Professional Documents

Culture Documents

Mukesh Kumar Parida: Contact: +91-8895821887, +91-7008824504, +91-8895704585

Mukesh Kumar Parida: Contact: +91-8895821887, +91-7008824504, +91-8895704585

Uploaded by

SurajPandeyCopyright:

Available Formats

You might also like

- Application of CalculusDocument7 pagesApplication of CalculusNoramira Ahmad Tajuddin88% (16)

- Sample FFS-Final ReportDocument22 pagesSample FFS-Final ReportSuparerk Sirivedin100% (4)

- National IndustriesDocument10 pagesNational IndustriesKishan makvanaNo ratings yet

- AdaniDocument95 pagesAdanirajput_chetan2904No ratings yet

- Special Power of AttorneyDocument2 pagesSpecial Power of AttorneyMelford Lapnawan88% (8)

- Field Joints Coating Offer-DemechDocument4 pagesField Joints Coating Offer-DemechVineet KhanduriNo ratings yet

- Essar Steel India Limited: Work OrderDocument4 pagesEssar Steel India Limited: Work OrderMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Steel FoundriesDocument2 pagesSteel Foundriesmahesh30032No ratings yet

- Booster Pump Quotation SPQ16-000169 PDFDocument4 pagesBooster Pump Quotation SPQ16-000169 PDFAdil Aziz0% (1)

- JaiRaj AncillariesDocument8 pagesJaiRaj Ancillariestajju_121No ratings yet

- Prospectus AICTE Approved ProgramesDocument34 pagesProspectus AICTE Approved ProgramesArunpandimurugan MVNo ratings yet

- Major Industrial UnitsDocument2 pagesMajor Industrial Unitsrahulgaurav72No ratings yet

- Circular On Office Timings and Work ScheduleDocument1 pageCircular On Office Timings and Work ScheduleSaad MasoodNo ratings yet

- PAD List 2022 23 As On 27 01 2023Document31 pagesPAD List 2022 23 As On 27 01 2023N SriramanNo ratings yet

- ISO CertificateDocument1 pageISO CertificateManash Protim GogoiNo ratings yet

- AMC Work OrderDocument2 pagesAMC Work OrderRahul PatelNo ratings yet

- PO - Tempsens InstrumentsDocument12 pagesPO - Tempsens InstrumentspernetiNo ratings yet

- Sr. No. Developer Name of Project Sector State Unit No Unit Capacity Date of Commissi Oning FGD Phasing Plan (DD/MM/Y FGD StatusDocument13 pagesSr. No. Developer Name of Project Sector State Unit No Unit Capacity Date of Commissi Oning FGD Phasing Plan (DD/MM/Y FGD StatusKoushik DeyNo ratings yet

- UntitledDocument2 pagesUntitledTulsi TandiNo ratings yet

- Quotation 1Document37 pagesQuotation 1Nikhil SutharNo ratings yet

- Location Wise FGD Projects in IndiaDocument16 pagesLocation Wise FGD Projects in IndiaVibhas KumarNo ratings yet

- Monoblock & Suction Pump SNB-SNK-CatalogDocument28 pagesMonoblock & Suction Pump SNB-SNK-Catalogbagus saputraNo ratings yet

- Fly Ash Brick PDFDocument8 pagesFly Ash Brick PDFmalaya tripathyNo ratings yet

- 07092014125520IMYB - 2012 - Iron OreDocument35 pages07092014125520IMYB - 2012 - Iron OreRahul MishraNo ratings yet

- Ludhiana Forging IndustriesDocument16 pagesLudhiana Forging IndustriesSourindra Mohan PandaNo ratings yet

- DI Pipe Manufacturer ListDocument11 pagesDI Pipe Manufacturer ListsmithNo ratings yet

- Reliable Sponge PVT Ltd-Unit-IIIDocument19 pagesReliable Sponge PVT Ltd-Unit-IIIReliableIndiaNo ratings yet

- A 153Document1 pageA 153AnuranjanNo ratings yet

- Reference List PDFDocument11 pagesReference List PDFAshok MallickNo ratings yet

- Present Professional ExperienceDocument3 pagesPresent Professional Experiencerahul srivastavaNo ratings yet

- Panoli IndDocument9 pagesPanoli Indanon_981731217No ratings yet

- QTN For 60 HP MachineDocument4 pagesQTN For 60 HP Machineheavenrocks upadhyayNo ratings yet

- 0002432194Document8 pages0002432194atripathi2009No ratings yet

- Verification Form VNGDocument6 pagesVerification Form VNGdibyanshu.goswamiNo ratings yet

- Customermanagementlist - SachinDocument4 pagesCustomermanagementlist - SachinSaurabh JainNo ratings yet

- IEQ Material DetailsDocument35 pagesIEQ Material DetailsDevendraNo ratings yet

- Varanasi Marketing Client ListDocument6 pagesVaranasi Marketing Client ListSwapnil VichareNo ratings yet

- Resume: Professional ExperienceDocument3 pagesResume: Professional ExperienceShankker KumarNo ratings yet

- Coal WasheryDocument2 pagesCoal Washerynitunagrawal100% (1)

- List Scs SadcDocument3 pagesList Scs SadcMukesh JainNo ratings yet

- 12 Integrated SteelDocument16 pages12 Integrated SteelKushagra JadhavNo ratings yet

- List of Sugar FactoriesDocument4 pagesList of Sugar FactoriesSuresh KumarNo ratings yet

- State Wise Cement IndustriesDocument12 pagesState Wise Cement IndustriesSharon SusmithaNo ratings yet

- Faculty List NIT DurgapurDocument18 pagesFaculty List NIT DurgapurAnkan RakshitNo ratings yet

- PrescriptionDocument2 pagesPrescriptionMurali KrishnaNo ratings yet

- Sugars Industries in KarnatakaDocument4 pagesSugars Industries in Karnatakadesaivilas60No ratings yet

- Introduction Letter - 3.4.21Document2 pagesIntroduction Letter - 3.4.21Gunjan PatelNo ratings yet

- New Resume SunilDocument5 pagesNew Resume SunilAnish Kumar DhirajNo ratings yet

- Senco GoldDocument1 pageSenco Goldtabu 1No ratings yet

- List of Power Stations in IndiaDocument11 pagesList of Power Stations in IndiaRushikeshKatkar0% (1)

- Email Contacts For Steel Company in IndiaDocument3 pagesEmail Contacts For Steel Company in IndiaTENDER AWADH GROUPNo ratings yet

- Hemco Engineering Private Limited PDFDocument4 pagesHemco Engineering Private Limited PDFakarshverma01No ratings yet

- EagleBurgmann - E110801 - E1 - High-Pressure Seals For ESPO Pipeline Pumps - 10.11 PDFDocument2 pagesEagleBurgmann - E110801 - E1 - High-Pressure Seals For ESPO Pipeline Pumps - 10.11 PDFkztro066No ratings yet

- Gear Technology India 2013 # 4 PDFDocument68 pagesGear Technology India 2013 # 4 PDFUday Sankar Sarma YerramilliNo ratings yet

- Mon Finlqaqce. 3Document4 pagesMon Finlqaqce. 3ulocksystemNo ratings yet

- List of Refineries & Petroleum / LPG Projects: Year Name of Project ClientDocument5 pagesList of Refineries & Petroleum / LPG Projects: Year Name of Project ClientSach KanhuNo ratings yet

- Kiswok Pipe Layout AdDocument1 pageKiswok Pipe Layout AdaroonkumaarvNo ratings yet

- Prosintech CatalogDocument6 pagesProsintech CatalogDeepak PatelNo ratings yet

- Ranchi Is The Capital of The Indian State of JharkhandDocument30 pagesRanchi Is The Capital of The Indian State of Jharkhandgurjit20No ratings yet

- PVC Pipe, Hdpe Pipe ManufacuringDocument10 pagesPVC Pipe, Hdpe Pipe ManufacuringPriyanshu ChokhaniNo ratings yet

- CustomerDocument9 pagesCustomerLokesh Reddy100% (1)

- Current List of Coal PowerPlants IndiaDocument6 pagesCurrent List of Coal PowerPlants IndiaAmit SarkarNo ratings yet

- CV - Arpit Rotary EngineerDocument3 pagesCV - Arpit Rotary Engineerarpit patelNo ratings yet

- Jonell: JVF Series Activated Carbon CanistersDocument2 pagesJonell: JVF Series Activated Carbon CanistersSurajPandeyNo ratings yet

- Volvo CE Vehicle CardDocument21 pagesVolvo CE Vehicle CardSurajPandeyNo ratings yet

- Sor 71Document3 pagesSor 71SurajPandeyNo ratings yet

- Ionian Sea FosDocument2 pagesIonian Sea FosSurajPandeyNo ratings yet

- Renewable Energy Sector in India: Chapter - IDocument9 pagesRenewable Energy Sector in India: Chapter - ISurajPandeyNo ratings yet

- Product Catalogue Price List: With New Generation Filter & Cabin FiltersDocument20 pagesProduct Catalogue Price List: With New Generation Filter & Cabin FiltersSurajPandeyNo ratings yet

- Unearthing Treasures: Safety Reliability SustainabilityDocument6 pagesUnearthing Treasures: Safety Reliability SustainabilitySurajPandey100% (1)

- Shelf Drilling Galveston Key Spec Sheet May 2015Document2 pagesShelf Drilling Galveston Key Spec Sheet May 2015SurajPandeyNo ratings yet

- Simplex Infrastructures LTD List of Equipment Available For HireDocument1 pageSimplex Infrastructures LTD List of Equipment Available For HireSurajPandeyNo ratings yet

- Minewise Return SubmissionDocument1,245 pagesMinewise Return SubmissionSurajPandeyNo ratings yet

- Production, Evacuation and Sale of Iron OreDocument38 pagesProduction, Evacuation and Sale of Iron OreSurajPandeyNo ratings yet

- Vadodara ZoneDocument30 pagesVadodara ZoneSurajPandeyNo ratings yet

- Check Out Our Recently Introduced Fleetguard Products: September 2012Document6 pagesCheck Out Our Recently Introduced Fleetguard Products: September 2012SurajPandeyNo ratings yet

- Statewise Mineral Wise ROM Mineral ProductionDocument396 pagesStatewise Mineral Wise ROM Mineral ProductionSurajPandeyNo ratings yet

- Dee Vee Projects Raipur Chhattisgarh IndiaDocument2 pagesDee Vee Projects Raipur Chhattisgarh IndiaSurajPandeyNo ratings yet

- Spare Part DevelopmentDocument10 pagesSpare Part DevelopmentSurajPandeyNo ratings yet

- Offshore Brochure CranesDocument91 pagesOffshore Brochure CranesSurajPandeyNo ratings yet

- Nishant Choubey GMR PurchaseDocument1 pageNishant Choubey GMR PurchaseSurajPandeyNo ratings yet

- List of Coal Mines Earmarked For 6 Tranche of AllotmentDocument1 pageList of Coal Mines Earmarked For 6 Tranche of AllotmentSurajPandeyNo ratings yet

- MB10453 1Document3 pagesMB10453 1SurajPandeyNo ratings yet

- Mahle Air Filter (Primary) For HM GM Terex: Industrial FiltrationDocument3 pagesMahle Air Filter (Primary) For HM GM Terex: Industrial FiltrationSurajPandeyNo ratings yet

- Anjesh Kumar Hindalco Mahan CPP MechDocument2 pagesAnjesh Kumar Hindalco Mahan CPP MechSurajPandeyNo ratings yet

- ACB (India) LimitedDocument2 pagesACB (India) LimitedSurajPandeyNo ratings yet

- Mahle Air Filter Clearner Assy For ELGIDocument7 pagesMahle Air Filter Clearner Assy For ELGISurajPandey0% (1)

- Pre Notes 6th Semcode CH 604Document42 pagesPre Notes 6th Semcode CH 604SurajPandeyNo ratings yet

- Mahle Air Filter (Primary) For Ashok Leyland: Industrial FiltrationDocument3 pagesMahle Air Filter (Primary) For Ashok Leyland: Industrial FiltrationSurajPandey100% (1)

- List of Nodal Officers For Msme Outreach ProgramDocument3 pagesList of Nodal Officers For Msme Outreach ProgramSurajPandeyNo ratings yet

- Mahle Air Filter (Primary) For Tata - HitachiDocument9 pagesMahle Air Filter (Primary) For Tata - HitachiSurajPandeyNo ratings yet

- Preferences Environment Variables Reference PLM TeamcenterDocument1,157 pagesPreferences Environment Variables Reference PLM TeamcenterBHUVANA SATEESHNo ratings yet

- Aritificial Vision YOLOV2 Part2Document9 pagesAritificial Vision YOLOV2 Part2David BenavidesNo ratings yet

- Bla BlaDocument8 pagesBla BladharwinNo ratings yet

- Inductive Lesson PlanDocument3 pagesInductive Lesson PlanLeah Jane Pelayo-Ibarrat67% (3)

- Yom Ha'atzmaut Missing Letters: Fill in The Missing Letters To Complete The WordsDocument34 pagesYom Ha'atzmaut Missing Letters: Fill in The Missing Letters To Complete The WordsRachel MalagaNo ratings yet

- Proposal Nanotechnology in GeotechnicsDocument4 pagesProposal Nanotechnology in GeotechnicsMOHAMED DiriyeNo ratings yet

- RESPIRATION IN PLANTS DPP by Seep PahujaDocument4 pagesRESPIRATION IN PLANTS DPP by Seep Pahujamaheshgutam8756No ratings yet

- College of Agriculture Department of Value Chain Management Name: Ermiyas Bogale Abera ID No: 0757/12Document10 pagesCollege of Agriculture Department of Value Chain Management Name: Ermiyas Bogale Abera ID No: 0757/12Ermiyas BogaleNo ratings yet

- Rudaga - Regulations - 2021Document7 pagesRudaga - Regulations - 2021sidharthNo ratings yet

- Deliverable 5 - Trend Analysis & PresentationDocument6 pagesDeliverable 5 - Trend Analysis & PresentationRamizNo ratings yet

- Lecture 14 - Housing For All Mission (PMAY) & Technology Sub-MissionDocument15 pagesLecture 14 - Housing For All Mission (PMAY) & Technology Sub-MissionRadhika KhandelwalNo ratings yet

- EL - 124 Electronic Devices & Circuits: Experiment # 04Document6 pagesEL - 124 Electronic Devices & Circuits: Experiment # 04Jawwad IqbalNo ratings yet

- Daily Coal Inventory 211220 PDFDocument1 pageDaily Coal Inventory 211220 PDFDedi SetyawanNo ratings yet

- 5G TransportDocument42 pages5G TransportDaniel Cafu100% (1)

- Innovation ReadingsDocument9 pagesInnovation Readingsafca32No ratings yet

- ReadingDocument2 pagesReadingLucíaNo ratings yet

- CV-Mushtaque AliDocument8 pagesCV-Mushtaque AliAnonymous sIQv5MDCzNo ratings yet

- Electrical Engineering Sem-2 All Question BankDocument2,178 pagesElectrical Engineering Sem-2 All Question BankGAURAV GUPTANo ratings yet

- Astm A307Document6 pagesAstm A307thakrarhits100% (3)

- 2fy2-01 Engineering Mathematics-I (A To D)Document3 pages2fy2-01 Engineering Mathematics-I (A To D)gwanfldlwjwuwNo ratings yet

- Business Objectives and Stakeholder ObjectivesDocument28 pagesBusiness Objectives and Stakeholder ObjectivesThin Zar Tin WinNo ratings yet

- Brad J Hornberger Cystoscopy Indications and Preparation. UAPA CME Conference 2012 (30 Min)Document36 pagesBrad J Hornberger Cystoscopy Indications and Preparation. UAPA CME Conference 2012 (30 Min)Cristian OrozcoNo ratings yet

- Sepco Online BilllDocument1 pageSepco Online Billlshaikh_piscesNo ratings yet

- Multiple Choice Practice Questions/Answer For Online/Omr AITT-2020 2 Year Electronics Mech. Trade TheoryDocument66 pagesMultiple Choice Practice Questions/Answer For Online/Omr AITT-2020 2 Year Electronics Mech. Trade TheoryAbcNo ratings yet

- The Food Supply Chain of India The EcosystemDocument6 pagesThe Food Supply Chain of India The EcosystemMoksh SharmaNo ratings yet

- Sheetmetal ProcessDocument88 pagesSheetmetal ProcessEre Gowda100% (1)

- APUSH Inside-Outside-Inside Discussion InstructionsDocument2 pagesAPUSH Inside-Outside-Inside Discussion InstructionscrolwesNo ratings yet

Mukesh Kumar Parida: Contact: +91-8895821887, +91-7008824504, +91-8895704585

Mukesh Kumar Parida: Contact: +91-8895821887, +91-7008824504, +91-8895704585

Uploaded by

SurajPandeyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mukesh Kumar Parida: Contact: +91-8895821887, +91-7008824504, +91-8895704585

Mukesh Kumar Parida: Contact: +91-8895821887, +91-7008824504, +91-8895704585

Uploaded by

SurajPandeyCopyright:

Available Formats

MUKESH KUMAR PARIDA

Plot No. 447/2167, Shree Vihar, P.O.- Patia GDS, P.S.- Chandrasekharpur, Bhubaneswar-751031(Orissa)

Contact: +91-8895821887, +91-7008824504, +91-8895704585; E-mail: mukesh.parida1982@gmail.com

<Date> 24/12/2020

<Name> MUKESH KUMAR PARIDA

<Designation> ASST.MANAGER

<Company Name> BHUSHAN POWER & STEEL LTD

< Present Address> PO-THELKOLOI, DIST- SAMBALPUR

<City, State> ORISSA

With reference to your Advertisement undersigned present myself as an important incumbent for the

same.

I am submitting to express my keen interest in the position of DEPUTY MANAGER in your company.

My resume is enclosed for your review and consideration. To describe myself in a nutshell, I am

hardworking; ready to take up any challenge of life abreast with the latest trends and a team player

with excellent communication skills.

My basic objective is to hone in my skills for comprehensive personality development and be an

epitome of trust and reliability in the corporate world. My prime goal is to understand professional

environment and capitalize on opportunities.

Professionally I am a Mechanical Engineer with an experience of 16+ years across Mechanical

Maintenance & Technical Troubleshooting; currently spearheading as ASST.MANAGER with Bhushan

power & steel Ltd.

Having experience of carrying out maintenance of all mechanical units of operation & maintenance of

D.R.I. Plant & Rotary Kilns 500 TPD, 350 TPD, 100TPD, conducted operation and maintenance of rotary

feeder {coal injector}, single stage radial flow, horizontal multistage centrifugal pumps, vertical

turbine pumps in utility, lobe compressor, screw compressor, ESP- Project and Construction (THERMAX

MAKE) & also operation & Maintenance of SILO systems for ash handling in ESP. Having well experience

in the field of coal handling plant and Raw material section ( Iron and Coal )have hands on experience

of different types of coal crusher, iron ore crushers, vibrating & circle-throw vibrating screens, Flip

flow screen and conveyor systems, vibratory feeders, grizzly feeders etc.

A hard working, creative & talented individual, with key competencies in:

Mechanical Engineering 🟂 Plant Operation / Maintenance 🟂 Breakdown Solutions 🟂 Manufacturing &

Process Engineering 🟂 Strategic Planning 🟂 Material Management 🟂 Cross Functional Coordination 🟂

Productivity Enhancement 🟂 Team Management 🟂 Project Planning & Execution 🟂 Quality Initiatives 🟂

Safety 🟂

I am a hard working & talented individual, seeking a challenging job that would synergize my skills

and knowledge with the objectives of the organization. A responsible, reliable and committed worker,

I will give my best both as a part of a team and working independently.

The above credentials along with my enclosed resume make me ideally suitable for a position in your

organization. I would appreciate an opportunity for a personal interview.

Thanking you,

Yours sincerely

MUKESH KUMAR PARIDA

MUKESH KUMAR PARIDA

Mobile: +91 8895821887/ +91 7008824504/ RES: +91 8895704585

E-Mail: mukesh.parida1982@gmail.com

Seeking for a managerial position for a dynamic and challenging career in the field of Mechanical Engineering, in a

growth oriented organization

Professional Synopsis

● An astute professional with over 16+ years of experience in

1. Mechanical Engineering

Mechanical Maintenance & Technical, Troubleshooting.

2. Plant Operation / Maintenance ● Currently linked with Bhushan power & steel LTD as an

Assistant Manager.

3. Breakdown Solutions ● Experience of carrying out maintenance & operations of all

4. Manufacturing & Process mechanical units of the D.R.I Plant & Rotary Kilns 500 TPD, 350

TPD. Operation and maintenance of coal rotary feeder, single

Engineering stage radial flow, multistage centrifugal pumps, Vertical pumps,

5. Strategic Planning Lobecompressor,Wetscrapper,Screw-compressor,Drum-

magnetic-separator etc. Worked with industrial centrifugal

6. Material Management fans for heavy duty and industrial duty.

● Proficient in operation & maintenance of coal handling plant

7. Cross Functional Coordination

and have hands on experience of different types of coal crusher

8. Productivity Enhancement iron ore crusher(Jaw crusher & cone crusher),&circle-throw

vibrating screens conveyor systems & vibrating feeders.

9. Team Management ● Coal Handling Plant (CHP) 800 TPH, Operation & Maintenance.

10. Project Planning & Execution ● Dealing with various types of hydraulic equipment’s

(Pneumatic cylinders,powerpacks,solenoid valves,cylinders).

11. Quality Initiatives ● Experience of both Instrumentation & Compressed airline-

12. Safety equipment’s.

Good knowledge of IS & International standards related to

welding material, quality, advance welding technology and

horizontal centrifugal split case Pumps erection & commissioning.

● ESP- Project, operation & maintenance (THERMAX MAKE).

● Operation & maintenance of FD & ID Fans.

Professional Forte

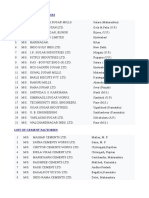

Sl. name & Post held Duration of Total year of Type of assignment

No. address of Experience Months of handled/specific nature of

organization (DD/MM/YY) Experience work/duty

worked To Performed

From

1. Bhushan power & steel ASST. 04/07/11 till 9 YEARS DRI (O&M)

ltd Manager 6 months

Sambalpur Odisha

2. Sree metallics ltd, Barbil ASST. Engineer 07/04/07 28/06/11 4 year DRI {O&M]&CHP[O&M]

Odisha 2 months

3. Rungta mines ltd, Barbil JR. Engineer 26/02/06 01/04/07 1 year DRI[O&M]&RAW MATERIAL DIV. (IRON

Odisha 1 month & COAL)[O&M]

4. Deepak steel & power, Shift-In-charge 10/01/05 05/02/06 1 year RAW MATERIAL DIV. & D.R.I MAINT.

Barbil Odisha

5. Sri Ganesh sponge iron Asst. shift-In- 02/12/03 05/01/05 1 year E.S.P PROJECT & COMISSIONING OF

Pvt. Ltd. Joda, Odisha charge 1 month D.R.I

TOTAL EXPERIENCE 16+ years

Responsibilities:

● Handling 2x500 TPD Rotary Kiln General Maintenances and complete shutdown maintenances since 4th July

2011.

● Handled Supervision and Maintenance of all mechanical units of the D.R.I. Plant 350 TPD Rotary Kiln General

Maintenances and complete shutdown maintenances including raw material section from 2007 April to 2011

June.

● Handling Operation & maintenance of Automatic lubrication systems or centralized lubrication systems

(Lincoln make lubrication systems and also pneumatic lubrication systems in D.R.I 2X500 TPD Kiln.

● Handled Supervision and Maintenance of all mechanical units of the D.R.I. Plant 6x100 TPD Rotary Kiln

General Maintenances and complete shutdown maintenances including raw material section

● Operation & maintenance of SILO systems for ash handling 2X500 TPD KILN (D.R.I) ESP.

● Also handling cold &hot ESP operation & maintenance for dedusting system in2x500 TPD DRI.

● Scheduling and carrying out mechanical maintenance, breakdown maintenance and handle the spare parts

management and accountable for installation & commissioning of in-house and local new machines and

design and development of machine parts.

● Having experience of Coal Handling Plant (Raw Material Process plant) of capacity up to 800 TPH for power

plant (500MW), &500X10 TPD DRI plant etc. & various types of coal crushers such as Double roll, D-Roll, coal

impactors, vibratory feeders, grizzly feeders, conveyer systems, vibrating screens& inclined circular motion

screens, Step deck vibrating screens, Flip Flop screens etc.

● Conveyer system, Crushing system ,Screening system, Feeding system, Magnetic separator/metal detector

system ,Bin/chute vibratory system, Coal sampling ,FIRE FIGHTING SYSTEM, Dust suppression system, Dust

extraction system etc.

● Responsibility of Monitoring PLC controlling, maintenance of USK & VSK Vibrating Screen, Double

Roll Crusher, Vibrating feeder, Shuttle conveyor, Belt Conveyor and its related equipment’s, Flip

flow screen.

● Worked with 50-400 TPH capacities of one to multi deck vibrating screens, inclined circular motion screens of

Moktali, Sayagi , Sanraj & IC make, FLIP FLOP SCREENS 2X100 TPH capacity make I.C,STEP DECK vibrating

screens, Worked with 50-200 TPH capacity of coal impactor of Hari machine and 100-200 TPH capacity of

double roll crusher primary & secondary (coal) of Moktali &Humble wedge make, D- roll crushers ,vibratory

ground feeders, and conveyor systems in raw material section.

● Carrying out 100 TPH primary jaw and cone (Taurion make mobile) crusher for maintenance ace and

replacement of spare parts. And also engage in 250-300 TPH cone and Jaw crusher ,(Metso make HP 200 cone

crusher) for maintenance ace and replacement of spare parts in iron ore crushing unit. .

● Handled general Maintenances and all shutdown maintenances of 100 X 6 TPD Rotary Kilns& Raw material

section.

● In product section, worked with magnetic concentrator of 25-100 TPH capacity of electro Zavod make, drum

magnetic separator of 05-150TPH capacity and one to multi deck vibrating screens, & circle-throw vibrating

screens etc.

● Operation and maintenance of E.S.P (Thermax make) 2X 500TPD WITH ID FANS, and also 350 TPD.

● Worked with Offline & online bag filters Thermax make (size- 6X10, 8X10, 9X10, 11X10 <20X10) and air volume

of 7900, 10500, 11000, 13500, 14300, 24200, off line - 350000m3/hr. (fan capacity).

● Experience of working with industrial centrifugal fans for heavy duty and industrial duty.

● Operation and maintenance of pneumatic ash handling & SILO systems (Bevocn wayors make) Ash Handling

for ESP.

● Operation & maintenance of Bucket elevator systems or Grain leg systems.

● Cooling tower operation & maintenance of both crossflow &counter flow types.

● Operation & maintenance of single stage radial flow & also multistage centrifugal pumps, Vertical pumps axial

flow, etc.

● Operation & maintenance of ID Fans, FD Fans, SAF fans, CB fans etc. Worked with Industrial centrifugal fans

for heavy duty and Industrial duty.

● Identifying root cause of failures and implemented quick breakdown solutions to put the machines back in

operation within minimum turnaround time.

● Preparing & implementing yearly preventive maintenance schedule and condition monitoring system to

minimize the breakdown and forced shutdown.

● Reporting of daily COB MIS to higher management as well as in SAP.

Achievements:

● Commissioning, operation and maintenance of 2 X 500 TPD D.R.I & plant and site work monitoring.

● Making the projects cost-effective by lowering the cost of the products, as well as machine installation cost

and handling the procurement of materials.

● Providing support planning cell to prepare the detailed project plan for the assigned project; coordinate with

other departments and vendors of four key packages and ESP.

● Organizing, monitoring and reviewing the progress of project against the baseline plan and timely submit the

progress project progress report.

● Alerting project manager and other functional head about deviation from plan and commitment made to the

customer and get corrective actions done.

● Maintaining the documents and machinery Q.C. Compliant; contributed towards efficiency improvement of

concerned equipment’s.

● Carried out projects on:

o Fabrication, Erection and commissioning of ESP.

o Supervision of ESP project.

o Fabrication and erection of conveyor line.

o Fabrication &Erection of pipe and duct line.

o Planning of erection as well as commissioning activities.

o Carry out all project work related to plant modification.

Educational Forte

2016-17

2 B.TECH [MECHANICAL ENGINEERING] from BPUT, ROURKELA, ODISHA.

2008 B.E (MECHANICAL ENGINEERING) from Institution of Mechanical Engineers, Mumbai, India

2004 Diploma (Mechanical Engineering) from SCTE & VT (BSET- Bhadrak, Odisha)

1997 10th from Karanjia Boys High School Karanjia,( Orissa.H.S.C.E)

Personal Dossier

Date of Birth: 23rd April 1982

Languages Known: English, Hindi and Oriya

Permanent Address: Plot No. 447/2167, Shree Vihar, P.O. - Patia, P.S. - Chandrasekharpur, Bhubaneswar-

751031 (Orissa)

REPORTING TO: MANAGER & AGM

REPORTEES: SR.ENGG, ENGG, ASSIST.ENGG & WORKERS ETC.

PRESENT CTC - 6 LPA +0.6LPA

EXPECTED CTC- 8LPA TO 9 LPA

Notice Period: 30 DAYS

FAMILY DETAILS- FATHER ,MOTHER,WIFE & ONLY ONE DAUGHTER.

REASON OF LOOKING FOR JOB CHANGE :1.FOR BETTERMENT OF MY CAREER & FUTURE

2. NEARER TO MY HOME TOWN TO LOOK AFTER MY OLD AGED PARENTS.

You might also like

- Application of CalculusDocument7 pagesApplication of CalculusNoramira Ahmad Tajuddin88% (16)

- Sample FFS-Final ReportDocument22 pagesSample FFS-Final ReportSuparerk Sirivedin100% (4)

- National IndustriesDocument10 pagesNational IndustriesKishan makvanaNo ratings yet

- AdaniDocument95 pagesAdanirajput_chetan2904No ratings yet

- Special Power of AttorneyDocument2 pagesSpecial Power of AttorneyMelford Lapnawan88% (8)

- Field Joints Coating Offer-DemechDocument4 pagesField Joints Coating Offer-DemechVineet KhanduriNo ratings yet

- Essar Steel India Limited: Work OrderDocument4 pagesEssar Steel India Limited: Work OrderMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Steel FoundriesDocument2 pagesSteel Foundriesmahesh30032No ratings yet

- Booster Pump Quotation SPQ16-000169 PDFDocument4 pagesBooster Pump Quotation SPQ16-000169 PDFAdil Aziz0% (1)

- JaiRaj AncillariesDocument8 pagesJaiRaj Ancillariestajju_121No ratings yet

- Prospectus AICTE Approved ProgramesDocument34 pagesProspectus AICTE Approved ProgramesArunpandimurugan MVNo ratings yet

- Major Industrial UnitsDocument2 pagesMajor Industrial Unitsrahulgaurav72No ratings yet

- Circular On Office Timings and Work ScheduleDocument1 pageCircular On Office Timings and Work ScheduleSaad MasoodNo ratings yet

- PAD List 2022 23 As On 27 01 2023Document31 pagesPAD List 2022 23 As On 27 01 2023N SriramanNo ratings yet

- ISO CertificateDocument1 pageISO CertificateManash Protim GogoiNo ratings yet

- AMC Work OrderDocument2 pagesAMC Work OrderRahul PatelNo ratings yet

- PO - Tempsens InstrumentsDocument12 pagesPO - Tempsens InstrumentspernetiNo ratings yet

- Sr. No. Developer Name of Project Sector State Unit No Unit Capacity Date of Commissi Oning FGD Phasing Plan (DD/MM/Y FGD StatusDocument13 pagesSr. No. Developer Name of Project Sector State Unit No Unit Capacity Date of Commissi Oning FGD Phasing Plan (DD/MM/Y FGD StatusKoushik DeyNo ratings yet

- UntitledDocument2 pagesUntitledTulsi TandiNo ratings yet

- Quotation 1Document37 pagesQuotation 1Nikhil SutharNo ratings yet

- Location Wise FGD Projects in IndiaDocument16 pagesLocation Wise FGD Projects in IndiaVibhas KumarNo ratings yet

- Monoblock & Suction Pump SNB-SNK-CatalogDocument28 pagesMonoblock & Suction Pump SNB-SNK-Catalogbagus saputraNo ratings yet

- Fly Ash Brick PDFDocument8 pagesFly Ash Brick PDFmalaya tripathyNo ratings yet

- 07092014125520IMYB - 2012 - Iron OreDocument35 pages07092014125520IMYB - 2012 - Iron OreRahul MishraNo ratings yet

- Ludhiana Forging IndustriesDocument16 pagesLudhiana Forging IndustriesSourindra Mohan PandaNo ratings yet

- DI Pipe Manufacturer ListDocument11 pagesDI Pipe Manufacturer ListsmithNo ratings yet

- Reliable Sponge PVT Ltd-Unit-IIIDocument19 pagesReliable Sponge PVT Ltd-Unit-IIIReliableIndiaNo ratings yet

- A 153Document1 pageA 153AnuranjanNo ratings yet

- Reference List PDFDocument11 pagesReference List PDFAshok MallickNo ratings yet

- Present Professional ExperienceDocument3 pagesPresent Professional Experiencerahul srivastavaNo ratings yet

- Panoli IndDocument9 pagesPanoli Indanon_981731217No ratings yet

- QTN For 60 HP MachineDocument4 pagesQTN For 60 HP Machineheavenrocks upadhyayNo ratings yet

- 0002432194Document8 pages0002432194atripathi2009No ratings yet

- Verification Form VNGDocument6 pagesVerification Form VNGdibyanshu.goswamiNo ratings yet

- Customermanagementlist - SachinDocument4 pagesCustomermanagementlist - SachinSaurabh JainNo ratings yet

- IEQ Material DetailsDocument35 pagesIEQ Material DetailsDevendraNo ratings yet

- Varanasi Marketing Client ListDocument6 pagesVaranasi Marketing Client ListSwapnil VichareNo ratings yet

- Resume: Professional ExperienceDocument3 pagesResume: Professional ExperienceShankker KumarNo ratings yet

- Coal WasheryDocument2 pagesCoal Washerynitunagrawal100% (1)

- List Scs SadcDocument3 pagesList Scs SadcMukesh JainNo ratings yet

- 12 Integrated SteelDocument16 pages12 Integrated SteelKushagra JadhavNo ratings yet

- List of Sugar FactoriesDocument4 pagesList of Sugar FactoriesSuresh KumarNo ratings yet

- State Wise Cement IndustriesDocument12 pagesState Wise Cement IndustriesSharon SusmithaNo ratings yet

- Faculty List NIT DurgapurDocument18 pagesFaculty List NIT DurgapurAnkan RakshitNo ratings yet

- PrescriptionDocument2 pagesPrescriptionMurali KrishnaNo ratings yet

- Sugars Industries in KarnatakaDocument4 pagesSugars Industries in Karnatakadesaivilas60No ratings yet

- Introduction Letter - 3.4.21Document2 pagesIntroduction Letter - 3.4.21Gunjan PatelNo ratings yet

- New Resume SunilDocument5 pagesNew Resume SunilAnish Kumar DhirajNo ratings yet

- Senco GoldDocument1 pageSenco Goldtabu 1No ratings yet

- List of Power Stations in IndiaDocument11 pagesList of Power Stations in IndiaRushikeshKatkar0% (1)

- Email Contacts For Steel Company in IndiaDocument3 pagesEmail Contacts For Steel Company in IndiaTENDER AWADH GROUPNo ratings yet

- Hemco Engineering Private Limited PDFDocument4 pagesHemco Engineering Private Limited PDFakarshverma01No ratings yet

- EagleBurgmann - E110801 - E1 - High-Pressure Seals For ESPO Pipeline Pumps - 10.11 PDFDocument2 pagesEagleBurgmann - E110801 - E1 - High-Pressure Seals For ESPO Pipeline Pumps - 10.11 PDFkztro066No ratings yet

- Gear Technology India 2013 # 4 PDFDocument68 pagesGear Technology India 2013 # 4 PDFUday Sankar Sarma YerramilliNo ratings yet

- Mon Finlqaqce. 3Document4 pagesMon Finlqaqce. 3ulocksystemNo ratings yet

- List of Refineries & Petroleum / LPG Projects: Year Name of Project ClientDocument5 pagesList of Refineries & Petroleum / LPG Projects: Year Name of Project ClientSach KanhuNo ratings yet

- Kiswok Pipe Layout AdDocument1 pageKiswok Pipe Layout AdaroonkumaarvNo ratings yet

- Prosintech CatalogDocument6 pagesProsintech CatalogDeepak PatelNo ratings yet

- Ranchi Is The Capital of The Indian State of JharkhandDocument30 pagesRanchi Is The Capital of The Indian State of Jharkhandgurjit20No ratings yet

- PVC Pipe, Hdpe Pipe ManufacuringDocument10 pagesPVC Pipe, Hdpe Pipe ManufacuringPriyanshu ChokhaniNo ratings yet

- CustomerDocument9 pagesCustomerLokesh Reddy100% (1)

- Current List of Coal PowerPlants IndiaDocument6 pagesCurrent List of Coal PowerPlants IndiaAmit SarkarNo ratings yet

- CV - Arpit Rotary EngineerDocument3 pagesCV - Arpit Rotary Engineerarpit patelNo ratings yet

- Jonell: JVF Series Activated Carbon CanistersDocument2 pagesJonell: JVF Series Activated Carbon CanistersSurajPandeyNo ratings yet

- Volvo CE Vehicle CardDocument21 pagesVolvo CE Vehicle CardSurajPandeyNo ratings yet

- Sor 71Document3 pagesSor 71SurajPandeyNo ratings yet

- Ionian Sea FosDocument2 pagesIonian Sea FosSurajPandeyNo ratings yet

- Renewable Energy Sector in India: Chapter - IDocument9 pagesRenewable Energy Sector in India: Chapter - ISurajPandeyNo ratings yet

- Product Catalogue Price List: With New Generation Filter & Cabin FiltersDocument20 pagesProduct Catalogue Price List: With New Generation Filter & Cabin FiltersSurajPandeyNo ratings yet

- Unearthing Treasures: Safety Reliability SustainabilityDocument6 pagesUnearthing Treasures: Safety Reliability SustainabilitySurajPandey100% (1)

- Shelf Drilling Galveston Key Spec Sheet May 2015Document2 pagesShelf Drilling Galveston Key Spec Sheet May 2015SurajPandeyNo ratings yet

- Simplex Infrastructures LTD List of Equipment Available For HireDocument1 pageSimplex Infrastructures LTD List of Equipment Available For HireSurajPandeyNo ratings yet

- Minewise Return SubmissionDocument1,245 pagesMinewise Return SubmissionSurajPandeyNo ratings yet

- Production, Evacuation and Sale of Iron OreDocument38 pagesProduction, Evacuation and Sale of Iron OreSurajPandeyNo ratings yet

- Vadodara ZoneDocument30 pagesVadodara ZoneSurajPandeyNo ratings yet

- Check Out Our Recently Introduced Fleetguard Products: September 2012Document6 pagesCheck Out Our Recently Introduced Fleetguard Products: September 2012SurajPandeyNo ratings yet

- Statewise Mineral Wise ROM Mineral ProductionDocument396 pagesStatewise Mineral Wise ROM Mineral ProductionSurajPandeyNo ratings yet

- Dee Vee Projects Raipur Chhattisgarh IndiaDocument2 pagesDee Vee Projects Raipur Chhattisgarh IndiaSurajPandeyNo ratings yet

- Spare Part DevelopmentDocument10 pagesSpare Part DevelopmentSurajPandeyNo ratings yet

- Offshore Brochure CranesDocument91 pagesOffshore Brochure CranesSurajPandeyNo ratings yet

- Nishant Choubey GMR PurchaseDocument1 pageNishant Choubey GMR PurchaseSurajPandeyNo ratings yet

- List of Coal Mines Earmarked For 6 Tranche of AllotmentDocument1 pageList of Coal Mines Earmarked For 6 Tranche of AllotmentSurajPandeyNo ratings yet

- MB10453 1Document3 pagesMB10453 1SurajPandeyNo ratings yet

- Mahle Air Filter (Primary) For HM GM Terex: Industrial FiltrationDocument3 pagesMahle Air Filter (Primary) For HM GM Terex: Industrial FiltrationSurajPandeyNo ratings yet

- Anjesh Kumar Hindalco Mahan CPP MechDocument2 pagesAnjesh Kumar Hindalco Mahan CPP MechSurajPandeyNo ratings yet

- ACB (India) LimitedDocument2 pagesACB (India) LimitedSurajPandeyNo ratings yet

- Mahle Air Filter Clearner Assy For ELGIDocument7 pagesMahle Air Filter Clearner Assy For ELGISurajPandey0% (1)

- Pre Notes 6th Semcode CH 604Document42 pagesPre Notes 6th Semcode CH 604SurajPandeyNo ratings yet

- Mahle Air Filter (Primary) For Ashok Leyland: Industrial FiltrationDocument3 pagesMahle Air Filter (Primary) For Ashok Leyland: Industrial FiltrationSurajPandey100% (1)

- List of Nodal Officers For Msme Outreach ProgramDocument3 pagesList of Nodal Officers For Msme Outreach ProgramSurajPandeyNo ratings yet

- Mahle Air Filter (Primary) For Tata - HitachiDocument9 pagesMahle Air Filter (Primary) For Tata - HitachiSurajPandeyNo ratings yet

- Preferences Environment Variables Reference PLM TeamcenterDocument1,157 pagesPreferences Environment Variables Reference PLM TeamcenterBHUVANA SATEESHNo ratings yet

- Aritificial Vision YOLOV2 Part2Document9 pagesAritificial Vision YOLOV2 Part2David BenavidesNo ratings yet

- Bla BlaDocument8 pagesBla BladharwinNo ratings yet

- Inductive Lesson PlanDocument3 pagesInductive Lesson PlanLeah Jane Pelayo-Ibarrat67% (3)

- Yom Ha'atzmaut Missing Letters: Fill in The Missing Letters To Complete The WordsDocument34 pagesYom Ha'atzmaut Missing Letters: Fill in The Missing Letters To Complete The WordsRachel MalagaNo ratings yet

- Proposal Nanotechnology in GeotechnicsDocument4 pagesProposal Nanotechnology in GeotechnicsMOHAMED DiriyeNo ratings yet

- RESPIRATION IN PLANTS DPP by Seep PahujaDocument4 pagesRESPIRATION IN PLANTS DPP by Seep Pahujamaheshgutam8756No ratings yet

- College of Agriculture Department of Value Chain Management Name: Ermiyas Bogale Abera ID No: 0757/12Document10 pagesCollege of Agriculture Department of Value Chain Management Name: Ermiyas Bogale Abera ID No: 0757/12Ermiyas BogaleNo ratings yet

- Rudaga - Regulations - 2021Document7 pagesRudaga - Regulations - 2021sidharthNo ratings yet

- Deliverable 5 - Trend Analysis & PresentationDocument6 pagesDeliverable 5 - Trend Analysis & PresentationRamizNo ratings yet

- Lecture 14 - Housing For All Mission (PMAY) & Technology Sub-MissionDocument15 pagesLecture 14 - Housing For All Mission (PMAY) & Technology Sub-MissionRadhika KhandelwalNo ratings yet

- EL - 124 Electronic Devices & Circuits: Experiment # 04Document6 pagesEL - 124 Electronic Devices & Circuits: Experiment # 04Jawwad IqbalNo ratings yet

- Daily Coal Inventory 211220 PDFDocument1 pageDaily Coal Inventory 211220 PDFDedi SetyawanNo ratings yet

- 5G TransportDocument42 pages5G TransportDaniel Cafu100% (1)

- Innovation ReadingsDocument9 pagesInnovation Readingsafca32No ratings yet

- ReadingDocument2 pagesReadingLucíaNo ratings yet

- CV-Mushtaque AliDocument8 pagesCV-Mushtaque AliAnonymous sIQv5MDCzNo ratings yet

- Electrical Engineering Sem-2 All Question BankDocument2,178 pagesElectrical Engineering Sem-2 All Question BankGAURAV GUPTANo ratings yet

- Astm A307Document6 pagesAstm A307thakrarhits100% (3)

- 2fy2-01 Engineering Mathematics-I (A To D)Document3 pages2fy2-01 Engineering Mathematics-I (A To D)gwanfldlwjwuwNo ratings yet

- Business Objectives and Stakeholder ObjectivesDocument28 pagesBusiness Objectives and Stakeholder ObjectivesThin Zar Tin WinNo ratings yet

- Brad J Hornberger Cystoscopy Indications and Preparation. UAPA CME Conference 2012 (30 Min)Document36 pagesBrad J Hornberger Cystoscopy Indications and Preparation. UAPA CME Conference 2012 (30 Min)Cristian OrozcoNo ratings yet

- Sepco Online BilllDocument1 pageSepco Online Billlshaikh_piscesNo ratings yet

- Multiple Choice Practice Questions/Answer For Online/Omr AITT-2020 2 Year Electronics Mech. Trade TheoryDocument66 pagesMultiple Choice Practice Questions/Answer For Online/Omr AITT-2020 2 Year Electronics Mech. Trade TheoryAbcNo ratings yet

- The Food Supply Chain of India The EcosystemDocument6 pagesThe Food Supply Chain of India The EcosystemMoksh SharmaNo ratings yet

- Sheetmetal ProcessDocument88 pagesSheetmetal ProcessEre Gowda100% (1)

- APUSH Inside-Outside-Inside Discussion InstructionsDocument2 pagesAPUSH Inside-Outside-Inside Discussion InstructionscrolwesNo ratings yet