Professional Documents

Culture Documents

Tram Kios TCS ZA IA en 10

Tram Kios TCS ZA IA en 10

Uploaded by

Hồ ThànhCopyright:

Available Formats

You might also like

- 230/460 and 460/575 Volt ModelsDocument104 pages230/460 and 460/575 Volt ModelsIan McNair100% (3)

- CAN and FPGA Communication Engineering: Implementation of a CAN Bus based Measurement System on an FPGA Development KitFrom EverandCAN and FPGA Communication Engineering: Implementation of a CAN Bus based Measurement System on an FPGA Development KitNo ratings yet

- BC138-139 User ManualDocument16 pagesBC138-139 User ManuallalociscoNo ratings yet

- Sma Sunny Tripower 15000tl 20000tl 25000tl Operating ManualDocument56 pagesSma Sunny Tripower 15000tl 20000tl 25000tl Operating ManualSadikNo ratings yet

- CAM-14 Acquisition Module: Field Service ManualDocument88 pagesCAM-14 Acquisition Module: Field Service ManualLászló BaloghNo ratings yet

- Berges Acm STDDocument64 pagesBerges Acm STDAdan Solano50% (4)

- SCS TA E1 en 11Document30 pagesSCS TA E1 en 11toky.zatovonirinaNo ratings yet

- Operating Manual: SUNNY TRIPOWER 20000TL / 25000TLDocument50 pagesOperating Manual: SUNNY TRIPOWER 20000TL / 25000TLakbar installNo ratings yet

- Auto Continuum PDFDocument164 pagesAuto Continuum PDFJosé Carlos de Alencar Dias100% (1)

- XMT 350 FieldPro ArcReachDocument92 pagesXMT 350 FieldPro ArcReachEsteban MartinezNo ratings yet

- Operating Manual SUNNY BOY 3000TL / 3600TL / 4000TL / 5000TLDocument68 pagesOperating Manual SUNNY BOY 3000TL / 3600TL / 4000TL / 5000TLDragos Virgil MosNo ratings yet

- Operating Manual: SUNNY TRIPOWER 20000TL / 25000TLDocument52 pagesOperating Manual: SUNNY TRIPOWER 20000TL / 25000TLprekNo ratings yet

- Sunny Boy 3000tl Us ManualDocument88 pagesSunny Boy 3000tl Us ManualAshraf CardiffNo ratings yet

- KBPC-225: Installation and Operating InstructionsDocument17 pagesKBPC-225: Installation and Operating InstructionsDiego MontanezNo ratings yet

- 215S-CP109 0 Weldmatic 215 SDocument21 pages215S-CP109 0 Weldmatic 215 SRogerNo ratings yet

- Operating Instruction ZETADYN 3BFDocument194 pagesOperating Instruction ZETADYN 3BFReaper68No ratings yet

- Sepam: Digital Protection Relays Installation Assistance GuideDocument80 pagesSepam: Digital Protection Relays Installation Assistance Guidealbert_f42No ratings yet

- Elite Manual de ServiçoDocument196 pagesElite Manual de ServiçoCarlos Flores100% (1)

- enDocument277 pagesenDannish R LailanNo ratings yet

- KBWM DC Drive Series ManualDocument9 pagesKBWM DC Drive Series ManualKBElectronicsincNo ratings yet

- PV Inverter: SUNNY MINI CENTRAL 9000TL / 10000TL / 11000TL With Reactive Power ControlDocument96 pagesPV Inverter: SUNNY MINI CENTRAL 9000TL / 10000TL / 11000TL With Reactive Power ControlIonut Robert BalasoiuNo ratings yet

- User Manual SMA Sunnyboy SB1100 SB1700Document66 pagesUser Manual SMA Sunnyboy SB1100 SB1700JonathonNo ratings yet

- Sma Pwcmod 10 Installation GuideDocument40 pagesSma Pwcmod 10 Installation GuideMohamed MourtagaNo ratings yet

- Vocia VA-8600 and VA-8600c Manual (Jan12)Document17 pagesVocia VA-8600 and VA-8600c Manual (Jan12)Ronaldo RomeroNo ratings yet

- InstructionsDocument146 pagesInstructionsCarlitos CastilloNo ratings yet

- EQP 8 Channel Analog Input Module InstructionsDocument143 pagesEQP 8 Channel Analog Input Module InstructionsJosë RodríguezNo ratings yet

- Im01c20c01-01en (9) - Ej210, Ej220Document73 pagesIm01c20c01-01en (9) - Ej210, Ej220Nguyen ThuongNo ratings yet

- Rosemount 848T Wireless Temperature Transmitter: Reference ManualDocument60 pagesRosemount 848T Wireless Temperature Transmitter: Reference ManualAxel Morales BNo ratings yet

- Dpharp Vigilantplant Eja310aDocument76 pagesDpharp Vigilantplant Eja310aOscarNo ratings yet

- M2600 ManaulDocument32 pagesM2600 ManaulSujith Panikkadan unnikrishnanNo ratings yet

- CMMT-AS-C2 3 5 7 12-11A-P3 - Manual 2021-04d 8153788g1Document130 pagesCMMT-AS-C2 3 5 7 12-11A-P3 - Manual 2021-04d 8153788g1Poom YoosornNo ratings yet

- Load Cell C16ADocument88 pagesLoad Cell C16AShigilNo ratings yet

- Installation Manual SMA STP 3.0 3AV 40Document100 pagesInstallation Manual SMA STP 3.0 3AV 40costelchelariuNo ratings yet

- KBRG 212d Thruhole ManualDocument17 pagesKBRG 212d Thruhole ManualJulio FerminNo ratings yet

- STP60 JP 10 IA en 12Document40 pagesSTP60 JP 10 IA en 12Bilal AsgharNo ratings yet

- BB 800 800X 800CA Duo Pro Air Pak TMDocument144 pagesBB 800 800X 800CA Duo Pro Air Pak TMAmbed ChanelNo ratings yet

- Engh Mastervolt Manu Combimaster SeriesDocument32 pagesEngh Mastervolt Manu Combimaster SeriesBeltazor HellboyNo ratings yet

- HOBART AIRFORCE 375 t2210b - HobDocument72 pagesHOBART AIRFORCE 375 t2210b - HobRoberto MoctezumaNo ratings yet

- Assembly Instructions ECblue Basic Version ULDocument45 pagesAssembly Instructions ECblue Basic Version ULMatei DanNo ratings yet

- STP8 10 3AV 40 BE en 10Document98 pagesSTP8 10 3AV 40 BE en 10Tiên Lê Trần MỹNo ratings yet

- MTD VR10 23 GVT-121495-001-07Document55 pagesMTD VR10 23 GVT-121495-001-07leigh.hamiltonNo ratings yet

- Infineon TC39x DataSheet v01 00 enDocument542 pagesInfineon TC39x DataSheet v01 00 enramya rajaramanNo ratings yet

- Assemly Instruction - ECblue - Motor Size - B - IP20 - 2014-09-08 - INT - enDocument39 pagesAssemly Instruction - ECblue - Motor Size - B - IP20 - 2014-09-08 - INT - enbzivkovicNo ratings yet

- Installation Manual: 9900 Series Models 9900, 9900A and 9900BDocument68 pagesInstallation Manual: 9900 Series Models 9900, 9900A and 9900BRandy SharpNo ratings yet

- WB2500 User ManualDocument84 pagesWB2500 User Manualaurel_c12-1No ratings yet

- Exsite Series Explosionproof Power Module: InstallationDocument16 pagesExsite Series Explosionproof Power Module: InstallationMohammed ElsayedNo ratings yet

- Im01c20h01-01en (9) Ej118Document70 pagesIm01c20h01-01en (9) Ej118Nguyen ThuongNo ratings yet

- Im01c20d01-01en (9) - Ej310, Ej430, Ej440Document79 pagesIm01c20d01-01en (9) - Ej310, Ej430, Ej440Nguyen ThuongNo ratings yet

- Inverter - EMC Basic Information - v1-3 - ENDocument26 pagesInverter - EMC Basic Information - v1-3 - ENILHNo ratings yet

- Auto-Axcess300 (LC499793)Document116 pagesAuto-Axcess300 (LC499793)José Carlos de Alencar DiasNo ratings yet

- Im01c22b01-01en (17) - Eja110, Eja120Document87 pagesIm01c22b01-01en (17) - Eja110, Eja120Nguyen ThuongNo ratings yet

- SUNNY BOY 1.5 / 2.5: Operating ManualDocument94 pagesSUNNY BOY 1.5 / 2.5: Operating ManualfidelNo ratings yet

- UPS 160 kVA EATONDocument226 pagesUPS 160 kVA EATONivan morelNo ratings yet

- JenCo - Electrical Systems O&MsDocument113 pagesJenCo - Electrical Systems O&MsNadia EspinozaNo ratings yet

- 95 8533 21.5 (Eqp) PDFDocument146 pages95 8533 21.5 (Eqp) PDFraulNo ratings yet

- MPC 3024 AceDocument39 pagesMPC 3024 Acezvh48588No ratings yet

- sc9000 PDFDocument128 pagessc9000 PDFmrepol02665No ratings yet

- RES 9242GC - V1.0 Note Manual 20160501 PDFDocument180 pagesRES 9242GC - V1.0 Note Manual 20160501 PDFpauloNo ratings yet

- Y JJ 1440056887Document20 pagesY JJ 1440056887Hồ ThànhNo ratings yet

- FP 31Document5 pagesFP 31Hồ ThànhNo ratings yet

- Sadara-Hvac Piping SchematicDocument1 pageSadara-Hvac Piping SchematicHồ ThànhNo ratings yet

- Thiet Bi Trung The Medium Voltage Products 0416 IntDocument33 pagesThiet Bi Trung The Medium Voltage Products 0416 IntHồ ThànhNo ratings yet

- Application: Heat-Shrinkable Three Core Xlpe Straight Joint Up To 36 KVDocument2 pagesApplication: Heat-Shrinkable Three Core Xlpe Straight Joint Up To 36 KVHồ ThànhNo ratings yet

- MV and LV Overhead Connectors 2017Document57 pagesMV and LV Overhead Connectors 2017Hồ ThànhNo ratings yet

- Dervasil Route de Popenot - 42800 Saint Joseph - France Tel: +33 (0) 4 77 83 22 81 - Fax: +33 (0) 4 77 83 22 80Document48 pagesDervasil Route de Popenot - 42800 Saint Joseph - France Tel: +33 (0) 4 77 83 22 81 - Fax: +33 (0) 4 77 83 22 80Hồ ThànhNo ratings yet

- Chong Set Trung The Surge Arrester CS-63RSADocument3 pagesChong Set Trung The Surge Arrester CS-63RSAHồ ThànhNo ratings yet

- Small-Area Orthogonal Drawings of 3-Connected Graphs: Therese Biedl Jens M. SchmidtDocument13 pagesSmall-Area Orthogonal Drawings of 3-Connected Graphs: Therese Biedl Jens M. SchmidtHồ ThànhNo ratings yet

- Slope 5.00 % L 4m: AHU Machine Room Hall, Salons, Game Room, Sports AreaDocument1 pageSlope 5.00 % L 4m: AHU Machine Room Hall, Salons, Game Room, Sports AreaHồ ThànhNo ratings yet

- Plan A: Doghmosh Lot38Document3 pagesPlan A: Doghmosh Lot38Hồ ThànhNo ratings yet

- Geberit New Sovent High Power 1474952245Document4 pagesGeberit New Sovent High Power 1474952245Hồ ThànhNo ratings yet

- SECTION 10 44 13 Fire Extinguisher Cabinets Spec Writer NoteDocument2 pagesSECTION 10 44 13 Fire Extinguisher Cabinets Spec Writer NoteHồ ThànhNo ratings yet

- BMS Wiring Diagram - Using RS-485 OnlyDocument1 pageBMS Wiring Diagram - Using RS-485 OnlyHồ ThànhNo ratings yet

- 02geberit Conventional Roof Drainage Systems 1474965625Document3 pages02geberit Conventional Roof Drainage Systems 1474965625Hồ ThànhNo ratings yet

- IJM009 - Jet - Engine Test Flight ManualDocument16 pagesIJM009 - Jet - Engine Test Flight ManualHồ ThànhNo ratings yet

- LC Doc Lms DWG TTR02Document6 pagesLC Doc Lms DWG TTR02Hồ ThànhNo ratings yet

- 5 Ways Your Move To Bim Pays OffDocument10 pages5 Ways Your Move To Bim Pays OffHồ ThànhNo ratings yet

- Ijm006a - Technical Manual Fuel - Tank Software Add-OnDocument22 pagesIjm006a - Technical Manual Fuel - Tank Software Add-OnHồ ThànhNo ratings yet

- QD 5270 Sua Doi Bo Sung Quy Dinh Dich Vu Chuyen Tien Qua He Thong Western Union Ma So QD DV 019 Ngay 31-8-2012Document9 pagesQD 5270 Sua Doi Bo Sung Quy Dinh Dich Vu Chuyen Tien Qua He Thong Western Union Ma So QD DV 019 Ngay 31-8-2012Hồ ThànhNo ratings yet

- Content: 1 Install The SoftDocument34 pagesContent: 1 Install The SoftAkhtar KhanNo ratings yet

- Introduction To Electrical and Computer Engineering Lab ManualDocument124 pagesIntroduction To Electrical and Computer Engineering Lab Manualkstu1112No ratings yet

- Fundamentals in Cavity PreprationDocument42 pagesFundamentals in Cavity PreprationNamrataNo ratings yet

- (New) Adjustable Voltage Power Supply 55 V - 20A High Power and Current - Automatic Fan On - OffDocument1 page(New) Adjustable Voltage Power Supply 55 V - 20A High Power and Current - Automatic Fan On - OffSek PyroNo ratings yet

- Audi A4 B8 Replace SubwooferDocument14 pagesAudi A4 B8 Replace SubwooferŽeljko MatićNo ratings yet

- UTP OTC PRICE Cust Cross Reference Records AccessDocument7 pagesUTP OTC PRICE Cust Cross Reference Records AccessvenkchNo ratings yet

- Automatic Sectionalizing Link: Life Cycle Cost - Cooper Bussmann vs. CompetitorDocument2 pagesAutomatic Sectionalizing Link: Life Cycle Cost - Cooper Bussmann vs. CompetitorNguyen Anh TuNo ratings yet

- Samsung SGH-F480i User ManualDocument82 pagesSamsung SGH-F480i User ManualClement DzinyembaNo ratings yet

- Autocad Mechanical EssentialsDocument3 pagesAutocad Mechanical EssentialsJigar Patel's100% (1)

- Calibration Procedure For An Inertial Measurement Unit Using A 6-Degree-of-Freedom HexapodDocument6 pagesCalibration Procedure For An Inertial Measurement Unit Using A 6-Degree-of-Freedom HexapodfitomenaNo ratings yet

- Lincoln-Electric Welding Inverter PC620&PC1030Document72 pagesLincoln-Electric Welding Inverter PC620&PC1030andtibNo ratings yet

- Amaia Trece - CheckListDocument32 pagesAmaia Trece - CheckListDick Anthony MabaoNo ratings yet

- Chapter 27 - AnswerDocument21 pagesChapter 27 - AnswerAnonymous CuUAaRSNNo ratings yet

- Crete Islands - Twin House BrochureDocument10 pagesCrete Islands - Twin House Brochuremostafa mohamedNo ratings yet

- 4 Cooling Load CalculationDocument11 pages4 Cooling Load Calculationfate7997No ratings yet

- City of Dallas PDFDocument526 pagesCity of Dallas PDFrafaelberaldiNo ratings yet

- Loss in Pipe and Fitting SystemDocument17 pagesLoss in Pipe and Fitting SystemGulshan Raza KhanNo ratings yet

- Cantilever Beam Design - AngleDocument1 pageCantilever Beam Design - Angleberylqz5878No ratings yet

- Rectangular Break Line: 1. Purpose and DescriptionDocument5 pagesRectangular Break Line: 1. Purpose and DescriptionNico InfanteNo ratings yet

- CT Series Step Motors: CTM Maximum Series CTP Performance SeriesDocument20 pagesCT Series Step Motors: CTM Maximum Series CTP Performance SeriesWagner GarciaNo ratings yet

- OpenVox G410E On Elastix Guide ManualDocument18 pagesOpenVox G410E On Elastix Guide ManualMarco CarvalhoNo ratings yet

- Sugar Crane Harvester BrosureDocument20 pagesSugar Crane Harvester BrosurenightfurryifyNo ratings yet

- A Review Paper On Technical Data of Present HVDC Links in IndiaDocument7 pagesA Review Paper On Technical Data of Present HVDC Links in IndiaEditor IJRITCCNo ratings yet

- Fingerprint Based Voting ProjectDocument2 pagesFingerprint Based Voting ProjectNajmuddin KapadiaNo ratings yet

- How To Hack The Website Site Kaskus - Us Indonesia Reaver Attack United StatesDocument12 pagesHow To Hack The Website Site Kaskus - Us Indonesia Reaver Attack United Statesedurawa100% (1)

- A General Solution For The Stress Around Internally Pressurized Circular Hole in Symmetric LaminatesDocument5 pagesA General Solution For The Stress Around Internally Pressurized Circular Hole in Symmetric LaminatesIoan-Lucian StanNo ratings yet

- Aerated Concrete Production Using Various Raw MaterialsDocument5 pagesAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- HP Petrochemical Process Handbook 2014 Comprimido PDFDocument233 pagesHP Petrochemical Process Handbook 2014 Comprimido PDFAndy VargasNo ratings yet

- Ilnas-En 12390-1:2021Document8 pagesIlnas-En 12390-1:2021HaniAminNo ratings yet

- Containership NTUA 2005Document79 pagesContainership NTUA 2005금동민No ratings yet

Tram Kios TCS ZA IA en 10

Tram Kios TCS ZA IA en 10

Uploaded by

Hồ ThànhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tram Kios TCS ZA IA en 10

Tram Kios TCS ZA IA en 10

Uploaded by

Hồ ThànhCopyright:

Available Formats

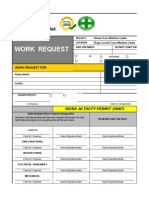

Installation Manual

TRANSFORMER COMPACT STATION 500SC-ZA/

630SC-ZA/800SC-ZA/900SC-ZA/1000SC-ZA/

1250SC-ZA/1600SC-ZA/1800SC-ZA

TCS-ZA-IA-en-10 | 98-40431110 | Version 1.0 ENGLISH

Legal Provisions SMA Solar Technology AG

Legal Provisions

The information contained in this document is the property of SMA Solar Technology AG. Publishing its content, either partially or

in full, requires the written permission of SMA Solar Technology AG. Any internal company copying of the document for the

purposes of evaluating the product or its correct implementation is allowed and does not require permission.

SMA Warranty

You can download the current warranty conditions from the Internet at www.SMA-Solar.com.

Trademarks

All trademarks are recognized even if these are not marked separately. Missing designations do not mean that a product or brand

is not a registered trademark.

The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and any use of such marks by

SMA Solar Technology AG is under licence.

QR Code® is a registered trademark of DENSO WAVE INCORPORATED.

SMA Solar Technology AG

Sonnenallee 1

34266 Niestetal

Germany

Tel. +49 561 9522-0

Fax +49 561 9522-100

www.SMA.de

E-mail: info@SMA.de

© 2004 to 2013 SMA Solar Technology AG. All rights reserved

2 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG Table of Contents

Table of Contents

1 Information on this Document. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Skills of Qualified Persons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Plant Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Transformer Compact Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Type Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Scope of Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Transport and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7 Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 Set up Electrical Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.2 Laying cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.2.1 Laying Cables between the Low-Voltage Switchgear and the

Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.2.2 Inserting the Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.3 Grounding of the Transformer Compact Station . . . . . . . . . . . . . . . . 20

7.3.1 Connection Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.3.2 Connecting the Grounding Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.4 Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.4.1 Connection area for the station sub-distribution board . . . . . . . . . . 22

7.4.2 Connecting Cables for Inverter's Internal Power Supply . . . . . . . . . 23

7.4.3 Connecting the Grounding Conductor. . . . . . . . . . . . . . . . . . . . . . . 23

7.4.4 Connecting Inverter to Output Terminal of Transformer Protection

Unit in Station Sub-Distribution Board . . . . . . . . . . . . . . . . . . . . . . . 24

7.4.5 Connecting the Internal Power Supply Cable for the

Transformer Compact Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.5 Set Voltage on Internal Power Supply Transformer . . . . . . . . . . . . . . 25

Installation Manual TCS-ZA-IA-en-10 3

Table of Contents SMA Solar Technology AG

8 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.1 Safety during Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.2 Commissioning the Transformer Compact Station . . . . . . . . . . . . . . . 27

8.3 Inspecting Cabling to the Transformer Compact Station . . . . . . . . . . 28

8.4 Examining Low AC Voltage in Low-Voltage Switchgear . . . . . . . . . . 29

8.5 Connecting the Internal Power Supply for the

Transformer Compact Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.6 Connecting the Internal Power Supply for the Inverter . . . . . . . . . . . 29

9 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.1 Transformer Compact Station 500SC . . . . . . . . . . . . . . . . . . . . . . . . 30

9.2 Transformer Compact Station 630SC . . . . . . . . . . . . . . . . . . . . . . . . 31

9.3 Transformer Compact Station 800SC . . . . . . . . . . . . . . . . . . . . . . . . 32

9.4 Transformer Compact Station 900SC . . . . . . . . . . . . . . . . . . . . . . . . 33

9.5 Transformer Compact Station 1000SC . . . . . . . . . . . . . . . . . . . . . . . 34

9.6 Transformer Compact Station 1250SC . . . . . . . . . . . . . . . . . . . . . . . 35

9.7 Transformer Compact Station 1600SC . . . . . . . . . . . . . . . . . . . . . . . 36

9.8 Transformer Compact Station 1800SC . . . . . . . . . . . . . . . . . . . . . . . 37

10 Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 1 Information on this Document

1 Information on this Document

Validity

This document is valid for the following device types:

• Transformer Compact Station 500SC‑ZA

• Transformer Compact Station 630SC‑ZA

• Transformer Compact Station 800SC‑ZA

• Transformer Compact Station 900SC‑ZA

• Transformer Compact Station 1000SC‑ZA

• Transformer Compact Station 1250SC‑ZA

• Transformer Compact Station 1600SC‑ZA

• Transformer Compact Station 1800SC‑ZA

Target Group

This document is intended for qualified persons. Only persons with the appropriate skills are allowed

to perform the tasks described in this document (see Section 2.2 "Skills of Qualified Persons", page 7).

Additional Information

Links to additional information can be found at www.SMA-Solar.com.

Title Document type

Installation Requirements for the Various Station Concepts of the Technical Information

Transformer Compact Stations 500SC/630SC/800SC/900SC/

1000SC/1250SC/1600SC/1800SC

Installation Manual TCS-ZA-IA-en-10 5

1 Information on this Document SMA Solar Technology AG

Symbols

Symbol Explanation

%"/(&3 Indicates a hazardous situation which, if not avoided, will result in death or

serious injury

8"3/*/( Indicates a hazardous situation which, if not avoided, can result in death or

serious injury

$"65*0/ Indicates a hazardous situation which, if not avoided, can result in minor or

moderate injury

/05*$& Indicates a situation which, if not avoided, can result in property damage

Information that is important for a specific topic or goal, but is not

safety-relevant

☐ Indicates a requirement for meeting a specific goal

☑ Desired result

✖ A problem that could occur

Nomenclature

Complete designation Designation in this document

Transformer Compact Stations 500SC-ZA/630SC-ZA/ Transformer Compact Station

800SC-ZA/900SC-ZA/1000SC-ZA/1250SC-ZA/

1600SC-ZA/1800SC-ZA

Sunny Central CP XT Sunny Central or inverter

Abbreviations

Abbreviations Designation Explanation

AC Alternating Current ‒

DC Direct Current ‒

MSL Mean Sea Level ‒

PE Protective Earth Protective conductor

PV Photovoltaics ‒

6 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 2 Safety

2 Safety

2.1 Intended Use

The Transformer Compact Station is a transformer unit that converts low voltage into medium voltage.

Depending on the option ordered, the Transformer Compact Station contains one or two low-voltage

switchgears plus a medium-voltage switchgear.

Only CP XT inverters of the same power class must be connected to the Transformer Compact Station.

The Transformer Compact Station is suitable for outdoor installation provided that the specified safety

clearances are maintained. The Station complies with degree of protection IP43.

For safety reasons, it is not permitted to modify the product or install components that are not explicitly

recommended or distributed by SMA Solar Technology AG for this product.

Use this product only in accordance with the enclosed documentation and with the local standards

and directives. Any other application may cause personal injury or property damage.

The enclosed documentation is an integral part of this product.

• Read and observe the documentation.

• Keep the documentation in a convenient place for future reference.

2.2 Skills of Qualified Persons

The tasks described in this document must be performed by qualified persons only. Qualified persons

must have the following skills:

• Knowledge of how inverters work and are operated

• Training in how to deal with the dangers and risks associated with installing and using electrical

devices and plants

• Training in the installation and commissioning of electrical devices and plants

• Knowledge of all applicable standards and directives

• Knowledge of and adherence to this document and all safety precautions

2.3 Safety Precautions

This section contains safety precautions that must be observed at all times when working on or with

the product. To prevent personal injury or property damage and to ensure long-term operation of the

product, read this section carefully and follow all safety precautions at all times.

Installation Manual TCS-ZA-IA-en-10 7

2 Safety SMA Solar Technology AG

%"/(&3

Danger to life from electric shock due to live voltage

High voltages are present in the Transformer Compact Station. Touching live components results in

death or serious injury due to electric shock.

• When working on the Transformer Compact Station, always wear suitable personal protective

equipment.

• Do not touch live components.

• Follow the instructions precisely.

• Observe all safety messages on the product and in the documentation.

• Before any work is performed, always disconnect the following components from voltage

sources if live voltage is not absolutely necessary:

– Low-voltage switchgear

– Medium-voltage switchgear

– External voltage supply

• Ensure that no disconnected components can be reconnected.

• Before performing any work on the Transformer Compact Station, ensure that no voltage is

present in any of the components.

• Ground and short-circuit the Transformer Compact Station.

• Cover or shield any adjacent live components.

Danger to life from electric shock if the Transformer Compact Station is damaged

Operating a damaged Transformer Compact Station can lead to hazardous situations that result in

death or serious injuries due to electric shock.

• Operate the Transformer Compact Station only if it is technically safe and in good working

order.

• Regularly check the Transformer Compact Station for visible damage.

• Make sure that all external safety equipment is freely accessible at all times.

• Make sure that all safety equipment is in good working order.

• When working on the Transformer Compact Station, always wear suitable personal protective

equipment.

8 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 2 Safety

$"65*0/

Risk of burns due to hot components

Some components of the Transformer Compact Station can get very hot during operation.

Touching these components can result in burn injuries.

• Observe the safety warnings on the components.

• Use suitable tools when working on the device.

• Wear gloves when working on the Transformer Compact Station.

Installation Manual TCS-ZA-IA-en-10 9

3 Product Description SMA Solar Technology AG

3 Product Description

3.1 Plant Overview

The Transformer Compact Station is a transformer unit that converts low voltage into medium voltage.

Depending on the option ordered, the Transformer Compact Station contains one or two low-voltage

switchgears plus a medium-voltage switchgear.

Figure 1: Principle of a grid-tie PV plant with a Transformer Compact Station

Item Description

A PV modules

B Sunny String-Monitor

C Sunny Central

D Transformer Compact Station

E Utility grid

CP XT inverters in the same power class are connected to the Transformer Compact Station. Inverters

convert direct current to alternating current. The alternating current is then supplied to the transformer.

The alternating current is transmitted from the transformer to the switchgear and fed into the utility grid.

10 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 3 Product Description

3.2 Transformer Compact Station

Figure 2: Design of the Transformer Compact Station

Item Description Explanation

A Communit communication distributor* Is used to hold and cable all

communication components used in large

PV plants with Sunny Central,

Sunny Mini Central, or Sunny Tripower

inverters.

B Station sub-distribution

C Transformer for auxiliary power supply* Supplies power to the Transformer

Compact Station and the inverter. The

supply voltage is 230 V/400 V (3/N/PE).

D Installation location for customer devices

E Disconnector for internal power supply

transformer*

F Low-voltage switchgear Connects the Transformer Compact Station

to the inverters. The low-voltage switchgear

can be used to disconnect the Transformer

Compact Station from the inverters.

Installation Manual TCS-ZA-IA-en-10 11

3 Product Description SMA Solar Technology AG

Item Description Explanation

G Medium-voltage switchgear* The medium-voltage switchgear is used to

disconnect the Transformer Compact

Station from the medium-voltage grid.

H Medium-voltage transformer Converts low voltages into medium

voltages.

* Optional

3.3 Type Label

The type label is used to identify the Transformer Compact Station. The type labels are attached to

the outside of the Transformer Compact Station, below the SMA labels. The following information is

listed on the type label:

• Type designation

• Serial number (Serial No.)

• Fabrication version

• Fabrication date

12 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 4 Scope of Delivery

4 Scope of Delivery

Check the scope of delivery for completeness and any visible external damage.

Contact SMA Solar Technology AG if the delivery is incomplete or damaged.

Figure 3: Scope of Delivery

Item Number Description

A 1 Transformer Compact Station

B 3/6* Busbar for the low-voltage switchgear**

C 18/36* Screw**

D 18/36* Nut**

E 18/36* Washer**

F 18/36* Spring lock washer**

G 12/24* ÖLFLEX® TRAFO cables***

H 1 Operating lever

I 1 Installation manual, circuit diagram, documentation

* Depending on whether one or two inverters are used

** Mounted by SMA Service after transportation

*** Optional

Installation Manual TCS-ZA-IA-en-10 13

5 Mounting Location SMA Solar Technology AG

5 Mounting Location

Ambient Conditions

• The mounting location must be accessible at all times.

• The mounting location must not be higher than 1,800 m above MSL.

• All minimum clearances must be observed.

• A safety clearance of 5,000 mm must be maintained from flammable objects.

• All ambient conditions must be met (see Section 9 "Technical Data", page 30).

Dimensions of the Transformer Compact Station

Figure 4: Dimensions of the Transformer Compact Station

Minimum Clearances

8"3/*/(

Fire hazard due to overheating of a cable

Differing cable lengths lead to overheating of the cables. Excessive heat can result in cable fires.

Death and serious injury due to fire can result.

• All line conductors from the inverter to the Transformer Compact Station must be of the same

length.

• The cable length between the connection points must not exceed a maximum of 15 m.

14 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 5 Mounting Location

Figure 5: Minimum clearances for the Transformer Compact Station

Item Description

A Inverter

B Cable route between the inverter and the Transformer Compact Station

C Transformer Compact Station

Installation Manual TCS-ZA-IA-en-10 15

6 Transport and Mounting SMA Solar Technology AG

6 Transport and Mounting

8"3/*/(

Crush hazard due to the Transformer Compact Station tipping over if not transported

properly

The Transformer Compact Station may tip or fall as a result of being lifted or transported carelessly

or too fast. The center of gravity of the Transformer Compact Station is not in the middle of the

device.

• The means of transportation must be designed for a weight of 13 t.

• Do not tip the Transformer Compact Station during transportation.

• Transport the Transformer Compact Station as low to the ground as possible.

• Always use all lifting holes when transporting the device.

• Avoid sudden, jerky movements during transportation.

/05*$&

Damage to the Transformer Compact Station due to moisture penetration

• Only transport and store the Transformer Compact Station with its doors closed.

Figure 6: Lifting holes for lifting equipment on the front and back

Item Description

A Anchoring points for lifting equipment

Requirement:

☐ The foundation of the Transformer Compact Station has to be built.

16 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 6 Transport and Mounting

Procedure:

1. Attach the lifting equipment to the anchoring points.

– Guide the bars of the lifting equipment through

the holes for the lifting equipment.

– Attach the struts of the lifting equipment to the

bars.

– Insert spacer bars between the struts above the

Transformer Compact Station.

– Insert spacer bars between the struts on the

sides the Transformer Compact Station.

– Use the shackles to hang metal chains through

the corresponding holes on the upper ends of

the lifting equipment.

– Hang all four metal chains in the crane hook.

2. Slowly raise the lifting equipment until the chains are taut.

3. Slowly lift the Transformer Compact Station.

4. Transport the Transformer Compact Station.

5. Set down the Transformer Compact Station in the

center of the foundation. Observe the foundation

boundaries.

6. Remove the lifting equipment from the anchoring points.

7. Attach the Transformer Compact Station to the foundation using screws.

Installation Manual TCS-ZA-IA-en-10 17

7 Electrical Connection SMA Solar Technology AG

7 Electrical Connection

7.1 Establishing Electrical Connection

Procedure See

1 Lay the cable from the low-voltage switchgear to the Section 7.2.1

inverter.

2 Lay the cable for the inverter power supply and for

the connection to the transformer protection unit.

3 Insert the cables. Section 7.2.2

4 Ground the Transformer Compact Station. Section 7.3

5 Connect the cable for the internal power supply to Section 7.4.2

the inverter.

6 Connect the grounding conductor. Section 7.4.3

7 Connect the inverter to the output terminal of the Section 7.4.4

transformer protection unit in the station

sub-distribution board.

8 Connect the internal power supply cable to the Section 7.4.5

Transformer Compact Station.

9 Connect the cable for the low-voltage switchgear. Documentation for the low-voltage

switchgear

10 Connect the cable for the medium-voltage Documentation for the

switchgear. medium-voltage switchgear

11 Close the cable entries. Documentation for the cable entries

7.2 Laying the Cables

7.2.1 Laying the Cables between the Low-Voltage Switchgear and

the Inverter

☐ The AC cables are three-phase cables.

☐ Between the low-voltage switchgear and the inverter there are four separate cable routes for

the AC cables, e. g. cable channels. After building the foundation and positioning the

Transformer Compact Station, you have to consider that holes have to be dug underneath the

foundation for the cables to be laid to the cable entries.

☐ The spacing between the cable routes must be at least twice the diameter of an AC cable.

18 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 7 Electrical Connection

Figure 7: Arrangement of AC cables with four cables per line conductor (example).

Observe cable clearances

Lay one L1, L2 and L3 line conductor in each cable route. Ensure that the distance between the

cable bundles is at least double that of the diameter of a cable. This prevents the cables from

heating up excessively.

Swapping the line conductors L1 and L3 prevents current imbalances.

Procedure:

• Lay the cables in accordance with the required configuration.

7.2.2 Inserting the Cables

Figure 8: Position of cable entries

Item Description

A Enclosure openings for the low-voltage switchgear

B Cable entries for cables for the following devices or components:

• Internal power supply for the inverter

• Communit

• Transformer protection

• If power is supplied by an external source: internal power supply for the

Transformer Compact Station

C Cable entries for the medium-voltage switchgear

Installation Manual TCS-ZA-IA-en-10 19

7 Electrical Connection SMA Solar Technology AG

Procedure:

• Lay the cables into the Transformer Compact Station

– The cables that connect the medium-voltage switchgear to the point of common connection

– The cables that connect the low-voltage switchgear to the inverters

– The cables for the internal power supply of the inverter

– The cables for the transformer protection unit

– If power is supplied by an external source: the cable for the internal power supply of the

Transformer Compact Station

7.3 Grounding of the Transformer Compact Station

7.3.1 Connection Overview

The Transformer Compact Station is equipped at two points with grounding bolts which enable

external grounding. The stainless steel grounding plates are each connected by a cable to the

grounding busbar in the Transformer Compact Station.

The external grounding must be executed by the customer on-site according to the grounding concept

of the entire PV plant. Influencing factors are the conditions or conductivity of the soil, the lightning

protection system and the type of ground electrode. The grounding devices can, for instance, be

executed as grounding straps or grounding electrodes.

Figure 9: Grounding points of the Transformer Compact Station

Item Description

A Grounding bolt

20 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 7 Electrical Connection

Figure 10: Screw connection for the grounding bolts

Item Description

A Spring washer

B Fender washer

C Nut

D Grounding bolt

E Terminal lug

F Transformer Compact Station

7.3.2 Connecting the Grounding Bolts

Requirements:

☐ Any required supplementary mounting material must be available.

Additionally required mounting material (not included in the scope of delivery):

☐ Screws, M12

☐ Spring washers, external diameter: 29 mm, internal diameter: 13.5 mm, thickness: 1.25 mm

☐ Fender washers, external diameter: 32 mm, internal diameter: 13 mm

☐ Nuts

☐ Plant ground electrodes suitable for the grounding concept of the PV plant

☐ Clean cloth

☐ Ethanol cleaning agent

☐ Non-woven abrasive

☐ Suitable material for sealing the grounding pads (e.g. durable zinc paint)

Installation Manual TCS-ZA-IA-en-10 21

7 Electrical Connection SMA Solar Technology AG

Grounding of the Transformer Compact Station

Ground the Transformer Compact Station in accordance with the applicable regulations.

Two grounding connections are provided on the Transformer Compact Station.

SMA Solar Technology AG recommends connecting both grounding bolts to the grounding

electrode.

Procedure:

1. Install the plant ground electrode in accordance with the applicable regulations.

2. Ensure that the required grounding resistance is reached.

3. If insulated cables are used, strip the insulation off the grounding cables.

4. Fit the grounding cables with terminal lugs.

5. Clean the contact surfaces with a clean cloth and ethanol cleaning agent.

6. Clean the contact surfaces with the non-woven abrasive until they have a light metallic sheen.

Ensure that the coated contact surfaces are not damaged in the process.

7. Remove metal dust with a clean cloth and do not touch the contact surfaces.

8. Connect the grounding cables to the grounding bolts.

9. Connect the grounding cables to the grounding electrodes.

10. Seal the grounding bolts and terminals.

7.4 Cable Connection

7.4.1 Connection Area for the Station Sub-Distribution Board

Figure 11: Connection area for the station sub-distribution board

22 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 7 Electrical Connection

Item Description

A Terminals for internal power supply

B Terminals of the transformer protection unit for the Sunny Central

C Terminals for the Sunny Central

D Busbars for the grounding conductor

7.4.2 Connecting Cables for the Internal Power Supply of the

Inverter

1. Connect the the internal power supply of the inverter in accordance with the circuit diagram.

– Dismantle the cable.

– Strip the insulation off the wires.

– Connect the conductors.

2. If two inverters are used: connect the internal power supply for the second inverter in

accordance with the circuit diagram.

– Dismantle the cable.

– Strip the insulation off the wires.

– Connect the cables.

7.4.3 Connecting the Grounding Conductor

Additionally required mounting material (not included in the scope of delivery):

☐ Terminal lug

☐ Screw, spring washer, fender washer, nut

Procedure:

• Connect the grounding conductor in accordance with the circuit diagram:

– Strip the cable insulation.

– Attach a terminal lug to the cable.

– Connect the cable.

Installation Manual TCS-ZA-IA-en-10 23

7 Electrical Connection SMA Solar Technology AG

7.4.4 Connecting the Inverter to the Output Terminal of the

Transformer Protection Unit in the Station Sub-Distribution

Board

1. Connect the transformer protection unit of the inverter in accordance with the circuit diagram.

– Dismantle the cable.

– Strip insulation off the wires.

– Connect the conductors.

2. If two inverters are used, connect the transformer protection unit for the second inverter in

accordance with the circuit diagram.

– Dismantle the cable.

– Strip insulation off the wires.

– Connect the conductors.

7.4.5 Connecting the Internal Power Supply Cable for the

Transformer Compact Station

Depending on the options ordered, the Transformer Compact Station may contain an internal power

supply transformer. If it does not contain an internal power supply transformer, the power will have to

be supplied by an external source.

Procedure:

• Connect the internal power supply to the Transformer Compact Station in accordance with the

circuit diagram:

– Dismantle the cable.

– Strip insulation off the wires.

– Connect the conductors.

24 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 7 Electrical Connection

7.5 Setting the Voltage on Internal Power Supply Transformer

The input voltage and the output voltage of the transformer for auxiliary power supply must match the

output voltage of the inverters. To do this, adapt the primary and secondary sides of the internal

power supply transformer to the inverter.

Figure 12: Position of connecting terminal plates

Item Description

A Connecting terminal plate on the secondary side

B Connecting terminal plate on the primary side

Requirement:

☐ The busbars of the low-voltage switchgear have to be installed by SMA Service.

Procedure:

1. Set the input voltage on the primary side. This adjusts the output voltage to the inverter's input

voltage (see circuit diagram for the Transformer Compact Station).

2. Set the output voltage on the secondary side. This adjusts the output voltage to the inverter's

input voltage (see circuit diagram for the Transformer Compact Station).

Installation Manual TCS-ZA-IA-en-10 25

8 Commissioning SMA Solar Technology AG

8 Commissioning

8.1 Safety during Commissioning

%"/(&3

Danger to life from electric shock due to live voltages

High voltages are present in the Transformer Compact Station. Touching live components results in

death or serious injury due to electric shock.

• When working on the Transformer Compact Station, always wear suitable personal protective

equipment.

• Do not touch live components.

• Follow the instructions precisely.

• Observe all safety messages on the product and in the documentation.

• Before any work is performed, always disconnect the following components from voltage

sources if live voltage is not absolutely necessary:

– Low-voltage switchgear

– Medium-voltage switchgear

– External voltage supply

• Ensure that no disconnected components can be reconnected.

• Before performing any work on the Transformer Compact Station, ensure that no voltage is

present in any of the components.

• Ground and short-circuit the Transformer Compact Station.

• Cover or shield any adjacent live components.

8"3/*/(

Risk of fire due to faulty connection

• Switch off all switching elements:

– Switch off the low-voltage switchgear (see the documentation for the low-voltage

switchgear).

– Switch off the medium-voltage switchgear (see the documentation for the medium-voltage

switchgear).

– Remove the fuses.

– Open the circuit breaker.

– Open the residual current device.

26 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 8 Commissioning

8.2 Commissioning the Transformer Compact Station

Warranty and guarantee claims

Warranty or guarantee claims can only be made valid if the initial start-up was carried out by

SMA Solar Technology AG or if the fully completed and signed "Initial Commissioning Report

for Sunny Central Systems" is completed and available at SMA Solar Technology AG.

The commissioning report is included in the scope of delivery of the Sunny Central.

Figure 13: Overview of station sub-distribution board

Item Description Explanation

A Main circuit breaker Circuit breaker for the entire Transformer Compact Station

B Discharger Overvoltage protection

C Voltage supply for Communit Circuit breaker for the Communit communication distribution

box

D Network solution Network terminal for the customer

E Hermetical full protection Circuit breaker for the transformer protection unit

and stop

F Reserve Reserve circuit breaker

G Voltage supply power outlet Circuit breaker with integrated RCD for outlet with ground

contact

H Voltage supply lighting Circuit breaker for station lighting

I Voltage supply SC2 Circuit breaker for the second inverter

K Voltage supply SC1 Circuit breaker for the first inverter

Installation Manual TCS-ZA-IA-en-10 27

8 Commissioning SMA Solar Technology AG

Requirements

☐ The medium-voltage switchgear has to be switched off.

☐ The low-voltage switchgear has to be switched off.

☐ All terminals have to be connected as per the instructions and the circuit diagram (see Section 7

"Electrical Connection", page 18).

Procedure:

1. Inspect the cabling to the Transformer Compact Station (see Section 8.4).

2. Make sure the temperature settings on the contact thermometer are correct:

– Warning temperature: +100°C

– Actuation temperature: +110°C

3. Only a duly authorized person trained in electrical safety is allowed to connect

the AC voltage of the medium-voltage transformer.

Have the AC voltage of the medium-voltage transformer connected externally.

4. Only a duly authorized person is allowed to switch on the medium-voltage

switchgear.

Have the medium-voltage switchgear switched on (see the documentation for the

medium-voltage switchgear).

5. Check the low AC voltage in the low-voltage switchgear (see Section 8.4).

6. If you have an internal power supply transformer: connect the internal power supply for the

Transformer Compact Station (see Section 8.5).

7. Turn on the power supply to the Transformer Compact Station with the "main circuit breaker".

8. Turn on the station lighting with the "voltage supply lighting" circuit breaker.

9. Energize the grounded outlet with the "voltage supply power outlet" circuit breaker with the

integrated residual current device.

10. Turn on the Communit with the "voltage supply Communit" circuit breaker.

11. Turn on the low-voltage switchgear (see the documentation for the low-voltage switchgear).

12. Connect the internal power supply for the inverter (see section 8.6).

13. Commission the inverter (see the inverter documentation).

8.3 Inspecting the Cabling to the Transformer Compact Station

1. Ensure that all connections have been made in accordance with the circuit diagram.

2. Ensure that all connections are securely in place.

3. Check the Transformer Compact Station's equipotential bonding to the installation site.

Bond them together if needed.

28 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 8 Commissioning

8.4 Examining the Low AC Voltage in the Low-Voltage Switchgear

1. Check the phase sequence of the low voltage. Correct if necessary.

2. Measure the low voltage difference between the line conductors and log it in the commissioning

report.

– L1 - L2

– L1 - L3

– L2 - L3

☑ The low voltage is within ± 5 V of the nominal voltage of the inverter.

✖ Does the low voltage vary from the nominal voltage of the inverter by more than ± 5 V?

• De-energize the medium-voltage transformer.

• Have a duly authorized person change the turns ratio of the medium-voltage transformer

by adjusting the on-load tap-changer.

☑ The on-load tap-changer will audibly click into place.

• Proceed to step 2.

8.5 Connecting the Internal Power Supply for the Transformer

Compact Station

1. Open the fuse switch-disconnector.

2. Insert the fuses in the fuse-switch-disconnector.

3. Close the fuse-switch-disconnector.

8.6 Connecting the Internal Power Supply for the Inverter

1. Close the "Voltage supply SC 1" circuit breaker for

the first inverter.

2. If two inverters are used, additionally switch on

"Voltage supply SC 2"

Installation Manual TCS-ZA-IA-en-10 29

9 Technical Data SMA Solar Technology AG

9 Technical Data

9.1 Transformer Compact Station 500SC

Medium-Voltage Side

Rated power (at 25°C) PACnom 550 kVA

AC nominal power (at 40°C) PAC 500 kVA

Rated grid voltage VACnom 22 kV / 33 kV

AC voltage range VAC 20 kV to 24 kV / 30 kV to 36 kV

Rated power frequency fAC 50 Hz

Nominal current IMVnom 13.1 A/8.7 A

Low-Voltage Side

Nominal input voltage VAC 270 V

Nominal input current ILVnom 1,070 A

Mechanical Data

Width x height x depth (base) 4,000 mm x 2,720 mm x 2,000 mm

Width x height x depth (roof) 4,050 mm x 2,720 mm x 2,000 mm

Weight with medium-voltage switchgear 9.0 t

Weight without medium-voltage switchgear 8.7 t

Degree of protection* IP43

* As per SANS 60529

Climatic Conditions

Operating temperature range − 5°C to +40°C

Relative humidity, non-condensing 15% to 98%

Maximum operating altitude above mean sea 1,800 m

level (MSL)

Options

Transformer for auxiliary power supply* 6 kVA

Medium-voltage switchgear RE-T1 / RE-T2 / C-C-T1 / C-C-T2

Low-voltage switchgear 1 fuse-disconnector

Pre-assembled cable set 7.5 m / 10 m / 15 m

Communication distributor Communit

* Additional power classes available on request

30 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 9 Technical Data

9.2 Transformer Compact Station 630SC

Medium-Voltage Side

Rated power (at 25°C) PACnom 700 kVA

AC nominal power (at 40°C) PAC 630 kVA

Rated grid voltage VACnom 22 kV / 33 kV

AC voltage range VAC 20 kV to 24 kV / 30 kV to 36 kV

Rated power frequency fAC 50 Hz

Nominal current IMVnom 16.5 A/11.0 A

Low-Voltage Side

Nominal input voltage VAC 315 V

Nominal input current ILVnom 1,155 A

Mechanical Data

Width x height x depth (base) 4,000 mm x 2,720 mm x 2,000 mm

Width x height x depth (roof) 4,050 mm x 2,720 mm x 2,000 mm

Weight with medium-voltage switchgear 9.5 t

Weight without medium-voltage switchgear 9.2 t

Degree of protection* IP43

* As per SANS 60529

Climatic Conditions

Operating temperature range − 5°C to +40°C

Relative humidity, non-condensing 15% to 98%

Maximum operating altitude above mean sea 1,800 m

level (MSL)

Options

Transformer for auxiliary power supply* 6 kVA

Medium-voltage switchgear RE-T1 / RE-T2 / C-C-T1 / C-C-T2

Low-voltage switchgear 1 fuse-disconnector

Pre-assembled cable set 7.5 m / 10 m / 15 m

Communication distributor Communit

* Additional power classes available on request

Installation Manual TCS-ZA-IA-en-10 31

9 Technical Data SMA Solar Technology AG

9.3 Transformer Compact Station 800SC

Medium-Voltage Side

Rated power (at 25°C) PACnom 880 kVA

AC nominal power (at 40°C) PAC 800 kVA

Rated grid voltage VACnom 22 kV / 33 kV

AC voltage range VAC 20 kV to 24 kV / 30 kV to 36 kV

Rated power frequency fAC 50 Hz

Nominal current IMVnom 21.0 A/14.0 A

Low-Voltage Side

Nominal input voltage VAC 360 V

Nominal input current ILVnom 1,283 A

Mechanical Data

Width x height x depth (base) 4,000 mm x 2,720 mm x 2,000 mm

Width x height x depth (roof) 4,050 mm x 2,720 mm x 2,000 mm

Weight with medium-voltage switchgear 9.6 t

Weight without medium-voltage switchgear 9.3 t

Degree of protection* IP43

* As per SANS 60529

Climatic Conditions

Operating temperature range − 5°C to +40°C

Relative humidity, non-condensing 15% to 98%

Maximum operating altitude above mean sea 1,800 m

level (MSL)

Options

Transformer for auxiliary power supply* 6 kVA

Medium-voltage switchgear RE-T1 / RE-T2 / C-C-T1 / C-C-T2

Low-voltage switchgear 1 fuse-disconnector

Pre-assembled cable set 7.5 m / 10 m / 15 m

Communication distributor Communit

* Additional power classes available on request

32 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 9 Technical Data

9.4 Transformer Compact Station 900SC

Medium-Voltage Side

Rated power (at 25°C) PACnom 990 kVA

AC nominal power (at 40°C) PAC 900 kVA

Rated grid voltage VACnom 22 kV / 33 kV

AC voltage range VAC 20 kV to 24 kV / 30 kV to 36 kV

Rated power frequency fAC 50 Hz

Nominal current IMVnom 23.6 A/15.7 A

Low-Voltage Side

Nominal input voltage VAC 405 V

Nominal input current ILVnom 1,283 A

Mechanical Data

Width x height x depth (base) 4,000 mm x 2,720 mm x 2,000 mm

Width x height x depth (roof) 4,050 mm x 2,720 mm x 2,000 mm

Weight with medium-voltage switchgear 9.7 t

Weight without medium-voltage switchgear 9.4 t

Degree of protection* IP43

* As per SANS 60529

Climatic Conditions

Operating temperature range − 5°C to +40°C

Relative humidity, non-condensing 15% to 98%

Maximum operating altitude above mean sea 1,800 m

level (MSL)

Options

Transformer for auxiliary power supply* 6 kVA

Medium-voltage switchgear RE-T1 / RE-T2 / C-C-T1 / C-C-T2

Low-voltage switchgear 1 fuse-disconnector

Pre-assembled cable set 7.5 m / 10 m / 15 m

Communication distributor Communit

* Additional power classes available on request

Installation Manual TCS-ZA-IA-en-10 33

9 Technical Data SMA Solar Technology AG

9.5 Transformer Compact Station 1000SC

Medium-Voltage Side

Rated power (at 25°C) PACnom 1,100 kVA

AC nominal power (at 40°C) PAC 1,000 kVA

Rated grid voltage VACnom 22 kV / 33 kV

AC voltage range VAC 20 kV to 24 kV / 30 kV to 36 kV

Rated power frequency fAC 50 Hz

Nominal current IMVnom 26.2 A/17.5 A

Low-Voltage Side

Nominal input voltage VAC 270 V

Nominal input current ILVnom 2 x 1,070 A

Mechanical Data

Width x height x depth (base) 4,000 mm x 2,720 mm x 2,000 mm

Width x height x depth (roof) 4,050 mm x 2,720 mm x 2,000 mm

Weight with medium-voltage switchgear 10.6 t

Weight without medium-voltage switchgear 10.3 t

Degree of protection* IP43

* As per SANS 60529

Climatic Conditions

Operating temperature range − 5°C to +40°C

Relative humidity, non-condensing 15% to 98%

Maximum operating altitude above mean sea 1,800 m

level (MSL)

Options

Transformer for auxiliary power supply* 6 kVA

Medium-voltage switchgear RE-T1 / RE-T2 / C-C-T1 / C-C-T2

Low-voltage switchgear 2 fuse-disconnectors

Pre-assembled cable set 7.5 m / 10 m / 15 m

Communication distributor Communit

* Additional power classes available on request

34 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 9 Technical Data

9.6 Transformer Compact Station 1250SC

Medium-Voltage Side

Rated power (at 25°C) PACnom 1,375 kVA

AC nominal power (at 40°C) PAC 1,250 kVA

Rated grid voltage VACnom 22 kV / 33 kV

AC voltage range VAC 20 kV to 24 kV / 30 kV to 36 kV

Rated power frequency fAC 50 Hz

Nominal current IMVnom 33.1 A/22.0 A

Low-Voltage Side

Nominal input voltage VAC 315 V

Nominal input current ILVnom 2 x 1,155 A

Mechanical Data

Width x height x depth (base) 4,000 mm x 2,720 mm x 2,000 mm

Width x height x depth (roof) 4,050 mm x 2,720 mm x 2,000 mm

Weight with medium-voltage switchgear 11.1 t

Weight without medium-voltage switchgear 10.8 t

Degree of protection* IP43

* As per SANS 60529

Climatic Conditions

Operating temperature range − 5°C to +40°C

Relative humidity, non-condensing 15% to 98%

Maximum operating altitude above mean sea 1,800 m

level (MSL)

Options

Transformer for auxiliary power supply* 6 kVA

Medium-voltage switchgear RE-T1 / RE-T2 / C-C-T1 / C-C-T2

Low-voltage switchgear 2 fuse-disconnectors

Pre-assembled cable set 7.5 m / 10 m / 15 m

Communication distributor Communit

* Additional power classes available on request

Installation Manual TCS-ZA-IA-en-10 35

9 Technical Data SMA Solar Technology AG

9.7 Transformer Compact Station 1600SC

Medium-Voltage Side

Rated power (at 25°C) PACnom 1,760 kVA

AC nominal power (at 40°C) PAC 1,600 kVA

Rated grid voltage VACnom 22 kV / 33 kV

AC voltage range VAC 20 kV to 24 kV / 30 kV to 36 kV

Rated power frequency fAC 50 Hz

Nominal current IMVnom 42.0 A/28.0 A

Low-Voltage Side

Nominal input voltage VAC 360 V

Nominal input current ILVnom 2 x 1,283 A

Mechanical Data

Width x height x depth (base) 4,000 mm x 2,720 mm x 2,000 mm

Width x height x depth (roof) 4,050 mm x 2,720 mm x 2,000 mm

Weight with medium-voltage switchgear 12.0 t

Weight without medium-voltage switchgear 11.7 t

Degree of protection* IP43

* As per SANS 60529

Climatic Conditions

Operating temperature range − 5°C to +40°C

Relative humidity, non-condensing 15% to 98%

Maximum operating altitude above mean sea 1,800 m

level (MSL)

Options

Transformer for auxiliary power supply* 6 kVA

Medium-voltage switchgear RE-T1 / RE-T2 / C-C-T1 / C-C-T2

Low-voltage switchgear 2 fuse-disconnectors

Pre-assembled cable set 7.5 m / 10 m / 15 m

Communication distributor Communit

* Additional power classes available on request

36 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology AG 9 Technical Data

9.8 Transformer Compact Station 1800SC

Medium-Voltage Side

Rated power (at 25°C) PACnom 1,980 kVA

AC nominal power (at 40°C) PAC 1,800 kVA

Rated grid voltage VACnom 22 kV / 33 kV

AC voltage range VAC 20 kV to 24 kV / 30 kV to 36 kV

Rated power frequency fAC 50 Hz

Nominal current IMVnom 47.2 A/31.5 A

Low-Voltage Side

Nominal input voltage VAC 405 V

Nominal input current ILVnom 2 x 1,283 A

Mechanical Data

Width x height x depth (base) 4,000 mm x 2,720 mm x 2,000 mm

Width x height x depth (roof) 4,050 mm x 2,720 mm x 2,000 mm

Weight with medium-voltage switchgear 12.2 t

Weight without medium-voltage switchgear 11.9 t

Degree of protection* IP43

* As per SANS 60529

Climatic Conditions

Operating temperature range − 5°C to +40°C

Relative humidity, non-condensing 15% to 98%

Maximum operating altitude above mean sea 1,800 m

level (MSL)

Options

Transformer for auxiliary power supply* 6 kVA

Medium-voltage switchgear RE-T1 / RE-T2 / C-C-T1 / C-C-T2

Low-voltage switchgear 1 fuse-disconnector

Pre-assembled cable set 7.5 m / 10 m / 15 m

Communication distributor Communit

* Additional power classes available on request

Installation Manual TCS-ZA-IA-en-10 37

10 Contact SMA Solar Technology AG

10 Contact

If you have technical problems concerning our products, contact the SMA Service Line.

We need the following data in order to provide you with the necessary assistance:

• Serial number of the Transformer Compact Station

• Type designation of the Transformer Compact Station

• Installation site address

South Africa SMA Solar Technology 08600 SUNNY

South Africa Pty Ltd. (08600 78669)

Centurion (Pretoria) International: +27 (12) 643 1785

38 TCS-ZA-IA-en-10 Installation Manual

SMA Solar Technology

www.SMA-Solar.com

You might also like

- 230/460 and 460/575 Volt ModelsDocument104 pages230/460 and 460/575 Volt ModelsIan McNair100% (3)

- CAN and FPGA Communication Engineering: Implementation of a CAN Bus based Measurement System on an FPGA Development KitFrom EverandCAN and FPGA Communication Engineering: Implementation of a CAN Bus based Measurement System on an FPGA Development KitNo ratings yet

- BC138-139 User ManualDocument16 pagesBC138-139 User ManuallalociscoNo ratings yet

- Sma Sunny Tripower 15000tl 20000tl 25000tl Operating ManualDocument56 pagesSma Sunny Tripower 15000tl 20000tl 25000tl Operating ManualSadikNo ratings yet

- CAM-14 Acquisition Module: Field Service ManualDocument88 pagesCAM-14 Acquisition Module: Field Service ManualLászló BaloghNo ratings yet

- Berges Acm STDDocument64 pagesBerges Acm STDAdan Solano50% (4)

- SCS TA E1 en 11Document30 pagesSCS TA E1 en 11toky.zatovonirinaNo ratings yet

- Operating Manual: SUNNY TRIPOWER 20000TL / 25000TLDocument50 pagesOperating Manual: SUNNY TRIPOWER 20000TL / 25000TLakbar installNo ratings yet

- Auto Continuum PDFDocument164 pagesAuto Continuum PDFJosé Carlos de Alencar Dias100% (1)

- XMT 350 FieldPro ArcReachDocument92 pagesXMT 350 FieldPro ArcReachEsteban MartinezNo ratings yet

- Operating Manual SUNNY BOY 3000TL / 3600TL / 4000TL / 5000TLDocument68 pagesOperating Manual SUNNY BOY 3000TL / 3600TL / 4000TL / 5000TLDragos Virgil MosNo ratings yet

- Operating Manual: SUNNY TRIPOWER 20000TL / 25000TLDocument52 pagesOperating Manual: SUNNY TRIPOWER 20000TL / 25000TLprekNo ratings yet

- Sunny Boy 3000tl Us ManualDocument88 pagesSunny Boy 3000tl Us ManualAshraf CardiffNo ratings yet

- KBPC-225: Installation and Operating InstructionsDocument17 pagesKBPC-225: Installation and Operating InstructionsDiego MontanezNo ratings yet

- 215S-CP109 0 Weldmatic 215 SDocument21 pages215S-CP109 0 Weldmatic 215 SRogerNo ratings yet

- Operating Instruction ZETADYN 3BFDocument194 pagesOperating Instruction ZETADYN 3BFReaper68No ratings yet

- Sepam: Digital Protection Relays Installation Assistance GuideDocument80 pagesSepam: Digital Protection Relays Installation Assistance Guidealbert_f42No ratings yet

- Elite Manual de ServiçoDocument196 pagesElite Manual de ServiçoCarlos Flores100% (1)

- enDocument277 pagesenDannish R LailanNo ratings yet

- KBWM DC Drive Series ManualDocument9 pagesKBWM DC Drive Series ManualKBElectronicsincNo ratings yet

- PV Inverter: SUNNY MINI CENTRAL 9000TL / 10000TL / 11000TL With Reactive Power ControlDocument96 pagesPV Inverter: SUNNY MINI CENTRAL 9000TL / 10000TL / 11000TL With Reactive Power ControlIonut Robert BalasoiuNo ratings yet

- User Manual SMA Sunnyboy SB1100 SB1700Document66 pagesUser Manual SMA Sunnyboy SB1100 SB1700JonathonNo ratings yet

- Sma Pwcmod 10 Installation GuideDocument40 pagesSma Pwcmod 10 Installation GuideMohamed MourtagaNo ratings yet

- Vocia VA-8600 and VA-8600c Manual (Jan12)Document17 pagesVocia VA-8600 and VA-8600c Manual (Jan12)Ronaldo RomeroNo ratings yet

- InstructionsDocument146 pagesInstructionsCarlitos CastilloNo ratings yet

- EQP 8 Channel Analog Input Module InstructionsDocument143 pagesEQP 8 Channel Analog Input Module InstructionsJosë RodríguezNo ratings yet

- Im01c20c01-01en (9) - Ej210, Ej220Document73 pagesIm01c20c01-01en (9) - Ej210, Ej220Nguyen ThuongNo ratings yet

- Rosemount 848T Wireless Temperature Transmitter: Reference ManualDocument60 pagesRosemount 848T Wireless Temperature Transmitter: Reference ManualAxel Morales BNo ratings yet

- Dpharp Vigilantplant Eja310aDocument76 pagesDpharp Vigilantplant Eja310aOscarNo ratings yet

- M2600 ManaulDocument32 pagesM2600 ManaulSujith Panikkadan unnikrishnanNo ratings yet

- CMMT-AS-C2 3 5 7 12-11A-P3 - Manual 2021-04d 8153788g1Document130 pagesCMMT-AS-C2 3 5 7 12-11A-P3 - Manual 2021-04d 8153788g1Poom YoosornNo ratings yet

- Load Cell C16ADocument88 pagesLoad Cell C16AShigilNo ratings yet

- Installation Manual SMA STP 3.0 3AV 40Document100 pagesInstallation Manual SMA STP 3.0 3AV 40costelchelariuNo ratings yet

- KBRG 212d Thruhole ManualDocument17 pagesKBRG 212d Thruhole ManualJulio FerminNo ratings yet

- STP60 JP 10 IA en 12Document40 pagesSTP60 JP 10 IA en 12Bilal AsgharNo ratings yet

- BB 800 800X 800CA Duo Pro Air Pak TMDocument144 pagesBB 800 800X 800CA Duo Pro Air Pak TMAmbed ChanelNo ratings yet

- Engh Mastervolt Manu Combimaster SeriesDocument32 pagesEngh Mastervolt Manu Combimaster SeriesBeltazor HellboyNo ratings yet

- HOBART AIRFORCE 375 t2210b - HobDocument72 pagesHOBART AIRFORCE 375 t2210b - HobRoberto MoctezumaNo ratings yet

- Assembly Instructions ECblue Basic Version ULDocument45 pagesAssembly Instructions ECblue Basic Version ULMatei DanNo ratings yet

- STP8 10 3AV 40 BE en 10Document98 pagesSTP8 10 3AV 40 BE en 10Tiên Lê Trần MỹNo ratings yet

- MTD VR10 23 GVT-121495-001-07Document55 pagesMTD VR10 23 GVT-121495-001-07leigh.hamiltonNo ratings yet

- Infineon TC39x DataSheet v01 00 enDocument542 pagesInfineon TC39x DataSheet v01 00 enramya rajaramanNo ratings yet

- Assemly Instruction - ECblue - Motor Size - B - IP20 - 2014-09-08 - INT - enDocument39 pagesAssemly Instruction - ECblue - Motor Size - B - IP20 - 2014-09-08 - INT - enbzivkovicNo ratings yet

- Installation Manual: 9900 Series Models 9900, 9900A and 9900BDocument68 pagesInstallation Manual: 9900 Series Models 9900, 9900A and 9900BRandy SharpNo ratings yet

- WB2500 User ManualDocument84 pagesWB2500 User Manualaurel_c12-1No ratings yet

- Exsite Series Explosionproof Power Module: InstallationDocument16 pagesExsite Series Explosionproof Power Module: InstallationMohammed ElsayedNo ratings yet

- Im01c20h01-01en (9) Ej118Document70 pagesIm01c20h01-01en (9) Ej118Nguyen ThuongNo ratings yet

- Im01c20d01-01en (9) - Ej310, Ej430, Ej440Document79 pagesIm01c20d01-01en (9) - Ej310, Ej430, Ej440Nguyen ThuongNo ratings yet

- Inverter - EMC Basic Information - v1-3 - ENDocument26 pagesInverter - EMC Basic Information - v1-3 - ENILHNo ratings yet

- Auto-Axcess300 (LC499793)Document116 pagesAuto-Axcess300 (LC499793)José Carlos de Alencar DiasNo ratings yet

- Im01c22b01-01en (17) - Eja110, Eja120Document87 pagesIm01c22b01-01en (17) - Eja110, Eja120Nguyen ThuongNo ratings yet

- SUNNY BOY 1.5 / 2.5: Operating ManualDocument94 pagesSUNNY BOY 1.5 / 2.5: Operating ManualfidelNo ratings yet

- UPS 160 kVA EATONDocument226 pagesUPS 160 kVA EATONivan morelNo ratings yet

- JenCo - Electrical Systems O&MsDocument113 pagesJenCo - Electrical Systems O&MsNadia EspinozaNo ratings yet

- 95 8533 21.5 (Eqp) PDFDocument146 pages95 8533 21.5 (Eqp) PDFraulNo ratings yet

- MPC 3024 AceDocument39 pagesMPC 3024 Acezvh48588No ratings yet

- sc9000 PDFDocument128 pagessc9000 PDFmrepol02665No ratings yet

- RES 9242GC - V1.0 Note Manual 20160501 PDFDocument180 pagesRES 9242GC - V1.0 Note Manual 20160501 PDFpauloNo ratings yet

- Y JJ 1440056887Document20 pagesY JJ 1440056887Hồ ThànhNo ratings yet

- FP 31Document5 pagesFP 31Hồ ThànhNo ratings yet

- Sadara-Hvac Piping SchematicDocument1 pageSadara-Hvac Piping SchematicHồ ThànhNo ratings yet

- Thiet Bi Trung The Medium Voltage Products 0416 IntDocument33 pagesThiet Bi Trung The Medium Voltage Products 0416 IntHồ ThànhNo ratings yet

- Application: Heat-Shrinkable Three Core Xlpe Straight Joint Up To 36 KVDocument2 pagesApplication: Heat-Shrinkable Three Core Xlpe Straight Joint Up To 36 KVHồ ThànhNo ratings yet

- MV and LV Overhead Connectors 2017Document57 pagesMV and LV Overhead Connectors 2017Hồ ThànhNo ratings yet

- Dervasil Route de Popenot - 42800 Saint Joseph - France Tel: +33 (0) 4 77 83 22 81 - Fax: +33 (0) 4 77 83 22 80Document48 pagesDervasil Route de Popenot - 42800 Saint Joseph - France Tel: +33 (0) 4 77 83 22 81 - Fax: +33 (0) 4 77 83 22 80Hồ ThànhNo ratings yet

- Chong Set Trung The Surge Arrester CS-63RSADocument3 pagesChong Set Trung The Surge Arrester CS-63RSAHồ ThànhNo ratings yet

- Small-Area Orthogonal Drawings of 3-Connected Graphs: Therese Biedl Jens M. SchmidtDocument13 pagesSmall-Area Orthogonal Drawings of 3-Connected Graphs: Therese Biedl Jens M. SchmidtHồ ThànhNo ratings yet

- Slope 5.00 % L 4m: AHU Machine Room Hall, Salons, Game Room, Sports AreaDocument1 pageSlope 5.00 % L 4m: AHU Machine Room Hall, Salons, Game Room, Sports AreaHồ ThànhNo ratings yet

- Plan A: Doghmosh Lot38Document3 pagesPlan A: Doghmosh Lot38Hồ ThànhNo ratings yet

- Geberit New Sovent High Power 1474952245Document4 pagesGeberit New Sovent High Power 1474952245Hồ ThànhNo ratings yet

- SECTION 10 44 13 Fire Extinguisher Cabinets Spec Writer NoteDocument2 pagesSECTION 10 44 13 Fire Extinguisher Cabinets Spec Writer NoteHồ ThànhNo ratings yet

- BMS Wiring Diagram - Using RS-485 OnlyDocument1 pageBMS Wiring Diagram - Using RS-485 OnlyHồ ThànhNo ratings yet

- 02geberit Conventional Roof Drainage Systems 1474965625Document3 pages02geberit Conventional Roof Drainage Systems 1474965625Hồ ThànhNo ratings yet

- IJM009 - Jet - Engine Test Flight ManualDocument16 pagesIJM009 - Jet - Engine Test Flight ManualHồ ThànhNo ratings yet

- LC Doc Lms DWG TTR02Document6 pagesLC Doc Lms DWG TTR02Hồ ThànhNo ratings yet

- 5 Ways Your Move To Bim Pays OffDocument10 pages5 Ways Your Move To Bim Pays OffHồ ThànhNo ratings yet

- Ijm006a - Technical Manual Fuel - Tank Software Add-OnDocument22 pagesIjm006a - Technical Manual Fuel - Tank Software Add-OnHồ ThànhNo ratings yet

- QD 5270 Sua Doi Bo Sung Quy Dinh Dich Vu Chuyen Tien Qua He Thong Western Union Ma So QD DV 019 Ngay 31-8-2012Document9 pagesQD 5270 Sua Doi Bo Sung Quy Dinh Dich Vu Chuyen Tien Qua He Thong Western Union Ma So QD DV 019 Ngay 31-8-2012Hồ ThànhNo ratings yet

- Content: 1 Install The SoftDocument34 pagesContent: 1 Install The SoftAkhtar KhanNo ratings yet

- Introduction To Electrical and Computer Engineering Lab ManualDocument124 pagesIntroduction To Electrical and Computer Engineering Lab Manualkstu1112No ratings yet

- Fundamentals in Cavity PreprationDocument42 pagesFundamentals in Cavity PreprationNamrataNo ratings yet

- (New) Adjustable Voltage Power Supply 55 V - 20A High Power and Current - Automatic Fan On - OffDocument1 page(New) Adjustable Voltage Power Supply 55 V - 20A High Power and Current - Automatic Fan On - OffSek PyroNo ratings yet

- Audi A4 B8 Replace SubwooferDocument14 pagesAudi A4 B8 Replace SubwooferŽeljko MatićNo ratings yet

- UTP OTC PRICE Cust Cross Reference Records AccessDocument7 pagesUTP OTC PRICE Cust Cross Reference Records AccessvenkchNo ratings yet

- Automatic Sectionalizing Link: Life Cycle Cost - Cooper Bussmann vs. CompetitorDocument2 pagesAutomatic Sectionalizing Link: Life Cycle Cost - Cooper Bussmann vs. CompetitorNguyen Anh TuNo ratings yet

- Samsung SGH-F480i User ManualDocument82 pagesSamsung SGH-F480i User ManualClement DzinyembaNo ratings yet

- Autocad Mechanical EssentialsDocument3 pagesAutocad Mechanical EssentialsJigar Patel's100% (1)

- Calibration Procedure For An Inertial Measurement Unit Using A 6-Degree-of-Freedom HexapodDocument6 pagesCalibration Procedure For An Inertial Measurement Unit Using A 6-Degree-of-Freedom HexapodfitomenaNo ratings yet

- Lincoln-Electric Welding Inverter PC620&PC1030Document72 pagesLincoln-Electric Welding Inverter PC620&PC1030andtibNo ratings yet

- Amaia Trece - CheckListDocument32 pagesAmaia Trece - CheckListDick Anthony MabaoNo ratings yet

- Chapter 27 - AnswerDocument21 pagesChapter 27 - AnswerAnonymous CuUAaRSNNo ratings yet

- Crete Islands - Twin House BrochureDocument10 pagesCrete Islands - Twin House Brochuremostafa mohamedNo ratings yet

- 4 Cooling Load CalculationDocument11 pages4 Cooling Load Calculationfate7997No ratings yet

- City of Dallas PDFDocument526 pagesCity of Dallas PDFrafaelberaldiNo ratings yet

- Loss in Pipe and Fitting SystemDocument17 pagesLoss in Pipe and Fitting SystemGulshan Raza KhanNo ratings yet

- Cantilever Beam Design - AngleDocument1 pageCantilever Beam Design - Angleberylqz5878No ratings yet

- Rectangular Break Line: 1. Purpose and DescriptionDocument5 pagesRectangular Break Line: 1. Purpose and DescriptionNico InfanteNo ratings yet

- CT Series Step Motors: CTM Maximum Series CTP Performance SeriesDocument20 pagesCT Series Step Motors: CTM Maximum Series CTP Performance SeriesWagner GarciaNo ratings yet

- OpenVox G410E On Elastix Guide ManualDocument18 pagesOpenVox G410E On Elastix Guide ManualMarco CarvalhoNo ratings yet

- Sugar Crane Harvester BrosureDocument20 pagesSugar Crane Harvester BrosurenightfurryifyNo ratings yet

- A Review Paper On Technical Data of Present HVDC Links in IndiaDocument7 pagesA Review Paper On Technical Data of Present HVDC Links in IndiaEditor IJRITCCNo ratings yet

- Fingerprint Based Voting ProjectDocument2 pagesFingerprint Based Voting ProjectNajmuddin KapadiaNo ratings yet

- How To Hack The Website Site Kaskus - Us Indonesia Reaver Attack United StatesDocument12 pagesHow To Hack The Website Site Kaskus - Us Indonesia Reaver Attack United Statesedurawa100% (1)

- A General Solution For The Stress Around Internally Pressurized Circular Hole in Symmetric LaminatesDocument5 pagesA General Solution For The Stress Around Internally Pressurized Circular Hole in Symmetric LaminatesIoan-Lucian StanNo ratings yet

- Aerated Concrete Production Using Various Raw MaterialsDocument5 pagesAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- HP Petrochemical Process Handbook 2014 Comprimido PDFDocument233 pagesHP Petrochemical Process Handbook 2014 Comprimido PDFAndy VargasNo ratings yet

- Ilnas-En 12390-1:2021Document8 pagesIlnas-En 12390-1:2021HaniAminNo ratings yet

- Containership NTUA 2005Document79 pagesContainership NTUA 2005금동민No ratings yet