - Ms - Office, Tab: Wiring Diagram Page 1 of 2Document2 pagesCummins Confidential: 146797638.xls - Ms - Office, Tab: Wiring Diagram Page 1 of 2Nova kurniawan 34100% (2)

- 7192 DR5021Document328 pages7192 DR5021Nova kurniawan 34No ratings yet

- 740 Vs Volvo A40D (TEJB8012)Document28 pages740 Vs Volvo A40D (TEJB8012)Nova kurniawan 34100% (1)

- Emergency Stop & Idle Timer System Liebh 9400Document2 pagesEmergency Stop & Idle Timer System Liebh 9400Nova kurniawan 34No ratings yet

- 345D HEX Dealer Recommended Parts Stocking ListDocument3 pages345D HEX Dealer Recommended Parts Stocking ListNova kurniawan 34No ratings yet

- Lincoln Auto Lubrication System: Maintenance Procedure ListDocument1 pageLincoln Auto Lubrication System: Maintenance Procedure ListNova kurniawan 34No ratings yet

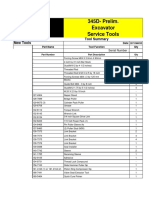

- 345D-Prelim. Excavator Service Tools: Tool Summary New ToolsDocument6 pages345D-Prelim. Excavator Service Tools: Tool Summary New ToolsNova kurniawan 34No ratings yet

- Product Manual: Idle Timer Etr Controller 12/24 VDocument20 pagesProduct Manual: Idle Timer Etr Controller 12/24 VNova kurniawan 34100% (2)

- PA No: 19/08 For GCN1, GCN2, Asia & India OnlyDocument8 pagesPA No: 19/08 For GCN1, GCN2, Asia & India OnlyNova kurniawan 34No ratings yet

- Engine: Technical TrainingDocument70 pagesEngine: Technical TrainingNova kurniawan 34No ratings yet

- Diagnostic Flash Codes For CAT C13 Engines: Troubleshooting. Contact Your Local Cat Dealer For More InformationDocument3 pagesDiagnostic Flash Codes For CAT C13 Engines: Troubleshooting. Contact Your Local Cat Dealer For More InformationNova kurniawan 34100% (1)