Professional Documents

Culture Documents

Electric Windlasses: Fact Sheet

Electric Windlasses: Fact Sheet

Uploaded by

riowahyuprabowoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electric Windlasses: Fact Sheet

Electric Windlasses: Fact Sheet

Uploaded by

riowahyuprabowoCopyright:

Available Formats

Fact Sheet

Electric windlasses

Double and single cablelifter types for anchor handling and mooring duties

Three types of electric drives

– AC invertor

– 3 speed squirrel cage

– DC thyristor

Compact robust design

Extreme temperature operation

-40OC to 55OC

Holding loads from 20 - 206 tonnes

Warping speeds up to 24m/min

Low noise and vibration signature

Designed to meet naval shock loads

Forward double cablelifter windlass

Compliant to Lloyd’s Rules for Naval

Designed to naval standards

Ships

This range of Rolls-Royce standard double options, which include an anti-condensation

and single cablelifter anchor and mooring stand-still heater. Motors incorporate DC

Other naval classification societies as

windlasses is designed specifically for naval operated magnetic brakes with easily

required

vessels. Compact and robust construction replaceable friction pads and require no

means few wearing parts, minimum adjustment. In the event of power failure

maintenance and simple installation. there is a manual release.

Designs suit cables from 28 – 84mm Control

diameter with a maximum brake holding The master controller is mounted in a

load of 206 tonnes. Cablelifter centers can watertight pedestal with integral anti-

be varied to meet specific deck layouts. In condensation stand-still heater and

standard configuration the electric motor is cooling. A control panel for mounting on

mounted on the windlass bedplate. Drive the bulkhead houses the motor protection

is through a fully enclosed and splash devices. Speed control can be stepless: the

lubricated worm and spur gear arrangement complete speed range and direction are

mounted in anti-friction bearings for controlled by a single lever.

optimum efficiency with quiet running. All

shafts run on gunmetal bearings for long life

and efficient operation.

Select from three low maintenance motor

Customised design options

Extended centre cablelifter shafting to suit specific deck dimensions

Wire rope drums for mooring duties

Bespoke capacity windlasses to suit athwartships anchor cables and large cables

Remote control units

Bowstoppers

Fact Sheet

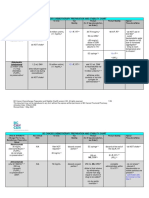

Duty table (in accordance with Lloyd’s Rules and Regulations for Naval Ships - January 2002)

Cables Cable duty Warp duty Cablelifter

Model brake holding Motor

reference U2 U3 Load Mean spead Load Speed load (kW)

(tonne) (m/min) (tonne) (m/min) (tonne)

28 N/A 3.33 20.63

W1 30 28 3.82 9 2 24 29.47 15

32 30 4.35 33.70

34 32 4.91 38.20

W2 36 34 5.51 9 3 24 42.95 20

38 36 6.14 47.97

40 38 6.80 53.24

W3 42 N/A 7.49 9 4 24 45.16 25

44 40 8.23 58.76

46 42 8.99 64.53

W4 48 44 9.79 9 5 24 70.54 35

50 46 10.62 76.79

52 48 11.49 83.29

W5 54 50 12.39 9 6 24 90.01 40

56 52 13.32 96.97

58 54 14.29 104.15

W6 60 56 15.30 9 8 24 111.55 50

62 58 16.33 119.18

64 60 17.40 127.02

W7 66 62 18.51 9 9 24 135.08 55

68 64 19.65 143.34

70 66 20.82 151.82

W8 73 68 22.64 9 11 24 160.49 70

76 70 24.54 169.36

78 73 25.85 183.04

W9 81 76 27.88 9 14 24 197.15 85

84 78 29.98 206.78

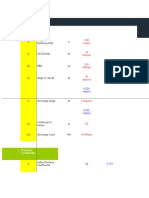

Dimensions and weights (all dimensions in mm)

A L G

C B C M C F

E E

D D J

Double cablelifter windlass Single cablelifter windlass

(left hand windlass shown)

Double Single

Model cablelifter cablelifter

reference A B C D E F G H J K L M windlass & windlass &

motor (kg) motor (kg)

W1 2310 1150 580 250 250 415 840 1900 725 1175 1440 860 3000 1950

W2 2590 1250 670 300 300 500 940 2000 826 1175 1600 930 4250 2750

W3 2860 1350 755 350 350 570 1040 2080 905 1175 1755 1000 5200 3550

W4 3200 1500 850 400 400 670 1210 2370 1040 1330 1970 1120 7000 4500

W5 3480 1600 940 450 450 720 1340 2580 1180 1400 2140 1200 9500 6200

W6 3800 1700 1050 500 500 820 1540 2970 1350 1620 2300 1250 12100 7750

W7 4400 2100 1150 550 550 850 1540 2930 1200 1730 2700 1550 14700 9650

W8 4700 2200 1250 600 600 950 1700 3350 1330 2020 2900 1650 17300 12000

W9 5000 2300 1350 650 650 1040 1860 3750 1450 2300 3100 1750 20300 14500

Rolls-Royce Power Engineering plc © 2006 Rolls-Royce plc

Naval Deck Machinery, RAS/FAS,

® Michelle Factory, Scotswood Rd,

Whilst this information is given in good faith, no warranty or

representation is given concerning such information, which must

Newcastle-upon-Tyne NE15 6LL not be taken as establishing any contractual or other commitment

Tel: +44 (0)191 256 2800, binding upon Rolls-Royce plc or any of its subsidiary companies.

Fax: +44 (0)191 256 2801 Ref: MMS/FS/09/06/4

You might also like

- Al Maths Pure Unit 6 MsDocument8 pagesAl Maths Pure Unit 6 MsHacjer EiNSTi3NNo ratings yet

- Specification Sheet PDFDocument60 pagesSpecification Sheet PDFmarvin17100% (1)

- Wb-225 Crane BargeDocument9 pagesWb-225 Crane Bargeramya100% (1)

- The Modern Cruising Sailboat: A Complete Guide to its Design, Construction, and OutfittingFrom EverandThe Modern Cruising Sailboat: A Complete Guide to its Design, Construction, and OutfittingRating: 5 out of 5 stars5/5 (4)

- Siren BS1 - Rev-E PDFDocument2 pagesSiren BS1 - Rev-E PDFConstantin Gurzu0% (1)

- 6FM200HXDocument2 pages6FM200HXRoyLoraGallardoNo ratings yet

- 12V 200ah (20hr) : Battery ConstructionDocument2 pages12V 200ah (20hr) : Battery ConstructionHakon ChileNo ratings yet

- 12V 120ah (10hr) : Battery ConstructionDocument2 pages12V 120ah (10hr) : Battery ConstructionRoberto KaltnerNo ratings yet

- FT Series: FTB12-150 12V150AhDocument2 pagesFT Series: FTB12-150 12V150AhJohn Edwin MuñozNo ratings yet

- Fta12 200HTDocument2 pagesFta12 200HTMohammedAbdulfattahNo ratings yet

- 12V 200ah (10hr) : Battery ConstructionDocument2 pages12V 200ah (10hr) : Battery ConstructionOjo de AguaNo ratings yet

- E-Catalogue Bicc - 150 Kv-r04Document1 pageE-Catalogue Bicc - 150 Kv-r04bimbremboNo ratings yet

- 6FM200 XDocument2 pages6FM200 XTuấn VũNo ratings yet

- 12V 33ah (10hr) - LONG LIFE: Battery ConstructionDocument2 pages12V 33ah (10hr) - LONG LIFE: Battery ConstructionJonathan CastilloNo ratings yet

- Ducab Cables-Pages-5Document1 pageDucab Cables-Pages-5Bilal JavaidNo ratings yet

- Tabla de Amperajes Fusibles HH 24 KVDocument1 pageTabla de Amperajes Fusibles HH 24 KVBastian OspinaNo ratings yet

- MPG12V155FDocument2 pagesMPG12V155FZeeme AhmadNo ratings yet

- 12V 7.2ah (20hr) - Ups: Battery ConstructionDocument2 pages12V 7.2ah (20hr) - Ups: Battery ConstructionJuan Sebastian CorreaNo ratings yet

- CP1290Document2 pagesCP1290mn2019No ratings yet

- Sacred Sun Fta 12-200Document2 pagesSacred Sun Fta 12-200ALEX ALEXNo ratings yet

- Solar Cable CatalogueDocument6 pagesSolar Cable CatalogueAnonymous MzF9d8vnQNo ratings yet

- Kaise Batera Agm 12v 200ahDocument2 pagesKaise Batera Agm 12v 200ahJOHN FREDY IBAÑEZ HERNANDEZNo ratings yet

- CP1290 Bateria Gel 12vDocument2 pagesCP1290 Bateria Gel 12vDaniel SevillaNo ratings yet

- Kaise Kbl12550Document2 pagesKaise Kbl12550Seba LopezNo ratings yet

- Rex 2000Document2 pagesRex 2000Md ShNo ratings yet

- According To Customers' Requirements: 4 Pair 24awg Cat5E Utp Cable Part No.:UPC-5004E-SODocument1 pageAccording To Customers' Requirements: 4 Pair 24awg Cat5E Utp Cable Part No.:UPC-5004E-SOphilip644No ratings yet

- 4OPzV ET200 0922Document2 pages4OPzV ET200 0922Races CHeNo ratings yet

- FT Series: FTB12-100 12V100AhDocument2 pagesFT Series: FTB12-100 12V100Ahari yuniantoNo ratings yet

- CL200Document2 pagesCL200Ltv Ltv LtvNo ratings yet

- Kaise KB1218 - Hoja de DatosDocument2 pagesKaise KB1218 - Hoja de DatosGermanYPNo ratings yet

- Series VRLA Battery: Main ApplicationsDocument2 pagesSeries VRLA Battery: Main ApplicationswaqasNo ratings yet

- Cable SelectionDocument4 pagesCable SelectionMuhammadThoriqAzmiNo ratings yet

- 6-FMX Series: 6-FMX-200 Front Terminal BatteryDocument2 pages6-FMX Series: 6-FMX-200 Front Terminal BatteryMajor Prince100% (1)

- 6FM80XDocument2 pages6FM80XSilvester SipayungNo ratings yet

- GFM-200 enDocument2 pagesGFM-200 enGermanYPNo ratings yet

- Manual Instalac. Victaulic I-6000 - Estilo 44Document3 pagesManual Instalac. Victaulic I-6000 - Estilo 44Nilton Inca TitoNo ratings yet

- 12V 100ah (20hr) : Battery ConstructionDocument2 pages12V 100ah (20hr) : Battery Constructionmr dangNo ratings yet

- GFM 600hesDocument2 pagesGFM 600heschee wy100% (1)

- Mechanical Bolt Torque TableDocument7 pagesMechanical Bolt Torque TablesitehabNo ratings yet

- HHC71BDocument3 pagesHHC71Bمحمدعبدالخالق العلوانيNo ratings yet

- Electric Duct Heaters - Installation GuideDocument2 pagesElectric Duct Heaters - Installation GuideLeandro SimonsNo ratings yet

- Motor Full Load Currents: Use This Chart To Select The CT Rating For Various Motor SizesDocument2 pagesMotor Full Load Currents: Use This Chart To Select The CT Rating For Various Motor SizesMd SharifNo ratings yet

- DCS SeriesDocument2 pagesDCS SeriesCharmer JiaNo ratings yet

- 6 FMX 200Document2 pages6 FMX 200Naqash AhmedNo ratings yet

- Performance Report: Caterpillar 325D L vs. Caterpillar 325C LDocument10 pagesPerformance Report: Caterpillar 325D L vs. Caterpillar 325C LDANIEL VARGAS RODRIGUEZNo ratings yet

- Shoto6 FMX 200Document2 pagesShoto6 FMX 200Станислав КлебановNo ratings yet

- 6fm200se X PDFDocument2 pages6fm200se X PDFMarco Antonio Mayta ZubizarretaNo ratings yet

- FT Series: FTA12-200 12V200Ah FTA12-200 12V200AhDocument2 pagesFT Series: FTA12-200 12V200Ah FTA12-200 12V200AhALEX ALEXNo ratings yet

- Hydrodynamic ForceDocument11 pagesHydrodynamic ForceSaurabh TiwariNo ratings yet

- Energy Substation Hvsa Mca Mda IecDocument14 pagesEnergy Substation Hvsa Mca Mda IecAndi JuralNo ratings yet

- CL300 PDFDocument2 pagesCL300 PDFDELMAR QUIROGA CALDERONNo ratings yet

- 12V 200ah (10hr) : Battery ConstructionDocument2 pages12V 200ah (10hr) : Battery ConstructionCristian Felipe Rangel TrianaNo ratings yet

- SuperSafe 12T92F NewbrochureDocument2 pagesSuperSafe 12T92F Newbrochureparahu ariefNo ratings yet

- KBL12650Document2 pagesKBL12650Anonymous btQ72dNo ratings yet

- Overhead Conveyor Products PDFDocument16 pagesOverhead Conveyor Products PDFPierre Hopkins100% (1)

- 12HRL700 Bateria 180ah-200ahDocument2 pages12HRL700 Bateria 180ah-200ahJesusGonzalesNo ratings yet

- Fag Series Vrla Battery: Technical SpecificationsDocument2 pagesFag Series Vrla Battery: Technical Specificationschee wyNo ratings yet

- PWL Series: A Super Long Life BatteryDocument2 pagesPWL Series: A Super Long Life BatteryTanveer AhmedNo ratings yet

- 2017 CWS THA Applied 12-48 MBH 50 HZDocument2 pages2017 CWS THA Applied 12-48 MBH 50 HZtuiNo ratings yet

- N2XYDocument5 pagesN2XYSamuel SantosNo ratings yet

- IMA Continental-TM27 enDocument2 pagesIMA Continental-TM27 enХелфор УкраинаNo ratings yet

- Brochure Ắc Quy VISIONDocument2 pagesBrochure Ắc Quy VISIONlong bạchNo ratings yet

- Comm 10Document2 pagesComm 10boopNo ratings yet

- DLL - Mathematics 6 - Q4 - W2Document8 pagesDLL - Mathematics 6 - Q4 - W2RirinNo ratings yet

- PSUR-PMSR UnterschiedDocument16 pagesPSUR-PMSR UnterschiedwNo ratings yet

- Innovative Strategies For Flood-Resilient CitiesDocument50 pagesInnovative Strategies For Flood-Resilient CitiesDaisy100% (1)

- MHA St. Bernadette of LourdesDocument1 pageMHA St. Bernadette of LourdesFitz JaminitNo ratings yet

- Arduino iOS Blueprints - Sample ChapterDocument15 pagesArduino iOS Blueprints - Sample ChapterPackt PublishingNo ratings yet

- Ulla-Talvikki Virta Measuring Cycling Environment For Internet of Things ApplicationsDocument66 pagesUlla-Talvikki Virta Measuring Cycling Environment For Internet of Things ApplicationsNikola CmiljanicNo ratings yet

- Sociology 13th Edition Macionis Test BankDocument20 pagesSociology 13th Edition Macionis Test Bankdoctorsantalumu9coab100% (34)

- Emma Sconyers, "I Carry You in My Heart: Facing An Incurable Prenatal Diagnosis"Document40 pagesEmma Sconyers, "I Carry You in My Heart: Facing An Incurable Prenatal Diagnosis"MIT Comparative Media Studies/WritingNo ratings yet

- Nightingale PledgeDocument26 pagesNightingale PledgeIcee SaputilNo ratings yet

- Lee 2005Document7 pagesLee 2005afiqah.saironiNo ratings yet

- Newmaninan Concept of A GentlemanDocument4 pagesNewmaninan Concept of A GentlemanSakib Abrar TasnimNo ratings yet

- Chemo Stability Chart - AtoKDocument59 pagesChemo Stability Chart - AtoKAfifah Nur Diana PutriNo ratings yet

- I) Height of Retaining Wall H: Preliminary DataDocument10 pagesI) Height of Retaining Wall H: Preliminary DataOmPrakashNo ratings yet

- SH Catalogue - Neuro & SpinalDocument17 pagesSH Catalogue - Neuro & SpinalSaqibullah ShahzadNo ratings yet

- Lesson 10 - Week 2 PerdevDocument15 pagesLesson 10 - Week 2 PerdevChristian OconNo ratings yet

- Assam 04092012Document53 pagesAssam 04092012Sahu PraveenNo ratings yet

- HexWeb HRH10 DataSheet EuDocument6 pagesHexWeb HRH10 DataSheet EuMatijaNo ratings yet

- Anh - 10Document50 pagesAnh - 10Hưng PhúNo ratings yet

- CFJ Zimmer SubfailureDocument8 pagesCFJ Zimmer SubfailureGayle ShallooNo ratings yet

- 55 MaintenanceDocument39 pages55 MaintenanceJefry Somarribas HerreraNo ratings yet

- WickedWhims v174h ExceptionDocument5 pagesWickedWhims v174h Exceptionjean rodriguezNo ratings yet

- Tutorial 1 Intro To PhotonicsDocument4 pagesTutorial 1 Intro To Photonicsamitgh88No ratings yet

- Naive BayesDocument36 pagesNaive BayesgibthaNo ratings yet

- Introductions To Valuation Methods and Requirements 1672683839Document51 pagesIntroductions To Valuation Methods and Requirements 1672683839v7qksq5bzg100% (1)

- 05T05Document9 pages05T05ralph aris100% (1)

- Introduction To Proof in AnalysisDocument113 pagesIntroduction To Proof in AnalysisAndreas DewantoNo ratings yet

- Assumptions of The StudyDocument2 pagesAssumptions of The StudyAnthony SaurinNo ratings yet