Professional Documents

Culture Documents

4539 Predator XP Perfform HMX

4539 Predator XP Perfform HMX

Uploaded by

Devia SuswodijoyoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4539 Predator XP Perfform HMX

4539 Predator XP Perfform HMX

Uploaded by

Devia SuswodijoyoCopyright:

Available Formats

REGISTERED DATA SHEET PERFORATING SYSTEM EVALUATION, API RP 19B SECTION 1

Service Company Baker Hughes Explosive Wt. 39 gm. HMX powder, Case Mat'l Zinc

Gun OD/Trade Name 4-1/2" Expendable Hollow Carrier Max. Temp. 400F/1h, 380F/3h, 335/24h 300F/100h,

Charge Name 4539 Predator XP Perfform HMX Max. Pressure Rating 17,000 psi, Carrier Mat'l Steel

Mfr. Charge Part No. F190680614 Date of Mfr. 9/16/05 Recommended Min. ID for Running 4.75 in.

Gun Type Expendable, Retreivable, Hollow Carrier Shot Density Tested 5 Shots/ft.

Phasing Tested 60 degrees, Firing X Top, Bottom Available Firing Mode X Selective, X Simultaneous

Debris Description Acid-soluble powder Debris Weight N/A gm/charge, Debris N/A cu.in/charge

Remarks Guns may be wireline or tubing conveyed. May be shot in gas environment.

Casing Data 7 in. OD, Weight 32.0 lb/ft, L-80 API Grade Date of Section 1 Test 10/19/05

Target Data 108 in. OD, Amt. Cement 10463 lb. Amount Sand 20938 lb. Amount Water 5445 lb.

Date of Compressive Strength Test 10/19/05 , Briquette Compressive Strength 7241 psi, Age of Target 96 days

Shot No. No. 1 No. 2 No. 3 No. 4 No. 5 No. 6 No. 7 No. 8 No. 9 No. 10

Clearance 0.00 0.32 1.12 1.59 1.12 0.32 0.00 0.32 1.12 1.59

Casing Hole Diameter, Short Axis, in. 0.30 0.32 0.33 0.37 0.34 0.30 0.28 0.32 0.32 0.41

Casing Hole Diameter, Long Axis, in. 0.31 0.33 0.34 0.41 0.34 0.30 0.30 0.34 0.34 0.42

Average Casing Hole Diameter, in. 0.31 0.33 0.34 0.39 0.34 0.30 0.29 0.33 0.33 0.42

Total Depth, in. 32.3 41.0 45.5 45.3 48.5 36.3 43.0 41.8 38.0 35.0

Burr Height, in 0.06 0.07 0.12 0.05 0.05 0.07 0.04 0.03 0.06 0.09

Shot No. No. 11 No. 12 No. 13 No. 14 No. 15 No. 16 No. 17 No. 18 No. 19 No. 20 Average

Clearance 1.12 0.32

Casing Hole Diameter, Short Axis, in. 0.36 0.31 0.33

Casing Hole Diameter, Long Axis, in. 0.38 0.32 0.34

Average Casing Hole Diameter, in. 0.37 0.32 0.34

Total Depth, in. 38.9 40.0 40.5

Burr Height, in 0.07 0.08 0.06

Remarks

WITNESSING INFORMATION

Date of Notice of Intent to Test 9/20/05 Witnessed by: Jerry Baldwin

Other Activities Witnessed: Target Pouring BriquettePreparation Briquette Testing Burr Ht. Measurement Sample Taken: Concrete X Casing X

CERTIFICATION

I certify that these tests were made according to the procedures as outlined in API RP 19B: Recommended Practices for Evaluation of Well Perforators, First Edition, (insert publication date). All of the

equipment used in these tests, such as guns, jet charges, detonating cord, etc., was standard equipment with our company for the use in the gun being tested and was not changed in any manner for

the test. Furthermore, the equipment was chosen at random from stock and therefore will be substantially the same as the equipment that would be furnished to perforate a well for any operator. The

American Petroleum Institute neither endorsed these test results nor recommends the use of the perforator system described.

X Certified Engineering Manager 12/29/05 Baker Hughes 14000 Betka Rd., Hempstead, TX 77445

ReCertified (Company Official) (Title) (Date) (Company) (Address)

API Form 19R-A 4-1/2" OD 5 SPF 4539 Predator XP Perfform HMX Page 1 of 1

You might also like

- Honda - CBR - 125R - Maintenance - and - Service - Manual PDFDocument20 pagesHonda - CBR - 125R - Maintenance - and - Service - Manual PDFMar0% (1)

- NZS 2403-2015 - v1-3Document118 pagesNZS 2403-2015 - v1-3Brian ChristiantoroNo ratings yet

- Depositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12From EverandDepositional History of Franchthi Cave: Stratigraphy, Sedimentology, and Chronology, Fascicle 12No ratings yet

- This Study Resource WasDocument5 pagesThis Study Resource WasDevia SuswodijoyoNo ratings yet

- Spe 96810 MS PDocument10 pagesSpe 96810 MS PSlim.BNo ratings yet

- Dan 3Document14 pagesDan 3Adanenche Daniel EdohNo ratings yet

- INVESTIGATION REPORT eFNCR 076 - BOP Test Plug Stuck in CHHDocument4 pagesINVESTIGATION REPORT eFNCR 076 - BOP Test Plug Stuck in CHHOmer Abd Al NasserNo ratings yet

- Underreamer - WikipediaDocument2 pagesUnderreamer - WikipediaHistory MatchingNo ratings yet

- OsisanyaDocument66 pagesOsisanyaSyed ShaiqNo ratings yet

- Galvanic Corrosion Lecture2Document12 pagesGalvanic Corrosion Lecture2Hashem Mohamed HashemNo ratings yet

- Section02 Drilling ApparatusDocument31 pagesSection02 Drilling ApparatusMohamed ElshoraNo ratings yet

- SPE-112544-Annular Pressure Loss Predictions For Various Stand-Off Devices CFDDocument8 pagesSPE-112544-Annular Pressure Loss Predictions For Various Stand-Off Devices CFDehsanNo ratings yet

- Brine Fluids PlanningDocument4 pagesBrine Fluids PlanningKolawole AdisaNo ratings yet

- Oil & Gas - Essential Quiz Questions Major Concepts: Pdhonline Course M558 (10 PDH)Document12 pagesOil & Gas - Essential Quiz Questions Major Concepts: Pdhonline Course M558 (10 PDH)priya dharshiniNo ratings yet

- Terminacion en Pozos de Gas ShaleDocument123 pagesTerminacion en Pozos de Gas ShalecesarherreragarzaNo ratings yet

- Drillstring DesignDocument1 pageDrillstring DesignberrouiNo ratings yet

- 1.8 Casing Design1.9 Burst, Collapse, TensionDocument19 pages1.8 Casing Design1.9 Burst, Collapse, TensionMobeen MurtazaNo ratings yet

- Field Testing of Casing Design FactorsDocument16 pagesField Testing of Casing Design Factorsswaala4realNo ratings yet

- Wellbore Stability - The PSI Software: SINTEF Petroleum ResearchDocument2 pagesWellbore Stability - The PSI Software: SINTEF Petroleum ResearchNagaLangit69No ratings yet

- Glossary of Drilling Report AbbreviationsDocument4 pagesGlossary of Drilling Report AbbreviationsFatima Al-nNo ratings yet

- Basic Log Interpretation Chart PDFDocument1 pageBasic Log Interpretation Chart PDFamaso95No ratings yet

- QY Full Hydraulic Drilling JarDocument7 pagesQY Full Hydraulic Drilling Jarsaeed65No ratings yet

- Iso Fdis 13679Document15 pagesIso Fdis 13679ahmed abdallahNo ratings yet

- Fundamentals of Drilling OperationsDocument93 pagesFundamentals of Drilling OperationsSAKNo ratings yet

- Confined Compressive Strength Model of Rock For Drilling OptimizationDocument7 pagesConfined Compressive Strength Model of Rock For Drilling Optimizationodex100% (2)

- EOWR CV-5X Combine 08may2008Document85 pagesEOWR CV-5X Combine 08may2008Them Bui XuanNo ratings yet

- The ProjectDocument19 pagesThe Projectمعتز سيداحمد100% (1)

- S2 2015 336441 Chapter1Document15 pagesS2 2015 336441 Chapter1arispriyatmonoNo ratings yet

- Top CO - Catalog February 2015 - R6 PDFDocument36 pagesTop CO - Catalog February 2015 - R6 PDFzapspazNo ratings yet

- TAMU - Pemex: Offshore DrillingDocument31 pagesTAMU - Pemex: Offshore DrillingkfranovskyNo ratings yet

- Motors Brochure EHODocument5 pagesMotors Brochure EHOaivanho63No ratings yet

- Well Completion and Its TypesDocument14 pagesWell Completion and Its TypesJagdish annayaNo ratings yet

- Type of WellsDocument10 pagesType of WellsAddrien Daniel100% (1)

- PerforationDocument3 pagesPerforationTeguh Akbar HarahapNo ratings yet

- Drilling PetroBowl Questions Flashcards - QuizletDocument7 pagesDrilling PetroBowl Questions Flashcards - QuizletJustice Appiah NuamahNo ratings yet

- Managed Pressure Drilling & Underbalanced Operations: Platinum SponsorsDocument4 pagesManaged Pressure Drilling & Underbalanced Operations: Platinum SponsorsSyed IrtazaNo ratings yet

- Defining HPHT PDFDocument2 pagesDefining HPHT PDFNikhil Barshettiwar100% (1)

- H-6DEL - Report - DOF - 2017.07.21 Coriendo TR de 20Document9 pagesH-6DEL - Report - DOF - 2017.07.21 Coriendo TR de 20PAZCOSL3 MEJIANo ratings yet

- 13B-2 E5 PADocument4 pages13B-2 E5 PAMichel Dorian VargasNo ratings yet

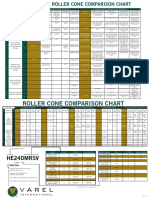

- VAREL RC Comparison Chart Final 2012Document2 pagesVAREL RC Comparison Chart Final 2012Baitaw WanwarangNo ratings yet

- Inflow Performance RelationshipDocument2 pagesInflow Performance RelationshipDjohan Pranata KabanNo ratings yet

- Dual Gradient DrillingDocument72 pagesDual Gradient DrillingJosue FishNo ratings yet

- CCS Brochure PDFDocument28 pagesCCS Brochure PDFChandra PramanaNo ratings yet

- New Criteria For Gravel and Screen Selection For Sand Control PDFDocument14 pagesNew Criteria For Gravel and Screen Selection For Sand Control PDFCharles DesmazuresNo ratings yet

- 5.5 DPDocument20 pages5.5 DPGobinda SinhaNo ratings yet

- MDT Formation Pressure DataDocument6 pagesMDT Formation Pressure DataAngelo Kristoff MacarioNo ratings yet

- Causes, Preventioi S, and Recovery of Stuck: PipetDocument10 pagesCauses, Preventioi S, and Recovery of Stuck: Pipetsaeed65No ratings yet

- Presentation 2 - Version 2.1Document32 pagesPresentation 2 - Version 2.1Nandani SudamaNo ratings yet

- 2 February - Onshore Vs Offshore DrillingDocument2 pages2 February - Onshore Vs Offshore DrillingHanly MauriceNo ratings yet

- Logging Basic: by Mr. Li Ming November. 2005, BeijingDocument151 pagesLogging Basic: by Mr. Li Ming November. 2005, BeijingRebar KakaNo ratings yet

- RTTS Circulating ValveDocument2 pagesRTTS Circulating ValveHamid Reza BabaeiNo ratings yet

- Aerated DrillingDocument10 pagesAerated DrillingDen YogaNo ratings yet

- Sperry DI Vol4Document52 pagesSperry DI Vol4Daniel Marulituah SinagaNo ratings yet

- Water: As A Drilling Fluid in Production Zone of Geothermal WellsDocument4 pagesWater: As A Drilling Fluid in Production Zone of Geothermal WellsSuci Nur HidayahNo ratings yet

- Cutting Transport 1999Document5 pagesCutting Transport 1999Dicky PratamaNo ratings yet

- Inflow Test Negative Test 1717362618Document7 pagesInflow Test Negative Test 1717362618saif khudhairNo ratings yet

- Radial Cement Bond LogDocument2 pagesRadial Cement Bond LogKarlexis Mendez Rodriguez100% (1)

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Registered Data Sheet Perforating System Evaluation, Api RP 19B Section 1Document1 pageRegistered Data Sheet Perforating System Evaluation, Api RP 19B Section 1Devia SuswodijoyoNo ratings yet

- Registered Data Sheet Perforating System Evaluation, API RP 19B Section 1Document1 pageRegistered Data Sheet Perforating System Evaluation, API RP 19B Section 1Zohaib MaqboolNo ratings yet

- Registered Data Sheet Perforating System Evaluation, API RP 19B Section 1Document1 pageRegistered Data Sheet Perforating System Evaluation, API RP 19B Section 1Zohaib MaqboolNo ratings yet

- Registered Data Sheet Perforating System Evaluation, Api RP 19B Section 1Document1 pageRegistered Data Sheet Perforating System Evaluation, Api RP 19B Section 1nanNo ratings yet

- 2010re Pot of BrazilDocument48 pages2010re Pot of BrazilDevia SuswodijoyoNo ratings yet

- Energy and Sustainable Development in Brazil: Recent Developments and OutlookDocument24 pagesEnergy and Sustainable Development in Brazil: Recent Developments and OutlookDevia SuswodijoyoNo ratings yet

- WFP 0000103491Document28 pagesWFP 0000103491Devia SuswodijoyoNo ratings yet

- Framework For SDG Aligned FinanceDocument36 pagesFramework For SDG Aligned FinanceDevia SuswodijoyoNo ratings yet

- 001 CP enDocument22 pages001 CP enDevia SuswodijoyoNo ratings yet

- Akua Acheampong Jody Grewal Kieng Iv Rhea RasquinhaDocument20 pagesAkua Acheampong Jody Grewal Kieng Iv Rhea RasquinhaDevia SuswodijoyoNo ratings yet

- WACC NikeDocument5 pagesWACC NikeDevia SuswodijoyoNo ratings yet

- This Study Resource Was: Business Case 1Document8 pagesThis Study Resource Was: Business Case 1Devia SuswodijoyoNo ratings yet

- This Study Resource Was: The Royal Bank of Scotland Group, The Human Capital StrategyDocument4 pagesThis Study Resource Was: The Royal Bank of Scotland Group, The Human Capital StrategyDevia SuswodijoyoNo ratings yet

- Keydeploymentindicators (Kdis) : Rev:B Wirelinewinchingprocedures-OpenholeDocument1 pageKeydeploymentindicators (Kdis) : Rev:B Wirelinewinchingprocedures-OpenholeDevia SuswodijoyoNo ratings yet

- Registered Data Sheet Perforating System Evaluation, Api RP 19B Section 1Document1 pageRegistered Data Sheet Perforating System Evaluation, Api RP 19B Section 1Devia SuswodijoyoNo ratings yet

- Titan 02KT27WHDocument59 pagesTitan 02KT27WHDevia SuswodijoyoNo ratings yet

- SPE 50421 MS Valko & Economides 1998Document11 pagesSPE 50421 MS Valko & Economides 1998Devia SuswodijoyoNo ratings yet

- S1 A1 - The Globalization of TechnologyDocument2 pagesS1 A1 - The Globalization of TechnologyFrancisco Calderón PozoNo ratings yet

- PWD P4Document39 pagesPWD P4RupaliNo ratings yet

- (DOC) SIWES BREAD Nwali Ejike - Academia - EduDocument1 page(DOC) SIWES BREAD Nwali Ejike - Academia - EduariyoayosNo ratings yet

- Walk 1Document6 pagesWalk 1Scott PhilipNo ratings yet

- FM 002 0001 H Catalog Aftermarket eDocument28 pagesFM 002 0001 H Catalog Aftermarket eDesa Luka BasticNo ratings yet

- Principles of Speech Delivery: Ezequiel D. QuijanoDocument26 pagesPrinciples of Speech Delivery: Ezequiel D. QuijanotintinNo ratings yet

- Course Outline Fourth Quarter Grade FiveDocument2 pagesCourse Outline Fourth Quarter Grade FiveRemer JalbunaNo ratings yet

- rd-m592 2Document1 pagerd-m592 2faizgpNo ratings yet

- Towards Agenda 2030Document23 pagesTowards Agenda 2030Muhammad Syailendra Prima PutraNo ratings yet

- Nut 1661818Document1 pageNut 1661818phantomboyz_aipNo ratings yet

- The Effect of Surface Roughness On The Adhesion of Elastic SolidsDocument14 pagesThe Effect of Surface Roughness On The Adhesion of Elastic SolidsFernandoNo ratings yet

- Gost R Iso 8579 2 99 PDFDocument12 pagesGost R Iso 8579 2 99 PDFfazzlieNo ratings yet

- Ozone Layer Depletion & Greenhouse EffectDocument34 pagesOzone Layer Depletion & Greenhouse EffectAhad Kanak ProttoyNo ratings yet

- System Analysis Information GatheringDocument21 pagesSystem Analysis Information GatheringChakra VarthyNo ratings yet

- AC Ripple Effects On VRLA BatteriesDocument9 pagesAC Ripple Effects On VRLA BatteriesPétala La MaisonNo ratings yet

- Finite Element Analysis of A Cantilevered BeamDocument17 pagesFinite Element Analysis of A Cantilevered BeamAnand ShahNo ratings yet

- Crain Etal2017Document30 pagesCrain Etal2017Antonio CodinaNo ratings yet

- Lakewood Building Department Violations 2019Document523 pagesLakewood Building Department Violations 2019Rise Up Ocean CountyNo ratings yet

- Week 1 Lesson Plan Math 8Document6 pagesWeek 1 Lesson Plan Math 8Marlon SuazoNo ratings yet

- EXP.2. Mapping EER To Relational Schema ModelDocument3 pagesEXP.2. Mapping EER To Relational Schema Model03 Bhingle AbhishekNo ratings yet

- Notes BootstrapDocument7 pagesNotes BootstrapAnonymous GuyNo ratings yet

- Whap Saq Instructions Cheat SheetDocument3 pagesWhap Saq Instructions Cheat Sheetapi-293282991No ratings yet

- 11english TestDocument2 pages11english TestSampiNo ratings yet

- Flyer Euro Rig 450t enDocument2 pagesFlyer Euro Rig 450t enHayLenLeeNo ratings yet

- Face Prep Capgemini Slot Analysis 23rd Aug 2021 Slot 1Document17 pagesFace Prep Capgemini Slot Analysis 23rd Aug 2021 Slot 1Pritam ChouguleNo ratings yet

- CarletonSOP AbhiDocument2 pagesCarletonSOP AbhiKeyurNo ratings yet

- Exam 01Document2 pagesExam 01Tanima KabirNo ratings yet

- Chapter 2 - FINAL Concept of InclusionDocument30 pagesChapter 2 - FINAL Concept of InclusionGena Duresa100% (1)

- Introduction To EconomicsDocument26 pagesIntroduction To EconomicsReyasat AliNo ratings yet