Professional Documents

Culture Documents

Paper and Board Identification of Machine and Cross Direction p2009-93

Paper and Board Identification of Machine and Cross Direction p2009-93

Uploaded by

Seputar Info0 ratings0% found this document useful (0 votes)

1 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views2 pagesPaper and Board Identification of Machine and Cross Direction p2009-93

Paper and Board Identification of Machine and Cross Direction p2009-93

Uploaded by

Seputar InfoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

SCAN-P 9:93

Revised 1993

Papers and boards

Identification of machine and cross directions

0 Introduction This Method does not include the identification of

running direction. Properties such as friction, gloss, fibre

This SCAN-test Method replaces SCAN-P 9:64. The

rising and surface strength are different in the running

major change is that Test 4, which defined machine and

direction and in the opposite direction.

cross directions by a curl test, is replaced by two new

test methods, which define machine and cross directions

by tensile stiffness measured by the speed of

2 References

propagation of ultra-sound (6.1.2) and by interpreting

the rupture pattern in a bursting test (6.2.4). SCAN-P 10 Papers and boards − Identification of

It is important to be able to identify the machine and wire side

cross directions of papers and boards since physical SCAN-P 24 Papers − Bursting strength and bursting

properties such as tensile properties, tear resistance, energy absorption

bending resistance and compression resistance are ISO 2759 Board − Determination of bursting

different in the two directions. strength

It is also important to be able to identify the wire side ISO 1924-2 Papers and boards − Determination of

of papers and boards. Procedures for the identification tensile properties − Part 2: Constant rate

of wire side are described in SCAN-P 10. of elongation method (EN ISO 1924-2)

Note – SCAN-test has withdrawn a number of test

1 Scope methods and refers instead to the corresponding

This SCAN-test Method applies to all kinds of machine- ISO and/or EN Standards.

made papers and boards except crêped or machine-

shrunk papers or specialties produced by techniques

which differ from normal paper machine practice. 3 Definitions

It is assumed that the test sheets are cut with their For the purpose of this Method, the following

sides parallel to or at right angles to the machine direc- definitions apply:

tion. To determine the machine and cross directions, a

clear difference in fibre orientation and/or elasticity 3.1 Machine direction, MD − The direction in paper

properties of the paper is required. and board which coincides with the longitudinal

direction of the web.

SCAN-P 9:93

Page 2

3.2 Cross direction, CD − The direction perpen- 6.2 Destructive tests

dicular to the machine direction. 6.2.1 Stiffness test. Cut two test pieces from the

specimen, measuring 250 mm x 15 mm, one parallel to

3.3 Running direction, RD − The direction in which the other perpendicular to the same edge of the

the paper web is running in the paper machine. The specimen. Mark each test piece so that its orientation in

running direction of a sample is defined by the end that the specimen is known.

passed first through the paper machine. Hold each piece in a horizontal plane by one edge.

When the pieces are held together, the stiffer piece is the

one which, when placed below the other, does not bend

4 Principle and fall away from the upper piece. The machine direction

The paper is tested to determine properties known to is the longitudinal direction of the stiffer test piece.

differ systematically between the machine and cross

directions. 6.2.2 Tensile test. Cut two test pieces from the specimen

The decision of the identification is made on the measuring 250 mm x 15 mm ± 0,1 mm, one parallel to and

basis of the results. the other perpendicular to the same edge of the specimen.

Determine the tensile strength of each of the two test pieces

in accordance with ISO 1924-2. The longitudinal direction

5 Apparatus of the stronger piece is the machine direction.

Depending on the test procedure to be used, the

following apparatus are applicable: 6.2.3 Tear test. For rapid determination, tear the

specimen at right angles to the edge inwards from the

5.1 The equipment described in the SCAN-test two edges and compare the tears. The tear that is most

Method and/or ISO standard referred to. delaminating is usually in the cross direction and the tear

5.2 Microscope. in the machine direction is usually the straightest.

5.3 Ultra sound speed tester.

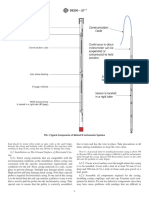

6.2.4 Bursting test. Perform a bursting test in

accordance with SCAN-P 24 or ISO 2759. Remove the

6 Procedure test piece from the bursting tester and observe the

principal line of rupture. This line, with approximately

Find the machine direction of paper and board by one or perpendicular fractures at either end, indicates the cross

preferably more of the following tests. It is recom- direction.

mended that experience in these tests be obtained by

practising with paper or board of known machine and

Note − The bursting test is convenient for paper

cross directions.

with a "normal" distribution of tensile and stretch

characteristics; however, there are numerous ex-

6.1 Non destructive tests

ceptions to this. The principal line of rupture is

6.1.1 Surface inspection. Note the orientation of the parallel to the direction with the higher stretch. In

fibres on the surface of the paper. The fibres, especially those papers where there is no significant diffe-

on the wire side, are preferentially oriented in the rence in the stretch for the two directions, the

machine direction. To view the paper, hold it rupture tends to be more random and less reliable

horizontally, with the light incident at an angle of about as an indication.

45° and with the line of vision also at an angle of about

45° to the normal to the paper. Observation of the paper

surface under a microscope (5.2) is helpful.

7 Report

6.1.2 Tensile stiffness test. Determine the tensile When machine and cross directions have been identified

stiffness index by the speed of propagation of ultra- according to this SCAN-test Method in connection with

sound (5.3). Measure the speed in two directions, one the determination of physical properties, it should be

parallel to and the other perpendicular to the same edge stated in the test report, including details of the kinds of

of the specimen. The highest value of the tensile tests used.

stiffness index, i.e. the highest speed of ultra-sound

propagation is in the machine direction.

SCAN-test Methods are issued and recommended by

KCL, PFI and STFI-Packforsk for the pulp, paper and

board industries in Finland, Norway and Sweden.

Distribution: Secretariat, Scandinavian Pulp, Paper

and Board Testing Committee, Box 5604,

SE-114 86 Stockholm, Sweden.

You might also like

- Williamoaks Construct GuideDocument14 pagesWilliamoaks Construct GuidefalergonNo ratings yet

- Astm G171 PDFDocument7 pagesAstm G171 PDFGAVILANES MARTINEZ GEISSON ANIBAL0% (1)

- Astm F-1874Document3 pagesAstm F-1874Richa RohillaNo ratings yet

- C365 - CompresionDocument3 pagesC365 - CompresionLucero Ponce de LeónNo ratings yet

- D 2718 - 00 Rdi3mtgtmda - PDFDocument6 pagesD 2718 - 00 Rdi3mtgtmda - PDFRufo CascoNo ratings yet

- Yoga Nidra Masterclass Training Notes 1 PDFDocument4 pagesYoga Nidra Masterclass Training Notes 1 PDFMino Zo SydneyNo ratings yet

- Johnston (1999) Why We Feel. The Science of Human EmotionsDocument221 pagesJohnston (1999) Why We Feel. The Science of Human EmotionsNavi Setnom ArieugonNo ratings yet

- Paper and Board Identification of Machine and Cross Direction p2009-93Document2 pagesPaper and Board Identification of Machine and Cross Direction p2009-93Meera PatelNo ratings yet

- Machine Direction of Paper and Paperboard: Standard Test Method ForDocument2 pagesMachine Direction of Paper and Paperboard: Standard Test Method ForALFONSO_08No ratings yet

- Paper Friction Johan91a PDFDocument9 pagesPaper Friction Johan91a PDFYessieNo ratings yet

- D 3389 - 94 R99 - RdmzodkDocument4 pagesD 3389 - 94 R99 - RdmzodkPrakash MakadiaNo ratings yet

- Methods of Test For Cables: Indian Standard Y& "M-,4 R-F/RDocument3 pagesMethods of Test For Cables: Indian Standard Y& "M-,4 R-F/RVatsalNo ratings yet

- E435 Steel PlatesDocument4 pagesE435 Steel PlatesLeina Rosa Wilches AtencioNo ratings yet

- Internal Tearing Resistance of Paper: Standard Test Method ForDocument7 pagesInternal Tearing Resistance of Paper: Standard Test Method ForAngel ValladaresNo ratings yet

- Section II A SA-435 - SA-435MDocument3 pagesSection II A SA-435 - SA-435MSocrates MoralesNo ratings yet

- Tearing Resistance of Roofing and Waterproofing Materials and MembranesDocument2 pagesTearing Resistance of Roofing and Waterproofing Materials and MembranesRed FolderNo ratings yet

- Weather Resistance of Slate: Standard Test Method ForDocument3 pagesWeather Resistance of Slate: Standard Test Method ForWaleed MedhatNo ratings yet

- Determining Geonet Breaking Force: Standard Test Method ForDocument2 pagesDetermining Geonet Breaking Force: Standard Test Method ForEdmundo Jaita Cuellar100% (1)

- Astm e 915 - 96 PDFDocument3 pagesAstm e 915 - 96 PDFLuis Fernando RuedaNo ratings yet

- C 886 - 98 - QZG4NGDocument2 pagesC 886 - 98 - QZG4NGneophymenNo ratings yet

- Astm A435 A435m-90 (1996)Document2 pagesAstm A435 A435m-90 (1996)FeteneNo ratings yet

- B Sa-435Document2 pagesB Sa-435Antonio GutierrezNo ratings yet

- AstmDocument8 pagesAstmramonNo ratings yet

- Scleroscope Hardness Testing of Carbon and Graphite MaterialsDocument2 pagesScleroscope Hardness Testing of Carbon and Graphite MaterialsOsama TaghlebiNo ratings yet

- ASTM D 2664 - 95-Triaxial Compressive Strength of Undrained Rock Core Specimens Without Measurement of Pore PressureDocument4 pagesASTM D 2664 - 95-Triaxial Compressive Strength of Undrained Rock Core Specimens Without Measurement of Pore PressureJuan Cruz HarasimiukNo ratings yet

- Internal Tearing Resistance of Paper: Standard Test Method ForDocument8 pagesInternal Tearing Resistance of Paper: Standard Test Method Forjamaljamal20No ratings yet

- Flexural Modulus of Elasticity of Dimension Stone: Standard Test Method ForDocument3 pagesFlexural Modulus of Elasticity of Dimension Stone: Standard Test Method ForRufo CascoNo ratings yet

- Astm d6230 - Part 2Document4 pagesAstm d6230 - Part 2leegoon82No ratings yet

- Astm C 886-98Document2 pagesAstm C 886-98YAMILETH CAMACHONo ratings yet

- C 120 - 00 - QzeymaDocument3 pagesC 120 - 00 - Qzeymamercab15No ratings yet

- Astm D 1663Document6 pagesAstm D 1663Rajesh KumarNo ratings yet

- Standard Specification F R ST Aight - Beam Ultrasonic Exa Ination of Steel PlatesDocument3 pagesStandard Specification F R ST Aight - Beam Ultrasonic Exa Ination of Steel Platesanon_935140585No ratings yet

- 463KB701Document8 pages463KB701jose luisNo ratings yet

- Hardness of RockDocument7 pagesHardness of RockPushpendra ChouhanNo ratings yet

- ASTM D412 Test Method For Vulcanized RubberDocument13 pagesASTM D412 Test Method For Vulcanized RubberElaine HuangNo ratings yet

- Film Hardness by Pencil Test: Standard Test Method ForDocument6 pagesFilm Hardness by Pencil Test: Standard Test Method ForBrian LinNo ratings yet

- Astm e 670 - 94Document10 pagesAstm e 670 - 94tomNo ratings yet

- Brief Description: Application Note - Industries & MarketDocument2 pagesBrief Description: Application Note - Industries & MarketJose Oliveros ArdilaNo ratings yet

- An Imaging Technique To Measure Rust Creepage at Scribe On Coated Test Panels Subjected To Corrosive EnvironmentsDocument4 pagesAn Imaging Technique To Measure Rust Creepage at Scribe On Coated Test Panels Subjected To Corrosive EnvironmentsAlejandro 20No ratings yet

- Sspc-Pa 16-2012 PDFDocument2 pagesSspc-Pa 16-2012 PDFRaul Sebastiam100% (2)

- Tensile Breaking Strength of Perforations in One-Part Continuous Forms PaperDocument3 pagesTensile Breaking Strength of Perforations in One-Part Continuous Forms PaperProvocateur SamaraNo ratings yet

- Astm D 903 - 98 (2010)Document3 pagesAstm D 903 - 98 (2010)sharma.sumeet2290No ratings yet

- Astm C446Document2 pagesAstm C446Alexis DominguezNo ratings yet

- Standard Specification For Straight-Beam Ultrasonic Examination of Steel PlatesDocument2 pagesStandard Specification For Straight-Beam Ultrasonic Examination of Steel PlatesHarshkulNo ratings yet

- ASTM-D642-00Document5 pagesASTM-D642-00Sutthavee KrairirkshNo ratings yet

- ASTM D642 Determining Compressive Resistance of ShippingDocument5 pagesASTM D642 Determining Compressive Resistance of ShippingMohd RazaNo ratings yet

- D4172-94. Test Method For Wear Preventive Characteristics of Lubricating Fluid (Four-Ball Method)Document5 pagesD4172-94. Test Method For Wear Preventive Characteristics of Lubricating Fluid (Four-Ball Method)Navneet YadavNo ratings yet

- Resistência Ao Rasgo (Elmendorf) - ASTM D1424-96Document8 pagesResistência Ao Rasgo (Elmendorf) - ASTM D1424-96raissaNo ratings yet

- Ultrasonic Testing of Weld Joints of StructuralsDocument13 pagesUltrasonic Testing of Weld Joints of StructuralsRakesh Ranjan100% (1)

- Postbuckling and Collapse AnalysisDocument8 pagesPostbuckling and Collapse AnalysisAtsis Papadopoulos100% (1)

- A 435 - A 435M - 90 (2012) PDFDocument2 pagesA 435 - A 435M - 90 (2012) PDFأسامة وحيد الدين رمضانNo ratings yet

- Abrasion Resistance of Horizontal Concrete Surfaces: Standard Test Method ForDocument5 pagesAbrasion Resistance of Horizontal Concrete Surfaces: Standard Test Method Forrajeshji_000No ratings yet

- Sa 435Document3 pagesSa 435KHALED OSMANNo ratings yet

- Type of TestingDocument31 pagesType of TestingEdwin VersteegNo ratings yet

- Astm D 7087 - 2010Document4 pagesAstm D 7087 - 2010Emmanuel BoquetNo ratings yet

- Edgewise Compressive Strength of Corrugated Fiberboard Using The Morris Method (Short Column Test) (Proposed Withdrawal of T 841 cm-03)Document7 pagesEdgewise Compressive Strength of Corrugated Fiberboard Using The Morris Method (Short Column Test) (Proposed Withdrawal of T 841 cm-03)guruprasadcvNo ratings yet

- D 1623 - 78 R95 - Rde2mjmtnzhsotuDocument6 pagesD 1623 - 78 R95 - Rde2mjmtnzhsotuSiddhesh Umesh MestryNo ratings yet

- Shear Properties of Sandwich Core Materials: Standard Test Method ForDocument4 pagesShear Properties of Sandwich Core Materials: Standard Test Method ForCarlos Raul Caballero LeonNo ratings yet

- ASTM - D - 1456 Test Method For Rubber Property - ElongationDocument4 pagesASTM - D - 1456 Test Method For Rubber Property - ElongationElaine HuangNo ratings yet

- C 120 - 90 r94 Qzeymc1sruqDocument4 pagesC 120 - 90 r94 Qzeymc1sruqJason RogersNo ratings yet

- Introduction to Optical Waveguide Analysis: Solving Maxwell's Equation and the Schrödinger EquationFrom EverandIntroduction to Optical Waveguide Analysis: Solving Maxwell's Equation and the Schrödinger EquationNo ratings yet

- AccommodationDocument16 pagesAccommodationHuy HeinekenNo ratings yet

- 2016 17 Moesm1 EsmDocument2 pages2016 17 Moesm1 EsmHuy HeinekenNo ratings yet

- Surface & Coatings TechnologyDocument9 pagesSurface & Coatings TechnologyHuy HeinekenNo ratings yet

- Perov S KitesDocument31 pagesPerov S KitesHuy HeinekenNo ratings yet

- FMX 004 DatasheetDocument2 pagesFMX 004 DatasheetHuy HeinekenNo ratings yet

- Melt Polycondensation of Lactic AcidDocument2 pagesMelt Polycondensation of Lactic AcidHuy HeinekenNo ratings yet

- Advanced Writing-TC333 - Reading - Elevator PitchDocument0 pagesAdvanced Writing-TC333 - Reading - Elevator PitchHuy HeinekenNo ratings yet

- TC 333 Assignment 1Document1 pageTC 333 Assignment 1Huy HeinekenNo ratings yet

- Basic Cover LetterDocument1 pageBasic Cover LetterHuy HeinekenNo ratings yet

- Hx-Chart Humid Air: Humidity Ratio, G/KG (Dry Air)Document1 pageHx-Chart Humid Air: Humidity Ratio, G/KG (Dry Air)KundzoNo ratings yet

- Drug StudyDocument7 pagesDrug StudydivineNo ratings yet

- Dreams LuDocument325 pagesDreams Luscrib3030100% (1)

- Module 5 Communication Aids and Strategies Using Tools of TechnologyDocument4 pagesModule 5 Communication Aids and Strategies Using Tools of TechnologyPammieNo ratings yet

- FAKRO Technical Specification DRF DU6 PDFDocument2 pagesFAKRO Technical Specification DRF DU6 PDFthomasNo ratings yet

- 2-2-Schedules NH-167K-05-08-2022Document187 pages2-2-Schedules NH-167K-05-08-2022hallmarkvenugopalNo ratings yet

- Printable Article Synthetic Materials Making Substances in The LabDocument2 pagesPrintable Article Synthetic Materials Making Substances in The LabJoshua BrewerNo ratings yet

- Resource Guide For New ChrosDocument23 pagesResource Guide For New Chroslane.a.mcfNo ratings yet

- Fire Catalog Alco-LiteDocument14 pagesFire Catalog Alco-LiteForum PompieriiNo ratings yet

- LAS Module 5 Applied Economics MARKET STRUCTURESDocument7 pagesLAS Module 5 Applied Economics MARKET STRUCTURESellamaecalamucha8No ratings yet

- Game Master's Kit: An Accessory For The Dragon Age RPGDocument32 pagesGame Master's Kit: An Accessory For The Dragon Age RPGLuiz Fernando Rodrigues CarrijoNo ratings yet

- Guided Reading Lesson PlanDocument4 pagesGuided Reading Lesson Planapi-311848745No ratings yet

- Short Questions For Ayub Khan DownfallDocument9 pagesShort Questions For Ayub Khan Downfallabdullah sheikhNo ratings yet

- Tugas 2 Bahasa Dan Terminologi Hukum 14Document2 pagesTugas 2 Bahasa Dan Terminologi Hukum 14Bayu Indra PamungkasNo ratings yet

- BSN1-2 Lab Activity 2.2 Proteins DenaturationDocument3 pagesBSN1-2 Lab Activity 2.2 Proteins DenaturationCristine EchaveNo ratings yet

- Bridge Alert Management PDFDocument18 pagesBridge Alert Management PDFbhabhasunilNo ratings yet

- Sparsh Idt FinalDocument12 pagesSparsh Idt FinalSparsh vatsNo ratings yet

- 7 - Simulations and PFDsDocument23 pages7 - Simulations and PFDsIslam SolimanNo ratings yet

- Math in Focus 4A WorksheetDocument9 pagesMath in Focus 4A WorksheetBobbili PooliNo ratings yet

- Grade 6 - Specific Outcomes: Can Affect Human Development From Conception Through BirthDocument49 pagesGrade 6 - Specific Outcomes: Can Affect Human Development From Conception Through Birthapi-253059746No ratings yet

- Importing Google Earth Data Into A GISDocument15 pagesImporting Google Earth Data Into A GISJONAMNo ratings yet

- CT6302B Datasheet V1.2: I. Product OverviewDocument17 pagesCT6302B Datasheet V1.2: I. Product Overviewrummy squaresNo ratings yet

- Building Up Good Mental Health: Guidelines Based On Existing KnowledgeDocument6 pagesBuilding Up Good Mental Health: Guidelines Based On Existing KnowledgerowanpurdyNo ratings yet

- Submarine Cable Installation ContractorsDocument19 pagesSubmarine Cable Installation Contractorswiji_thukulNo ratings yet

- Customers Satisfaction On ATMDocument33 pagesCustomers Satisfaction On ATMabdullahi shafiuNo ratings yet

- Ijfeat: Design and Fabrication of Pneumatic TricycleDocument8 pagesIjfeat: Design and Fabrication of Pneumatic TricycleOkta FerliNo ratings yet

- Ashta Karma Eight Magical Acts PDFDocument4 pagesAshta Karma Eight Magical Acts PDFErnest GomezNo ratings yet