Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

23 viewsData Sheet STRAUB-FLEX 2: Pipe Joint Without Axial Restraining For All Pipe Materials

Data Sheet STRAUB-FLEX 2: Pipe Joint Without Axial Restraining For All Pipe Materials

Uploaded by

iulb79This document provides specifications for the STRAUB-FLEX 2 pipe joint, including:

- Acceptable materials for different casing, screw, bolt, and sealing sleeve components for various pipe joint models.

- Dimensions and pressure ratings for each pipe joint size from 180mm to 1600mm diameter pipes.

- Required installation torque values for locking bolts.

- Notes on proper installation and limitations, including a maximum 10mm of axial pipe movement and optional strip inserts for large gaps or special conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Formato 172a - Manual de Diagramas Elétricos Irizar I6 - Revisão 9 - 21.03.2016 - Especial A3 PDFDocument42 pagesFormato 172a - Manual de Diagramas Elétricos Irizar I6 - Revisão 9 - 21.03.2016 - Especial A3 PDFNeftali Antonio Rodriguez CastroNo ratings yet

- 00 DRAINAGE - Funke HS Sewer Pipe BrochureDocument44 pages00 DRAINAGE - Funke HS Sewer Pipe BrochurenextomegagenNo ratings yet

- Elastomer Bellows Seal: Applications Operating ConditionsDocument3 pagesElastomer Bellows Seal: Applications Operating ConditionsSingit Wahyu SaputraNo ratings yet

- MefaDocument250 pagesMefaStephane ChaminadeNo ratings yet

- Oxygen and Helium HoseDocument2 pagesOxygen and Helium HoseAbdullah FazilNo ratings yet

- Sridhan Level SwitchDocument95 pagesSridhan Level SwitchvaibhavnriitmNo ratings yet

- BLMT Data SheetDocument3 pagesBLMT Data SheetTiagoNo ratings yet

- Ancon 25-14 Restraint SystemDocument2 pagesAncon 25-14 Restraint SystemabudabeejajaNo ratings yet

- Beam Details PDFDocument1 pageBeam Details PDFHilton D. CalawenNo ratings yet

- Tgi33 7Document2 pagesTgi33 7infoNo ratings yet

- Ic2024 - 17 - 1Document26 pagesIc2024 - 17 - 1sk tripathiNo ratings yet

- Seagull Daily AttdncDocument28 pagesSeagull Daily Attdncpraveenraj murugadassNo ratings yet

- Screw in Plug Type Connectors HX HLDocument8 pagesScrew in Plug Type Connectors HX HLra5tr@No ratings yet

- ITT - Trident ConnectorDocument1 pageITT - Trident ConnectorhNo ratings yet

- Furse New Earth Rod Seals FlyerDocument2 pagesFurse New Earth Rod Seals FlyerImran Mughle AzamNo ratings yet

- Clarkson - Ord-NeedDocument3 pagesClarkson - Ord-NeednikilokumaNo ratings yet

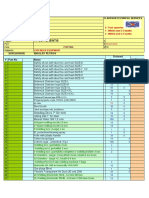

- Load Schedule: Proposed Two-Storey ResidenceDocument1 pageLoad Schedule: Proposed Two-Storey Residencear.christdelvivar.uapNo ratings yet

- Apron - HB 250 To HB 250Document17 pagesApron - HB 250 To HB 250Hendri HermawanNo ratings yet

- ZP00707 GB 2Document40 pagesZP00707 GB 2grandtrading.egNo ratings yet

- Tools&ConsumablesDocument8 pagesTools&ConsumablesZeeshan HashmiNo ratings yet

- H F200 - 0916 Flexible Connector DN15 To 50Document2 pagesH F200 - 0916 Flexible Connector DN15 To 50ROBERTO RAFAELNo ratings yet

- Brush Plug Use:: Product Sheet June 2004Document1 pageBrush Plug Use:: Product Sheet June 2004Enrico ManfrinatoNo ratings yet

- Pipes Flexnetflexible Pipes-2020Document12 pagesPipes Flexnetflexible Pipes-2020Bengaluru CommonmanNo ratings yet

- 4 - Compakt Seals Special - GB - 2012Document5 pages4 - Compakt Seals Special - GB - 2012Akshay PoddarNo ratings yet

- GS Range Couplings and Adaptors DatasheetDocument2 pagesGS Range Couplings and Adaptors Datasheetdurrant bilankuluNo ratings yet

- Scheda Tecnica - Cartella SpecialeDocument1 pageScheda Tecnica - Cartella Specialemassi.95No ratings yet

- Funke Kunststoffe Pipe Liner Lateral Connection System Connex Brochure 10 2018Document4 pagesFunke Kunststoffe Pipe Liner Lateral Connection System Connex Brochure 10 2018Tranda ZaineaNo ratings yet

- Hansun Tube Fitting - (S-LOK TYPE)Document60 pagesHansun Tube Fitting - (S-LOK TYPE)qasim_maqboolNo ratings yet

- Talbot Straps and FerrulesDocument8 pagesTalbot Straps and Ferrulesphiliptoh1No ratings yet

- Socitec - HH16Document2 pagesSocitec - HH16Andrzej RogalaNo ratings yet

- Bircher DWSK Profile & Rail - E PDFDocument2 pagesBircher DWSK Profile & Rail - E PDFSuleman KhanNo ratings yet

- S-LOK Tube FittingsDocument58 pagesS-LOK Tube FittingsCesar YalanNo ratings yet

- Mumbai CSSD Electrical Material ListDocument1 pageMumbai CSSD Electrical Material Listm devdasNo ratings yet

- "T" Shaped Post Base: InvisibleDocument6 pages"T" Shaped Post Base: Invisiblemilivoj ilibasicNo ratings yet

- Decoduct UPVC Conduits & Fittings Manufactured To BS 6099 & BS 4607 and BS EN 50086 / BS EN 61386 Price ListDocument3 pagesDecoduct UPVC Conduits & Fittings Manufactured To BS 6099 & BS 4607 and BS EN 50086 / BS EN 61386 Price ListAly SamirNo ratings yet

- Tuc SandvikDocument2 pagesTuc SandvikYsraels Santisteban DurandNo ratings yet

- Lift-Off Restraints: No Welding - No Drilling - Just ClampingDocument20 pagesLift-Off Restraints: No Welding - No Drilling - Just ClampingRamzi Ben AhmedNo ratings yet

- Funke Kunststoffe CONNEX Junction Brochure 10 2020.pdfDocument8 pagesFunke Kunststoffe CONNEX Junction Brochure 10 2020.pdfTranda ZaineaNo ratings yet

- DECO Catalogue14 ( Õ É)Document16 pagesDECO Catalogue14 ( Õ É)KH Samuel LeeNo ratings yet

- Development and Splice Length Calculation For Aci-318 08Document1 pageDevelopment and Splice Length Calculation For Aci-318 08dantevarias100% (1)

- Linde Service GuideDocument5 pagesLinde Service GuideMário AndradeNo ratings yet

- Instru BOQ - 21027 Rev-01 PDFDocument2 pagesInstru BOQ - 21027 Rev-01 PDFnavtej singhNo ratings yet

- En HQ 52006130 Content TB BrochureDocument16 pagesEn HQ 52006130 Content TB Brochurethanh_cdt01No ratings yet

- 3 Hit-Hy150 HisnDocument9 pages3 Hit-Hy150 Hisndd160179No ratings yet

- Rockfall Protection Netting: Galvanized & Polymer Coated (10x12)Document2 pagesRockfall Protection Netting: Galvanized & Polymer Coated (10x12)Sudipto PaulNo ratings yet

- Cephas ValvulasMariposaDocument31 pagesCephas ValvulasMariposarezaNo ratings yet

- Optronics - Single Loose Tube With Steel Tape Armour Fibre Optic CableDocument3 pagesOptronics - Single Loose Tube With Steel Tape Armour Fibre Optic CableblegedesNo ratings yet

- SLT Sta With e Glass 2 5954Document3 pagesSLT Sta With e Glass 2 5954Marlon Fukunaga RomeroNo ratings yet

- SL3488D-Plus Multipath Ultrasonic Flowmeter BrochureDocument10 pagesSL3488D-Plus Multipath Ultrasonic Flowmeter BrochureNaji OmarNo ratings yet

- Level SwitchesDocument94 pagesLevel SwitchesPremjith SudhakaranNo ratings yet

- Strutfast Clamps, Fasteners & Anchors LRDocument7 pagesStrutfast Clamps, Fasteners & Anchors LRzimtonyNo ratings yet

- Krausz Spesifications Hymax-Flensemuffe enDocument4 pagesKrausz Spesifications Hymax-Flensemuffe enibrahimNo ratings yet

- Epcon C8 XtremDocument6 pagesEpcon C8 XtremAhmed TahaNo ratings yet

- FM Hilti MAB13 PDFDocument2 pagesFM Hilti MAB13 PDFIgor CvijovicNo ratings yet

- ISOBUS Flyer Amphenol ConnectorDocument4 pagesISOBUS Flyer Amphenol ConnectorGustavo ParlantiNo ratings yet

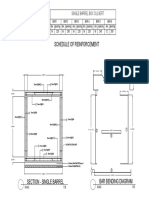

- Reinforced Line CanalDocument1 pageReinforced Line CanalJoefel BessatNo ratings yet

- 9379 PDFDocument2 pages9379 PDFrahimi mohamadNo ratings yet

- 9379 PDFDocument2 pages9379 PDFrahimi mohamadNo ratings yet

- Pipe Clamps & Accessories: Chilled Water Clamp LKS 19 (M)Document2 pagesPipe Clamps & Accessories: Chilled Water Clamp LKS 19 (M)rahimi mohamadNo ratings yet

- Parts List - GSZ5-37-6 (JIS10K) NewDocument5 pagesParts List - GSZ5-37-6 (JIS10K) NewtylerdoriusNo ratings yet

- Best Practices For Producing High Quality PDF FilesDocument7 pagesBest Practices For Producing High Quality PDF FilesSyed ShahNo ratings yet

- XE700D液压挖掘机技术规格书Document22 pagesXE700D液压挖掘机技术规格书abangNo ratings yet

- Yash Sir Sanchit Sir: Visit Our WebsiteDocument6 pagesYash Sir Sanchit Sir: Visit Our WebsiteHimank MaheshwariNo ratings yet

- NG160 - 16 To 160A Modular Incoming Circuit BrakersDocument27 pagesNG160 - 16 To 160A Modular Incoming Circuit BrakerssomeontorrenteNo ratings yet

- I. Organizational Structure of The IPO: Intellectual Property I. Intellectual Property OfficeDocument10 pagesI. Organizational Structure of The IPO: Intellectual Property I. Intellectual Property OfficeBonbon CavalesNo ratings yet

- Navman DDR MiVue 1000 - 1100 EN R01Document2 pagesNavman DDR MiVue 1000 - 1100 EN R01joxof42296No ratings yet

- Rear Suspension: Group 34Document6 pagesRear Suspension: Group 34Davit OmegaNo ratings yet

- Error CorrectionDocument15 pagesError Correctionrishi srivastavaNo ratings yet

- Individual AssignmentDocument5 pagesIndividual AssignmentHao LimNo ratings yet

- Modern Technology ImpactDocument5 pagesModern Technology ImpactDeep ChoudharyNo ratings yet

- PNB V SAYODocument2 pagesPNB V SAYONica09_foreverNo ratings yet

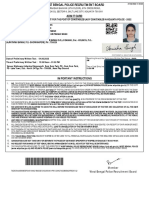

- Admit Card: Araksha Bhavan (5Th Floor), 6Th Cross Road, Block-Dj, Sector-Ii, Salt Lake City, Kolkata-700 091Document1 pageAdmit Card: Araksha Bhavan (5Th Floor), 6Th Cross Road, Block-Dj, Sector-Ii, Salt Lake City, Kolkata-700 091Ayesha HignisNo ratings yet

- G.R. No. 152496 - Sps. German Anunciacion, Et Al. v. Perpetua M. Bocanegra, Et Al. - July 2009 - Philipppine Supreme Court DecisionsDocument7 pagesG.R. No. 152496 - Sps. German Anunciacion, Et Al. v. Perpetua M. Bocanegra, Et Al. - July 2009 - Philipppine Supreme Court DecisionssejinmaNo ratings yet

- TT Lubricating Oils Greases Shelf Life RecommendationsDocument2 pagesTT Lubricating Oils Greases Shelf Life RecommendationsSanogo YayaNo ratings yet

- Military Courtesy and DisciplineDocument33 pagesMilitary Courtesy and DisciplineCherry EyreNo ratings yet

- CH 8Document107 pagesCH 8Sri NahdaNo ratings yet

- 13OBDG06 Hybrid DiagnosticsDocument462 pages13OBDG06 Hybrid DiagnosticsIonflorin TelegaruNo ratings yet

- List All Major/critical TasksDocument4 pagesList All Major/critical TasksIndra Mulyana0% (1)

- Flywheel Energy Storage System Design For: Distribution NetworkDocument5 pagesFlywheel Energy Storage System Design For: Distribution NetworkMohamed AlNo ratings yet

- E Business Assignment 2Document7 pagesE Business Assignment 2Shikha MishraNo ratings yet

- CapersJones - Scoring and Evaluating Software Methods, Practices, and ResultsDocument17 pagesCapersJones - Scoring and Evaluating Software Methods, Practices, and ResultsSharing Caring100% (1)

- TMP Nedjo Jarsao For PrintDocument20 pagesTMP Nedjo Jarsao For PrintGenetNo ratings yet

- Citrix XenApp 6 5 - Enterprise Scalable XenApp Deployments - 1293Document49 pagesCitrix XenApp 6 5 - Enterprise Scalable XenApp Deployments - 1293trshenoyNo ratings yet

- Syllabus EntrepreneurshipDocument8 pagesSyllabus Entrepreneurshipchokrib100% (5)

- National Greening ProgramDocument58 pagesNational Greening ProgramArnelCorpuzNo ratings yet

- District Memo District Nat Sts Kto12 FormsDocument2 pagesDistrict Memo District Nat Sts Kto12 FormsNica SalentesNo ratings yet

- Gas ExpanderDocument12 pagesGas ExpanderArun KumarNo ratings yet

- Agreement in Restraint of Trade-ExceptionsDocument15 pagesAgreement in Restraint of Trade-ExceptionsNishita GuptaNo ratings yet

- 4-Port - RFS (Antenna) - Multi Ret - ScriptDocument2 pages4-Port - RFS (Antenna) - Multi Ret - Scriptyou are awesomeNo ratings yet

Data Sheet STRAUB-FLEX 2: Pipe Joint Without Axial Restraining For All Pipe Materials

Data Sheet STRAUB-FLEX 2: Pipe Joint Without Axial Restraining For All Pipe Materials

Uploaded by

iulb790 ratings0% found this document useful (0 votes)

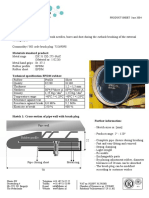

23 views1 pageThis document provides specifications for the STRAUB-FLEX 2 pipe joint, including:

- Acceptable materials for different casing, screw, bolt, and sealing sleeve components for various pipe joint models.

- Dimensions and pressure ratings for each pipe joint size from 180mm to 1600mm diameter pipes.

- Required installation torque values for locking bolts.

- Notes on proper installation and limitations, including a maximum 10mm of axial pipe movement and optional strip inserts for large gaps or special conditions.

Original Description:

Original Title

straub flex 2L

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for the STRAUB-FLEX 2 pipe joint, including:

- Acceptable materials for different casing, screw, bolt, and sealing sleeve components for various pipe joint models.

- Dimensions and pressure ratings for each pipe joint size from 180mm to 1600mm diameter pipes.

- Required installation torque values for locking bolts.

- Notes on proper installation and limitations, including a maximum 10mm of axial pipe movement and optional strip inserts for large gaps or special conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

23 views1 pageData Sheet STRAUB-FLEX 2: Pipe Joint Without Axial Restraining For All Pipe Materials

Data Sheet STRAUB-FLEX 2: Pipe Joint Without Axial Restraining For All Pipe Materials

Uploaded by

iulb79This document provides specifications for the STRAUB-FLEX 2 pipe joint, including:

- Acceptable materials for different casing, screw, bolt, and sealing sleeve components for various pipe joint models.

- Dimensions and pressure ratings for each pipe joint size from 180mm to 1600mm diameter pipes.

- Required installation torque values for locking bolts.

- Notes on proper installation and limitations, including a maximum 10mm of axial pipe movement and optional strip inserts for large gaps or special conditions.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

Data Sheet STRAUB-FLEX 2

Pipe joint without axial restraining for all pipe materials

Casing AISI 1024, hot-dip galvanized AISI 316 Ti AISI 316 Ti

Screws AISI 4135** AISI 4135** AISI 316 L

Bolts AISI 12L 14, galvanized AISI 12L 14, galvanised AISI 316 L

Strip insert (option) AISI 316 L / HDPE AISI 316 L / HDPE AISI 316 L / HDPE

Sealing sleeve -20°C up to +80°C

EPDM all qualities of water, waste water, air, solids and chemical products (chemical resistance on request)

Sealing sleeve -20°C up to +80°C

NBR water, gas, oil, fuel and other hydrocarbons

L-, LS-, and LU-version in W2 or W5. H- and XS-version in W1

* Two-piece execution

DV = Outside diameter of the

assembled pipe joint (mm)

DV = AD + 27 mm

B = Width of the pipe joint (mm)

FLEX 2L = 138mm

FLEX 2LS = 139mm

FLEX 2LU = 141mm

FLEX 2H = 142mm

FLEX 2XS = 153mm

Pipe Clamping Working pressure Torque rate

Distance Distance Locking bolts

range between between

the pipe ends

FLEX2 FLEX2 sealing Rmax. FLEX2

L LS/LS* LU/LU* H/H* XS L LS/ LU/ H/H* XS lips without with L/ LU/ XS

AD PBMin PBMin PBMin PBMin PBMin LS* LU* C strip insert LS/ LU*/

(mm) (mm) (bar) (bar) (bar) (bar) (bar) (Nm) (Nm) (Nm) (Nm) (Nm) (mm) (mm) LS* H/H*

180.0 178 - 182 12.0 16.5 25.0 - 10 15 20 -

200.0 198 - 202 11.0 15.0 25.0 - 10 15 30 -

219.1 217 - 222 10.0 13.5 25.0 - 10 15 30 -

250.0 248 - 253 9.0 12.0 24.0 - 10 15 30 -

Available for all pipe sizes from 180 up to 1600

267.0 264 - 270 8.0 11.0 22.5 - 15 15 30 -

273.0 270 - 276 8.0 11.0 22.0 25.0 15 15 30 30

2 (4*) x M12 with socket head 10 mm

2 (4*) x M10 with socket head 8 mm

304.0 301 - 307 7.0 10.0 19.5 25.0 15 20 30 30

2 x M20 with socket head 17 mm

323.9 321 - 327 7.0 9.5 18.5 25.0 15 20 30 30

355.6 353 - 358 6.0 8.5 17.0 25.0 15 20 30 30

406.4 404 - 409 5.5 7.5 15.0 22.0 25 20 20 30 40 120

457.2 454 - 460 5.0 6.5 13.0 19.0 25 20 20 40 40 120

508.0 505 - 511 4.5 6.0 12.0 17.0 25 20 25 40 40 120

558.8 556 - 562 4.0 5.5 10.5 16.0 25 25 25 40 50 140 91 10 35

609.6 606 - 613 3.5 5.0/5.0* 10.0 14.0 25 25 25/20* 40 50 140

711.2 708 - 715 - 4.0/4.0* 8.5 12.0 25 - 30/25* 50 50 140

762.0 758 - 766 - 4.0/4.0* 8.0 12.0 23.5 - 30/25* 50 60 160

812.8 809 - 817 - 3.5/3.5* 7.5 11.0 22 - 30/25* 50 60 160

914.4 910 - 918 - 3.5/3.5* 6.5 10.0 20 - 35/30* 60 60 160

1016.0 1012 - 1020 - 3.0/3.0* 6.0 9.0 18 - 35/30* 60 70 160

1117.6 1114 - 1122 - 2.5/2.5* 5.5 8.0 16 - 40/35* 70 70 180

1219.2 1215 - 1224 - 2.5/2.5* 5.0/5.0* 7.0/7.0* 15 - 40/40* 70/50* 80/60* 180

1320.8 1316 - 1325 - 2.5* 4.5* 7.0* - - 45* 60* 70* -

1422.4 1418 - 1427 - 2.0* 4.0* 6.0* - - 45* 60* 70* -

1524.0 1519 - 1529 - 2.0* 4.0* 6.0* - - 45* 70* 80* -

1600.0 1595 - 1605 - 2.0* 4.0* 6.0* - - 50* 70* 80* -

Right of alteration reserved.

Legend: - W1 - W5 according to DIN Standard 86128 (ASTM F 1476 / F1548, ISO/NP-15837 / 15838).

** Property class 12.9, Cacromet 500 (zinc-chromate with integrated lubricant).

* Casing in two-piece execution

Remarks: - Follow fitting /disassembly instructions.

- Admissible maximum axial movement of the pipes l: 10 mm.

- Weight of the pipe jonts see packing specifications.

- Strip insert are required when the gap between the pipe ends is excessive, in presence of swelling, at vacuum/depression (suction line, or

external pressure. Strip inserts are available, under separate order, at additional costs.

You might also like

- Formato 172a - Manual de Diagramas Elétricos Irizar I6 - Revisão 9 - 21.03.2016 - Especial A3 PDFDocument42 pagesFormato 172a - Manual de Diagramas Elétricos Irizar I6 - Revisão 9 - 21.03.2016 - Especial A3 PDFNeftali Antonio Rodriguez CastroNo ratings yet

- 00 DRAINAGE - Funke HS Sewer Pipe BrochureDocument44 pages00 DRAINAGE - Funke HS Sewer Pipe BrochurenextomegagenNo ratings yet

- Elastomer Bellows Seal: Applications Operating ConditionsDocument3 pagesElastomer Bellows Seal: Applications Operating ConditionsSingit Wahyu SaputraNo ratings yet

- MefaDocument250 pagesMefaStephane ChaminadeNo ratings yet

- Oxygen and Helium HoseDocument2 pagesOxygen and Helium HoseAbdullah FazilNo ratings yet

- Sridhan Level SwitchDocument95 pagesSridhan Level SwitchvaibhavnriitmNo ratings yet

- BLMT Data SheetDocument3 pagesBLMT Data SheetTiagoNo ratings yet

- Ancon 25-14 Restraint SystemDocument2 pagesAncon 25-14 Restraint SystemabudabeejajaNo ratings yet

- Beam Details PDFDocument1 pageBeam Details PDFHilton D. CalawenNo ratings yet

- Tgi33 7Document2 pagesTgi33 7infoNo ratings yet

- Ic2024 - 17 - 1Document26 pagesIc2024 - 17 - 1sk tripathiNo ratings yet

- Seagull Daily AttdncDocument28 pagesSeagull Daily Attdncpraveenraj murugadassNo ratings yet

- Screw in Plug Type Connectors HX HLDocument8 pagesScrew in Plug Type Connectors HX HLra5tr@No ratings yet

- ITT - Trident ConnectorDocument1 pageITT - Trident ConnectorhNo ratings yet

- Furse New Earth Rod Seals FlyerDocument2 pagesFurse New Earth Rod Seals FlyerImran Mughle AzamNo ratings yet

- Clarkson - Ord-NeedDocument3 pagesClarkson - Ord-NeednikilokumaNo ratings yet

- Load Schedule: Proposed Two-Storey ResidenceDocument1 pageLoad Schedule: Proposed Two-Storey Residencear.christdelvivar.uapNo ratings yet

- Apron - HB 250 To HB 250Document17 pagesApron - HB 250 To HB 250Hendri HermawanNo ratings yet

- ZP00707 GB 2Document40 pagesZP00707 GB 2grandtrading.egNo ratings yet

- Tools&ConsumablesDocument8 pagesTools&ConsumablesZeeshan HashmiNo ratings yet

- H F200 - 0916 Flexible Connector DN15 To 50Document2 pagesH F200 - 0916 Flexible Connector DN15 To 50ROBERTO RAFAELNo ratings yet

- Brush Plug Use:: Product Sheet June 2004Document1 pageBrush Plug Use:: Product Sheet June 2004Enrico ManfrinatoNo ratings yet

- Pipes Flexnetflexible Pipes-2020Document12 pagesPipes Flexnetflexible Pipes-2020Bengaluru CommonmanNo ratings yet

- 4 - Compakt Seals Special - GB - 2012Document5 pages4 - Compakt Seals Special - GB - 2012Akshay PoddarNo ratings yet

- GS Range Couplings and Adaptors DatasheetDocument2 pagesGS Range Couplings and Adaptors Datasheetdurrant bilankuluNo ratings yet

- Scheda Tecnica - Cartella SpecialeDocument1 pageScheda Tecnica - Cartella Specialemassi.95No ratings yet

- Funke Kunststoffe Pipe Liner Lateral Connection System Connex Brochure 10 2018Document4 pagesFunke Kunststoffe Pipe Liner Lateral Connection System Connex Brochure 10 2018Tranda ZaineaNo ratings yet

- Hansun Tube Fitting - (S-LOK TYPE)Document60 pagesHansun Tube Fitting - (S-LOK TYPE)qasim_maqboolNo ratings yet

- Talbot Straps and FerrulesDocument8 pagesTalbot Straps and Ferrulesphiliptoh1No ratings yet

- Socitec - HH16Document2 pagesSocitec - HH16Andrzej RogalaNo ratings yet

- Bircher DWSK Profile & Rail - E PDFDocument2 pagesBircher DWSK Profile & Rail - E PDFSuleman KhanNo ratings yet

- S-LOK Tube FittingsDocument58 pagesS-LOK Tube FittingsCesar YalanNo ratings yet

- Mumbai CSSD Electrical Material ListDocument1 pageMumbai CSSD Electrical Material Listm devdasNo ratings yet

- "T" Shaped Post Base: InvisibleDocument6 pages"T" Shaped Post Base: Invisiblemilivoj ilibasicNo ratings yet

- Decoduct UPVC Conduits & Fittings Manufactured To BS 6099 & BS 4607 and BS EN 50086 / BS EN 61386 Price ListDocument3 pagesDecoduct UPVC Conduits & Fittings Manufactured To BS 6099 & BS 4607 and BS EN 50086 / BS EN 61386 Price ListAly SamirNo ratings yet

- Tuc SandvikDocument2 pagesTuc SandvikYsraels Santisteban DurandNo ratings yet

- Lift-Off Restraints: No Welding - No Drilling - Just ClampingDocument20 pagesLift-Off Restraints: No Welding - No Drilling - Just ClampingRamzi Ben AhmedNo ratings yet

- Funke Kunststoffe CONNEX Junction Brochure 10 2020.pdfDocument8 pagesFunke Kunststoffe CONNEX Junction Brochure 10 2020.pdfTranda ZaineaNo ratings yet

- DECO Catalogue14 ( Õ É)Document16 pagesDECO Catalogue14 ( Õ É)KH Samuel LeeNo ratings yet

- Development and Splice Length Calculation For Aci-318 08Document1 pageDevelopment and Splice Length Calculation For Aci-318 08dantevarias100% (1)

- Linde Service GuideDocument5 pagesLinde Service GuideMário AndradeNo ratings yet

- Instru BOQ - 21027 Rev-01 PDFDocument2 pagesInstru BOQ - 21027 Rev-01 PDFnavtej singhNo ratings yet

- En HQ 52006130 Content TB BrochureDocument16 pagesEn HQ 52006130 Content TB Brochurethanh_cdt01No ratings yet

- 3 Hit-Hy150 HisnDocument9 pages3 Hit-Hy150 Hisndd160179No ratings yet

- Rockfall Protection Netting: Galvanized & Polymer Coated (10x12)Document2 pagesRockfall Protection Netting: Galvanized & Polymer Coated (10x12)Sudipto PaulNo ratings yet

- Cephas ValvulasMariposaDocument31 pagesCephas ValvulasMariposarezaNo ratings yet

- Optronics - Single Loose Tube With Steel Tape Armour Fibre Optic CableDocument3 pagesOptronics - Single Loose Tube With Steel Tape Armour Fibre Optic CableblegedesNo ratings yet

- SLT Sta With e Glass 2 5954Document3 pagesSLT Sta With e Glass 2 5954Marlon Fukunaga RomeroNo ratings yet

- SL3488D-Plus Multipath Ultrasonic Flowmeter BrochureDocument10 pagesSL3488D-Plus Multipath Ultrasonic Flowmeter BrochureNaji OmarNo ratings yet

- Level SwitchesDocument94 pagesLevel SwitchesPremjith SudhakaranNo ratings yet

- Strutfast Clamps, Fasteners & Anchors LRDocument7 pagesStrutfast Clamps, Fasteners & Anchors LRzimtonyNo ratings yet

- Krausz Spesifications Hymax-Flensemuffe enDocument4 pagesKrausz Spesifications Hymax-Flensemuffe enibrahimNo ratings yet

- Epcon C8 XtremDocument6 pagesEpcon C8 XtremAhmed TahaNo ratings yet

- FM Hilti MAB13 PDFDocument2 pagesFM Hilti MAB13 PDFIgor CvijovicNo ratings yet

- ISOBUS Flyer Amphenol ConnectorDocument4 pagesISOBUS Flyer Amphenol ConnectorGustavo ParlantiNo ratings yet

- Reinforced Line CanalDocument1 pageReinforced Line CanalJoefel BessatNo ratings yet

- 9379 PDFDocument2 pages9379 PDFrahimi mohamadNo ratings yet

- 9379 PDFDocument2 pages9379 PDFrahimi mohamadNo ratings yet

- Pipe Clamps & Accessories: Chilled Water Clamp LKS 19 (M)Document2 pagesPipe Clamps & Accessories: Chilled Water Clamp LKS 19 (M)rahimi mohamadNo ratings yet

- Parts List - GSZ5-37-6 (JIS10K) NewDocument5 pagesParts List - GSZ5-37-6 (JIS10K) NewtylerdoriusNo ratings yet

- Best Practices For Producing High Quality PDF FilesDocument7 pagesBest Practices For Producing High Quality PDF FilesSyed ShahNo ratings yet

- XE700D液压挖掘机技术规格书Document22 pagesXE700D液压挖掘机技术规格书abangNo ratings yet

- Yash Sir Sanchit Sir: Visit Our WebsiteDocument6 pagesYash Sir Sanchit Sir: Visit Our WebsiteHimank MaheshwariNo ratings yet

- NG160 - 16 To 160A Modular Incoming Circuit BrakersDocument27 pagesNG160 - 16 To 160A Modular Incoming Circuit BrakerssomeontorrenteNo ratings yet

- I. Organizational Structure of The IPO: Intellectual Property I. Intellectual Property OfficeDocument10 pagesI. Organizational Structure of The IPO: Intellectual Property I. Intellectual Property OfficeBonbon CavalesNo ratings yet

- Navman DDR MiVue 1000 - 1100 EN R01Document2 pagesNavman DDR MiVue 1000 - 1100 EN R01joxof42296No ratings yet

- Rear Suspension: Group 34Document6 pagesRear Suspension: Group 34Davit OmegaNo ratings yet

- Error CorrectionDocument15 pagesError Correctionrishi srivastavaNo ratings yet

- Individual AssignmentDocument5 pagesIndividual AssignmentHao LimNo ratings yet

- Modern Technology ImpactDocument5 pagesModern Technology ImpactDeep ChoudharyNo ratings yet

- PNB V SAYODocument2 pagesPNB V SAYONica09_foreverNo ratings yet

- Admit Card: Araksha Bhavan (5Th Floor), 6Th Cross Road, Block-Dj, Sector-Ii, Salt Lake City, Kolkata-700 091Document1 pageAdmit Card: Araksha Bhavan (5Th Floor), 6Th Cross Road, Block-Dj, Sector-Ii, Salt Lake City, Kolkata-700 091Ayesha HignisNo ratings yet

- G.R. No. 152496 - Sps. German Anunciacion, Et Al. v. Perpetua M. Bocanegra, Et Al. - July 2009 - Philipppine Supreme Court DecisionsDocument7 pagesG.R. No. 152496 - Sps. German Anunciacion, Et Al. v. Perpetua M. Bocanegra, Et Al. - July 2009 - Philipppine Supreme Court DecisionssejinmaNo ratings yet

- TT Lubricating Oils Greases Shelf Life RecommendationsDocument2 pagesTT Lubricating Oils Greases Shelf Life RecommendationsSanogo YayaNo ratings yet

- Military Courtesy and DisciplineDocument33 pagesMilitary Courtesy and DisciplineCherry EyreNo ratings yet

- CH 8Document107 pagesCH 8Sri NahdaNo ratings yet

- 13OBDG06 Hybrid DiagnosticsDocument462 pages13OBDG06 Hybrid DiagnosticsIonflorin TelegaruNo ratings yet

- List All Major/critical TasksDocument4 pagesList All Major/critical TasksIndra Mulyana0% (1)

- Flywheel Energy Storage System Design For: Distribution NetworkDocument5 pagesFlywheel Energy Storage System Design For: Distribution NetworkMohamed AlNo ratings yet

- E Business Assignment 2Document7 pagesE Business Assignment 2Shikha MishraNo ratings yet

- CapersJones - Scoring and Evaluating Software Methods, Practices, and ResultsDocument17 pagesCapersJones - Scoring and Evaluating Software Methods, Practices, and ResultsSharing Caring100% (1)

- TMP Nedjo Jarsao For PrintDocument20 pagesTMP Nedjo Jarsao For PrintGenetNo ratings yet

- Citrix XenApp 6 5 - Enterprise Scalable XenApp Deployments - 1293Document49 pagesCitrix XenApp 6 5 - Enterprise Scalable XenApp Deployments - 1293trshenoyNo ratings yet

- Syllabus EntrepreneurshipDocument8 pagesSyllabus Entrepreneurshipchokrib100% (5)

- National Greening ProgramDocument58 pagesNational Greening ProgramArnelCorpuzNo ratings yet

- District Memo District Nat Sts Kto12 FormsDocument2 pagesDistrict Memo District Nat Sts Kto12 FormsNica SalentesNo ratings yet

- Gas ExpanderDocument12 pagesGas ExpanderArun KumarNo ratings yet

- Agreement in Restraint of Trade-ExceptionsDocument15 pagesAgreement in Restraint of Trade-ExceptionsNishita GuptaNo ratings yet

- 4-Port - RFS (Antenna) - Multi Ret - ScriptDocument2 pages4-Port - RFS (Antenna) - Multi Ret - Scriptyou are awesomeNo ratings yet