Professional Documents

Culture Documents

Plan de Surveillance Exemple

Plan de Surveillance Exemple

Uploaded by

Audrey GavaletOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plan de Surveillance Exemple

Plan de Surveillance Exemple

Uploaded by

Audrey GavaletCopyright:

Available Formats

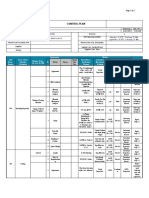

Control Plan #: Plant: XYZ Company, City, State, Zip

Date:

Part Number: Key Contact:

Prototype

Pre-launch Production

Part Name/Description: Revision: 1.0 WO#:

Methods

Characteristics

Sample

Step # SMT Process Step Machine / Device Evaluation Reaction Plan

Specification /

Measurement Control Method Accept/Reject Criteria

Product Process Tollerance Size Frequency

Technique

Each Lot Halt Production, Notify Supervisor, Complete a

Correct Quantity Visual Check Packing Slip Physical Count 100% Circuit Cam, BaaN

Received PIF

1 Receive Materials Stock Room

Incomming Material Segregate Non-Conforming Material, Notify

Packaging Quality Visual Check Not Visibly Damaged Gross Visual 100% Each Lot

Procedure Supervisor

Right raw material Each Lot Incoming Inspection Segregate Non-Conforming Material, Notify

Visual Check Packing slip Visual inspection 1

quantity Received Procedure Supervisor

Incomming Material Segregate Non-Conforming Material, Notify

Packaging Quality Visual Check Not Visibly Damaged Gross Visual 100% Each Lot

Procedure Supervisor

Moisture Sensitive Per: Material Bake and Incoming Inspection Segregate Non-Conforming Material, Notify

Visual Check Visual inspection 100% Each Lot

Components Dry Storage procedure Procedure Supervisor

2 Incoming inspection Stock Room

Incoming inspection

According to component Optical comparator / Segregate Non-Conforming Material, Notify

PCB out of specification Visual Check By AQL Each lot procedure/Product

specification / drawing caliper/surface plate Supervisor

specification

Cosmetic verification of According to component Incoming inspection Segregate Non-Conforming Material, Notify

Visual Check Visual inspection By AQL Each lot

components specification / drawing procedure Supervisor

Process audit ICS-WIP Do not put label on PCB, stop printing and

Serial number ICS System ICS WIP Page 100% Continuous notify to the Supervisor and Process/mfg

Bar code reader in Engineering

process

Bar code reader in

3 Board Labeling Kitting Area Every side of the panel Remove label that was placed wrong and place

Board labeling Visual inspection 100% Continuous process/ process work

(top and bottom) a new label. Notify Supervisor.

instruction

Bar code reader in Stop printing, and notify line supervisor if label

Label legible Bar Code legible Bar code reader 100% Continuous

process is not legible and do not placed it on theboard.

Correct orientation of the Every change If the PCB has not been correctly oriented, it

4 Load board to loader Manual Conveyor width Per PCB width Visually 1st piece Manual

PCB over. has to be removed and reoriented.

0-5°C or per

Call Mfg or QE if the temperature changes out

Solder paste storage specifications shown in

Refrigerator Solder Paste Thermometer One reading Continuous Alarm of the specified ranges (alarm) and reset the

temperature the Technical Data

proper temperature

Sheet

6 months from the date If the expiration date has been reached, the

Perishable Material Log

of manufacture or per tube has to be scrapped.

Solder paste expiration Expiration date on

Refrigerator Solder Paste specifications shown in 100% Every tube

date solder paste label

the Technical Data Dispose of Expired Material and get a new

Label on tube

Sheet tube form Matls.

Type or Make or part No Clean or Water ICS/Circuit Cam/Doc Hold the product built with the wrong paste

Refrigerator Per Customer Drawing Visual inspection 100% Per Tube

number of solder paste Soluble Pack and notify supervisor for disposition.

If the stabilization period is undeterminable

6 hrs minimum before Perishable Materials

Refrigerator Solder Paste Solder paste stabilization 100% Every tube Audit log then a 8 hrs wait period is required and begins

production use Log

at time of discovery

Operator checks for proper adjustment and

60 % coverage of the Automatic vision 60 % coverage of the aperture as a

5 Print solder paste Solder Paste Paste coverage 4 corners 100% Continuous Alarm cleanliness of stencil. Stop the machine,

aperture as a minimum. system minimum.

contact Eng or QE to take a corrective action

Stencil Printer

Stop production if any of the solder paste

Automatic vision

Solder Paste Solder paste shorting -20% 4 corners 100% Continuous Alarm measurements is out of the limits. Notify the

system

technician and QE.

Screen Print verification

& Setup Reference Periodic audit to insure

Train the operators. Insure that the printer is

Stencil Printer Solder Paste Correct Print Parameters documents TCC-00004, Visual 100% Every product run that correct printing

password protected.

EOP-00004 & PML- parameters are used.

00004

Elcoteq SA de CV Confidential Control Plan Page 1

Control Plan #: Plant: XYZ Company, City, State, Zip

Date:

Part Number: Key Contact:

5 Print solder paste Prototype

Pre-launch Production

Part Name/Description: Revision: 1.0 WO#:

Methods

Characteristics

Sample

Step # SMT Process Step Machine / Device Evaluation Reaction Plan

Specification /

Measurement Control Method Accept/Reject Criteria

Product Process Tollerance Size Frequency

Technique

No overprinting or as

shown in Screen Print

Verify that initial

verification & Setup

Stencil Printer Solder Paste Print Registration Visual 100% Every product run machine setup is

Reference documents

correct.

TCC-00004, EOP-00004

& PML-00004

Solder on all intended QC first article Stop production if any pads do not have solder

Stencil Printer Stencil Correct Stencil Visual 1st Article 1st Article Every run

pads inspection paste. Notify Engineering. Get correct stencil.

Stop the line and report to the Supervisor and

Automatic Machine By product specification QC first article Engineer. Segregate suspect units for

Component polarity Visual inspection 1st Article Every run

Placement and work instruction inspection inspection. Modify assembly program as

needed.

Stop the line and report to the Supervisor and

QC first article Engineer. Segregate suspect units for

Visual inspection 1st Article Every run

inspection inspection. Modify assembly program as

needed.

Automatic Machine By product drawing and

Component alignment

Placement specification

SMT Component Placement Stop the line and report to the Supervisor and

6 PLACEMENT MACHINES QC first article Engineer. Segregate suspect units for

Top / Bottom (as required) X-Ray Inspection 1st Article Every run

inspection inspection. Modify assembly program as

needed.

Stop the line and report to the Supervisor and

Automatic Machine By product drawing and QC first article Engineer. Segregate suspect units for

Component seating Visual inspection 1st Article Every run

Placement specification inspection inspection. Modify assembly program as

needed.

Stop the line and report to the Supervisor and

By bill of material and Every reel Process audit by QC

Automatic Machine Engineer. Segregate suspect units for

Right component product drawing (blue Visual inspection 100% replaced and new inspector. First article

Placement inspection. Modify assembly program / feeders

print) reel sheet

as needed.

Per Solder Paste Type Oven parameters, first Stop the line and verify oven parameters,

Every product/

Quality of Solder Machine Reflow Soldering as shown in the Work 1 time article cheek list. separate suspect material.

new run

7 Reflow Relfow Oven Order Profile device Process audit by QC

Notify the Supervisor / Engineer

Per reflow oven Per reflow oven Hold Process, Notify Engineering and

Repeatability 1 time once per day

verification procedure verification procedure Supervisor

RTI 6520 Product program for

AOI Inspection Top / Bottom Components location Automatic Cam Stop the line and notify Engineering. Verify

8 By product program 100% Every lot components location

(as required) and presence inspection material in process.

PCB Inspection System and characteristics

Stop the process, notify to the supervisor and

By product drawing and QC in process

Components seating Visual inspection 100% Every run separate suspect material for inspection and

specification inspection

disposition

By solder Tip QC in process Stop the process and inspect suspect material.

9 Second level assembly Hand solder components Solder tip temperature By product specification 100% Every lot

specification inspection Verify Tip specifications

QC in process Stop the process and inspect suspect material.

Quality of Solder IPC-A-610 standard Visual inspection 100% Every unit

inspection Verify Tip specifications

QC in process

10 Mechanical Assembly Manual Quality of assembly By product specification Visual inspection 100% Every Unit Stop the process and Notify Engineering

inspection

Stop the line and report to the Supervisor and

QC in process

11 Depanelize IPC-A-610 standard Visual inspection 100% Every unit Engineer the problem. Separate the suspect

inspection

units for inspection.

Electrical test Test procedure and Stop the test process, notify Engineering and

12 Final test By product specification Test equipment 100% Continuous

performance work instruction verify material using a golden unit.

Elcoteq SA de CV Confidential Control Plan Page 2

You might also like

- SMT Generic Control PlanDocument2 pagesSMT Generic Control Plansmtdrkd81% (21)

- SMT Generic Control PlanDocument3 pagesSMT Generic Control Plantuan mai vanNo ratings yet

- LWG Versus ISO 14001Document4 pagesLWG Versus ISO 14001Raajha Munibathiran100% (1)

- Design Acceptance LetterDocument1 pageDesign Acceptance LetterMurali kumarNo ratings yet

- Cette Demande de Consignation Requiert Des Signatures ManuellesDocument1 pageCette Demande de Consignation Requiert Des Signatures ManuellessamiraNo ratings yet

- ISO 9001:2015 Lead Auditor Training CourseDocument3 pagesISO 9001:2015 Lead Auditor Training CourseM KassemNo ratings yet

- ISO 13485-2016 - DR - Pack - Control of Non Conforming ProductsDocument4 pagesISO 13485-2016 - DR - Pack - Control of Non Conforming ProductskmasanNo ratings yet

- Api 579-1 - Asme FFS-1 PaDocument14 pagesApi 579-1 - Asme FFS-1 PaZdravko Ivancic20% (5)

- Checks and Maintenance AM120iC-12LDocument16 pagesChecks and Maintenance AM120iC-12LDaniel Garcia100% (1)

- Plan de Comunication HSEDocument6 pagesPlan de Comunication HSERACHID ZAMRAKNo ratings yet

- Supplier Logistics Manual-FAU-S-PSG-2025-en-02Document136 pagesSupplier Logistics Manual-FAU-S-PSG-2025-en-02Rx DentviewNo ratings yet

- Bonne Pratique D'hygiéne PoissonDocument147 pagesBonne Pratique D'hygiéne PoissonLaila HomeNo ratings yet

- Liste de Vérification Du MagasinDocument1,700 pagesListe de Vérification Du MagasinAnonymous a5KZQA100% (1)

- SY 01 EnglishDocument8 pagesSY 01 EnglishPramodh PalukalNo ratings yet

- Identification Danger Evaluation Des Risques SMTTDocument17 pagesIdentification Danger Evaluation Des Risques SMTTmazen fakhfakhNo ratings yet

- VACCPDocument21 pagesVACCPSherylNo ratings yet

- Procedure For HACCP PlanDocument22 pagesProcedure For HACCP PlanrikyNo ratings yet

- IFS Food v8 Audit Checklist Guideline v1 en 1712750463Document101 pagesIFS Food v8 Audit Checklist Guideline v1 en 1712750463MEDNo ratings yet

- Pro-Operations de LevageDocument44 pagesPro-Operations de LevageAnarchimiNo ratings yet

- Amdec PDFDocument2 pagesAmdec PDFAhmed IdiNo ratings yet

- List of Documents ISO 9001 Documentation Toolkit Light EN PDFDocument1 pageList of Documents ISO 9001 Documentation Toolkit Light EN PDFgheoda8926No ratings yet

- QIP Audit Standard: List of DocumentsDocument5 pagesQIP Audit Standard: List of Documentsawdhut kulkarniNo ratings yet

- ProCert ISO 22000 Decision TreeDocument1 pageProCert ISO 22000 Decision Treechocoboom100% (1)

- HSE FOM 047 QHSE Prequalification QuestionnaireDocument2 pagesHSE FOM 047 QHSE Prequalification QuestionnaireaymenmoatazNo ratings yet

- Guideformation 130702033440 Phpapp02Document132 pagesGuideformation 130702033440 Phpapp02LopezNo ratings yet

- Ldpe L07920Document1 pageLdpe L07920Luis Fernando Camacho VargasNo ratings yet

- CDP Climate Change Rapport France Benelux2016 (2017!10!29 23-25-33 UTC)Document64 pagesCDP Climate Change Rapport France Benelux2016 (2017!10!29 23-25-33 UTC)lolobeboyNo ratings yet

- Comparison IFS Food v7 and IFS Food v6.1 For All Parts of The StandardsDocument49 pagesComparison IFS Food v7 and IFS Food v6.1 For All Parts of The StandardsSzabó TamásNo ratings yet

- Fiche Technique CameraDocument1 pageFiche Technique CamerasafaealghzaliNo ratings yet

- MarketingDocument6 pagesMarketingTasmeemRahmanNo ratings yet

- 2020 Amdec - Action Plan FVDocument22 pages2020 Amdec - Action Plan FVSameh ChaiebNo ratings yet

- Cqi Audit ChecklistDocument1 pageCqi Audit ChecklistFavis Joseph BalinadoNo ratings yet

- Notes: Completion of Afr/Air Workbook: Project NameDocument110 pagesNotes: Completion of Afr/Air Workbook: Project NameNassim AkroucheNo ratings yet

- Microsoft Word - Emergency-Evac-Drill-ReportDocument3 pagesMicrosoft Word - Emergency-Evac-Drill-ReportAmal SalimNo ratings yet

- VQHSE MS ProcedureDocument22 pagesVQHSE MS ProcedureSyahrul RizalNo ratings yet

- BRC Global Standards Self-Assessment Tool Basic Hygiene CategoryDocument31 pagesBRC Global Standards Self-Assessment Tool Basic Hygiene CategoryDevi MaharaniNo ratings yet

- Lifting and HoistingDocument81 pagesLifting and HoistingnwosuchibuikesunNo ratings yet

- Apqp Ppap Psa - Abpm - Trainer - en v3.1Document232 pagesApqp Ppap Psa - Abpm - Trainer - en v3.1Karim JAOUHARYNo ratings yet

- Irca 173 CPD LogDocument19 pagesIrca 173 CPD LogSerdar Aldanmazlar100% (1)

- FHHR 013 Red Tag Procedure PDFDocument5 pagesFHHR 013 Red Tag Procedure PDFN3N5YNo ratings yet

- FSMS Training ModuleDocument3 pagesFSMS Training ModuleRude Gal SheenaNo ratings yet

- Aptive Customer Specific RequirementsDocument13 pagesAptive Customer Specific RequirementsyatheendravarmaNo ratings yet

- 95th Percentile Values 005 Levels f095 For The F DistributionDocument3 pages95th Percentile Values 005 Levels f095 For The F DistributionOmar KharifiNo ratings yet

- Lean Audit ChecklistDocument3 pagesLean Audit ChecklistFátima Macario Monzón100% (1)

- Drill DeepDocument9 pagesDrill DeepDiogo Andrade FonteneleNo ratings yet

- General Environmental Management Systems Awareness TrainingDocument44 pagesGeneral Environmental Management Systems Awareness TrainingRamaKantDixitNo ratings yet

- 01.seance LDP Générique OPTIMISATION V3P - ENDocument151 pages01.seance LDP Générique OPTIMISATION V3P - ENManuela VNo ratings yet

- Securite ADV Nivellement Rails Tournées PN Autres VOIE Permis Joints Docum Entatio N Encadrem EntDocument19 pagesSecurite ADV Nivellement Rails Tournées PN Autres VOIE Permis Joints Docum Entatio N Encadrem EntOuass AkilNo ratings yet

- Communication Plan Covering Objectives Goals Message Implement WDDocument5 pagesCommunication Plan Covering Objectives Goals Message Implement WDNilson CostaNo ratings yet

- Potential Failure Mode and Effect Analysis: (Process Fmea)Document9 pagesPotential Failure Mode and Effect Analysis: (Process Fmea)SACHIN KUMARNo ratings yet

- GMs Drill Deep WorkshopDocument47 pagesGMs Drill Deep WorkshopEduardo Magaña Gutierrez0% (1)

- GRS 102 V4.0 GRS Certification ProceduresDocument6 pagesGRS 102 V4.0 GRS Certification ProceduresLamia ould amerNo ratings yet

- CL 27 01 011e Vda6 2Document40 pagesCL 27 01 011e Vda6 2fmfs60No ratings yet

- 02 - Fast Response - QIP V3Document85 pages02 - Fast Response - QIP V3HOSSIENNo ratings yet

- ISO 9001 Implementation Plan 2Document2 pagesISO 9001 Implementation Plan 2KayNo ratings yet

- Parametric Cost Deployment Dean NasaDocument8 pagesParametric Cost Deployment Dean Nasamosros123No ratings yet

- 006 MMF Section 1 Playbook Rev 2.0 09142012Document69 pages006 MMF Section 1 Playbook Rev 2.0 09142012Peter RNo ratings yet

- Incident Flash Report: HPI Reportable InjuryDocument1 pageIncident Flash Report: HPI Reportable InjurysebastianNo ratings yet

- APQP - Advance Product Quality PlaningDocument12 pagesAPQP - Advance Product Quality PlaningPrakashNo ratings yet

- InternalAuditChecklistISO9001 2015Document28 pagesInternalAuditChecklistISO9001 2015syamimi balkhis100% (1)

- 1 - ISO 9001 Department Audit QuestDocument2 pages1 - ISO 9001 Department Audit QuestMAYMODERN STEEL100% (1)

- CP20200804-A Model Control Plan - FoundationsDocument6 pagesCP20200804-A Model Control Plan - Foundationsmanno200No ratings yet

- Brigss Straton 6 KW PDFDocument72 pagesBrigss Straton 6 KW PDFJulio VilchezNo ratings yet

- Region Range Manufacturer Model Spec - DateDocument72 pagesRegion Range Manufacturer Model Spec - DateGaming BebasNo ratings yet

- Beauty Secrets Facility Layout: Done By: Laith Rahim Al-Mutaz Elayan Rashed Janadieh Izzat ZahidahDocument13 pagesBeauty Secrets Facility Layout: Done By: Laith Rahim Al-Mutaz Elayan Rashed Janadieh Izzat ZahidahLaith Abdul RahimNo ratings yet

- Docslide Us Jet Blue Airways Managing Growth Case SolutionDocument12 pagesDocslide Us Jet Blue Airways Managing Growth Case SolutionprateekNo ratings yet

- Ndii 1st Term Result 2013davidDocument19 pagesNdii 1st Term Result 2013davidtaridanNo ratings yet

- PP Clyrell Rc213m Random Cast FilmDocument1 pagePP Clyrell Rc213m Random Cast FilmTrung HoNo ratings yet

- Sand CatDocument2 pagesSand CatHassan KhalidNo ratings yet

- Non-Reinforced Liquid Coating Encapsulation Products For Leaded Paint in BuildingsDocument6 pagesNon-Reinforced Liquid Coating Encapsulation Products For Leaded Paint in BuildingsEric GozzerNo ratings yet

- KSR Kuebler Transparent Level Gauge Attc 5Document56 pagesKSR Kuebler Transparent Level Gauge Attc 5Hassan Sleem100% (1)

- Study On The Production of AACDocument8 pagesStudy On The Production of AACVignesh AyyathuraiNo ratings yet

- TPS65150 Low Input Voltage, Compact LCD Bias IC With VCOM BufferDocument48 pagesTPS65150 Low Input Voltage, Compact LCD Bias IC With VCOM BufferHamza Abbasi AbbasiNo ratings yet

- WeishauptDocument24 pagesWeishauptpatitay036817No ratings yet

- Three Axis TrailerDocument9 pagesThree Axis TrailerDeepak sutarNo ratings yet

- BBB8Document5 pagesBBB8abd alkaderNo ratings yet

- Fiber Optical CableDocument21 pagesFiber Optical CabletusharmhaNo ratings yet

- Scilution Autoclave TBT Bench TopDocument3 pagesScilution Autoclave TBT Bench TopSunisa MimpNo ratings yet

- Health Facility Planning and Healthcare Architecture Final PDFDocument48 pagesHealth Facility Planning and Healthcare Architecture Final PDFvovoNo ratings yet

- ProgramDocument18 pagesProgramRadu IuliaNo ratings yet

- Wall Ties PDFDocument12 pagesWall Ties PDFMarkEvansNo ratings yet

- Sl2012-552 Crankcase InspectionDocument4 pagesSl2012-552 Crankcase Inspectionargentum19619692100% (1)

- Motor Electrical FlutingDocument30 pagesMotor Electrical Fluting921157No ratings yet

- Kikeh CementDocument9 pagesKikeh CementHari Tharan100% (1)

- Cooper Surge Arrestors - 23587Document16 pagesCooper Surge Arrestors - 23587Matthew CooneyNo ratings yet

- Cat Automatics AC&RDocument32 pagesCat Automatics AC&RaguilavmNo ratings yet

- Nichrome Wire Power Supply DesignDocument4 pagesNichrome Wire Power Supply DesignxiaoboshiNo ratings yet

- PDFDocument3 pagesPDFSSSRGI TURNITINNo ratings yet

- BX 9000 enDocument209 pagesBX 9000 enThinh NguyenNo ratings yet

- Floor Systems guideEN PDFDocument96 pagesFloor Systems guideEN PDFkurtainNo ratings yet