Professional Documents

Culture Documents

Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.A

Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.A

Uploaded by

A. Βρατσιστα0 ratings0% found this document useful (0 votes)

26 views1 pageThis ultrasonic test report documents an inspection of welded I-sections intended for use in a bridge. The report provides details of the component, drawings, acceptance standards, test level, equipment and techniques used, and the results of the inspection. No defects were found in welds W1 or W2, so both passed acceptance criteria according to EN1712. The inspector certified the results.

Original Description:

Original Title

22

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis ultrasonic test report documents an inspection of welded I-sections intended for use in a bridge. The report provides details of the component, drawings, acceptance standards, test level, equipment and techniques used, and the results of the inspection. No defects were found in welds W1 or W2, so both passed acceptance criteria according to EN1712. The inspector certified the results.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

26 views1 pageUltrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.A

Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.A

Uploaded by

A. ΒρατσισταThis ultrasonic test report documents an inspection of welded I-sections intended for use in a bridge. The report provides details of the component, drawings, acceptance standards, test level, equipment and techniques used, and the results of the inspection. No defects were found in welds W1 or W2, so both passed acceptance criteria according to EN1712. The inspector certified the results.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

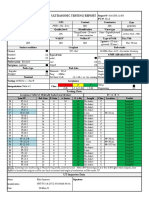

Χάλυβες Καραλή Α.Ε.Β.Ε.

ULTRASONIC TEST Έκδοση (Edition) : 01-08/2006

Karalis Steel S.A.

REPORT

Τμήμα Διαχείρησης Ποιότητας (IN CONFORMITY WITH REQUIREMENTS OF EN1714 TEST

Quality Management Dept. Σελίδα (Page) : 1 of 1

LEVEL B AND EN25817 /B)

project : BRIDGE T8 contract nr. : 240-EMEK

component : welded I-sections client : EGNATIA

system : 17-2/23 Manufacturer : KARALIS STEEL S.A.

drawing Nr. : attached REPORT NR. : 22-240/08 sheet 1 of 2

acceptance standard : EN 1712 date of examination/Site : 11-11-08/Larisa

work instruction : According to Table A2 EN1714 Thickness : see below

test level : B according to EN1714 welding process : Double V But-Weld

base metal : S355J2G3 Submerged Arc Welding (12),

MAG(135)

heat treatment : no

indication's recording : written description surface condition : machined :ground √

Ultrasonic Technique

instrument type: KARL DEUTSCH -ECHOGRAPH 1090 reference blocks : V1 ,DAC coupling medium : glutolin

A. 1 .straight beam √ 2. angled beam √ scanning position : pos.A, C, A2 EN 1714 coupling difference correction(Vt) : 2dB

B. 1 .contact √ 2.imersion - reference level of flaw : Φ3 DAC Amplification : 0o DAC+ 8dB, 60o DAC+ 14dB

Test Probes

1. KRAUT KRAMMER MSEB4 2. KARL DEUTSCH WK70 PB 4 3 KARL DEUTSCH WK60 PB 4

refraction angle(φ) : 0 Grad refraction angle(φ) : - refraction angle(φ) : 60 Grad

frequency(f) :4MHz frequency(f) : - frequency(f) :4MHz

DECISION

WELD DATA EXAMINATION FINDINGS ACCORDING TO EN1712

weld thickness welding serial defect distance defect defect nature of After Repair

number (mm) process number of from reference length depth defect

Acc Rej Remarks

defect point (mm) (mm) (mm) Acc Rej

W1 30 to 30 12+135 0 - - - -

√

W2 45 to 45 12+135 0 - - - -

√

#

#

LF: Lack of Fusion, GP: Gas pores, CR:crack, IN:Inclusions

INSPECTOR Third Party

A. VRATSISTA

LEVEL II UT

You might also like

- Solved Problems in Engineering Economy 2014 PDFDocument61 pagesSolved Problems in Engineering Economy 2014 PDFAngela Lapuz100% (1)

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Welding Questions PDFDocument42 pagesWelding Questions PDFA. ΒρατσισταNo ratings yet

- TWI ppt-WPE1-Course-Notes PDFDocument72 pagesTWI ppt-WPE1-Course-Notes PDFA. ΒρατσισταNo ratings yet

- En1011 7Document44 pagesEn1011 7A. ΒρατσισταNo ratings yet

- Business Analyst Interview QuestionsDocument11 pagesBusiness Analyst Interview QuestionsALI RIZWAN100% (2)

- Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.ADocument1 pageUltrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.AA. ΒρατσισταNo ratings yet

- PA UTR 2021 053 (Final)Document1 pagePA UTR 2021 053 (Final)Elias JarjouraNo ratings yet

- 1-UT-Pot Shell 588Document2 pages1-UT-Pot Shell 588Azhar GulzarNo ratings yet

- Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.ADocument1 pageUltrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.AA. ΒρατσισταNo ratings yet

- Ultrasonic Testing Report: Famsco - LebanonDocument1 pageUltrasonic Testing Report: Famsco - LebanonElias JarjouraNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

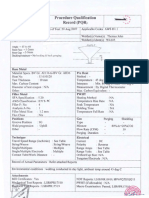

- Procedure Qualification Record (PQR) : 1-2mm 2-5mmDocument26 pagesProcedure Qualification Record (PQR) : 1-2mm 2-5mmDHANEESH VELLILAPULLINo ratings yet

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- Phased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateDocument1 pagePhased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateshervinyNo ratings yet

- HRP Ii WPS LGP 332Document4 pagesHRP Ii WPS LGP 332RohiNo ratings yet

- HRP Ii WPS STR 225Document4 pagesHRP Ii WPS STR 225RohiNo ratings yet

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- Je C 008 WPSDocument4 pagesJe C 008 WPScameron toolseeNo ratings yet

- 1LE1523-1DB29-0AF5-Z L22+L23+M2F+Q01+Y82 Datasheet enDocument1 page1LE1523-1DB29-0AF5-Z L22+L23+M2F+Q01+Y82 Datasheet enaminullahsharifNo ratings yet

- Solid Filter - DatasheetDocument1 pageSolid Filter - Datasheetbmanojkumar16No ratings yet

- WG-WPS-0099 Rev 2Document1 pageWG-WPS-0099 Rev 2mb.pipingNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Aluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Document1 pageAluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Amin ThabetNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- 03 WPS PQR For FCAWDocument3 pages03 WPS PQR For FCAWBrijesh Yadav100% (1)

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Pqr-Band Ring PDFDocument3 pagesPqr-Band Ring PDFamitNo ratings yet

- PQR FC-12-22Document2 pagesPQR FC-12-22cycsi02No ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Toaz - Info Wps PQR Saw PRDocument6 pagesToaz - Info Wps PQR Saw PRMustafaNo ratings yet

- Eqt RecordDocument41 pagesEqt RecordShaikh sohilNo ratings yet

- Lamination Test ReportDocument1 pageLamination Test Reportسعید اینانلوNo ratings yet

- Ultrasonic Inspection Report: REPORT NO.-UT-HB-1003723Document1 pageUltrasonic Inspection Report: REPORT NO.-UT-HB-1003723Ahmed GomaaNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- RK PWPS PC 001Document2 pagesRK PWPS PC 001SudeepDPoojaryNo ratings yet

- Je C 006 WPSDocument4 pagesJe C 006 WPScameron toolseeNo ratings yet

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- Panel Under Test: ( D08) - GT-3: Record No.: Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoDocument2 pagesPanel Under Test: ( D08) - GT-3: Record No.: Drawing Ref.: Sheet: Contractor: Contract No.: Substation NoShijumon KpNo ratings yet

- 1MB1511-1BB29-0AA4-Z M1Y+Q02+Y54 Datasheet enDocument1 page1MB1511-1BB29-0AA4-Z M1Y+Q02+Y54 Datasheet enJoe GrosirNo ratings yet

- HRP Ii WPS STR 209aDocument4 pagesHRP Ii WPS STR 209aRohiNo ratings yet

- H02 Duobias Relay Report 87TDocument4 pagesH02 Duobias Relay Report 87TKalimuthuNo ratings yet

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- PWPS 102Document2 pagesPWPS 102Cyril J PadiyathNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewDocument4 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04-NewBIIS QAQC Babu SivaNo ratings yet

- China Civil Engineering Construction Corperation: Repair Welding Procedure Qualification-Manual Metal ArcDocument1 pageChina Civil Engineering Construction Corperation: Repair Welding Procedure Qualification-Manual Metal ArcMakamu Max Las MokgaoganyiNo ratings yet

- D1xB2x05 - Xenon Strobe 5 J - E2SDocument2 pagesD1xB2x05 - Xenon Strobe 5 J - E2SAntonio Chuman MedinaNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument2 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Document2 pagesWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, MoDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 122, - , - : Pressure Vessel Plate, Low Alloy Steel, Mobaskaran ayyapparajNo ratings yet

- DS 4013 Rev-0Document4 pagesDS 4013 Rev-0Dinesh RajNo ratings yet

- PQR FC-19-23Document2 pagesPQR FC-19-23cycsi02No ratings yet

- PQR FC-19-23.1Document2 pagesPQR FC-19-23.1cycsi02No ratings yet

- 1LE1503-2DB09-0AJ4-Z E52+M1Y Datasheet enDocument1 page1LE1503-2DB09-0AJ4-Z E52+M1Y Datasheet enopplusNo ratings yet

- WPS SertipDocument3 pagesWPS SertipMassimo FumarolaNo ratings yet

- Ut 02Document1 pageUt 02Omar S. AliNo ratings yet

- Electromagnetic Compatibility (EMC) Design and Test Case AnalysisFrom EverandElectromagnetic Compatibility (EMC) Design and Test Case AnalysisNo ratings yet

- SHC 200x8 S235 JRH LegsDocument1 pageSHC 200x8 S235 JRH LegsA. ΒρατσισταNo ratings yet

- hot rolled Φ60 AISI 304L (14.230)Document3 pageshot rolled Φ60 AISI 304L (14.230)A. ΒρατσισταNo ratings yet

- Welder CertificateDocument6 pagesWelder CertificateA. ΒρατσισταNo ratings yet

- WPS SumDocument61 pagesWPS SumA. ΒρατσισταNo ratings yet

- Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.ADocument1 pageUltrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.AA. ΒρατσισταNo ratings yet

- Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.ADocument1 pageUltrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.AA. ΒρατσισταNo ratings yet

- ,E/'IAS: Welder Approval Test CertilicateDocument1 page,E/'IAS: Welder Approval Test CertilicateA. ΒρατσισταNo ratings yet

- Α/Α Cet d HD Q Tp (oC)Document1 pageΑ/Α Cet d HD Q Tp (oC)A. ΒρατσισταNo ratings yet

- 121 T BW FPDocument4 pages121 T BW FPA. ΒρατσισταNo ratings yet

- Water Pull 0ff PDFDocument83 pagesWater Pull 0ff PDFA. ΒρατσισταNo ratings yet

- Präpositions - Time: English Usage ExampleDocument3 pagesPräpositions - Time: English Usage ExampleA. ΒρατσισταNo ratings yet

- Infinitive As The Subject of A Clause (Followed by The Verbs Below)Document1 pageInfinitive As The Subject of A Clause (Followed by The Verbs Below)A. ΒρατσισταNo ratings yet

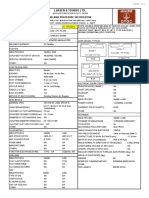

- T.C.L. Co. - Test & Control LaboratoriesDocument2 pagesT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταNo ratings yet

- Lrtec: Ek9Eih Epraithpiakcn AokimcnDocument2 pagesLrtec: Ek9Eih Epraithpiakcn AokimcnA. ΒρατσισταNo ratings yet

- Ipc2022-87090 Modification of Existing Pipeline Corrosion Assessment Methods ForDocument9 pagesIpc2022-87090 Modification of Existing Pipeline Corrosion Assessment Methods ForOswaldo MontenegroNo ratings yet

- 2ndSEM2021MMW W1PPT1Document55 pages2ndSEM2021MMW W1PPT1Glenn EscañanNo ratings yet

- GeopolymerDocument20 pagesGeopolymerAhmed TahaNo ratings yet

- 2023 TJPhO v1Document11 pages2023 TJPhO v1Phúc NguyễnNo ratings yet

- Possibility of The Use Polish Soda Lime As The Absorbent in The Canisters of The Oxygen Breathing Apparatus Type Oxy-NGDocument11 pagesPossibility of The Use Polish Soda Lime As The Absorbent in The Canisters of The Oxygen Breathing Apparatus Type Oxy-NGindiomajaderoNo ratings yet

- Pic16f84a PDFDocument88 pagesPic16f84a PDFBenjamin Michael LandisNo ratings yet

- Liebherr Product Advantage Mobile Crane 210 LTM 1200-5-1 PN 210 00 E02 2014Document18 pagesLiebherr Product Advantage Mobile Crane 210 LTM 1200-5-1 PN 210 00 E02 2014RosauroRoldanNo ratings yet

- Tutorial Fpga Spartan-3eDocument53 pagesTutorial Fpga Spartan-3eCarlos Muñoz BacaNo ratings yet

- Linear Algebra Done WrongDocument231 pagesLinear Algebra Done WrongS NandaNo ratings yet

- Full Paper IMPACT OF TEAMWORK ON ORGANIZATIONAL PRODUCTIVITY IN SOME SELECTED BASIC SCHOOLSDocument13 pagesFull Paper IMPACT OF TEAMWORK ON ORGANIZATIONAL PRODUCTIVITY IN SOME SELECTED BASIC SCHOOLSPrasad SirsangiNo ratings yet

- Climax and Structure in OdysseyDocument6 pagesClimax and Structure in Odysseygratielageorgianastoica0% (1)

- C Part 1 - CodemithraDocument28 pagesC Part 1 - CodemithraAnirudh GowdaNo ratings yet

- Sanyo ICs STKs PDFDocument117 pagesSanyo ICs STKs PDFFreddy Monge BarbaranNo ratings yet

- SPC Pulsar NS 200 BS IV - AS200 (2018 07 24)Document105 pagesSPC Pulsar NS 200 BS IV - AS200 (2018 07 24)Willy Mansilla ANo ratings yet

- Advanced Java - Exceptions, Annotations, Basics of ReflectionsDocument13 pagesAdvanced Java - Exceptions, Annotations, Basics of ReflectionsIoan PopescuNo ratings yet

- Introduction To Discrete StructuresDocument52 pagesIntroduction To Discrete StructuresfarwaNo ratings yet

- Updated NewDocument73 pagesUpdated NewAbhishek GaurNo ratings yet

- CMS V1.4Document82 pagesCMS V1.4ShtomaNo ratings yet

- Object-Oriented and Event-Driven Programming: Prelude To Programming, 6Th Edition by Elizabeth DrakeDocument43 pagesObject-Oriented and Event-Driven Programming: Prelude To Programming, 6Th Edition by Elizabeth DrakeSadieNo ratings yet

- Ch12 - Peter NolanDocument22 pagesCh12 - Peter Nolanjohnb2bNo ratings yet

- FlywheelDocument10 pagesFlywheelKasam SantoshrishiNo ratings yet

- Python Data Science HandbookDocument7 pagesPython Data Science Handbookhassaanahmed.idcNo ratings yet

- COMPOSING - Creating Orchestral Music With Sampled InstrumentsDocument8 pagesCOMPOSING - Creating Orchestral Music With Sampled InstrumentsEstudio Arte100% (1)

- Msunit 2 GraspsDocument6 pagesMsunit 2 Graspsapi-338845804No ratings yet

- Mooring of Ships - Forces (Document168 pagesMooring of Ships - Forces (shakirhamid6687100% (5)

- D - and F-Block - Eklavya (Q)Document10 pagesD - and F-Block - Eklavya (Q)Dhruv KuchhalNo ratings yet

- Load Characterstics of DC Shunt GeneratorDocument2 pagesLoad Characterstics of DC Shunt Generatorravi12rNo ratings yet

- Die Casting: From Wikipedia, The Free EncyclopediaDocument6 pagesDie Casting: From Wikipedia, The Free EncyclopediagodseNo ratings yet