Professional Documents

Culture Documents

Programmable Unitary Controller: Product Data

Programmable Unitary Controller: Product Data

Uploaded by

manhquyet711Copyright:

Available Formats

You might also like

- Allis-Chalmers Model D-14 D-15 D-15series2 D-17 D-17series3 SecDocument92 pagesAllis-Chalmers Model D-14 D-15 D-15series2 D-17 D-17series3 SecDmitry40% (5)

- GV Series: Variable Speed Booster Sets With The New Sd60 Control CardDocument40 pagesGV Series: Variable Speed Booster Sets With The New Sd60 Control CardJano Pi100% (1)

- Controlpanel S508Document4 pagesControlpanel S508Thinh TranNo ratings yet

- FAQ 92 Port Number 8000 Occupied enDocument3 pagesFAQ 92 Port Number 8000 Occupied enYar BadshahNo ratings yet

- Section C.3 FAT For DCSDocument11 pagesSection C.3 FAT For DCSChava TejaNo ratings yet

- Bitronics ArevaDocument8 pagesBitronics ArevaSunil KumarNo ratings yet

- Letter of Introduction-SWORD ElevatorDocument2 pagesLetter of Introduction-SWORD ElevatorMohamad Ikhwan0% (1)

- 1.2 Points, Lines, PlanesDocument24 pages1.2 Points, Lines, PlanesDeo Di Lyn100% (1)

- SeminarDocument10 pagesSeminarSridharNo ratings yet

- Fault Diagnostic in MDB Panels PDFDocument2 pagesFault Diagnostic in MDB Panels PDFkkn1234No ratings yet

- PC D235 A - Ac 800pec Cio-Fu Combined Input Output Data SheetDocument2 pagesPC D235 A - Ac 800pec Cio-Fu Combined Input Output Data SheetNguyen Duc Nha100% (1)

- Elevator Controller As360Document81 pagesElevator Controller As360Carlos NotarioNo ratings yet

- QA/QC CHECKLIST: Installation of M.V SwitchgearDocument2 pagesQA/QC CHECKLIST: Installation of M.V SwitchgearehteshamNo ratings yet

- HD30 InversorDocument189 pagesHD30 Inversorsantiago pablo alberto100% (1)

- Interoffice Memorandum: 11411E1111Iitah 0iiii Gas 13,.V, Co 'Document4 pagesInteroffice Memorandum: 11411E1111Iitah 0iiii Gas 13,.V, Co 'will bill100% (1)

- Pac-E100 Modbus Map 2Document26 pagesPac-E100 Modbus Map 2Murat BulutNo ratings yet

- User Manual-PM - PE5120Document47 pagesUser Manual-PM - PE5120NM Group50% (2)

- User Manual IP Video IntercomDocument6 pagesUser Manual IP Video Intercomarialdy escNo ratings yet

- Rishab Delta - Energy - Manual - REV - GDocument57 pagesRishab Delta - Energy - Manual - REV - GSIVA KAVYANo ratings yet

- Output Module S-A4045Document2 pagesOutput Module S-A4045Ashiq SalmanNo ratings yet

- 01 Process Indicator Controller Single Display UT-101 102 PDFDocument12 pages01 Process Indicator Controller Single Display UT-101 102 PDFvishadkapadiaNo ratings yet

- Hooseki Fire AlarmDocument6 pagesHooseki Fire AlarmAgus Mahfudz0% (1)

- Qa16 (1o 00015 024)Document36 pagesQa16 (1o 00015 024)MhmmdanwarNo ratings yet

- Powernet Elevators BroucherDocument16 pagesPowernet Elevators BroucherDEEPU KRISHNAN0% (1)

- Monitor Module S-A4042Document2 pagesMonitor Module S-A4042Ashiq Salman100% (1)

- Invent CHE 100Document135 pagesInvent CHE 100williamtroya50% (2)

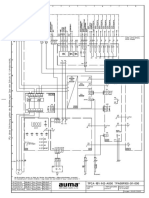

- Tpca-1b1-1h2-A000tpa00r100-0i1-000 (1) (Auma)Document2 pagesTpca-1b1-1h2-A000tpa00r100-0i1-000 (1) (Auma)Heber Alejandro Gahona JeriaNo ratings yet

- Conventional Fire Alarm PanelDocument29 pagesConventional Fire Alarm Panelnastyn-1No ratings yet

- Relay GE Multilin f650Document10 pagesRelay GE Multilin f650Singgih PrayogoNo ratings yet

- 26 09 13 Electrical Power Monitoring System - Data CentersDocument35 pages26 09 13 Electrical Power Monitoring System - Data CentersHujiLokoNo ratings yet

- PS451 ManualDocument106 pagesPS451 ManualUsama Sheikh100% (1)

- ACT500 Hardware Manual V 1.1.9 Rev1Document6 pagesACT500 Hardware Manual V 1.1.9 Rev1Surender ReddyNo ratings yet

- Ups Train3Document157 pagesUps Train3Younes SaifiNo ratings yet

- HLP-A100 Operating Manual PDFDocument207 pagesHLP-A100 Operating Manual PDFGuillermo HernándezNo ratings yet

- Inspection and Test Plan (Quality - Plan) : Product Type: Medium Voltage - Manufacturer: P.T. Siemens IndonesiaDocument6 pagesInspection and Test Plan (Quality - Plan) : Product Type: Medium Voltage - Manufacturer: P.T. Siemens IndonesiavinodNo ratings yet

- 4010ES IDNAC CPU Card and Main BoardDocument2 pages4010ES IDNAC CPU Card and Main BoardEliud100% (1)

- Variable Voltage Variable Frequency Motor Drive - Vector Control VX2 Series PDFDocument11 pagesVariable Voltage Variable Frequency Motor Drive - Vector Control VX2 Series PDFKhaled ZakariaNo ratings yet

- GD20-en V1.3 PDFDocument122 pagesGD20-en V1.3 PDFjhonnyNo ratings yet

- Sy8000 InstructionDocument50 pagesSy8000 InstructionHernando Fang PedrozaNo ratings yet

- ARCODE EU-Type Examination CertificateDocument1 pageARCODE EU-Type Examination CertificateMazen Alhouseen100% (1)

- PR 15D ManualDocument5 pagesPR 15D ManualJonathan GarcésNo ratings yet

- Spesifikasi PM710Document73 pagesSpesifikasi PM710Phan'iphan'No ratings yet

- Modbus RTU - Register Mapping List 1. H.TDocument2 pagesModbus RTU - Register Mapping List 1. H.TJehangir PhoneNo ratings yet

- HMK7 Intelligentized Controller: Operating InstructionsDocument16 pagesHMK7 Intelligentized Controller: Operating InstructionsRayan IbrahimNo ratings yet

- Installation Manual Multi-Function PROTECTION RELAY GRE110, GRE120, GRE130Document22 pagesInstallation Manual Multi-Function PROTECTION RELAY GRE110, GRE120, GRE130Cecep Marfu100% (2)

- User Manual: Security at FingertipsDocument5 pagesUser Manual: Security at FingertipsElite infotechNo ratings yet

- 15 - Test Format For SCADA Test (OUTGOING)Document1 page15 - Test Format For SCADA Test (OUTGOING)Gajendran SriramNo ratings yet

- Mitsubishi Heavy - VRF KXZ - CatalogueDocument47 pagesMitsubishi Heavy - VRF KXZ - CatalogueHung TranNo ratings yet

- Dataloggers Configuration Manual - v1.1Document26 pagesDataloggers Configuration Manual - v1.1Paun ValentinNo ratings yet

- Tip Test Report UpsDocument5 pagesTip Test Report UpsDarwin ColinaNo ratings yet

- Delivery Report FormDocument2 pagesDelivery Report FormsuriantoNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - ADocument2 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - AAmy100% (1)

- Adr141c PDFDocument11 pagesAdr141c PDFNamrata Shetti100% (1)

- Old LT Panel 400 AmpDocument5 pagesOld LT Panel 400 AmpAbhinav TewariNo ratings yet

- Comparison - Cooper-Notifier-Edwards-morlayDocument1 pageComparison - Cooper-Notifier-Edwards-morlayaryan sharma100% (1)

- P3APS19001EN IEC 61850 - Configuration - Instructions PDFDocument32 pagesP3APS19001EN IEC 61850 - Configuration - Instructions PDFTienda MixNo ratings yet

- Fire Alarm BOQDocument3 pagesFire Alarm BOQalkamishra1984No ratings yet

- BOQ-Access Control SystemDocument5 pagesBOQ-Access Control System毕文强No ratings yet

- 00 E560 SD R 9 0Document116 pages00 E560 SD R 9 0ptheabstractNo ratings yet

- Technical Proposal: BKT Wellhead PlatformDocument43 pagesTechnical Proposal: BKT Wellhead PlatformMaina MathengeNo ratings yet

- BILLION BIPAC User - Manual - 2073R2 - 2074R2Document45 pagesBILLION BIPAC User - Manual - 2073R2 - 2074R2MorrisNo ratings yet

- User Manual: S-24Ge-M-2Ug-400W-Ai-Vlan 24 Port Gigabit Layer 2 Managed Ai Poe SwitchDocument21 pagesUser Manual: S-24Ge-M-2Ug-400W-Ai-Vlan 24 Port Gigabit Layer 2 Managed Ai Poe SwitchMahipal SinghNo ratings yet

- Zxv10 B760H Zxv10 B760E Richmedia Box: User GuideDocument21 pagesZxv10 B760H Zxv10 B760E Richmedia Box: User GuideUqy BarajaNo ratings yet

- Design Process in ElectrochemistryDocument92 pagesDesign Process in ElectrochemistryWulan SariNo ratings yet

- Homemade Doughnuts - Techniques and RecipesDocument179 pagesHomemade Doughnuts - Techniques and RecipesDennis BilangNo ratings yet

- CV - Sanjay Kumar GuptaDocument5 pagesCV - Sanjay Kumar GuptaSanjay GuptaNo ratings yet

- Ba SyllabusDocument5 pagesBa SyllabusKamlesh Kumar MandalNo ratings yet

- Session - 2 Other Sources HintsDocument36 pagesSession - 2 Other Sources HintsJohn KAlespiNo ratings yet

- كيفية التفكير المعماري- د.إبراهيم رزقDocument38 pagesكيفية التفكير المعماري- د.إبراهيم رزقAhmed HusseinNo ratings yet

- Compressed Air - 2 PDFDocument18 pagesCompressed Air - 2 PDFnuwaNo ratings yet

- NCR 7403 Uzivatelska PriruckaDocument149 pagesNCR 7403 Uzivatelska Priruckadukindonutz123No ratings yet

- Rev0 (Technical and User's Manual)Document72 pagesRev0 (Technical and User's Manual)mohamedNo ratings yet

- State Map TSP Kayin MIMU696v03 09sep2016 ENG A3Document1 pageState Map TSP Kayin MIMU696v03 09sep2016 ENG A3Naing SoeNo ratings yet

- LEAP Brochure 2013Document15 pagesLEAP Brochure 2013Reparto100% (1)

- Yaesu Fc757at Instruction ManualDocument28 pagesYaesu Fc757at Instruction ManualAudio TecnologiaNo ratings yet

- Essay On All The Light We Cannot SeeDocument2 pagesEssay On All The Light We Cannot SeeJosh StephanNo ratings yet

- ALTITUDE Presentation DeckDocument35 pagesALTITUDE Presentation DeckVikas ChaudharyNo ratings yet

- Cat 336eh Hybrid ExcavatorDocument30 pagesCat 336eh Hybrid ExcavatorPHÁT NGUYỄN THẾ100% (1)

- DONE LESSON PLAN - Weather and ClimateDocument5 pagesDONE LESSON PLAN - Weather and ClimateStygian DoggoNo ratings yet

- Adi ss7Document29 pagesAdi ss7adityamishra244100% (4)

- Tips and Tricks Motivation LetterDocument5 pagesTips and Tricks Motivation LetterTousif RahmanNo ratings yet

- Dead Phone Testing1Document12 pagesDead Phone Testing1HEM SHRESTHANo ratings yet

- BMS Sequence of Operation SOO For HVAC SystemDocument4 pagesBMS Sequence of Operation SOO For HVAC SystemDong VanraNo ratings yet

- Idf Full Paper - 177Document10 pagesIdf Full Paper - 177Muhamed AlfahadNo ratings yet

- Murray Thomson Thesis HandbookDocument257 pagesMurray Thomson Thesis HandbookSherif Mohamed KhattabNo ratings yet

- Eat Lots of Chocolates When Time Gets Tough, and Eat Even More When Times Are Great.Document2 pagesEat Lots of Chocolates When Time Gets Tough, and Eat Even More When Times Are Great.Miruna MocleașăNo ratings yet

- Internal Audit Checklist Food Safety-MRDocument5 pagesInternal Audit Checklist Food Safety-MRRavi BaghelNo ratings yet

- 2.1 Photography Exposure Assignment 1 (Lesson 5) PDFDocument3 pages2.1 Photography Exposure Assignment 1 (Lesson 5) PDFFebin FelixNo ratings yet

- Control Charts in SAP QM: Step by StepDocument10 pagesControl Charts in SAP QM: Step by StepPiyush BoseNo ratings yet

Programmable Unitary Controller: Product Data

Programmable Unitary Controller: Product Data

Uploaded by

manhquyet711Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Programmable Unitary Controller: Product Data

Programmable Unitary Controller: Product Data

Uploaded by

manhquyet711Copyright:

Available Formats

Programmable Unitary Controller

PUC Series

Product Data

Overview

Honeywell PUC Series PUC8445 programmable unitary

controller supports Ethernet BACNet IP communication

which offers fast response in data downloading and

updating. The controller supports numerous network

topologies allowing flexible networking and wiring. The

controller is programmable and can be widely used to

control different building equipment.

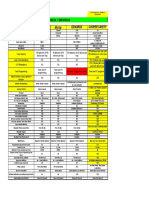

Features Technical Specification

• Support Ethernet BACNet IP communication Description

• Fully programmable to meet different HVAC

Table 1 Ordering Part Number

applications

• Fast response in downloading and updating Part Number UI DI AO DO

data PUC8445-PB1 8 4 4 5

• Dual-Ethernet port allows it to support both star

and daisy chain connection, as well as ring Electrical

connection (optional RSTP switch required)

Nominal voltage: 24VAC; 50/60Hz

• Elegant design, light weight and easy to operate

• Color-coded removable terminal blocks enable Power consumption: 5VA max. (controller only)

convenient and fault free termination

15VA max. (including controller

• Built-in input/output ports allowing expansion

and all input, output and

module through RS-485 port

communication channels)

• Additional network security with advanced

Operating Environment

security encryption standard

• Embedded programmable tool under Niagara • Operating temperature

platform with user friendly interface 0 °C - +50 °C

• CE, BTL, UL and RoHS certification • Relative humidity: 5%~95% Non-condensating

• Protection rating: IP20

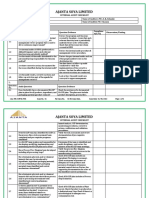

LED Display Table 5 ETH LED status description

Controller’s status can be displayed via LED BACnet IP communication status. After the controller is

Table 3 STA LED status description powered on, LED will display one of the following status as

STA LED Stats Controller Status described in Table 5.

Off No power; damaged LED; ETH LED Status Communication Status

insufficient power supply; initial Solid ON Equipment fault or system crushed

power-on; or boot loader Solid on, blink Bootloader running with no IP link

damaged once every 2.5

Solid on Start up power insufficient. seconds

Check power supply – this Solid on, blink Bootloader running with BACNet

requires about 3.5 sec – occurs twice every 2.5 communication

on power up, reset and refresh seconds

Blinking mode 1 – Operating normally Solid on, blink 3 Bootloader running with BACNet

continuously blinks times every 2.5 communication and data

on for 1 sec and off seconds tranmission

for 1 sec Solid Off No power supply, equipment

Blinking mode 2 – Equipment alarm active; malfunction or system crushed

continuously blinks downloading configuration; loss Solid off, blink Controller is operating normally,

on for 0.5 sec and off of configuration once every 2.5 without IP link

for 0.5 sec seconds

Blinking mode 3 – Equipment in firmware Solid off, blink Controller is operating normally

continuously blinks upgrading mode. twice every 2.5 with BACnet communication.

on for 0.25 sec and seconds

off for 0.25 sec Solid off, blink 3 Controller is operating normally

times every 2.5 with communication and data

Table 4 485 LED status instructions seconds transmission.

RS485 Communication status Rapid blinking Equipment fault or system crashed

485 LED Status Communication Status

Solid off Modbus equipment not installed

or configuration document

corrupted

Solid off, blink once Controller is operating normally

every 2.5 seconds with no Modbus communication.

Solid off, blink twice Controller is operating normally

every 2.5 seconds with Modbus communication.

Solid off, blink 3 Controller is operating normally

times every 2.5 with transmission of document in

seconds progress.

Product Dimensions (unit: mm)

Product Installation

Installation notes

• Removable terminals make it easier for installation and

maintenance;

• Controller must be installed in adequate space for

wiring, maintenance and removal;

• Product supports DIN rail. DIN rail specification:

EN50022 7.5 mm x 35 mm.

Instructions:

1. Pull both hooks at the base of the controller. Tilt the

controller and fix the hooks on the top of the controller

onto the guide rails;

2. Press the controller for it to fit the guide rail;

3. Push in both hooks at the base to fasten the controller;

4. The controller after the hooks are pushed in is as

shown in Figure 4.

Honeywell Environmental and Combustion

Controls (Tianjin) Co., Ltd.

No. 158, Nanhai Road, Tianjin

Economic-Technological Development Area

Postal Code: 300457

Tel: +86-22-66287000 HBT-Building-BCS-WEBs-Apr.2019 –EN01

Fax: +86-22-25325214

You might also like

- Allis-Chalmers Model D-14 D-15 D-15series2 D-17 D-17series3 SecDocument92 pagesAllis-Chalmers Model D-14 D-15 D-15series2 D-17 D-17series3 SecDmitry40% (5)

- GV Series: Variable Speed Booster Sets With The New Sd60 Control CardDocument40 pagesGV Series: Variable Speed Booster Sets With The New Sd60 Control CardJano Pi100% (1)

- Controlpanel S508Document4 pagesControlpanel S508Thinh TranNo ratings yet

- FAQ 92 Port Number 8000 Occupied enDocument3 pagesFAQ 92 Port Number 8000 Occupied enYar BadshahNo ratings yet

- Section C.3 FAT For DCSDocument11 pagesSection C.3 FAT For DCSChava TejaNo ratings yet

- Bitronics ArevaDocument8 pagesBitronics ArevaSunil KumarNo ratings yet

- Letter of Introduction-SWORD ElevatorDocument2 pagesLetter of Introduction-SWORD ElevatorMohamad Ikhwan0% (1)

- 1.2 Points, Lines, PlanesDocument24 pages1.2 Points, Lines, PlanesDeo Di Lyn100% (1)

- SeminarDocument10 pagesSeminarSridharNo ratings yet

- Fault Diagnostic in MDB Panels PDFDocument2 pagesFault Diagnostic in MDB Panels PDFkkn1234No ratings yet

- PC D235 A - Ac 800pec Cio-Fu Combined Input Output Data SheetDocument2 pagesPC D235 A - Ac 800pec Cio-Fu Combined Input Output Data SheetNguyen Duc Nha100% (1)

- Elevator Controller As360Document81 pagesElevator Controller As360Carlos NotarioNo ratings yet

- QA/QC CHECKLIST: Installation of M.V SwitchgearDocument2 pagesQA/QC CHECKLIST: Installation of M.V SwitchgearehteshamNo ratings yet

- HD30 InversorDocument189 pagesHD30 Inversorsantiago pablo alberto100% (1)

- Interoffice Memorandum: 11411E1111Iitah 0iiii Gas 13,.V, Co 'Document4 pagesInteroffice Memorandum: 11411E1111Iitah 0iiii Gas 13,.V, Co 'will bill100% (1)

- Pac-E100 Modbus Map 2Document26 pagesPac-E100 Modbus Map 2Murat BulutNo ratings yet

- User Manual-PM - PE5120Document47 pagesUser Manual-PM - PE5120NM Group50% (2)

- User Manual IP Video IntercomDocument6 pagesUser Manual IP Video Intercomarialdy escNo ratings yet

- Rishab Delta - Energy - Manual - REV - GDocument57 pagesRishab Delta - Energy - Manual - REV - GSIVA KAVYANo ratings yet

- Output Module S-A4045Document2 pagesOutput Module S-A4045Ashiq SalmanNo ratings yet

- 01 Process Indicator Controller Single Display UT-101 102 PDFDocument12 pages01 Process Indicator Controller Single Display UT-101 102 PDFvishadkapadiaNo ratings yet

- Hooseki Fire AlarmDocument6 pagesHooseki Fire AlarmAgus Mahfudz0% (1)

- Qa16 (1o 00015 024)Document36 pagesQa16 (1o 00015 024)MhmmdanwarNo ratings yet

- Powernet Elevators BroucherDocument16 pagesPowernet Elevators BroucherDEEPU KRISHNAN0% (1)

- Monitor Module S-A4042Document2 pagesMonitor Module S-A4042Ashiq Salman100% (1)

- Invent CHE 100Document135 pagesInvent CHE 100williamtroya50% (2)

- Tpca-1b1-1h2-A000tpa00r100-0i1-000 (1) (Auma)Document2 pagesTpca-1b1-1h2-A000tpa00r100-0i1-000 (1) (Auma)Heber Alejandro Gahona JeriaNo ratings yet

- Conventional Fire Alarm PanelDocument29 pagesConventional Fire Alarm Panelnastyn-1No ratings yet

- Relay GE Multilin f650Document10 pagesRelay GE Multilin f650Singgih PrayogoNo ratings yet

- 26 09 13 Electrical Power Monitoring System - Data CentersDocument35 pages26 09 13 Electrical Power Monitoring System - Data CentersHujiLokoNo ratings yet

- PS451 ManualDocument106 pagesPS451 ManualUsama Sheikh100% (1)

- ACT500 Hardware Manual V 1.1.9 Rev1Document6 pagesACT500 Hardware Manual V 1.1.9 Rev1Surender ReddyNo ratings yet

- Ups Train3Document157 pagesUps Train3Younes SaifiNo ratings yet

- HLP-A100 Operating Manual PDFDocument207 pagesHLP-A100 Operating Manual PDFGuillermo HernándezNo ratings yet

- Inspection and Test Plan (Quality - Plan) : Product Type: Medium Voltage - Manufacturer: P.T. Siemens IndonesiaDocument6 pagesInspection and Test Plan (Quality - Plan) : Product Type: Medium Voltage - Manufacturer: P.T. Siemens IndonesiavinodNo ratings yet

- 4010ES IDNAC CPU Card and Main BoardDocument2 pages4010ES IDNAC CPU Card and Main BoardEliud100% (1)

- Variable Voltage Variable Frequency Motor Drive - Vector Control VX2 Series PDFDocument11 pagesVariable Voltage Variable Frequency Motor Drive - Vector Control VX2 Series PDFKhaled ZakariaNo ratings yet

- GD20-en V1.3 PDFDocument122 pagesGD20-en V1.3 PDFjhonnyNo ratings yet

- Sy8000 InstructionDocument50 pagesSy8000 InstructionHernando Fang PedrozaNo ratings yet

- ARCODE EU-Type Examination CertificateDocument1 pageARCODE EU-Type Examination CertificateMazen Alhouseen100% (1)

- PR 15D ManualDocument5 pagesPR 15D ManualJonathan GarcésNo ratings yet

- Spesifikasi PM710Document73 pagesSpesifikasi PM710Phan'iphan'No ratings yet

- Modbus RTU - Register Mapping List 1. H.TDocument2 pagesModbus RTU - Register Mapping List 1. H.TJehangir PhoneNo ratings yet

- HMK7 Intelligentized Controller: Operating InstructionsDocument16 pagesHMK7 Intelligentized Controller: Operating InstructionsRayan IbrahimNo ratings yet

- Installation Manual Multi-Function PROTECTION RELAY GRE110, GRE120, GRE130Document22 pagesInstallation Manual Multi-Function PROTECTION RELAY GRE110, GRE120, GRE130Cecep Marfu100% (2)

- User Manual: Security at FingertipsDocument5 pagesUser Manual: Security at FingertipsElite infotechNo ratings yet

- 15 - Test Format For SCADA Test (OUTGOING)Document1 page15 - Test Format For SCADA Test (OUTGOING)Gajendran SriramNo ratings yet

- Mitsubishi Heavy - VRF KXZ - CatalogueDocument47 pagesMitsubishi Heavy - VRF KXZ - CatalogueHung TranNo ratings yet

- Dataloggers Configuration Manual - v1.1Document26 pagesDataloggers Configuration Manual - v1.1Paun ValentinNo ratings yet

- Tip Test Report UpsDocument5 pagesTip Test Report UpsDarwin ColinaNo ratings yet

- Delivery Report FormDocument2 pagesDelivery Report FormsuriantoNo ratings yet

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - ADocument2 pagesJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - AAmy100% (1)

- Adr141c PDFDocument11 pagesAdr141c PDFNamrata Shetti100% (1)

- Old LT Panel 400 AmpDocument5 pagesOld LT Panel 400 AmpAbhinav TewariNo ratings yet

- Comparison - Cooper-Notifier-Edwards-morlayDocument1 pageComparison - Cooper-Notifier-Edwards-morlayaryan sharma100% (1)

- P3APS19001EN IEC 61850 - Configuration - Instructions PDFDocument32 pagesP3APS19001EN IEC 61850 - Configuration - Instructions PDFTienda MixNo ratings yet

- Fire Alarm BOQDocument3 pagesFire Alarm BOQalkamishra1984No ratings yet

- BOQ-Access Control SystemDocument5 pagesBOQ-Access Control System毕文强No ratings yet

- 00 E560 SD R 9 0Document116 pages00 E560 SD R 9 0ptheabstractNo ratings yet

- Technical Proposal: BKT Wellhead PlatformDocument43 pagesTechnical Proposal: BKT Wellhead PlatformMaina MathengeNo ratings yet

- BILLION BIPAC User - Manual - 2073R2 - 2074R2Document45 pagesBILLION BIPAC User - Manual - 2073R2 - 2074R2MorrisNo ratings yet

- User Manual: S-24Ge-M-2Ug-400W-Ai-Vlan 24 Port Gigabit Layer 2 Managed Ai Poe SwitchDocument21 pagesUser Manual: S-24Ge-M-2Ug-400W-Ai-Vlan 24 Port Gigabit Layer 2 Managed Ai Poe SwitchMahipal SinghNo ratings yet

- Zxv10 B760H Zxv10 B760E Richmedia Box: User GuideDocument21 pagesZxv10 B760H Zxv10 B760E Richmedia Box: User GuideUqy BarajaNo ratings yet

- Design Process in ElectrochemistryDocument92 pagesDesign Process in ElectrochemistryWulan SariNo ratings yet

- Homemade Doughnuts - Techniques and RecipesDocument179 pagesHomemade Doughnuts - Techniques and RecipesDennis BilangNo ratings yet

- CV - Sanjay Kumar GuptaDocument5 pagesCV - Sanjay Kumar GuptaSanjay GuptaNo ratings yet

- Ba SyllabusDocument5 pagesBa SyllabusKamlesh Kumar MandalNo ratings yet

- Session - 2 Other Sources HintsDocument36 pagesSession - 2 Other Sources HintsJohn KAlespiNo ratings yet

- كيفية التفكير المعماري- د.إبراهيم رزقDocument38 pagesكيفية التفكير المعماري- د.إبراهيم رزقAhmed HusseinNo ratings yet

- Compressed Air - 2 PDFDocument18 pagesCompressed Air - 2 PDFnuwaNo ratings yet

- NCR 7403 Uzivatelska PriruckaDocument149 pagesNCR 7403 Uzivatelska Priruckadukindonutz123No ratings yet

- Rev0 (Technical and User's Manual)Document72 pagesRev0 (Technical and User's Manual)mohamedNo ratings yet

- State Map TSP Kayin MIMU696v03 09sep2016 ENG A3Document1 pageState Map TSP Kayin MIMU696v03 09sep2016 ENG A3Naing SoeNo ratings yet

- LEAP Brochure 2013Document15 pagesLEAP Brochure 2013Reparto100% (1)

- Yaesu Fc757at Instruction ManualDocument28 pagesYaesu Fc757at Instruction ManualAudio TecnologiaNo ratings yet

- Essay On All The Light We Cannot SeeDocument2 pagesEssay On All The Light We Cannot SeeJosh StephanNo ratings yet

- ALTITUDE Presentation DeckDocument35 pagesALTITUDE Presentation DeckVikas ChaudharyNo ratings yet

- Cat 336eh Hybrid ExcavatorDocument30 pagesCat 336eh Hybrid ExcavatorPHÁT NGUYỄN THẾ100% (1)

- DONE LESSON PLAN - Weather and ClimateDocument5 pagesDONE LESSON PLAN - Weather and ClimateStygian DoggoNo ratings yet

- Adi ss7Document29 pagesAdi ss7adityamishra244100% (4)

- Tips and Tricks Motivation LetterDocument5 pagesTips and Tricks Motivation LetterTousif RahmanNo ratings yet

- Dead Phone Testing1Document12 pagesDead Phone Testing1HEM SHRESTHANo ratings yet

- BMS Sequence of Operation SOO For HVAC SystemDocument4 pagesBMS Sequence of Operation SOO For HVAC SystemDong VanraNo ratings yet

- Idf Full Paper - 177Document10 pagesIdf Full Paper - 177Muhamed AlfahadNo ratings yet

- Murray Thomson Thesis HandbookDocument257 pagesMurray Thomson Thesis HandbookSherif Mohamed KhattabNo ratings yet

- Eat Lots of Chocolates When Time Gets Tough, and Eat Even More When Times Are Great.Document2 pagesEat Lots of Chocolates When Time Gets Tough, and Eat Even More When Times Are Great.Miruna MocleașăNo ratings yet

- Internal Audit Checklist Food Safety-MRDocument5 pagesInternal Audit Checklist Food Safety-MRRavi BaghelNo ratings yet

- 2.1 Photography Exposure Assignment 1 (Lesson 5) PDFDocument3 pages2.1 Photography Exposure Assignment 1 (Lesson 5) PDFFebin FelixNo ratings yet

- Control Charts in SAP QM: Step by StepDocument10 pagesControl Charts in SAP QM: Step by StepPiyush BoseNo ratings yet