Professional Documents

Culture Documents

Mechanisms of Deformations: Lecture 3 - Defects and Dislocations

Mechanisms of Deformations: Lecture 3 - Defects and Dislocations

Uploaded by

abiyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanisms of Deformations: Lecture 3 - Defects and Dislocations

Mechanisms of Deformations: Lecture 3 - Defects and Dislocations

Uploaded by

abiyCopyright:

Available Formats

Deformations

Mechanisms of deformations

Lecture 3 – defects and dislocations

Mechanical Engineering Design - N.Bonora 2018

Deformations

Type of deformations

• In metals and alloys we can recognize the

following type of deformations:

INITIAL LOAD UNLOAD

• Elastic deformations. Fully recoverable, they

appears immediately with the application of

stress

• Inelastic deformations. Not (all) recoverable,

irreversible. They do not disappear when

the stress is removed.

Mechanical Engineering Design - N.Bonora 2018

Deformations

Deformation

• The ability to deform depends on material structure

• Deformation can occur along specific crystal planes only

Mechanical Engineering Design - N.Bonora 2018

Deformations

Deformation and strain

• In a perfect crystal the stress necessary to move

a crystal plane over another can be estimated

from the bond strength:

𝐺

𝜏=

2𝜋

• No real materials exhibit such strength!

Mechanical Engineering Design - N.Bonora 2018

Deformations

Deformation and strain

• In 1934 Orowan, Polanyi e Taylor, almost at the

same time, understood that the ability of a

material to plastically deform was due to the

presence of defects in the lattice

• Line defects called: dislocations

• Theory of dislocations was firstly proposed by

Vito Volterra in 1907, although the term

dislocation was used by Taylor in 1934.

Mechanical Engineering Design - N.Bonora 2018

Deformations

Dislocations can move

• Dislocation glide

• Dislocation climb

• Twinning

Mechanical Engineering Design - N.Bonora 2018

Deformations

Dislocations can move

• Dislocation glide

• Dislocation climb

• Twinning

Mechanical Engineering Design - N.Bonora 2018

Deformations

Dislocations can move

• Dislocation glide

• Dislocation climb

• Twinning

Mechanical Engineering Design - N.Bonora 2018

Deformations

Dislocations can move

• Dislocation glide

• Dislocation climb

• Twinning

Twinning results when a portion of a crystal takes up an

orientation that is related to the orientation of the

untwinned lattice in a definite, symmetrical way.

Mechanical Engineering Design - N.Bonora 2018

Deformations

Dislocations can move

• Edge dislocation forms «surface steps»

• Uniaxial deformation by twinning

CDM - N.Bonora 2016

Deformations

Stress state induced by dislocations

• The region deformed by a dislocation

affect the ability of dislocation to move

and to multiply

• Most of the deformation internal

energy is due to dislocations

CDM - N.Bonora 2016

Deformations

Stress state induced by dislocations

• For same sign dislocations, laying on the

same plane, the action of the

deformation field is repulsive

• The action on opposite sign dislocations is

attractive. When in contact the

restoration of the crystal plane takes

place (annihilation)

CDM - N.Bonora 2016

Deformations

Multiplication of dislocations

• The «Frank-Read source» is the mechanism

that explain the generation of multiple

dislocation on slip planes when deformation

occurs

• Consider the straight dislocation pinned in A

and B. Under shear, the dislocation bends.

When

𝐺

𝜏=

2𝜋

CDM - N.Bonora 2016

Deformations

Multiplication of dislocations

• The «Frank-Read source» is the mechanism

that explain the generation of multiple

dislocation on slip planes when deformation

occurs

• Dislocations have to develop to produce a slip

in a deformed crystal. This implies that during

deformation, dislocations are formed mainly

along that sliding plane.

• Hardening increases the number of

dislocations according to Frank-Read

mechanism

• High dislocation density increases the yield

stress and causes material hardening

CDM - N.Bonora 2016

Deformations

Le dislocazioni nella realtà

CDM - N.Bonora 2016

Deformations

Orowan equation

𝜀 = 𝜌𝑏𝑣

• From theory and experimental evidences

we know that dislocation density is

function of stress and plastic

deformation:

𝜎 2

𝜌=𝛼

𝑏

𝜌 = 𝜌0 + 𝐶𝜀𝑝𝑛

CDM - N.Bonora 2016

Deformations

Orowan equation

𝑚

𝜎

𝑣=𝐴

𝜎0

• During hardening dislocations continue to

move. This cause a «back stress» che that

reduces the effective stress. Assuming

linear hardening we can write

𝜎 = 𝜎𝑎𝑝𝑝 − 𝜃𝜀

𝑚

𝜎𝑎𝑝𝑝 − 𝜃𝜀

𝑣=𝐴

𝜎0

CDM - N.Bonora 2016

Deformations

Orowan equation

𝑚

𝜎 𝜎𝑎𝑝𝑝 − 𝜃𝜀

𝜀 = 𝜀𝑒𝑙 + 𝜀𝑝 = + 𝐴′ 𝜌0 + 𝐶𝜀𝑝𝑛 𝑏

𝐸 𝜎0

1/𝑚

𝜀

For hardening only: 𝜎𝑎𝑝𝑝 = 𝜃𝜀 + 𝜎0

𝐴′ 𝜌0 + 𝐶𝜀𝑝𝑛 𝑏

1/𝑚

𝜀

At yield: 𝜎𝑈𝑃𝑆 = 𝜎0

𝐴′ 𝜌0 𝑏

This explains the increase of the yield stress with strain rate

CDM - N.Bonora 2016

Deformations

L’equazione di Orowan

CDM - N.Bonora 2016

Deformations

Slip on preferred crystal planes

• Plastic deformation occurs on preferred

crystal planes

• The number of planes depends on the

crystal structure:

• FCC 12 independent slip planes

• BCC 5 independent slip planes

CDM - N.Bonora 2016

Deformations

Temperature effect

• High temperature promotes climbing

• Low temperature limits the capability to

slip particularly in BCC

CDM - N.Bonora 2016

Deformations

Conclusions

• Deformation in metals and alloys is

related to defects (dislocazions)

• Dilocations motion is the basic

mechanisms for plastic deformation to

• Dilocations can move also at very low

stress (elastic at macroscopic scale) –

Peierls stress

• Orowan law allow to predict plastic flow

and strain rate effect on material yield

stress

CDM - N.Bonora 2016

Deformations

Suggested readings

• http://www.mech.utah.edu/~brannon/public/Mohrs_Circle.pdf

• Schaum's Outline of Strength of Materials, Fifth Edition (Schaum's

Outline Series) Fifth (5th) Edition Paperback – September 12, 2010

• Strength of Materials (Dover Books on Physics) Reprinted Edition

by J. P. Den Hartog, ISBN-10: 0486607550

Mechanical Engineering Design - N.Bonora 2018

You might also like

- Fault and Joint Development in Brittle and Semi-Brittle Rock: The Commonwealth and International Library: Geology DivisionFrom EverandFault and Joint Development in Brittle and Semi-Brittle Rock: The Commonwealth and International Library: Geology DivisionNo ratings yet

- Lecture-Slope Deflection and Moment DistributionDocument10 pagesLecture-Slope Deflection and Moment DistributionFanisNo ratings yet

- 01 - Fundamentals of MetalworkingDocument54 pages01 - Fundamentals of MetalworkingJabbar AljanabyNo ratings yet

- Module #15Document27 pagesModule #15kamel touilebNo ratings yet

- Mechanics of Materials: Week # 10Document12 pagesMechanics of Materials: Week # 10Dhikri AlmuzahirNo ratings yet

- Mechanical Working of Materials: Sheet Metal Forming-2Document10 pagesMechanical Working of Materials: Sheet Metal Forming-2Sahil MaharNo ratings yet

- Structure and DeformationDocument7 pagesStructure and DeformationKumar ankitNo ratings yet

- Mechanical Properties and TestingDocument25 pagesMechanical Properties and TestingbasitNo ratings yet

- Deep Drawing ProcessDocument24 pagesDeep Drawing ProcessanupalNo ratings yet

- Expression of Stress and StrainDocument38 pagesExpression of Stress and StrainAlly TNo ratings yet

- Matlab 1Document63 pagesMatlab 1Orhan YanyatmazNo ratings yet

- Week 5 - DislocationsDocument46 pagesWeek 5 - DislocationsJB HIFINo ratings yet

- Outline: Movement Dislocations: ReviewDocument6 pagesOutline: Movement Dislocations: ReviewAbberNo ratings yet

- Shear & Diagonal Tension in BeamsDocument29 pagesShear & Diagonal Tension in BeamsS. M. ZAHIDUR RAHMAN 1301129No ratings yet

- Plate Buckling SlidesDocument117 pagesPlate Buckling SlidesdominiojhtNo ratings yet

- 322 F22 Lecture15 Plasticity Vs Defects1Document59 pages322 F22 Lecture15 Plasticity Vs Defects1lokeshNo ratings yet

- 02 Som - MDocument28 pages02 Som - MSafikul HossainNo ratings yet

- Rock Deformation Geology 11 1 Sem AY 2016-2017Document2 pagesRock Deformation Geology 11 1 Sem AY 2016-2017Jasmine Bianca CastilloNo ratings yet

- M. Design Note1Document40 pagesM. Design Note1Tamari SeaNo ratings yet

- Week 11 - Design of Steel Structures - ColumnsDocument57 pagesWeek 11 - Design of Steel Structures - ColumnsSajid MehmoodNo ratings yet

- Types of Loading: Point Loading Uniformly Distributed Loading (UDL) Varying Distributed Loading (VDL)Document33 pagesTypes of Loading: Point Loading Uniformly Distributed Loading (UDL) Varying Distributed Loading (VDL)bilal NaseemNo ratings yet

- Folding PPT Week 9 RealDocument39 pagesFolding PPT Week 9 RealDylan HelpsNo ratings yet

- Week 6 - Strengthening MechanismsDocument54 pagesWeek 6 - Strengthening MechanismsJB HIFINo ratings yet

- Structural Geology and Rock Mechanics: October 10, 2019 Presented By: Arizval MendozaDocument19 pagesStructural Geology and Rock Mechanics: October 10, 2019 Presented By: Arizval MendozaDaryl Sy Su100% (1)

- Geometry of Deformation 1: Last Class-ContactsDocument11 pagesGeometry of Deformation 1: Last Class-ContactsRMNo ratings yet

- Structure Lec 10Document41 pagesStructure Lec 10keshavyadav7340161895No ratings yet

- Chapter 7 FracturesDocument60 pagesChapter 7 Fracturesenerb ntvwadzigtvyNo ratings yet

- Deflections Elastic Curves: by Dr. Fawwad MasoodDocument14 pagesDeflections Elastic Curves: by Dr. Fawwad MasoodhamidNo ratings yet

- Deformational Features of RocksDocument42 pagesDeformational Features of Rocksthareenda100% (1)

- Reinforced Concrete Design: (CIVL 3320)Document33 pagesReinforced Concrete Design: (CIVL 3320)taiman chanNo ratings yet

- CE015-Module 5 - Analysis and Design of Singly-Reinforced Concrete BeamDocument35 pagesCE015-Module 5 - Analysis and Design of Singly-Reinforced Concrete BeamGeoville R. VidalNo ratings yet

- 1 Stress, Strain and Deformation of SolidsDocument51 pages1 Stress, Strain and Deformation of SolidsMwanamomo MpambaNo ratings yet

- Folding Faulting - NegiDocument31 pagesFolding Faulting - NegiSumit SagarNo ratings yet

- Lecture 2 - Rock Deformation in NatureDocument27 pagesLecture 2 - Rock Deformation in NatureBrian KissingerNo ratings yet

- 02 Som - MDocument27 pages02 Som - M22ev06002No ratings yet

- C2 1) StrainDocument3 pagesC2 1) Strainbce23090017No ratings yet

- Geologi Struktur: Geologi Dasar (Teknik Perminyakan)Document70 pagesGeologi Struktur: Geologi Dasar (Teknik Perminyakan)Dimas GalistanNo ratings yet

- Vibration - Lecture 1Document23 pagesVibration - Lecture 1helmyNo ratings yet

- Mandar Failure AnalysisDocument21 pagesMandar Failure Analysisraghavendrajoshi87No ratings yet

- Chapter 05 - Compression MembersDocument32 pagesChapter 05 - Compression MembersJohn Eduard GallegoNo ratings yet

- Folds: Ranjan K DahalDocument8 pagesFolds: Ranjan K Dahalyaman bhattaraiNo ratings yet

- Fract. DúctilDocument69 pagesFract. DúctilMANFREED CARVAJAL PILLIMUENo ratings yet

- 3.1 - Analysis of Singly Reinforced Beams 1Document15 pages3.1 - Analysis of Singly Reinforced Beams 1Marcelo AbreraNo ratings yet

- Moment Area Method ProjectDocument36 pagesMoment Area Method Projectfarisdanialfadli100% (1)

- FailureDocument47 pagesFailureAlexia Armas100% (1)

- Avanthikaa Sri M 22Y105Document25 pagesAvanthikaa Sri M 22Y105avanthikaasri mNo ratings yet

- Leveling: Making Metal FlatDocument29 pagesLeveling: Making Metal FlatgoranNo ratings yet

- Chapter-6 Bending StudentDocument13 pagesChapter-6 Bending Studentbilal NaseemNo ratings yet

- Struc Stbility-2Document53 pagesStruc Stbility-2Aiman ZhafriNo ratings yet

- Fold GeologyDocument32 pagesFold GeologyShashank167100% (1)

- Joints Anf FracturesDocument88 pagesJoints Anf Fracturesarnaz.sNo ratings yet

- 2.7 Fractures and Different Kinds of Fractures: SrkraoDocument54 pages2.7 Fractures and Different Kinds of Fractures: SrkraorameshqcNo ratings yet

- Lecture 3-StrainDocument21 pagesLecture 3-StrainabiyNo ratings yet

- Chp3 Part1 Torsion-ITDocument17 pagesChp3 Part1 Torsion-ITschool800saNo ratings yet

- Mechanics of MaterialsDocument27 pagesMechanics of MaterialsSrinivas NeeliNo ratings yet

- Geologi DasarDocument88 pagesGeologi DasaraisyahssNo ratings yet

- Endogenic - Rocks, Stress, and DeformationDocument23 pagesEndogenic - Rocks, Stress, and DeformationChristine Joy PatagNo ratings yet

- Lecture 4 PDFDocument25 pagesLecture 4 PDFH R ChowdhuryNo ratings yet

- Fault and Joint Development: In Brittle and Semi-Brittle RockFrom EverandFault and Joint Development: In Brittle and Semi-Brittle RockNo ratings yet

- Deformation Geometry for Materials Scientists: International Series on Materials Science and TechnologyFrom EverandDeformation Geometry for Materials Scientists: International Series on Materials Science and TechnologyRating: 5 out of 5 stars5/5 (1)

- Design Aims: - Electrical Installations HaveDocument18 pagesDesign Aims: - Electrical Installations HaveabiyNo ratings yet

- Short-Circuit CurrentDocument22 pagesShort-Circuit CurrentabiyNo ratings yet

- Design: Overall View: Abnormal Operating ConditionsDocument7 pagesDesign: Overall View: Abnormal Operating ConditionsabiyNo ratings yet

- Protection Systems Against Overcurrents in LV: - Functions (Protection of Circuits)Document16 pagesProtection Systems Against Overcurrents in LV: - Functions (Protection of Circuits)abiyNo ratings yet

- Electric Power System Engineering: EPSE - 21 - 22 1Document24 pagesElectric Power System Engineering: EPSE - 21 - 22 1abiyNo ratings yet

- Grid Types: Electric Power System EngineeringDocument17 pagesGrid Types: Electric Power System EngineeringabiyNo ratings yet

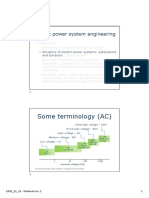

- Some Terminology (AC) : Electric Power System EngineeringDocument22 pagesSome Terminology (AC) : Electric Power System EngineeringabiyNo ratings yet

- Failure Theories: Lecture 7 - Stress Controlled FatigueDocument26 pagesFailure Theories: Lecture 7 - Stress Controlled FatigueabiyNo ratings yet

- Lecture 5-Mechanics of MaterialsDocument24 pagesLecture 5-Mechanics of MaterialsabiyNo ratings yet

- Lecture 3-StrainDocument21 pagesLecture 3-StrainabiyNo ratings yet

- Stress: Lecture 2 - Loads, Traction, StressDocument23 pagesStress: Lecture 2 - Loads, Traction, StressabiyNo ratings yet

- CMV Springer Draft 2016 Chapters 1 12Document316 pagesCMV Springer Draft 2016 Chapters 1 12abiyNo ratings yet

- CMV Springer Draft 2016 - Chapters 21 33Document311 pagesCMV Springer Draft 2016 - Chapters 21 33abiyNo ratings yet

- Mathematics Exercises On Structures Class MaterialsDocument2 pagesMathematics Exercises On Structures Class MaterialsabiyNo ratings yet

- Concordia Presidential Scholarship Guidance For NominatorsDocument4 pagesConcordia Presidential Scholarship Guidance For NominatorsabiyNo ratings yet

- Proton Therapy Power PointDocument14 pagesProton Therapy Power PointCorbin OsborneNo ratings yet

- Modelling The Daily Reference Evapotranspiration in Semi-Arid Region of South India: A Case Study Comparing ANFIS and Empirical ModelsDocument12 pagesModelling The Daily Reference Evapotranspiration in Semi-Arid Region of South India: A Case Study Comparing ANFIS and Empirical ModelsteekamNo ratings yet

- LWCA-30 Series: Product CharacteristicDocument22 pagesLWCA-30 Series: Product CharacteristicYoussef HalloumNo ratings yet

- Graaff GeneratorDocument11 pagesGraaff GeneratorLeonardo MuñozNo ratings yet

- Parabola DesignerDocument9 pagesParabola DesignerFaisal BashirNo ratings yet

- Brookfield Spindles BrochureDocument5 pagesBrookfield Spindles BrochureOnee NothwrNo ratings yet

- English FinalDocument12 pagesEnglish Finaluday ARYANo ratings yet

- Structural Steel Design: Specifications, Loads, Philosophies of Design Specifications, Loads, Philosophies of DesignDocument40 pagesStructural Steel Design: Specifications, Loads, Philosophies of Design Specifications, Loads, Philosophies of DesignfadhlanNo ratings yet

- Unit 2 (Part I) General PhysicsDocument51 pagesUnit 2 (Part I) General PhysicsTedros Ras TeshomeNo ratings yet

- Bondgraph Modeling1 Compatibility ModeDocument27 pagesBondgraph Modeling1 Compatibility ModeJonny LozadaNo ratings yet

- Classical and Quantum Nonlinear Integrable SystemsDocument297 pagesClassical and Quantum Nonlinear Integrable SystemsAgustín CastilloNo ratings yet

- Hydraulics ModuleDocument44 pagesHydraulics ModuleJohn Miko CanlasNo ratings yet

- EMPC2015 - Wire Bonding of Au-Coated Ag Wire Bondwire Properties, Bondability andDocument4 pagesEMPC2015 - Wire Bonding of Au-Coated Ag Wire Bondwire Properties, Bondability andChong Leong GanNo ratings yet

- CIEN 30043 Lecture No. 4Document24 pagesCIEN 30043 Lecture No. 4One Less than TwiceNo ratings yet

- Serre1980 Book TreesDocument151 pagesSerre1980 Book TreesajschollNo ratings yet

- 1967-Gupta-Outgassing From Epoxy Resins and Methods For Its ReductionDocument3 pages1967-Gupta-Outgassing From Epoxy Resins and Methods For Its ReductionroxanaNo ratings yet

- Flexural Strengthening of Preloaded Reinforced Concrete 2019 Alexandria EngiDocument10 pagesFlexural Strengthening of Preloaded Reinforced Concrete 2019 Alexandria EngiSoumitra DasNo ratings yet

- Activity 2 Thermo 1 & 2 PDFDocument4 pagesActivity 2 Thermo 1 & 2 PDFonyxNo ratings yet

- Fluid Mechanics With Engineering Applications by E.John Finnemore and Joseph B.Franzini (10th Edition) - Allpdf - in PDFDocument621 pagesFluid Mechanics With Engineering Applications by E.John Finnemore and Joseph B.Franzini (10th Edition) - Allpdf - in PDFTOOBA KHALILNo ratings yet

- Ch13-Dennis G. Zill - Warren S. Wright-Advanced Engineering Mathematics-Jones - Amp - Bartlett Learning (2012)Document38 pagesCh13-Dennis G. Zill - Warren S. Wright-Advanced Engineering Mathematics-Jones - Amp - Bartlett Learning (2012)Nguyễn Chí NguyệnNo ratings yet

- SssssDocument11 pagesSssssalandrzgaNo ratings yet

- Determination of Performance Degradation of A Marine Diesel Engine by Using Curve Based ApproachDocument30 pagesDetermination of Performance Degradation of A Marine Diesel Engine by Using Curve Based ApproachDhanaNo ratings yet

- Lecture Electromagnetic WavesDocument14 pagesLecture Electromagnetic WavesBill WhiteNo ratings yet

- CombinepdfDocument46 pagesCombinepdfSoby K ThomasNo ratings yet

- Activity 4Document7 pagesActivity 4TerraNo ratings yet

- 2023-JEE Main-5 - (Gen-1 & 2) PaperDocument15 pages2023-JEE Main-5 - (Gen-1 & 2) PaperAryanNo ratings yet

- Unit-1: Mode Theory of Circular WaveguideDocument16 pagesUnit-1: Mode Theory of Circular WaveguideRahul KumarNo ratings yet

- Std. X - Maths PAPER II Mock 2Document10 pagesStd. X - Maths PAPER II Mock 2YashodhaNo ratings yet

- 4th Grade Science Safety Acknowledgement Form PDFDocument1 page4th Grade Science Safety Acknowledgement Form PDFapi-505825348No ratings yet

- Department of Aerospace Engineering: Chapter-1 Review of Basic Definitions & EquationsDocument53 pagesDepartment of Aerospace Engineering: Chapter-1 Review of Basic Definitions & EquationsJASHANPREET SINGHNo ratings yet