Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

51 viewsHolding Down Bolts

Holding Down Bolts

Uploaded by

Salvatore ShwThis document calculates the pull-out capacity of holding down bolts embedded in concrete. It determines that the maximum tension force per bolt is 60 kN, which is less than the bolt's tension capacity of 70.7 kN. It also finds that the design pull-out resistance per bolt is 65 kN, which exceeds the maximum tension force. Therefore, the bolts provide adequate anchorage in the concrete.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Holding Down Bolts ExampleDocument1 pageHolding Down Bolts ExampleMarcelo MachadoNo ratings yet

- Design of Rectangular Water Tank: SN Design Parameters Symbol Formula Value Unit RemarksDocument5 pagesDesign of Rectangular Water Tank: SN Design Parameters Symbol Formula Value Unit Remarkskiran_karki_8100% (1)

- Analysis and Design of Base Plate and Anchor Bolt For Pinned BaseDocument4 pagesAnalysis and Design of Base Plate and Anchor Bolt For Pinned BaseSunil PulikkalNo ratings yet

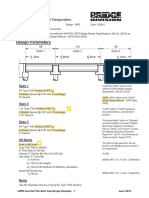

- BDM Example 6 - 20180101Document23 pagesBDM Example 6 - 20180101mustafurade1No ratings yet

- 05a - HORIZONTAL BRACEDocument10 pages05a - HORIZONTAL BRACEShyamontika Choudhury ChakrabartiNo ratings yet

- My Travel PassDocument3 pagesMy Travel PassSalvatore ShwNo ratings yet

- Holding Down Bolts ExampleDocument1 pageHolding Down Bolts ExampleKhalid ElazharyNo ratings yet

- Holding Down BoltsDocument1 pageHolding Down BoltsWin ThanNo ratings yet

- Design of Anchor Bolt Rev ADocument8 pagesDesign of Anchor Bolt Rev ACalvin TehNo ratings yet

- Bering Pad Example-TexasDocument16 pagesBering Pad Example-TexasXiomara M Santiago OramaNo ratings yet

- Holding Down BoltsDocument1 pageHolding Down Boltsatokku100% (2)

- ستيل ستركشرDocument73 pagesستيل ستركشرAws SamaNo ratings yet

- Design of Bearing PadDocument3 pagesDesign of Bearing Padaris tanNo ratings yet

- Bolted Connections: DR S R Satish Kumar, IIT Madras 1Document30 pagesBolted Connections: DR S R Satish Kumar, IIT Madras 1jss_devNo ratings yet

- BoltDocument26 pagesBoltsixramesh123No ratings yet

- B-1 - Canopy Base PlateDocument2 pagesB-1 - Canopy Base PlateSaurabh GuptaNo ratings yet

- 4.T&Angle-Brace Connection (M Project) - 0618Document49 pages4.T&Angle-Brace Connection (M Project) - 0618Omprakash KhodkeNo ratings yet

- Rigid Connection DesignDocument215 pagesRigid Connection DesignUmer AziqNo ratings yet

- Member Design - Reinforced Concrete Beam BS8110Document37 pagesMember Design - Reinforced Concrete Beam BS8110sanusi69No ratings yet

- Beam Column ConnectionDocument2 pagesBeam Column ConnectionHAZIRACFS SURATNo ratings yet

- Div Syd Detailing of Reinforcement in Concrete StructuresDocument82 pagesDiv Syd Detailing of Reinforcement in Concrete Structuresتقوى طهNo ratings yet

- Session 11 - Design of Steel ConnectionsDocument32 pagesSession 11 - Design of Steel Connectionsshan kumarNo ratings yet

- Purchaser NEA Rs Infra Project STR DGN of TT "Da (0 Deg.) " With Htls Conductor (WZ 4) 132KV D/C Transmission Line From Kusaha To BiratnagarDocument1 pagePurchaser NEA Rs Infra Project STR DGN of TT "Da (0 Deg.) " With Htls Conductor (WZ 4) 132KV D/C Transmission Line From Kusaha To BiratnagarRakshit KumarNo ratings yet

- Design and Calculation of Bearing Pad SpreadsheetDocument5 pagesDesign and Calculation of Bearing Pad SpreadsheetSaurav KumarNo ratings yet

- Column Base Plate Design CalculationDocument3 pagesColumn Base Plate Design CalculationPilippenge Asanka Iraj LaknathaNo ratings yet

- Design Capacity of HCS: 265 Carpark 2 - Basement Level 1Document9 pagesDesign Capacity of HCS: 265 Carpark 2 - Basement Level 1anilkv66No ratings yet

- Moment ConnectionsDocument16 pagesMoment Connectionsankit kadam0% (1)

- Design SheetDocument20 pagesDesign SheetPrayush RajbhandariNo ratings yet

- Bracing - Angles - Single RowDocument2 pagesBracing - Angles - Single RowSakthivel VNo ratings yet

- SPT Girder L 38.75m, S 2.26m (43 Strands) - 0507Document53 pagesSPT Girder L 38.75m, S 2.26m (43 Strands) - 0507Trần Dinh BảoNo ratings yet

- Design of Anchor Bolt & Reinforcement in Concrete Column (Per ACI-318-08) - 54mDocument7 pagesDesign of Anchor Bolt & Reinforcement in Concrete Column (Per ACI-318-08) - 54mhenjie mirasolNo ratings yet

- Body Flange .PVDB FlangeDocument1 pageBody Flange .PVDB FlangeAnonymous aBg51lbe18No ratings yet

- Inverted T 1475547480Document88 pagesInverted T 1475547480กิตติพงศ์ ศรีอาจNo ratings yet

- Lec-12 Development LengthDocument47 pagesLec-12 Development LengthMuhammad UsmanNo ratings yet

- Connection - Foundation To PileDocument5 pagesConnection - Foundation To PileSandesh Kumar100% (1)

- Actual Base Plate Design V1 2 42 210Document6 pagesActual Base Plate Design V1 2 42 210Alphyl BalasabasNo ratings yet

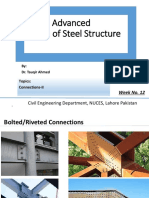

- Advanced Design of Steel Structure: Civil Engineering Department, NUCES, Lahore PakistanDocument23 pagesAdvanced Design of Steel Structure: Civil Engineering Department, NUCES, Lahore Pakistansyed muneeb haiderNo ratings yet

- Bearing Design Method BDocument38 pagesBearing Design Method BTeguh FahrezaNo ratings yet

- Bearing Design MethodDocument38 pagesBearing Design MethodTeguh FahrezaNo ratings yet

- Idn - 0.decking Slab 1Document6 pagesIdn - 0.decking Slab 1Anh KyNo ratings yet

- Base Plate Design - Rev-0Document8 pagesBase Plate Design - Rev-0KINGSUK PALNo ratings yet

- Screw Threads #2Document221 pagesScrew Threads #2boo huNo ratings yet

- Balok GirderDocument40 pagesBalok GirdertriNo ratings yet

- 8 CE133P Ultimate Strength Design One Way Slabs Rev (Robles) 2Document12 pages8 CE133P Ultimate Strength Design One Way Slabs Rev (Robles) 2KC Paguinto100% (1)

- IX Connections Tatiana FINALDocument10 pagesIX Connections Tatiana FINALlucianolimauerjrm4No ratings yet

- Connection Design Steel Base Plate Bs5950 v2015 01Document4 pagesConnection Design Steel Base Plate Bs5950 v2015 01Anonymous j9PxwnoNo ratings yet

- Kns3703 Structural Steel Design Design Bolted Connections Bolted ConnectionsDocument25 pagesKns3703 Structural Steel Design Design Bolted Connections Bolted ConnectionsBernardine BenedictNo ratings yet

- Pinned Base Plate (Rs Shear Key)Document7 pagesPinned Base Plate (Rs Shear Key)winlugue3059100% (2)

- Baris Ke-Klik Disini Untuk Mengcopy Tipe Kolom: Proyek: Lokasi: Jenis Bangunan: PerhitunganDocument15 pagesBaris Ke-Klik Disini Untuk Mengcopy Tipe Kolom: Proyek: Lokasi: Jenis Bangunan: PerhitunganmudifNo ratings yet

- The World Bank: Uttarakhand Disaster Recovery ProjectDocument14 pagesThe World Bank: Uttarakhand Disaster Recovery Projectvicky rawatNo ratings yet

- R1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelDocument12 pagesR1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelPete Rueangchim100% (3)

- SVP Walk Way Support Structure: Embedment Plate and Bolt Design 1 For Top Support - Ismc 100Document6 pagesSVP Walk Way Support Structure: Embedment Plate and Bolt Design 1 For Top Support - Ismc 100aakash prabhuNo ratings yet

- R0 Trench Bracket, Bolt & Plate Loading CalculationsDocument2 pagesR0 Trench Bracket, Bolt & Plate Loading CalculationsAkd DeshmukhNo ratings yet

- High Performance ConcreteDocument62 pagesHigh Performance ConcreteabdoNo ratings yet

- Member Design - Prestressed Concrete Beam and Slab BS8110 (EC2), ACI318, AS3600 v2021.03 PDFDocument98 pagesMember Design - Prestressed Concrete Beam and Slab BS8110 (EC2), ACI318, AS3600 v2021.03 PDFlau lauNo ratings yet

- Member Design Reinforced Concrete Corbel bs8110 v2015 01Document10 pagesMember Design Reinforced Concrete Corbel bs8110 v2015 01Aboalmaali100% (1)

- Base Plate Andf Anchor Bolt Design For Minor Axis MomentDocument2 pagesBase Plate Andf Anchor Bolt Design For Minor Axis MomentSunil Pulikkal100% (1)

- Bending in Beam 2: Reinforced Concrete Design IDocument53 pagesBending in Beam 2: Reinforced Concrete Design IMongkol JirawacharadetNo ratings yet

- 9.3 Strut Design ISMB (Hor)Document7 pages9.3 Strut Design ISMB (Hor)24x7civilconsultantNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- PURLINDocument5 pagesPURLINSalvatore ShwNo ratings yet

- AssemblyDocument4 pagesAssemblySalvatore ShwNo ratings yet

- Material RateDocument1 pageMaterial RateSalvatore ShwNo ratings yet

- Staff Quarters - StaircaseDocument3 pagesStaff Quarters - StaircaseSalvatore ShwNo ratings yet

- Untuk Tetuan China Tangxing Equipment (M) SDN BHDDocument1 pageUntuk Tetuan China Tangxing Equipment (M) SDN BHDSalvatore ShwNo ratings yet

- Factory - Checkered Plate For StaircaseDocument1 pageFactory - Checkered Plate For StaircaseSalvatore ShwNo ratings yet

- Untuk Tetuan China Tangxing Equipment (M) SDN BHDDocument1 pageUntuk Tetuan China Tangxing Equipment (M) SDN BHDSalvatore ShwNo ratings yet

- Z7 - Purlin 200X75X1.6Document1 pageZ7 - Purlin 200X75X1.6Salvatore ShwNo ratings yet

- Lug Design CalculationDocument1 pageLug Design CalculationSalvatore ShwNo ratings yet

- Strap: Structural Analysis ProgramsDocument2 pagesStrap: Structural Analysis ProgramsSalvatore ShwNo ratings yet

- 2 Nos 12Mm THK M.S Plate 2 Nos M16 Bolts Grade 8.8Document1 page2 Nos 12Mm THK M.S Plate 2 Nos M16 Bolts Grade 8.8Salvatore ShwNo ratings yet

- C Purlin Design Calculation With Single Sag Rods: y 2 3 3 3 3 3 6 4 Y-Y X-XDocument1 pageC Purlin Design Calculation With Single Sag Rods: y 2 3 3 3 3 3 6 4 Y-Y X-XSalvatore ShwNo ratings yet

- Top & Bot Chord - Shs 50X50X4Mm THK Internal Chord - Shs 38X38X3Mm THKDocument1 pageTop & Bot Chord - Shs 50X50X4Mm THK Internal Chord - Shs 38X38X3Mm THKSalvatore ShwNo ratings yet

Holding Down Bolts

Holding Down Bolts

Uploaded by

Salvatore Shw0 ratings0% found this document useful (0 votes)

51 views1 pageThis document calculates the pull-out capacity of holding down bolts embedded in concrete. It determines that the maximum tension force per bolt is 60 kN, which is less than the bolt's tension capacity of 70.7 kN. It also finds that the design pull-out resistance per bolt is 65 kN, which exceeds the maximum tension force. Therefore, the bolts provide adequate anchorage in the concrete.

Original Description:

Original Title

237177223 Holding Down Bolts

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document calculates the pull-out capacity of holding down bolts embedded in concrete. It determines that the maximum tension force per bolt is 60 kN, which is less than the bolt's tension capacity of 70.7 kN. It also finds that the design pull-out resistance per bolt is 65 kN, which exceeds the maximum tension force. Therefore, the bolts provide adequate anchorage in the concrete.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

51 views1 pageHolding Down Bolts

Holding Down Bolts

Uploaded by

Salvatore ShwThis document calculates the pull-out capacity of holding down bolts embedded in concrete. It determines that the maximum tension force per bolt is 60 kN, which is less than the bolt's tension capacity of 70.7 kN. It also finds that the design pull-out resistance per bolt is 65 kN, which exceeds the maximum tension force. Therefore, the bolts provide adequate anchorage in the concrete.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

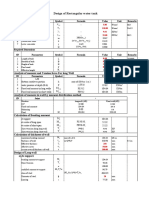

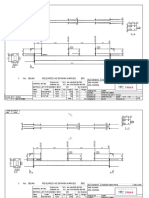

L_proj (Clear projection of bolt above nut)

t_was (Washer thickness) t_p (Base plate thickness)

t_gr (Thickness of bedding)

L_bolt (Overall length of bolts) Concrete

PULL-OUT CAPACITY OF HOLDING DOWN BOLTS

TEDDS calculation version 1.0.01

These calculations assume that there is no coexistent shear in the holding-down bolts.

Tension capacity of bolts

; Maximum tension force per bolt; Ft = 60.0 kN

; Try M16 (Grade 8.8); bolts; Pt = 70.7 kN ; dnut = 13 mm

Check Ft Pt ; Pass - Bolt tension capacity;

Pull-out resistance of concrete

;; Overall length of bolts; Lbolt = 350 mm

; Clear projection of bolt above nut; Lproj = 50 mm

;;; Thickness of washer, baseplate & grout; twas = 3 mm ; tp = 16 mm ; tgr = 20 mm

Depth of embedment; de = Lbolt - Lproj - dnut - twas - tp - tgr = 248 mm

From BCSA HDBolts document, effective conical surface area; for two bolts; Aec = 3821.4 cm2

Depth of embedment selected; de = 248 mm

Design spacing of bolts (c/c); Xccs = 150 mm

; Shear strength of concrete; vc = 0.34 N/mm2

Design pull-out resistance, per bolt; Ptc = Aec vc / 2 = 65.0 kN

Check Ft Ptc ; Pass - Concrete pull-out resistance

Bolts require adequate anchorage by suitably sized washer plates or equivalent under the bolt heads.

BS 5950: Part 1: 2000: Sections 4.13 & 6.6

'Holding down systems for steel stanchions' BCSA / Constrado 1980

;

You might also like

- Holding Down Bolts ExampleDocument1 pageHolding Down Bolts ExampleMarcelo MachadoNo ratings yet

- Design of Rectangular Water Tank: SN Design Parameters Symbol Formula Value Unit RemarksDocument5 pagesDesign of Rectangular Water Tank: SN Design Parameters Symbol Formula Value Unit Remarkskiran_karki_8100% (1)

- Analysis and Design of Base Plate and Anchor Bolt For Pinned BaseDocument4 pagesAnalysis and Design of Base Plate and Anchor Bolt For Pinned BaseSunil PulikkalNo ratings yet

- BDM Example 6 - 20180101Document23 pagesBDM Example 6 - 20180101mustafurade1No ratings yet

- 05a - HORIZONTAL BRACEDocument10 pages05a - HORIZONTAL BRACEShyamontika Choudhury ChakrabartiNo ratings yet

- My Travel PassDocument3 pagesMy Travel PassSalvatore ShwNo ratings yet

- Holding Down Bolts ExampleDocument1 pageHolding Down Bolts ExampleKhalid ElazharyNo ratings yet

- Holding Down BoltsDocument1 pageHolding Down BoltsWin ThanNo ratings yet

- Design of Anchor Bolt Rev ADocument8 pagesDesign of Anchor Bolt Rev ACalvin TehNo ratings yet

- Bering Pad Example-TexasDocument16 pagesBering Pad Example-TexasXiomara M Santiago OramaNo ratings yet

- Holding Down BoltsDocument1 pageHolding Down Boltsatokku100% (2)

- ستيل ستركشرDocument73 pagesستيل ستركشرAws SamaNo ratings yet

- Design of Bearing PadDocument3 pagesDesign of Bearing Padaris tanNo ratings yet

- Bolted Connections: DR S R Satish Kumar, IIT Madras 1Document30 pagesBolted Connections: DR S R Satish Kumar, IIT Madras 1jss_devNo ratings yet

- BoltDocument26 pagesBoltsixramesh123No ratings yet

- B-1 - Canopy Base PlateDocument2 pagesB-1 - Canopy Base PlateSaurabh GuptaNo ratings yet

- 4.T&Angle-Brace Connection (M Project) - 0618Document49 pages4.T&Angle-Brace Connection (M Project) - 0618Omprakash KhodkeNo ratings yet

- Rigid Connection DesignDocument215 pagesRigid Connection DesignUmer AziqNo ratings yet

- Member Design - Reinforced Concrete Beam BS8110Document37 pagesMember Design - Reinforced Concrete Beam BS8110sanusi69No ratings yet

- Beam Column ConnectionDocument2 pagesBeam Column ConnectionHAZIRACFS SURATNo ratings yet

- Div Syd Detailing of Reinforcement in Concrete StructuresDocument82 pagesDiv Syd Detailing of Reinforcement in Concrete Structuresتقوى طهNo ratings yet

- Session 11 - Design of Steel ConnectionsDocument32 pagesSession 11 - Design of Steel Connectionsshan kumarNo ratings yet

- Purchaser NEA Rs Infra Project STR DGN of TT "Da (0 Deg.) " With Htls Conductor (WZ 4) 132KV D/C Transmission Line From Kusaha To BiratnagarDocument1 pagePurchaser NEA Rs Infra Project STR DGN of TT "Da (0 Deg.) " With Htls Conductor (WZ 4) 132KV D/C Transmission Line From Kusaha To BiratnagarRakshit KumarNo ratings yet

- Design and Calculation of Bearing Pad SpreadsheetDocument5 pagesDesign and Calculation of Bearing Pad SpreadsheetSaurav KumarNo ratings yet

- Column Base Plate Design CalculationDocument3 pagesColumn Base Plate Design CalculationPilippenge Asanka Iraj LaknathaNo ratings yet

- Design Capacity of HCS: 265 Carpark 2 - Basement Level 1Document9 pagesDesign Capacity of HCS: 265 Carpark 2 - Basement Level 1anilkv66No ratings yet

- Moment ConnectionsDocument16 pagesMoment Connectionsankit kadam0% (1)

- Design SheetDocument20 pagesDesign SheetPrayush RajbhandariNo ratings yet

- Bracing - Angles - Single RowDocument2 pagesBracing - Angles - Single RowSakthivel VNo ratings yet

- SPT Girder L 38.75m, S 2.26m (43 Strands) - 0507Document53 pagesSPT Girder L 38.75m, S 2.26m (43 Strands) - 0507Trần Dinh BảoNo ratings yet

- Design of Anchor Bolt & Reinforcement in Concrete Column (Per ACI-318-08) - 54mDocument7 pagesDesign of Anchor Bolt & Reinforcement in Concrete Column (Per ACI-318-08) - 54mhenjie mirasolNo ratings yet

- Body Flange .PVDB FlangeDocument1 pageBody Flange .PVDB FlangeAnonymous aBg51lbe18No ratings yet

- Inverted T 1475547480Document88 pagesInverted T 1475547480กิตติพงศ์ ศรีอาจNo ratings yet

- Lec-12 Development LengthDocument47 pagesLec-12 Development LengthMuhammad UsmanNo ratings yet

- Connection - Foundation To PileDocument5 pagesConnection - Foundation To PileSandesh Kumar100% (1)

- Actual Base Plate Design V1 2 42 210Document6 pagesActual Base Plate Design V1 2 42 210Alphyl BalasabasNo ratings yet

- Advanced Design of Steel Structure: Civil Engineering Department, NUCES, Lahore PakistanDocument23 pagesAdvanced Design of Steel Structure: Civil Engineering Department, NUCES, Lahore Pakistansyed muneeb haiderNo ratings yet

- Bearing Design Method BDocument38 pagesBearing Design Method BTeguh FahrezaNo ratings yet

- Bearing Design MethodDocument38 pagesBearing Design MethodTeguh FahrezaNo ratings yet

- Idn - 0.decking Slab 1Document6 pagesIdn - 0.decking Slab 1Anh KyNo ratings yet

- Base Plate Design - Rev-0Document8 pagesBase Plate Design - Rev-0KINGSUK PALNo ratings yet

- Screw Threads #2Document221 pagesScrew Threads #2boo huNo ratings yet

- Balok GirderDocument40 pagesBalok GirdertriNo ratings yet

- 8 CE133P Ultimate Strength Design One Way Slabs Rev (Robles) 2Document12 pages8 CE133P Ultimate Strength Design One Way Slabs Rev (Robles) 2KC Paguinto100% (1)

- IX Connections Tatiana FINALDocument10 pagesIX Connections Tatiana FINALlucianolimauerjrm4No ratings yet

- Connection Design Steel Base Plate Bs5950 v2015 01Document4 pagesConnection Design Steel Base Plate Bs5950 v2015 01Anonymous j9PxwnoNo ratings yet

- Kns3703 Structural Steel Design Design Bolted Connections Bolted ConnectionsDocument25 pagesKns3703 Structural Steel Design Design Bolted Connections Bolted ConnectionsBernardine BenedictNo ratings yet

- Pinned Base Plate (Rs Shear Key)Document7 pagesPinned Base Plate (Rs Shear Key)winlugue3059100% (2)

- Baris Ke-Klik Disini Untuk Mengcopy Tipe Kolom: Proyek: Lokasi: Jenis Bangunan: PerhitunganDocument15 pagesBaris Ke-Klik Disini Untuk Mengcopy Tipe Kolom: Proyek: Lokasi: Jenis Bangunan: PerhitunganmudifNo ratings yet

- The World Bank: Uttarakhand Disaster Recovery ProjectDocument14 pagesThe World Bank: Uttarakhand Disaster Recovery Projectvicky rawatNo ratings yet

- R1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelDocument12 pagesR1 - Calculation Report of Waste Water Storage Tank - Bangchack BiofuelPete Rueangchim100% (3)

- SVP Walk Way Support Structure: Embedment Plate and Bolt Design 1 For Top Support - Ismc 100Document6 pagesSVP Walk Way Support Structure: Embedment Plate and Bolt Design 1 For Top Support - Ismc 100aakash prabhuNo ratings yet

- R0 Trench Bracket, Bolt & Plate Loading CalculationsDocument2 pagesR0 Trench Bracket, Bolt & Plate Loading CalculationsAkd DeshmukhNo ratings yet

- High Performance ConcreteDocument62 pagesHigh Performance ConcreteabdoNo ratings yet

- Member Design - Prestressed Concrete Beam and Slab BS8110 (EC2), ACI318, AS3600 v2021.03 PDFDocument98 pagesMember Design - Prestressed Concrete Beam and Slab BS8110 (EC2), ACI318, AS3600 v2021.03 PDFlau lauNo ratings yet

- Member Design Reinforced Concrete Corbel bs8110 v2015 01Document10 pagesMember Design Reinforced Concrete Corbel bs8110 v2015 01Aboalmaali100% (1)

- Base Plate Andf Anchor Bolt Design For Minor Axis MomentDocument2 pagesBase Plate Andf Anchor Bolt Design For Minor Axis MomentSunil Pulikkal100% (1)

- Bending in Beam 2: Reinforced Concrete Design IDocument53 pagesBending in Beam 2: Reinforced Concrete Design IMongkol JirawacharadetNo ratings yet

- 9.3 Strut Design ISMB (Hor)Document7 pages9.3 Strut Design ISMB (Hor)24x7civilconsultantNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- PURLINDocument5 pagesPURLINSalvatore ShwNo ratings yet

- AssemblyDocument4 pagesAssemblySalvatore ShwNo ratings yet

- Material RateDocument1 pageMaterial RateSalvatore ShwNo ratings yet

- Staff Quarters - StaircaseDocument3 pagesStaff Quarters - StaircaseSalvatore ShwNo ratings yet

- Untuk Tetuan China Tangxing Equipment (M) SDN BHDDocument1 pageUntuk Tetuan China Tangxing Equipment (M) SDN BHDSalvatore ShwNo ratings yet

- Factory - Checkered Plate For StaircaseDocument1 pageFactory - Checkered Plate For StaircaseSalvatore ShwNo ratings yet

- Untuk Tetuan China Tangxing Equipment (M) SDN BHDDocument1 pageUntuk Tetuan China Tangxing Equipment (M) SDN BHDSalvatore ShwNo ratings yet

- Z7 - Purlin 200X75X1.6Document1 pageZ7 - Purlin 200X75X1.6Salvatore ShwNo ratings yet

- Lug Design CalculationDocument1 pageLug Design CalculationSalvatore ShwNo ratings yet

- Strap: Structural Analysis ProgramsDocument2 pagesStrap: Structural Analysis ProgramsSalvatore ShwNo ratings yet

- 2 Nos 12Mm THK M.S Plate 2 Nos M16 Bolts Grade 8.8Document1 page2 Nos 12Mm THK M.S Plate 2 Nos M16 Bolts Grade 8.8Salvatore ShwNo ratings yet

- C Purlin Design Calculation With Single Sag Rods: y 2 3 3 3 3 3 6 4 Y-Y X-XDocument1 pageC Purlin Design Calculation With Single Sag Rods: y 2 3 3 3 3 3 6 4 Y-Y X-XSalvatore ShwNo ratings yet

- Top & Bot Chord - Shs 50X50X4Mm THK Internal Chord - Shs 38X38X3Mm THKDocument1 pageTop & Bot Chord - Shs 50X50X4Mm THK Internal Chord - Shs 38X38X3Mm THKSalvatore ShwNo ratings yet