Professional Documents

Culture Documents

Gyproc: Ceiling Specification Sheet

Gyproc: Ceiling Specification Sheet

Uploaded by

Amar ShaikhCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hospital BOQDocument66 pagesHospital BOQIshan Ranganath67% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fdocuments - in Planning The Powder Room Yourhomeworksolutions Planning The Powder Room by DeniseDocument3 pagesFdocuments - in Planning The Powder Room Yourhomeworksolutions Planning The Powder Room by DeniseAishi Paul0% (1)

- Goa State Disaster Management Authority Government of Goa: Annexure ADocument1 pageGoa State Disaster Management Authority Government of Goa: Annexure AAmar ShaikhNo ratings yet

- List of Provisionally Selected Candidates For Bangalore-Programme Centre - 2014Document4 pagesList of Provisionally Selected Candidates For Bangalore-Programme Centre - 2014Amar ShaikhNo ratings yet

- HDB Properties For March - Apr 2021Document6 pagesHDB Properties For March - Apr 2021Amar ShaikhNo ratings yet

- Pri Ci NG Gui De: Di Agnost I Cs I NF or Mat I On Syst emDocument6 pagesPri Ci NG Gui De: Di Agnost I Cs I NF or Mat I On Syst emAmar ShaikhNo ratings yet

- Simple, Secure & Smart HealthcareDocument28 pagesSimple, Secure & Smart HealthcareAmar ShaikhNo ratings yet

- Dga 2000Document44 pagesDga 2000Amar ShaikhNo ratings yet

- Rebar EstimateDocument2 pagesRebar EstimateJim Harold ALfarasNo ratings yet

- DMP Assignment - 1 PDFDocument9 pagesDMP Assignment - 1 PDFCharan ReddyNo ratings yet

- Presentación Completa ArupDocument105 pagesPresentación Completa ArupCarlos Eduardo Rodriguez100% (1)

- Pagoda Taman Alam Lumbini Bahasa InggrisDocument3 pagesPagoda Taman Alam Lumbini Bahasa InggrisToko Bandung BerastagiNo ratings yet

- History of EngineeringDocument59 pagesHistory of EngineeringDanica Dayday100% (2)

- 401 Structural Design of Reinforced Concrete Tall Buildings PDFDocument9 pages401 Structural Design of Reinforced Concrete Tall Buildings PDFFunky DopeNo ratings yet

- Redefiningrevival Asystematicreviewonvernacularandnon Place BoundrevivalDocument18 pagesRedefiningrevival Asystematicreviewonvernacularandnon Place BoundrevivalAmruta PatilNo ratings yet

- General Construction Notes: FC Engineering ServicesDocument1 pageGeneral Construction Notes: FC Engineering ServicesMac KYNo ratings yet

- STM Stage Curtains Layout GuideDocument4 pagesSTM Stage Curtains Layout GuideKin J SzetoNo ratings yet

- Installation On CMU WallsDocument1 pageInstallation On CMU WallsAbbasi HussainNo ratings yet

- SGP All Plan: Tampak Depan 3D View Detail WastafelDocument1 pageSGP All Plan: Tampak Depan 3D View Detail WastafelBima WiraNo ratings yet

- Design Note PSCDocument10 pagesDesign Note PSCMenaka kmsNo ratings yet

- Seg# Casting Type Casting Date: Rit No. Rit No. 7 Days Test Date 7 Days Test Status 28 Days Test Date 28 Days Test StatusDocument3 pagesSeg# Casting Type Casting Date: Rit No. Rit No. 7 Days Test Date 7 Days Test Status 28 Days Test Date 28 Days Test Statusahmed sleemNo ratings yet

- Sustainability in High Rise Buildings PDFDocument9 pagesSustainability in High Rise Buildings PDFDeepak Kumar Yadav100% (1)

- APM Series: Compact Axial FansDocument4 pagesAPM Series: Compact Axial FansCong VietNo ratings yet

- HVAC Grill ScheduleDocument2 pagesHVAC Grill ScheduleRami BalbesiNo ratings yet

- Zatrzaski Kulowe BOSSARDDocument10 pagesZatrzaski Kulowe BOSSARDja2ja1No ratings yet

- Is 4082 1996Document14 pagesIs 4082 1996ABISHKAR SARKARNo ratings yet

- NAtional Artist For ArchitectureDocument19 pagesNAtional Artist For ArchitectureSmartsoft LibraryNo ratings yet

- KORADO Radik Steel Panel RadiatorsDocument74 pagesKORADO Radik Steel Panel RadiatorsTamir EnkhNo ratings yet

- Paris Architecture Map PDF by Virginia Duran 2020Document27 pagesParis Architecture Map PDF by Virginia Duran 2020Alessandro SiccoNo ratings yet

- Movex 2015 L PDFDocument356 pagesMovex 2015 L PDFLuis Angel BecerrilNo ratings yet

- RCC41 Continuous Beams (A & D)Document17 pagesRCC41 Continuous Beams (A & D)Amit Kumar Paul0% (1)

- Unit-1 - Stone Masonry-Bmc Part-IDocument24 pagesUnit-1 - Stone Masonry-Bmc Part-IMukesh Kumar Shankhwar100% (1)

- Wall Putty Manufacturers in IndiaDocument6 pagesWall Putty Manufacturers in IndiaMagna GreenNo ratings yet

- 5 Order of ArchitectureDocument10 pages5 Order of ArchitectureLawrence ConananNo ratings yet

- ACC-17-705 (Planter Box Ground Floor Dan Lift Lobby) - Shop DrawingDocument2 pagesACC-17-705 (Planter Box Ground Floor Dan Lift Lobby) - Shop DrawingAgung SetiawanNo ratings yet

- House Plans, 2 Story House Plans, 40 X 40 House Plans, 100121Document6 pagesHouse Plans, 2 Story House Plans, 40 X 40 House Plans, 100121MittuNo ratings yet

Gyproc: Ceiling Specification Sheet

Gyproc: Ceiling Specification Sheet

Uploaded by

Amar ShaikhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gyproc: Ceiling Specification Sheet

Gyproc: Ceiling Specification Sheet

Uploaded by

Amar ShaikhCopyright:

Available Formats

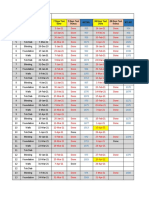

SR.

No CSS-0011

Ceiling Specification DATE 21-Jun-2017

Sheet REV. NO 00

Gypserra™ MF Suspended Ceiling with Plain Board

14

6

13

6 2 1 3

3 2 1

3D VIEW

OC

11 11

2 3 4 2 3

4

8

PR

8

12 12

9

GY

7

7

Detail A Detail B

With Bolt & Nut With Metal to Metal Screw

DETAIL VIEW DETAIL VIEW

1 12.5mm Gypboard® Plain ( Certified board) 7 Ø 2.64mm Gyproc® Connecting Clip

8 27x37x25x1.6mm Gyproc® Soffit Cleat

2 80x26x0.5mm Gypserra™ Ceiling Section

at 457mm c/c 9 Ø4.2x13 Gyproc ® Metal to Metal Screw

3 15x45x15x0.9mm Gypserra™ Intermediate 10 Gyproc® Drywall Screws

Channel at 1220 c/c

11 Gyproc® Rawl Plug

4 20x28x30x0.5mm Gypserra™ Perimeter Channel

12 M6x12mm Hex Bolt & Hex Nut

5 25x10x0.5mm Gypserra™ Ceiling Angle

at 1220mm c/c

13 Brick/RCC Wall

6 9x10x28x0.5mm Gypsteel® Shadow line bead 14 Concrete Slab

Prepared by :- Mohini Bandare Approved by:- Shailendra Shinde Page 1 of 2

SR. No CSS-0011

Ceiling Specification DATE 21-Jun-2017

Sheet REV. NO 00

• 80x26x0.5mm Gypserra™ • 20x28x30x0.5mm Gypserra™

• 15x45x15x0.9mm Gypserra™

Ceiling Section Perimeter Channel

Intermediate Channel

• Material-GI(IS513) • Material-GI(IS513)

• Material-GI(IS513)

YS-260Mpa YS-260Mpa

YS-260Mpa

• Finish-Galvanised • Finish-Galvanised

• Finish-Galvanised

150GSM(IS277) 150GSM(IS277)

150GSM(IS277)

• 25x10x0.5mm Gypserra™ • Gypboard® Plain: • Ø8x45mm Gyproc® Rawl Plug

Ceiling Angle 1219x2438x12.5mm • Material-IS 513 CR1

• Material-GI(IS513) Certified board grade, Zinc coating

YS-260Mpa • Pull Out Load-6.8kN for

• Finish-Galvanised M30 concrete grade.

150GSM(IS277)

• 27x37x25x1.6mm • Ø 2.64mm Gyproc® • 9x10x28x0.5mm Gyproc®

Gyproc® Soffit Cleat Connecting Clip Shadow line bead

• Material-GI(IS513) • Material-High carbon spring • Material-GI(IS513)

YS-260Mpa steel wire(BS970Gr.En42)- YS-260Mpa

• Finish- Galvanized 46-48HRC • Finish-Galvanised

120GSM(IS277) • Finish-Zinc plating 4-6Micron 120GSM(IS277)

• Gyproc® drywall Screw

• Material-As per JIS G3507-1 • Ø4.2x13 Gyproc ® • Gyproc® Pro-Fill

standard metal to metal screws Jointing compound

• Finish-Case Hardened Grey • Material- Carbon steel Conforms to ASTM C475

•

phosphate

M6 x 12/50 mm Hex Bolt •

OC

(JIS G3507-1)

Finish- Case hardened,

& Hex Nut blue zinc plated • Approx. Weight – 10 Kg/m2

• Material – As per EN 10083

• Finish – Zinc Plating

PR

Maximum recommended loads on Gyproc board linings

Suspension point centers mm Intermediate channel centers Max load including weight of board

Kg/m2

1220 1220 30

GY

1220 914 40

1. M/F Suspended Plain Ceiling includes Gypserra™ Perimeter Channel {Material-GI(IS513),YS-260Mpa,Finish-

Galvanised 150GSM(IS27 )} is fixed along the perimeter of existing wall/ partition with the help of HILTI HPS - 1

(6x40) impact anchor, at 600mm centres.

2. Gypserra™ Ceiling Angle {Material-GI(IS513),YS-260Mpa,Finish-Galvanised 150GSM(IS277)} is suspended by

fixing it to the Gyproc® soffit cleat {GI(IS513)YS-260Mpa,Finish-Galvanised 150GSM(IS277) }. Soffit Cleat and

Gyproc® Rawl Plug- Ø8x45mm {Material-IS 513 CR2 grade, Zinc coating (7 to 8 microns) pull out load- 6.8kN for

M30 concrete grade} creating 1220mm x 1220mm grid.

3. Gypserra™ Intermediate channel {Material-GI(IS513),YS-260Mpa,Finish-Galvanised 150GSM(IS277) } is fixed to

the Gypserra™ Ceiling Angle with M6 x 12mm Hex Bolt & Hex Nut arrangement {Material–As per EN 10083 Finish

– Zinc Plating} or with 2 Nos of Ø4.2x13 Gyproc® metal to metal screw {Material-Carbon steel EN-ISO 7049/50

Finish- Zinc Coating Thickness- 4.14micron.}

4. The Gypserra™ Ceiling Section {Material-GI(IS513),YS-260Mpa,Finish-Galvanised 150GSM(IS277)} is then fixed

to the Gypserra™ Intermediate Channel {Material-GI(IS513),YS-260Mpa,Finish-Galvanised 150GSM(IS277)} with

the help of Gyproc® Connecting Clip {Material-High carbon spring steel wire(BS970Gr.En42)-46-48HRC,Finish-

Zinc plating 4-6 micron} and in direction perpendicular to the Intermediate channel at 457mm c/c.

5. Single layer of 12.5mm tapered edge Gypboard® Plain (conforming to IS 2095-Part 1:2011, Certified board) is

then screw fixed to ceiling section with 25mm drywall screws {Material-Carbon steel EN-ISO 7049/50,Finish-Case

hardened Grey Phosphating} at 230mm centres on ceiling section & 150mm at periphery of ceiling.

6. Finally square and tapered edges of the boards are to be jointed and finished so as to have a flush look which

includes filling and finishing with Gyproc® Pro-Fill Jointing compound (Conforms to ASTM C475), Gyproc® Joint

Paper tape.

7. Serrated section has effective thickness of 2T ( 2xdepth), better load carrying capacity, enhanced screw retention,

Improved acoustic performance & fire resistance as compared to plain steel section.

8. All Gypserra™ metal components are patent applied for.(Application No. 201741018271)

Prepared by :- Mohini Bandare Approved by:- Shailendra Shinde Page 2 of 2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hospital BOQDocument66 pagesHospital BOQIshan Ranganath67% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fdocuments - in Planning The Powder Room Yourhomeworksolutions Planning The Powder Room by DeniseDocument3 pagesFdocuments - in Planning The Powder Room Yourhomeworksolutions Planning The Powder Room by DeniseAishi Paul0% (1)

- Goa State Disaster Management Authority Government of Goa: Annexure ADocument1 pageGoa State Disaster Management Authority Government of Goa: Annexure AAmar ShaikhNo ratings yet

- List of Provisionally Selected Candidates For Bangalore-Programme Centre - 2014Document4 pagesList of Provisionally Selected Candidates For Bangalore-Programme Centre - 2014Amar ShaikhNo ratings yet

- HDB Properties For March - Apr 2021Document6 pagesHDB Properties For March - Apr 2021Amar ShaikhNo ratings yet

- Pri Ci NG Gui De: Di Agnost I Cs I NF or Mat I On Syst emDocument6 pagesPri Ci NG Gui De: Di Agnost I Cs I NF or Mat I On Syst emAmar ShaikhNo ratings yet

- Simple, Secure & Smart HealthcareDocument28 pagesSimple, Secure & Smart HealthcareAmar ShaikhNo ratings yet

- Dga 2000Document44 pagesDga 2000Amar ShaikhNo ratings yet

- Rebar EstimateDocument2 pagesRebar EstimateJim Harold ALfarasNo ratings yet

- DMP Assignment - 1 PDFDocument9 pagesDMP Assignment - 1 PDFCharan ReddyNo ratings yet

- Presentación Completa ArupDocument105 pagesPresentación Completa ArupCarlos Eduardo Rodriguez100% (1)

- Pagoda Taman Alam Lumbini Bahasa InggrisDocument3 pagesPagoda Taman Alam Lumbini Bahasa InggrisToko Bandung BerastagiNo ratings yet

- History of EngineeringDocument59 pagesHistory of EngineeringDanica Dayday100% (2)

- 401 Structural Design of Reinforced Concrete Tall Buildings PDFDocument9 pages401 Structural Design of Reinforced Concrete Tall Buildings PDFFunky DopeNo ratings yet

- Redefiningrevival Asystematicreviewonvernacularandnon Place BoundrevivalDocument18 pagesRedefiningrevival Asystematicreviewonvernacularandnon Place BoundrevivalAmruta PatilNo ratings yet

- General Construction Notes: FC Engineering ServicesDocument1 pageGeneral Construction Notes: FC Engineering ServicesMac KYNo ratings yet

- STM Stage Curtains Layout GuideDocument4 pagesSTM Stage Curtains Layout GuideKin J SzetoNo ratings yet

- Installation On CMU WallsDocument1 pageInstallation On CMU WallsAbbasi HussainNo ratings yet

- SGP All Plan: Tampak Depan 3D View Detail WastafelDocument1 pageSGP All Plan: Tampak Depan 3D View Detail WastafelBima WiraNo ratings yet

- Design Note PSCDocument10 pagesDesign Note PSCMenaka kmsNo ratings yet

- Seg# Casting Type Casting Date: Rit No. Rit No. 7 Days Test Date 7 Days Test Status 28 Days Test Date 28 Days Test StatusDocument3 pagesSeg# Casting Type Casting Date: Rit No. Rit No. 7 Days Test Date 7 Days Test Status 28 Days Test Date 28 Days Test Statusahmed sleemNo ratings yet

- Sustainability in High Rise Buildings PDFDocument9 pagesSustainability in High Rise Buildings PDFDeepak Kumar Yadav100% (1)

- APM Series: Compact Axial FansDocument4 pagesAPM Series: Compact Axial FansCong VietNo ratings yet

- HVAC Grill ScheduleDocument2 pagesHVAC Grill ScheduleRami BalbesiNo ratings yet

- Zatrzaski Kulowe BOSSARDDocument10 pagesZatrzaski Kulowe BOSSARDja2ja1No ratings yet

- Is 4082 1996Document14 pagesIs 4082 1996ABISHKAR SARKARNo ratings yet

- NAtional Artist For ArchitectureDocument19 pagesNAtional Artist For ArchitectureSmartsoft LibraryNo ratings yet

- KORADO Radik Steel Panel RadiatorsDocument74 pagesKORADO Radik Steel Panel RadiatorsTamir EnkhNo ratings yet

- Paris Architecture Map PDF by Virginia Duran 2020Document27 pagesParis Architecture Map PDF by Virginia Duran 2020Alessandro SiccoNo ratings yet

- Movex 2015 L PDFDocument356 pagesMovex 2015 L PDFLuis Angel BecerrilNo ratings yet

- RCC41 Continuous Beams (A & D)Document17 pagesRCC41 Continuous Beams (A & D)Amit Kumar Paul0% (1)

- Unit-1 - Stone Masonry-Bmc Part-IDocument24 pagesUnit-1 - Stone Masonry-Bmc Part-IMukesh Kumar Shankhwar100% (1)

- Wall Putty Manufacturers in IndiaDocument6 pagesWall Putty Manufacturers in IndiaMagna GreenNo ratings yet

- 5 Order of ArchitectureDocument10 pages5 Order of ArchitectureLawrence ConananNo ratings yet

- ACC-17-705 (Planter Box Ground Floor Dan Lift Lobby) - Shop DrawingDocument2 pagesACC-17-705 (Planter Box Ground Floor Dan Lift Lobby) - Shop DrawingAgung SetiawanNo ratings yet

- House Plans, 2 Story House Plans, 40 X 40 House Plans, 100121Document6 pagesHouse Plans, 2 Story House Plans, 40 X 40 House Plans, 100121MittuNo ratings yet