Professional Documents

Culture Documents

2014 Yang MaterialEffectonShrinkage WJ 2014 11 s421

2014 Yang MaterialEffectonShrinkage WJ 2014 11 s421

Uploaded by

hgagselim2012Copyright:

Available Formats

You might also like

- Chapter 1Document5 pagesChapter 1AlecsisRoeEstañolFrasco100% (1)

- Steel Storage Tanks Excel Sheet (API 650-2009) Free-09122209467Document42 pagesSteel Storage Tanks Excel Sheet (API 650-2009) Free-09122209467Hamid Mansouri100% (6)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- PWHT Requirement As Per API-650Document1 pagePWHT Requirement As Per API-650hgagselim2012No ratings yet

- TANK DESIGN AWWA - 05 (2) - Final (106 M)Document29 pagesTANK DESIGN AWWA - 05 (2) - Final (106 M)hgagselim2012No ratings yet

- 14310A ch4 PDFDocument96 pages14310A ch4 PDFmiguelNo ratings yet

- 2014 Yang MaterialEffectonShrinkage WJ 2014 11 s421Document11 pages2014 Yang MaterialEffectonShrinkage WJ 2014 11 s421Abu Anas M.SalaheldinNo ratings yet

- Welded Lap Joints of Thin Steel Sheets With DiffeDocument11 pagesWelded Lap Joints of Thin Steel Sheets With DiffeRicardo HernandezNo ratings yet

- Powder Technology: Qing Shuai Cao, Yang Zhao, Li Xing, Ru Zhang, Ben Yue LiDocument11 pagesPowder Technology: Qing Shuai Cao, Yang Zhao, Li Xing, Ru Zhang, Ben Yue LiSohail ShaikhNo ratings yet

- Flexural-Torsional Buckling Tests of Cold-Formed Lipped Channel Beams Under Restrained Boundary ConditionsDocument10 pagesFlexural-Torsional Buckling Tests of Cold-Formed Lipped Channel Beams Under Restrained Boundary ConditionsPhạm Quang VinhNo ratings yet

- FEAnalysisof Buckling Behavior Causedby Weldingin Thin Platesof High Tensile Strength SteelDocument9 pagesFEAnalysisof Buckling Behavior Causedby Weldingin Thin Platesof High Tensile Strength SteelJose Marie Rmgrocks BatoNo ratings yet

- Prediction of Welding Distortion in Butt Joint of Thin Plates - Long-2009Document11 pagesPrediction of Welding Distortion in Butt Joint of Thin Plates - Long-2009DonatasNo ratings yet

- Author Manuscript: Microstructure and Thickness Effects On Impact Behavior and Separation Formation in X70 Pipeline SteelDocument20 pagesAuthor Manuscript: Microstructure and Thickness Effects On Impact Behavior and Separation Formation in X70 Pipeline Steelvijayaraman rajendranNo ratings yet

- Journal of Constructional Steel Research: V.K.R. Kodur, M.Z. NaserDocument12 pagesJournal of Constructional Steel Research: V.K.R. Kodur, M.Z. NasernnmmNo ratings yet

- 2019 A Review On Resistance Spot Welding of Steel MaterialDocument13 pages2019 A Review On Resistance Spot Welding of Steel Materialguravshubham7777No ratings yet

- Effect of Sequence and Stiffener Shape On Welding DistortionDocument12 pagesEffect of Sequence and Stiffener Shape On Welding DistortionRafi ZhaffNo ratings yet

- The Application of High Strength Steels For Fatigue Loaded StructuresDocument13 pagesThe Application of High Strength Steels For Fatigue Loaded StructuresmukulNo ratings yet

- Effect of Tempering Temperature, Plate Thickness and Presence of Holes On Ballistic Impact Behavior and ASB Formation of A High Strength SteelDocument13 pagesEffect of Tempering Temperature, Plate Thickness and Presence of Holes On Ballistic Impact Behavior and ASB Formation of A High Strength Steelm1601295No ratings yet

- Forgings For Low Temperature ApplicationsDocument1 pageForgings For Low Temperature ApplicationsTasmanijskaNemaNo ratings yet

- Martensitic Steel Sheets of 1300 and 1500mpa GradesDocument5 pagesMartensitic Steel Sheets of 1300 and 1500mpa Gradesmohamed ahmedNo ratings yet

- Effect of Welding Speed On The Microstructure and Texture Development in The Individual Weld Zone of Friction Stir Welded DP780 SteelDocument14 pagesEffect of Welding Speed On The Microstructure and Texture Development in The Individual Weld Zone of Friction Stir Welded DP780 SteelARUNPRAKASH SNo ratings yet

- Thin-Walled StructuresDocument13 pagesThin-Walled StructuresAnis SuissiNo ratings yet

- Qwerty PDFDocument2 pagesQwerty PDFNagalingaraja RnrNo ratings yet

- 6 PDFDocument2 pages6 PDFchtganduNo ratings yet

- Anch 003Document5 pagesAnch 003arun arunNo ratings yet

- Module 4 Lecture 5Document7 pagesModule 4 Lecture 5Silverio AcuñaNo ratings yet

- 2023 Turning - 230519 - 134402Document11 pages2023 Turning - 230519 - 134402Hassan LotfizadehNo ratings yet

- IRJET Distortional Buckling Study of ColDocument5 pagesIRJET Distortional Buckling Study of ColssierroNo ratings yet

- Forming Notes PDFDocument4 pagesForming Notes PDFMuthuKumarNo ratings yet

- BD C Candidate Handbook 2018 6.12.18 FINALDocument13 pagesBD C Candidate Handbook 2018 6.12.18 FINALmadhav sreekumarNo ratings yet

- Structures: Ahmad Siar Mahmood Shah, Saber Moradi TDocument13 pagesStructures: Ahmad Siar Mahmood Shah, Saber Moradi THAMID BOUDAGHINo ratings yet

- 2012-Fracture Toughness of Friction Hydro-Pillar Processing Welding in C-MN SteelDocument5 pages2012-Fracture Toughness of Friction Hydro-Pillar Processing Welding in C-MN SteelPedro CunhaNo ratings yet

- Influence of Process Parameters On Microstructure and Mechanical Properties in AA2024-T3 Friction Stir WeldingDocument10 pagesInfluence of Process Parameters On Microstructure and Mechanical Properties in AA2024-T3 Friction Stir WeldingYazid HelalNo ratings yet

- 10.1515 - JMBM 2022 0006Document12 pages10.1515 - JMBM 2022 0006jiji wangNo ratings yet

- Structural Performance of Corrosion-Damaged Concrete BeamsDocument13 pagesStructural Performance of Corrosion-Damaged Concrete BeamspublikgerNo ratings yet

- Study of Mach Inability in Boring Operation of Micro Alloyed and Heat Treated Alloy SteelsDocument10 pagesStudy of Mach Inability in Boring Operation of Micro Alloyed and Heat Treated Alloy SteelsmariotonNo ratings yet

- Lateral Torsion BucklingDocument11 pagesLateral Torsion BucklingkyleNo ratings yet

- Engineered Casting Solutions 2006 CastinDocument6 pagesEngineered Casting Solutions 2006 CastinMandeep SinghNo ratings yet

- Influence of Imperfections in The Buckling ResistaDocument6 pagesInfluence of Imperfections in The Buckling Resistahasan19994ggffNo ratings yet

- Design-of-Experiments Study To Examine The Effect of Polarity On Stud WeldingDocument8 pagesDesign-of-Experiments Study To Examine The Effect of Polarity On Stud WeldingtazzorroNo ratings yet

- 6.LII 2012 Residual-Stress SWDDocument12 pages6.LII 2012 Residual-Stress SWDDimitrios ManolakosNo ratings yet

- Sandwich Panels 2006 Special1Document4 pagesSandwich Panels 2006 Special1haidardiwantara83No ratings yet

- Materials and Design: G. Agarwal, A. Kumar, I.M. Richardson, M.J.M. HermansDocument12 pagesMaterials and Design: G. Agarwal, A. Kumar, I.M. Richardson, M.J.M. Hermanstolentino.jason1222No ratings yet

- Die Design ProgramDocument5 pagesDie Design ProgramSundar KaruppiahNo ratings yet

- Commentary On Highly Restrained Welded ConnectionsDocument13 pagesCommentary On Highly Restrained Welded ConnectionstrabajosicNo ratings yet

- Microstructure and Failure Behaviour ofDocument8 pagesMicrostructure and Failure Behaviour ofVipin MishraNo ratings yet

- The Effect of Anchorage On The Effectiveness of The Shear Reinforcement in The Punching ZoneDocument11 pagesThe Effect of Anchorage On The Effectiveness of The Shear Reinforcement in The Punching ZoneVinh LENo ratings yet

- Wang 2018Document12 pagesWang 2018n.salemizadehNo ratings yet

- Welding - SteelConstructionDocument19 pagesWelding - SteelConstructionsiroliver39No ratings yet

- Punching Shear of Thick Plates With and Without SHDocument12 pagesPunching Shear of Thick Plates With and Without SHShaikh ImranNo ratings yet

- Steel ConnectionsDocument29 pagesSteel ConnectionsSHRADDHA KADAM100% (1)

- Journal of Manufacturing Processes: Jastej Singh, A.S. ShahiDocument10 pagesJournal of Manufacturing Processes: Jastej Singh, A.S. ShahiSorabh SinghalNo ratings yet

- Tech Uddeholm Die Casting ENDocument24 pagesTech Uddeholm Die Casting ENSajal GoelNo ratings yet

- Resistance Welding of FeCrNiSi AlloyDocument18 pagesResistance Welding of FeCrNiSi Alloytqzw7p8m2kNo ratings yet

- Metals 13 00187 v2Document18 pagesMetals 13 00187 v2shatayu deshpandeNo ratings yet

- Design Guidelines - Spot Welding ChapterDocument11 pagesDesign Guidelines - Spot Welding ChapterJoel BrasilBorgesNo ratings yet

- Weld Overlaycladding of HSLA With ASSDocument11 pagesWeld Overlaycladding of HSLA With ASSUjjawal PathakNo ratings yet

- JSP1265SSWPAPERFeb O9Document19 pagesJSP1265SSWPAPERFeb O9Hussain AlsaadyNo ratings yet

- Experiment On The Flexural Functioning of Cold-Formed Steel Built-Up Complex Hat SectionDocument7 pagesExperiment On The Flexural Functioning of Cold-Formed Steel Built-Up Complex Hat SectionIJRASETPublicationsNo ratings yet

- Weld Joint DesignDocument21 pagesWeld Joint DesignKoushik SarkarNo ratings yet

- Guidance Note Plate Bending No. 5.04: ScopeDocument3 pagesGuidance Note Plate Bending No. 5.04: ScoperoldoguidoNo ratings yet

- Advances and Trends On Tube Bending Forming TechnoDocument12 pagesAdvances and Trends On Tube Bending Forming Techno1ere année ingNo ratings yet

- Welding Defects at Friction Stir Welding: P. Podržaj, B. Jerman, D. KlobčarDocument3 pagesWelding Defects at Friction Stir Welding: P. Podržaj, B. Jerman, D. Klobčarsanjay_dutta_5No ratings yet

- 1 s2.0 S0263823123002185 MainDocument14 pages1 s2.0 S0263823123002185 MainHari Om Tamrakar ce21d019No ratings yet

- Effect of Stiffeners On Shear Lag in Steel Box GirdersDocument14 pagesEffect of Stiffeners On Shear Lag in Steel Box Girderserky arkvathonejhNo ratings yet

- Ubc 2013 Fall Salem HayderDocument117 pagesUbc 2013 Fall Salem Hayderhgagselim2012No ratings yet

- Pipe Spool DWG List: Total Q'Ty 42Document2 pagesPipe Spool DWG List: Total Q'Ty 42hgagselim2012No ratings yet

- Design Calculation of Recycle Oil Injection Insert (Sheet-37)Document30 pagesDesign Calculation of Recycle Oil Injection Insert (Sheet-37)hgagselim2012No ratings yet

- Overview of Stainless Steel and Stainless Plate - Stainless Processing, Inc. - Coatesville, PennsylvaniaDocument7 pagesOverview of Stainless Steel and Stainless Plate - Stainless Processing, Inc. - Coatesville, Pennsylvaniahgagselim2012No ratings yet

- Open TankDocument27 pagesOpen Tankhgagselim2012No ratings yet

- Design of 5 Tons Capacity Cone Bottom STDocument26 pagesDesign of 5 Tons Capacity Cone Bottom SThgagselim2012No ratings yet

- Self-Supported Cone Roof Design Data: Design of Steel Storage Tanks As Per Api-650 (Diameter 3M)Document23 pagesSelf-Supported Cone Roof Design Data: Design of Steel Storage Tanks As Per Api-650 (Diameter 3M)hgagselim2012No ratings yet

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument14 pagesStorage Tank Design Calculation - Api 650: Close Floating Roofhgagselim2012No ratings yet

- Air Vessel (Final Sent To AI) - 1Document38 pagesAir Vessel (Final Sent To AI) - 1hgagselim2012No ratings yet

- Flate EndDocument3 pagesFlate Endhgagselim2012No ratings yet

- Desalinated Water TankDocument34 pagesDesalinated Water Tankhgagselim2012No ratings yet

- Ch02 PartIDocument44 pagesCh02 PartIgirm2002No ratings yet

- Compression EngineDocument15 pagesCompression EngineAlina RajputNo ratings yet

- DiaphragmsDocument26 pagesDiaphragmsHello WorldNo ratings yet

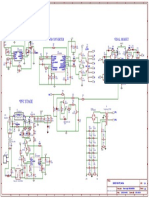

- Schematic SMPS-PFC Sheet-1 20190424001902 PDFDocument1 pageSchematic SMPS-PFC Sheet-1 20190424001902 PDFАлексей АндрияшNo ratings yet

- Stair Expert: User ManualDocument19 pagesStair Expert: User Manualcoc08No ratings yet

- RCC Drain 002Document1 pageRCC Drain 002GOMASH RCPNo ratings yet

- Thermal Energy Storage For Space CoolingDocument32 pagesThermal Energy Storage For Space CoolingAzim AdamNo ratings yet

- Esci341 Lesson11 Energy Minimum PrincipleDocument8 pagesEsci341 Lesson11 Energy Minimum PrincipleDilaraa AtılganNo ratings yet

- Carrier Frame PartsDocument40 pagesCarrier Frame PartsSales AydinkayaNo ratings yet

- pv5n6 2 PDFDocument112 pagespv5n6 2 PDFCharles SandersNo ratings yet

- Answer All Questions. Each Question Carries 2 MarksDocument2 pagesAnswer All Questions. Each Question Carries 2 MarksJaferNo ratings yet

- MSDS - CHIMEC 1038 - Gas Corr. InhibitorDocument6 pagesMSDS - CHIMEC 1038 - Gas Corr. InhibitorAnonymous LfeGI2hM0% (1)

- Subdivision Storm Sewers SampleDocument1 pageSubdivision Storm Sewers Sampleaggrey noahNo ratings yet

- Simple Data Types in C: Alan L. Cox Alc@rice - EduDocument44 pagesSimple Data Types in C: Alan L. Cox Alc@rice - EduDavinder SinghNo ratings yet

- CS 3853 Computer Architecture - Memory HierarchyDocument37 pagesCS 3853 Computer Architecture - Memory HierarchyJothi RamasamyNo ratings yet

- StressHead - Design Concept - 170223Document15 pagesStressHead - Design Concept - 170223Juan ManuelNo ratings yet

- Recce Checklist: Things To TakeDocument3 pagesRecce Checklist: Things To Takehsmedia16No ratings yet

- Aeci Mining Explosives Differentitated Products AccessoriesDocument11 pagesAeci Mining Explosives Differentitated Products AccessoriesMashudu MbulayeniNo ratings yet

- Activity Ans AssessmentDocument2 pagesActivity Ans AssessmentOhmark VeloriaNo ratings yet

- Akp Associates Event Profile FinalDocument27 pagesAkp Associates Event Profile FinalanupkpandaNo ratings yet

- U0 8801Document133 pagesU0 8801vicbalt07No ratings yet

- Short Literature Review On T5 Lighting SystemDocument2 pagesShort Literature Review On T5 Lighting SystemChing Wai YongNo ratings yet

- ME4447-ME6405 Course OutlineDocument13 pagesME4447-ME6405 Course OutlineAnonymous qTKCWlxNo ratings yet

- Clamping Force: Security and Safety in Application - by DesignDocument15 pagesClamping Force: Security and Safety in Application - by DesignIna IoanaNo ratings yet

- Mobile FTP Client - An Android ApplicationDocument41 pagesMobile FTP Client - An Android ApplicationOscar ParraNo ratings yet

- SCHEDULES - National Highways Authority of IndiaDocument101 pagesSCHEDULES - National Highways Authority of IndiaIrfanNo ratings yet

- AgileDocument4 pagesAgileSakriti VermaNo ratings yet

- Windows Sockets 2Document29 pagesWindows Sockets 2ntarylNo ratings yet

2014 Yang MaterialEffectonShrinkage WJ 2014 11 s421

2014 Yang MaterialEffectonShrinkage WJ 2014 11 s421

Uploaded by

hgagselim2012Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2014 Yang MaterialEffectonShrinkage WJ 2014 11 s421

2014 Yang MaterialEffectonShrinkage WJ 2014 11 s421

Uploaded by

hgagselim2012Copyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/281006634

Material Strength Effect on Weld Shrinkage and Distortion

Article in Welding Journal · November 2014

CITATIONS READS

13 2,225

5 authors, including:

Y.P. Yang

Edison Welding Institute (EWI)

108 PUBLICATIONS 477 CITATIONS

SEE PROFILE

All content following this page was uploaded by Y.P. Yang on 08 September 2015.

The user has requested enhancement of the downloaded file.

Yang Supplement November 2014[1]_Layout 1 10/14/14 3:59 PM Page 421

WELDING RESEARCH

Material Strength Effect on Weld Shrinkage

and Distortion

The effects of material strength and heat input on inplane shrinkage and outofplane dis

tortion were studied by welding and measuring 44 smallscale panels in the laboratory

BY Y. P. YANG, R. DULL, H. CASTNER, T. D. HUANG, AND D. FANGUY

try and variable quality of products.

ABSTRACT Preventive and corrective actions have

to be taken in order to avoid degraded

Highstrength steels have been increasingly used to reduce thickness and weight dimensional quality induced by distor-

in cars, trucks, cranes, bridges, ships, and other structures that are designed to han tion. These actions are time consuming

dle large amounts of stress or need a good strengthtoweight ratio. However, thinner and associated with significant costs.

structures are more likely to deform during welding because of a lack of rigidity. Welding distortions can be classi-

Welding shrinkage and distortion become major issues during fabrication of welded fied into transverse and longitudinal

structures made of highstrength steels. Manufacturers are interested in estimating shrinkage, angular distortion, longitu-

shrinkages and compensate for them by starting with bigger parts. However, there dinal bowing, and buckling (Ref. 3).

are no accurate empirical formulas to calculate weld shrinkage for thin structures

Transverse and longitudinal shrink-

made of highstrength steel since the weld shrinkage allowance data and formulas

developed by worldwide researchers are primarily for thick plate and lowstrength ages are the in-plane modes, and buck-

steels. The effects of material strength and heat input on inplane shrinkage and out ling, longitudinal bowing, and angular

ofplane distortion were studied by welding and measuring 44 smallscale panels in change are out-of-plane modes (Ref.

the laboratory. It was found that inplane weld shrinkage is lower for highstrength 4). In general, in-plane distortion is

steels (HSLA80, HY80, and HY100) than for the typical hull structural steel (ABS negligible in small parts. In large com-

Grade DH36) at normal welding heat input. Higher strength HY80 and HY100 steels ponents, such as shipbuilding, in-

have less outofplane distortion than lower strength DH36 steel while HSLA80 steel plane distortion can be significant so

has similar outofplane distortion compared to DH36. As welding heat input that manufacturers have to use theo-

increases, shrinkage and distortion are increased for both lower and higher strength retical and empirical formulas (Refs.

materials. For the same heat input, as thickness increases, both shrinkage and distor

5–8) and shrinkage data models (Refs.

tion are reduced.

9, 10) to estimate shrinkages and com-

pensate for them by starting with big-

ger parts. Out-of-plane distortion

KEYWORDS modes, often observed in a thin-

walled structure where fusion welding

• HighStrength Steels • Residual Stress • Distortion • Flux Cored Arc Welding

is applied, are very common and need

• Weld Shrinkage • Heat Input

special techniques (Refs. 4, 11–15) to

control. This paper concentrates on in-

plane shrinkage and briefly discusses

Introduction From the point of view of structural in- out-of-plane distortions.

tegrity, welding distortion acts as an ini- A large number of factors affect the

Welding distortion, a result of the tial imperfection of welded compo- type and extent of in-plane shrinkage

nonuniform expansion and contraction nents. These initial imperfections can and out-of-plane distortion due to

of weld metal and adjacent base metal have a significant influence on the be- welding. The magnitude and distribu-

during the heating and cooling cycle of havior of the structure under variable tion of shrinkage and distortion in a

the welding process, is a major concern loading (Ref. 1) and reduce the buckling welded structure are dependent on

during the fabrication of a welded struc- strength of the structure (Ref. 2). From geometric parameters, material prop-

ture. Welding distortion causes complex the perspective of manufacturing tech- erties, welding process parameters,

consequences, most of which are detri- nology, the consequences of welding and the degree of restraint during

mental during fabrication and service. distortion are out-of-tolerance geome- welding. Geometric parameters such

Y. P. YANG (yyang@ewi.org), R. DULL, and H. CASTNER are with Edison Welding Institute (EWI), Columbus, Ohio. T. D. HUANG is with Ingalls Shipbuilding,

Pascagoula, Miss. D. FANGUY is with Bollinger Shipyards, Lockport, La.

NOVEMBER 2014 / WELDING JOURNAL 421-s

Yang Supplement November 2014[1]_Layout 1 10/16/14 9:36 AM Page 422

WELDING RESEARCH

Fig. 1 — Double Vgroove joint design.

as the dimensions of the structure and In recent years, high-

the type and size of welded joints, and strength steels have

welding parameters such as heat in- been increasingly used Fig. 2 — Table, clamps, and measurement points.

put, welding sequence, preheating, to reduce thickness and

and postheating will affect weld weight in cars, trucks, for high-strength steels.

shrinkage and distortion. cranes, bridges, ships, and other struc-

Watanabe and Satoh (Ref. 16) used tures that are designed to handle large

a combination of empirical and ana- amounts of stress or need a good Technical Approach

lytical methods to study the effects of strength-to-weight ratio. However,

welding conditions on the distortion thinner structures are more likely to Three high-strength steels and one

in welded structures. Gunaraj and deform because of lack of rigidity. The typical grade of hull structural steel

Murugan (Ref. 17) studied the effect shrinkage allowance data and formu- were used to compare weld shrinkage

of process parameters on angular dis- las developed by world-wide re- and distortion among the different

tortion in gas metal arc welding of searchers are primarily for thick plate materials. A mockup panel was de-

structural steel plates. Sadat et al. and low-strength steels (Refs. 6–8). To signed with a double-sided butt joint

(Ref. 18) modeled the effects of pre- investigate the effect of material and welded by flux cored arc welding

heating on angular distortions in strength on shrinkage and distortion, (FCAW). Weld consumables and

one-sided fillet weld joints. Welding 44 small-scale specimens made from grooves were selected based on mate-

fixtures are widely used to control both high-strength steels (HSLA-80, rial and thickness, respectively. The

distortion by providing restraint HY-80, and HY-100) and the typical deformation induced by welding was

against thermal expansion and con- hull structural steel (DH-36) were fab- measured, and the data were

traction (Ref. 19). Material properties ricated under laboratory conditions. processed to obtain weld shrinkage

such as temperature-dependent ther- This paper describes controlled weld- and distortion for each panel.

mophysical and mechanical properties ing and shrinkage measurement trials

also contribute to the magnitude of on these small-scale specimens. The Materials and Mockup Panel

shrinkage and distortion, although data gathered were used to determine Geometry

there is little published information in the effect of material type and heat in-

this regard (Ref. 20). put on weld shrinkage and distortion The steel plate materials evaluated

Table 1 — Experimental Matrix

Material Nominal Thickness (mm) Total Heat Input (kJ/mm) Groove Root Opening (mm) Number of Panel Panel

4.76 1.14 Square 0 3 43,44,45

1.57 0 3 40,41,42

2.09 0 3 46,47,48

HSLA80 6.35 1.14 Square 0 3 25,26,27

1.69 0 5 8,9,10,17,18

2.13 0 3 28,29,30

9.53 1.65 Double V 0 3 34,35,36

2.20 0 3 31,32,33

2.56 0 3 37,38,39

DH36 6.35 1.14 Square 0 3 19,20,21

1.65 0 3 2,3,4

2.09 0 3 22,23,24

HY80 6.35 1.65 Square 0 3 5,6,7

HY100 6.35 1.65 Square 0 3 11,12,13

422-s WELDING JOURNAL / NOVEMBER 2014, VOL. 93

Yang Supplement November 2014[1]_Layout 1 10/16/14 9:36 AM Page 423

WELDING RESEARCH

Fig. 3 — Measurement point locations. Fig. 4 — Coordinate measuring machine measurement repeatability.

Fig. 6 — Panel deformed shape.

3

⁄16 in. (4.76 mm) and ¼ in. Fixturing and Clamping

(6.35 mm) thick plates

were double-sided welds A fixture was designed to restrain

on square groove joints the plates adjacent to the weld joint and

with no root opening. The along the edges as shown in Fig. 2. A

edges of the plates to be table was used to support the plate with

Fig. 5 — Data pairs used to calculate inplane shrinkage. welded were machined to a 4-in. (101.6 mm) wide slot centered

provide a tight fit, i.e., along the weld joint. A bridge was fabri-

minimum root opening cated from 2-in. (50.8-mm) square steel

in this task were DH-36, HSLA-80, HY- along the length of the weld. The weld tubing and welded to the table. Clamp-

80, and HY-100. The DH-36 plate was joint design for the 3⁄8-in. (9.53-mm) ing was provided by means of four 12⁄ -in.

used to compare shrinkage and distor- plate was a double-sided V-groove (12.7-mm) threaded rods on each side

tion with the high-strength materials with no root opening as shown in Fig. of the joint spaced approximately 15 in.

(HSLA-80, HY-80, and HY-100) and 1. It should be pointed out that the (381 mm) apart.

also called low-strength steel in the fol- 9.53 mm is a nominal thickness. The The first plate was located length-

lowing discussion. The plate size was real plate thickness used in the experi- wise on the table by means of a locat-

24 48 in. (610 1219 mm), providing ment was about 10 mm. Three replicas ing bar that was tack welded to the

a 48-in. (1219-mm) square mockup were conducted for each experimental table. The joint length was aligned

panel when welded with a single butt condition to ensure the reliability of with two spacer blocks located at the

joint. Plate thickness was nominally ¼ measured data. machined plate edge to the center of

in. (6.35 mm) for panels fabricated to

compare the effects of material type.

Additional HSLA-80 panels were weld- Table 2 — Material Strength Properties

ed using nominally 31⁄ 6 in. (4.76 mm)

and 38⁄ in. (9.53 mm) thick plates. Material Property DH36 HSLA80 HY80 HY100

0.2% Yield Strength MPa 423.9 607.4 629.2 751.0

Joint Design Ultimate Strength MPa 553.1 646.7 713.6 828.3

Elongation % 33.0 25.2 22.8 18.9

Most of the butt-joint welds on the

NOVEMBER 2014 / WELDING JOURNAL 423-s

Yang Supplement November 2014[1]_Layout 1 10/16/14 9:36 AM Page 424

WELDING RESEARCH

electrodes used were

• AWS E81T1-Ni1MJDH4 for DH-36,

HSLA 80, and HY80

• AWS E111T1-K3M for HY100.

The shielding gas was 75% Ar and

25% CO2. The welding equipment con-

sisted of a welding power source, elec-

trode wire feeder, welding gun, and a

side-beam carriage.

The welding parameters were nomi-

nally as follows. After welding, all

plates were allowed to cool down to

less than 100°F (38°C) while still being

clamped. Three travel speeds were

used to achieve high, middle, and low

heat input.

• Travel angle: 15-deg dragging

• Work angle: 90 deg

• Contact tip-to-work distance: ¾ in.

(19 mm)

• Electrode wire feed speed (WFS): 233

mm/s

• Voltage setting: 33.3 V

• Welding current: 290 A

Fig. 7 — Comparison of weld cross sections of different materials. • Travel speed: 9.0, 11.6, 16.2 mm/s

• Gas flow rate: 40 ft3/h.

the 4-in. (101.6 mm) wide slot. This genous gas tungsten arc welding Experimental Matrix

provided consistent alignment with (GTAW).

the weld axis for each plate. After the Table 1 shows the experimental ma-

first plate was located, it was clamped Welding Equipment, trix for the mockup panels that were

by means of four C-clamps along the Consumables, and Parameters fabricated. The mockup panels includ-

outer edge and four threaded rods on ed four different materials, three

the bridge. The spacer blocks were re- Equipment was set up and welding thicknesses, three heat inputs (low,

moved and the second plate was parameters were adjusted to provide medium, and high), and two groove

butted against the first and clamped the appropriate welding conditions de- types. Three replicas were made for

down in the same manner as the first. scribed in the following sections. The each condition. The total heat input

The clamped plates were tack welded welding process used for fabricating all was the sum of heat input for welding

together in four locations using auto- of the panels was FCAW. The welding both sides of the joint.

Table 3 — AcrossWeld and AlongWeld Shrinkage Data (DH36, HY80, and HY100)

Plate Material Thickness Total Heat Input Average AcrossWeld Shrinkage (mm) Average AlongWeld Shrinkage (mm/m)

(mm) (kJ/mm)

AH BG CF Av Avm IQ JP KO Av Avm

19 DH36 6.30 6.31 1.16 1.2 0.37 0.34 0.29 0.34 0.25 0.33 0.24 0.45 0.34 0.24

20 DH36 6.28 1.14 0.19 0.16 0.12 0.16 0.23 0.21 0.09 0.18

21 DH36 6.33 1.16 0.37 0.20 0.20 0.25 0.22 0.19 0.16 0.19

2 DH36 6.30 6.31 1.62 1.6 0.45 0.50 0.40 0.45 0.46 0.63 0.61 0.38 0.54 0.49

3 DH36 6.31 1.63 0.39 0.33 0.30 0.34 0.33 0.24 0.21 0.26

4 DH36 6.33 1.67 0.83 0.49 0.45 0.59 0.67 0.60 0.70 0.66

22 DH36 6.31 6.40 2.10 2.1 0.98 0.58 0.58 0.71 0.67 0.61 0.54 0.50 0.55 0.51

23 DH36 6.59 2.13 1.02 0.65 0.56 0.74 0.53 0.51 0.41 0.48

24 DH36 6.30 2.08 0.73 0.47 0.49 0.56 0.52 0.49 0.50 0.50

5 HY80 6.71 6.70 1.67 1.7 0.25 0.26 0.24 0.23 0.26 0.32 0.35 0.24 0.30 0.34

6 HY80 6.67 1.65 0.25 0.23 0.24 0.24 0.35 0.31 0.25 0.30

7 HY80 6.72 1.65 0.31 0.32 0.27 0.30 0.48 0.38 0.39 0.42

11 HY100 6.77 6.77 1.61 1.6 0.30 0.21 0.20 0.25 0.26 0.38 0.35 0.25 0.33 0.29

12 HY100 6.77 1.63 0.34 0.31 0.30 0.30 0.31 0.23 0.16 0.23

13 HY100 6.78 1.64 0.15 0.23 0.26 0.22 0.36 0.24 0.32 0.31

424-s WELDING JOURNAL / NOVEMBER 2014, VOL. 93

Yang Supplement November 2014[1]_Layout 1 10/16/14 9:36 AM Page 425

WELDING RESEARCH

The 6.35-mm materials were used

to study the effect of material strength

on shrinkage and distortion. The ef-

fect of heat input on shrinkage and

distortion was studied with materials

HSLA-80 and DH-36. The combina-

tion effect of thickness and heat input

was studied with material HSLA-80,

which has three thicknesses and three

heat inputs were used.

Measurements

Each mockup panel was measured

with a coordinate measuring machine

(CMM) prior to and after welding the

butt joints. Data were recorded for

each set of measurements. Flat plate

specimens were prepared and marked

with the locations of data points Fig. 8 — Effect of material on outofplane distortion.

where shrinkage measurements would

be taken, as shown in Fig. 3. Plate were taken after each side was welded. points

specimens were fit up and tack welded The detailed panel fabrication and • Measurement 1

in preparation for welding of the sin- measurement processes used were as • Clamp down

gle butt joint with the plates re- follows: • Weld first side and keep clamped

strained at the edges. Butt-joint welds • Clamp down and tack weld • Release fixture and clamp at three

were produced and measurements • Release clamps and clamp at three points

Table 4 — AcrossWeld and AlongWeld Shrinkage Data (HSLA80)

Plate Material Thickness Total Heat Input Average AcrossWeld Shrinkage (mm) Average AlongWeld Shrinkage (mm/m)

(mm) (kJ/mm) AH BG CF Av Avm IQ JP KO Av Avm

43 HSLA80 5.10 5.08 1.14 1.1 0.60 0.33 0.26 0.34 0.29 0.27 0.32 0.26 0.28

44 HSLA80 5.12 1.13 0.46 0.26 0.30 0.30 0.35 0.30 0.21 0.29 0.30

45 HSLA80 5.01 1.13 0.25 0.28 0.25 0.23 0.38 0.27 0.32 0.32

†

40 HSLA80 5.07 5.06 1.60 1.6 0.64 0.51 0.52 0.53 0.60 0.56 0.36 0.25 0.39

41 HSLA80 5.07 1.53 0.87 0.56 0.50 0.60 0.75 0.57 0.36 0.56 0.44

42 HSLA80 5.04 1.55 1.07 0.64 0.53 0.67 0.45 0.38 0.30 0.38

46 HSLA80 5.03 5.05 2.11 2.1 1.23 0.81 0.70 0.86 0.77 0.64 0.56 0.30 0.50

47 HSLA80 5.09 2.08 0.88 0.73 0.62 0.70 0.73 0.57 0.37 0.56 0.55

48 HSLA80 5.03 2.12 0.93 0.71 0.75 0.77 0.82 0.60 0.38 0.60

25 HSLA80 6.17 6.19 1.14 1.1 0.10 0.09 0.05 0.07 0.10 0.20 0.15 0.13 0.16

26 HSLA80 6.22 1.15 0.15 0.15 0.14 0.15 0.19 0.19 0.20 0.19 0.18

27 HSLA80 6.17 1.15 0.13 0.13 0.08 0.09 0.24 0.17 0.16 0.19

8 HSLA80 6.41 6.48 1.68 1.7 0.55 0.37 0.31 0.38 0.31 0.47 0.56 0.57 0.53

9 HSLA80 6.52 1.68 0.07 0.23 0.32 0.23 0.34 0.34 0.24 0.31

10 HSLA80 6.54 1.72 0.62 0.24 0.32 0.32 0.57 0.50 0.30 0.46 0.36

17 HSLA80 6.46 1.63 0.68 0.24 0.22 0.34 0.21 0.23 0.15 0.20

18 HSLA80 6.50 1.66 0.32 0.28 0.24 0.27 0.33 0.23 0.29 0.28

28 HSLA80 6.24 6.19 2.11 2.1 1.10 0.71 0.57 0.71 0.66 0.38 0.43 0.34 0.38

29 HSLA80 6.18 2.13 1.04 0.60 0.49 0.64 0.45 0.42 0.37 0.41 0.39

30 HSLA80 6.15 2.14 0.87 0.63 0.54 0.62 0.39 0.33 0.39 0.37

34 HSLA80 9.86 9.90 1.62 1.6 0.30 0.19 0.19 0.22 0.17 0.13 0.15 0.15 0.14

35 HSLA80 9.96 1.67 0.13 0.09 0.09 0.09 0.13 0.18 0.10 0.14 0.14

36 HSLA80 9.87 1.66 0.22 0.21 0.19 0.19 0.16 0.15 0.15 0.15

31 HSLA80 9.98 9.96 2.21 2.2 0.58 0.35 0.33 0.41 0.42 0.25 0.28 0.31 0.28

32 HSLA80 10.07 2.22 0.67 0.38 0.44 0.47 0.16 0.31 0.41 0.29 0.29

33 HSLA80 9.83 2.14 0.51 0.37 0.32 0.37 0.28 0.29 0.31 0.29

37 HSLA80 9.88 9.89 2.63 2.6 0.70 0.43 0.44 0.50 0.45 0.32 0.32 0.30 0.31

38 HSLA80 9.87 2.54 0.68 0.45 0.36 0.44 0.43 0.47 0.46 0.45 0.34

39 HSLA80 9.92 2.53 0.59 0.36 0.30 0.40 0.25 0.27 0.27 0.26

NOVEMBER 2014 / WELDING JOURNAL 425-s

Yang Supplement November 2014[1]_Layout 1 10/16/14 10:21 AM Page 426

WELDING RESEARCH

A B

C Fig. 9 — Outofplane distortion distributions: A — Low heat

input (1.14 kJ/mm); B — middle heat input (1.65 kJ/mm); C

— high heat input (2.09 kJ/mm).

transverse materials will be contour plotted with

shrinkage. the data points shown in Fig. 5.

Across-weld

and along-weld Results and Discussion

shrinkage were

calculated by The results of this work are pre-

subtracting the sented in the following sections with

distance between respect to welded panel shape, weld

pairs of points af- macrographs, measured shrinkage and

ter welding from distortion data, material type, and

• Measurement 2 the distance before welding as shown in

• Turn panel over, clamp down, weld heat input.

Fig. 5. The data pairs used for calculat-

second side ing across-weld shrinkage were the dis-

• Turn panel back, align the panel close tances between rows A-H, B-G, and C-F,

Welded Panels and

to the original coordinate system (not respectively. The data pairs used for cal- Macrographs

exact), and clamp at three points culating along-weld shrinkage were the

• Measurement 3 (final). distances between columns I-Q, J-P, and All panels listed in Table 1 were weld-

A series of measurements was taken K-O, respectively. The L-N data pairs ed with the fixture and procedures dis-

using the portable coordinate measur- were not used for calculating shrinkages cussed in the previous section. Figure 6

ing machine to determine measurement because the L-N measurements are rela- shows a typical panel deformed shape

repeatability. The results of this study tively less accurate than the I-Q, J-P, for all materials. The panel edges at

are shown in Fig. 4. The mean measure- and K-O. Generally, the points in a data weld start and weld stop were pulled up

ment error is 0.026 mm. pair are far away from each other. The while the middle of panel edges along

measurement has high accuracy. the welding direction were pushed

Shrinkage and Distortion While weld shrinkage and distortion down. The deformation was a typical

Calculation were calculated after welding side 1 and saddle buckling distortion, which is of-

after welding side 2, only the total ten observed in bead-on-plate welding

Corresponding to the welding direc- shrinkage and distortion (after welding (Refs. 11, 21).

tion, weld shrinkages include along- side 2) are discussed in this paper. The change in buckling distortion

weld shrinkage and across-weld Out-of-plane distortion was calcu- mode was observed after welding ¼-in.-

shrinkage. Along-weld shrinkage is lated by taking the Z-coordinate dif- (6.4 mm) thick HSLA-80 with high heat

also called longitudinal shrinkage and ference before welding and after weld- input (Panels 28–30). After the first side

across-weld shrinkage is also called ing. The distortion maps for the four was welded and the clamps were loos-

ened, the panel distorted such that the

middle of the panel rose up while both

Table 5 — Effect of Materials on AcrossWeld and AlongWeld Shrinkage ends of the weld curved down. Measure-

ments were taken in this configuration.

Panel Material Thickness Total Heat AcrossWeld AlongWeld When the panel was moved to turn it

(mm) Input (kJ/mm) Shrinkage (mm) Shrinkage (mm) over, it was noticed that the buckling

2, 3, 4 DH36 6.31 1.64 0.46 0.49

mode was changed to the opposite

5, 6, 7 HY80 6.70 1.66 0.26 0.34 shape. For a thin sheet, the mode could

8, 9, 10, 17, 18 HSLA80 6.48 1.68 0.31 0.36 be readily changed and there was no

11, 12, 13 HY100 6.77 1.62 0.26 0.29 preference for one mode over the other.

426-s WELDING JOURNAL / NOVEMBER 2014, VOL. 93

Yang Supplement November 2014[1]_Layout 1 10/16/14 9:36 AM Page 427

WELDING RESEARCH

A B

C Fig. 10 — Effect of heat input on inplane shrinkage and outof

plane distortion for DH36: A — Acrossweld shrinkage; B —

alongweld shrinkage; C — maximum outofplane distortion.

Measured Panel to develop the relationships between

Shrinkages and material strength and distortion and

between heat input and distortion.

Distortion Data

Across-weld and Material Strength Effect on

along-weld shrink- Shrinkage and Distortion

age data are shown

in Table 3 for the The effect of material strength on

DH-36, HY-80, and shrinkage and distortion can be deter-

HY-100 panels, and mined from the data from Tables 3

A small force or pressure change on the in Table 4 for the and 4 for the same nominal thickness

plate can change the buckling mode HSLA-80 panels. In the tables, Avm is (6.35 mm) for the four materials.

shape. After turning the plate over, the the averages values for a material.

plate weight could result in the change Each table includes the measured plate Shrinkage

of buckling mode. After welding the sec- thickness and total heat input. Total

ond side, the buckling was locked in heat input is the sum of side-1 and Table 5 lists the weld shrinkage

with the middle of the plate low, and side-2 heat input. data for DH-36, HY-80, HSLA-80, and

the ends of the weld up. In Table 3, the values in column Av HY-100 with a nominal ¼ in. (6.35

Weld cross-section macrographs are the average values of column A-H, mm) thickness and welded with medi-

were prepared to investigate the weld B-G, and C-F, which are the across- um heat input. The shrinkage data

bead profiles for materials of DH-36, weld shrinkages for panels. The val- were extracted from Tables 3 and 4.

HSLA-80, HY-80, and HY-100 at the ues in the column Avm are the aver- The average thickness was 6.31 mm

same thickness and heat input. Three age of values in the column Av, which for DH-36, 6.70 mm for HY-80, 6.48

macrographs taken in the middle of are the average across-weld shrink- mm for HSLA-80, and 6.77 mm for

three welded panels were prepared for ages for materials. HY-100. The average total heat input

each material. Representative cross In Table 4, the values in column Av was 1.64 kJ/mm for DH-36, 1.66

sections of double-sided square groove is the average values of column I-Q, kJ/mm for HY-80, 1.68 kJ/mm for

welds on the different materials are J-P, and K-O, which are the along- HSLA-80, and 1.62 kJ/mm for HY-

shown in Fig. 7. The similar weld-bead weld shrinkages for panels. The val- 100. Both the thicknesses and heat in-

shapes were found among the four ues in the column AVM are the aver- puts between the four materials have

materials. HSLA-80 had slightly more age of values in the column Av, which some differences. These differences

penetration than DH-36 and HY-80. are the average along-weld shrinkages will be considered in the comparison

HY-100 had the least penetration for materials. of weld shrinkage between the four

among the four materials. By processing and understanding materials.

Tensile tests were conducted to the measured shrinkage data, the re- It should be noted that data varia-

check the material strength of DH-36, lationships between material tions were observed on the HSLA-80

HSLA-80, HY-80, and HY-100. Table 2 strength and shrinkage and between steel. Therefore, two additional panels

shows the average values of three heat input and shrinkage were estab- were welded to ensure the reliability of

replicas. It was found that HSLA-80 lished. This relationship will be dis- the measured shrinkage data.

has lower strength than HY-80. All cussed in the following sections. By comparing the across-weld

materials met the minimum required The out-of-plate distortion data shrinkage and along-weld shrinkages

strength for the material class. for each panel are discussed in the among the four materials in Table 5, it

following section using contour plots was found that the higher strength

NOVEMBER 2014 / WELDING JOURNAL 427-s

Yang Supplement November 2014[1]_Layout 1 10/16/14 10:18 AM Page 428

WELDING RESEARCH

A B

C

Fig. 11 — Effect of heat input on inplane shrinkage and outof

plane distortion for HSLA80: A — Acrossweld shrinkage; B —

alongweld shrinkage; C — maximum outofplane distortion.

has lower the section titled Shrinkage and Distor-

strength than tion Calculation and were contour plot-

HY-80, as shown ted as shown in Fig. 8. Figure 8 shows

in Table 2, and the typical out-of-plane distortion dis-

HSLA-80 has tributions for each material. All four

slightly more materials have the same buckling mode.

weld penetration The numbers in Fig. 8 are the highest

than HY-80, as and lowest distortion magnitude for the

materials (HY-80, HSLA-80, and HY- shown in Fig. 7. materials. The maximum distortions

100) shrink less than the lower The measured and normalized can be calculated by taking the differ-

strength material (DH-36). However, along-weld shrinkage data are shown ence between the highest and lowest

the higher strength materials are in Table 7. The shrinkage ratio relative distortion. It can be found that the

slightly thicker than the lower to DH-36 was calculated, which was maximum distortion magnitude is 19.1

strength materials when welded using used as a multiplier in the shrinkage mm for DH-36, 16.7 mm for HY-80,

the same conditions, including weld- models developed for a uniform panel 20.4 mm for HSLA-80, and 14 mm for

ing heat input. Thus, normalized (Ref. 9) and a complex panel (Ref. 10). HY-100, respectively. HY-80 and HY-

shrinkage was calculated with Equa- HY-80, HSLA-80, and HY-100 have 76, 100 material had lower magnitudes of

tion 1 to take into account the minor 79, and 63% of along-weld shrinkage out-of-plane distortion than DH-36 ma-

variations of thickness and heat input of DH-36, respectively. terial, while HSLA-80 has slightly high-

in order to compare shrinkage be- er distortion magnitude than DH-36.

tween the higher strength materials OutofPlane Distortion

and the lower strength material. Discussion

Out-of-plane distortions were calcu-

t q

δn = δ (1) lated based on the method discussed in The data show that higher strength

tn qn

where is shrinkage, n is the normal- Table 6 — Effect of Materials on AcrossWeld Shrinkage

ized shrinkage, t is thickness, tn is the

normalized thickness 0.25 in. (6.35 AcrossWeld Shrinkage (mm)

Material Shrinkage After normalized Ratio

mm), q is total heat input, and qn is the both thickness and heat input

normalized total heat input 1.68

kJ/mm. DH36 0.46 0.47 1.00

HY80 0.26 0.28 0.60

The measured and normalized HSLA80 0.31 0.32 0.67

across-weld shrinkage data are shown HY100 0.26 0.28 0.60

in Table 6. The shrinkage ratio relative

to DH-36 was calculated, which was

Table 7 — Effect of Materials on AlongWeld Shrinkage

used as a multiplier in the shrinkage

models developed for a uniform panel

AlongWeld Shrinkage (mm)

(Ref. 9) and a complex panel (Ref. 10).

Material Shrinkage After normalized both thickness and heat input Ratio

HY-80, HSLA-80, and HY-100 have 60,

67, and 60% of across-weld shrinkage DH36 0.49 0.47 1.00

of DH-36, respectively. HSLA-80 has HY80 0.34 0.36 0.76

more shrinkage than HY-80. This may HSLA80 0.36 0.37 0.79

be the result of two factors: HSLA-80 HY100 0.29 0.30 0.63

428-s WELDING JOURNAL / NOVEMBER 2014, VOL. 93

Yang Supplement November 2014[1]_Layout 1 10/16/14 9:36 AM Page 429

WELDING RESEARCH

A B

Fig. 12 — Comparison of shrinkage between material DH36

C and HSLA80: A — Acrossweld shrinkage ( t = 6.35 mm); B—

alongweld shrinkage (t = 6.35 mm); C — maximum outof

plane distortion.

middle heat input ure 10C plots the Delta values (maxi-

of 1.6 kJ/mm, and mum out-of-plane distortion) in Fig. 9.

panels 22–24 with After heat input increases beyond 1.65

high heat input of kJ/mm, along-weld shrinkage and out-

2.1 kJ/mm. The of-plane distortion increase slowly.

measured data for

the nine panels HSLA80 Steel

were processed to

steels (HY-80, HSLA-80, and HY-100) calculate the across-weld shrinkage and The effect of heat input on shrink-

shrink less than the lower strength along-weld shrinkage with the same age and distortion for 4.76-, 6.35-, and

steel (DH-36). This fact could be ex- method illustrated in Table 3. 9.53-mm-thick HSLA-80 was studied

plained by material strength differ- The typical out-of-plane distortions by welding 29 panels as shown in

ences between these materials. for low, middle, and high heat input Table 1. The measured data for the 29

Higher strength materials will have were contour plotted, as shown in Fig. panels, as shown in Table 4, were

less along-weld shrinkage than lower 9. As heat input increases, out-of-plane processed to calculate the across-weld

strength materials if applying the distortion increases. Note that the dis- shrinkage and along-weld shrinkage

same force because more plastic strain tortions were magnified five times to with the same method illustrated in

will be induced in the lower strength better visualize the distortion shape. Table 3. Only the average across-weld

material. Since shrinkage is the out- The maximum distortion was also cal- shrinkage and average along-weld

come of plastic strains, lower strength culated as shown in each figure. Panel shrinkage were plotted in Fig. 11A, B.

materials will have more shrinkage. 19 with low heat input had 12.9-mm As shown in Fig. 11A, across-weld

maximum distortion, panel 2 with mid- shrinkages for 4.76-, 6.4-, and 9.53-

HeatInput Effect on Shrinkage dle heat input had 19.1-mm maximum mm-thick HSLA-80 increases as heat

and Distortion distortion, and panel 22 with high heat input increases. When heat input in-

input had 21.4-mm maximum distor- creases beyond 2.2 kJ/mm, the across-

A comparison of the in-plane tion. The maximum distortions for all weld shrinkage increases slowly. For

shrinkages and out-of-plane distor- nine panels were plotted in Fig. 10C. the same heat input, as the plate thick-

tions as a function of heat input for Only the average across-weld ness increases, across-weld shrinkage

DH-36 and HSLA-80 material was in- shrinkage and average along-weld reduces. This is because material melt-

vestigated. One thickness (6.35 mm) shrinkage for each panel were plotted, ing area will be reduced when material

was conducted for DH-36 and three as shown in Fig. 10. Figure 10 shows thickness increases.

thicknesses (4.76, 6.35, and 9.53 mm) the relationships between across-weld Figure 11B shows that along-weld

were conducted for HSLA-80. shrinkage, along-weld shrinkage, and shrinkage increases almost linearly as

out-of-plane distortion and heat in- heat input increases. For the same heat

DH36 Steel puts, respectively, for DH-36. This re- input, as the plate thickness increases,

lationship will be implemented in the along-weld shrinkage reduces. This is

The effect of heat input on shrinkage shrinkage model developed for uni- because shrinkage resistance increases

and distortion for 6.35-mm-thick DH- form panel (Ref. 9) and complex panel as material thickness increases.

36 was studied by processing the data of (Ref. 10). Across-weld shrinkage (Fig. Figure 11C plots the maximum out-

nine panels (panels 19–21, 2–4, and 10A) increases linearly as heat input of-plane distortion that was calculated

22–24). As shown in Table 3, panels increases. Along-weld shrinkage and with the same method used in Figs. 9

19–21 were welded with a low heat in- out-of-plane distortion do not increase and 10C. The contour plots similar to

put of 1.2 kJ/mm, panels 2–4 with a linearly, as shown in Fig. 10B, C. Fig- Fig. 9 were omitted in this paper and

NOVEMBER 2014 / WELDING JOURNAL 429-s

Yang Supplement November 2014[1]_Layout 1 10/16/14 9:36 AM Page 430

WELDING RESEARCH

only the maximum out-of-plane distor- • HY-80 and HY-100 steels have construction ship design engineering.

tion in panels were plotted, as shown in lower out-of-plane distortion than Journal of Ship Production and Design 29(1):

Fig. 11C. Figure 11C shows that maxi- lower strength EH36 steel, while 1–16.

mum out-of-plane distortion increases HSLA-80 steel has similar out-of-plane 10. Yang, Y. P., Castner, H., Dull R., Dydo,

J., Huang, T. D., Fanguy, D., Dlugokecki, V.,

linearly as heat input increases. High distortion compared to DH-36. For

and Hepinstall, L. 2014. Complex-panel weld

heat input induces high out-of-plane high heat input (larger than 2 shrinkage data model for neat construction

distortion. For the same heat input, as kJ/mm), HSLA-80 steel has slightly ship design engineering. Journal of Ship Pro-

the plate thickness increases, out-of- higher out-of-plane distortion than duction and Design 30(1): 1–24.

plane distortion reduces. This is because lower strength EH36 steel. 11. Yang, Y. P., and Dong, P. 2012. Buck-

structural rigidity increases as material • Shrinkage and out-of-plane distor- ling distortions and mitigation techniques

thickness increases. tion increase as heat input increases. for thin-section structures. Journal of Ma-

Overall, in all cases, the extent of • For the same heat input, as thick- terials Engineering and Performance 21(2):

shrinkage and distortion increase as a ness increases, both shrinkage and 153–160.

function of heat input. This relationship out-of-plane distortion decreases. 12. Conrardy, C., Huang, T. D., Harwig,

D., Dong, P., Kvidahl, L., Evans, N., and

will be implemented in the shrinkage

Treaster, A. 2006. Practical welding tech-

model developed for the uniform (Ref. niques to minimize distortion in light-

Acknowledgments

9) and complex panels (Ref. 10). weight ship structures. Journal of Ship Pro-

duction 22(4): 239–247.

Comparison of DH36 and HSLA80 The results of this paper were from 13. Yang, Y. P., Dull, R., Conrardy, C.,

Steels the project Weld Shrinkage and Dis- Porter, N., Dong, P., and Huang, T. D. 2008.

tortion Allowance Data Model for Neat Transient thermal tensioning and numerical

The effect of heat input on shrinkage Construction Ship Design Engineer- modeling of thin steel ship panel structures.

and distortion was conducted on both ing, funded by the National Shipbuild- Journal of Ship Production 24(1): 37–49.

DH-36 and HSLA-80 materials with a ing Research Program Advanced Ship- 14. Huang, T. D., Harwig, D. D., Dong,

P., and DeCan, L. A. 2005. Engineering and

nominal thickness of 6.35 mm. By com- building Enterprise (NSRP-ASE). The

ship production technology for lightweight

paring the shrinkage and distortion for authors thank NSRP-ASE for support- structures. Technology Review Journal

the two materials, it was found that ing this study. 13(1): 1–22.

HSLA-80 had less shrinkage than DH- 15. Huang, T. D., Conrardy, C., Dong, P.,

36 at low and middle heat inputs. References Keene, P., Kvidahl, L., and DeCan, L. 2007.

For high heat input, HSLA-80 and Engineering and production technology

DH-36 have similar across-weld shrink- for lightweight ship structures, Part II: Dis-

age, as shown in Fig. 12A. Therefore, tortion mitigation technique and imple-

1. Gurney, T. R. 1979. Fatigue of Welded mentation. J. Ship Production, The Society

the ratio of HSLA-80 and DH-36 in Structures, 2nd Ed. Cambridge, UK: Cam-

Table 6 depends on the heat input. It of Naval Architects and Marine Engineers

bridge University Press. pp. 226–243. 23(2): 82–93.

was found that HSLA-80 has less along- 2. Yin, D., and Qiang, S. 1991. Influence 16. Watanabe, M., and Satoh, K. 1961.

weld shrinkage than DH-36 for all heat of residual stresses and deformation on Effect of welding conditions on the shrink-

inputs, as shown in Fig. 12B. Figure 12C buckling behaviour of plates. Mechanical age and distortion in welded structures.

shows that HSLA-80 has similar maxi- Effects of Welding (Eds. L. Karlsson, L. E. Welding Journal 40(8): 377-s to 384-s.

mum out-of-distortion as DH-36 at low Lindgren, and M. Jonsson). IUTAM Sym- 17. Gunaraj, V., and Murugan, V. V. 2005.

and middle heat inputs. At high heat in- posium, Sweden. pp. 269–276. Effect of process parameters on angular dis-

put, HSLA-80 has higher maximum 3. Masubuchi, K. 1980. Analysis of Weld- tortion of GMAW structural steel plates.

ed Structures. Oxford, UK: Pergamon Press. Welding Journal 84(11): 165-s to 171-s.

out-of-plane distortion than DH-36. 4. Michaleris, P. 2011. Minimization of 18. Sadat, A. M., Rao, S., and Rao, N.

Welding Distortion and Buckling: Modeling 2012. Modelling the effects of preheating

Conclusions and Implementation. Cambridge, UK: on angular distortions in one sided fillet

Woodhead Publishing Limited. welds. Journal of Achievements in Materials

5. Feng, Z. 2005. Processes and Mecha- and Manufacturing Engineering 55(2):

The following conclusions could be nisms of Welding Residual Stress and Distor-

drawn based on the weld shrinkage 578–582.

tion. Woodhead Publishing Limited and 19. Vural, M., Muzafferoglu, H. F., and

and distortion data gathered in this CRC Press LLC: 13–24. Tapici, U. C. 2007. The effect of welding

paper: 6. Verhaeghe, G. 1998. Predictive for- fixtures on welding distortions. Journal of

• High-strength steels (HSLA-80, mula for weld distortion — A critical re- Achievements in Materials and Manufactur-

HY-80, and HY-100) have less across- view. TWI Research Document, PRAD NO. ing Engineering 20(1-2): 511–514.

weld shrinkage than low-strength 7346.02/97/961.3. 20. Zhu, X. K., and Chao, Y. J. 2002. Ef-

steel (DH-36) for normal heat input. 7. Spraragen, W., and Ettinger, W. G. fects of temperature-dependent material

For high heat input (larger than 2 1950. Shrinkage distortion in welding. properties on welding simulation. Comput-

kJ/mm), high-strength steel (HSLA- Welding Journal 29(6): 292-s to 294-s. ers and Structures 80: 967–976.

8. White, J. D., Leggatt, R. H., and 21. Wang, J., Yin, X., and Murakawa, H.

80) has similar across-weld shrinkage Dwight, J. B. 1980. Weld shrinkage predic-

as low-strength steel (DH-36). 2013. Experimental and computational

tion. Welding and Metal Fabrication 11: analysis of residual buckling distortion of

• Higher strength steels have less 587–596. bead-on-plate welded joint. Journal of Ma-

along-weld shrinkage than low- 9. Yang, Y. P., Castner, H., Dull, R., terials Processing Technology 213(8): 1447–

strength steels for all heat inputs stud- Dydo, J., and Fanguy, D. 2013. Uniform- 1458.

ied when the thickness is the same. panel weld shrinkage data model for neat

430-s WELDING JOURNAL / NOVEMBER 2014, VOL. 93

View publication stats

You might also like

- Chapter 1Document5 pagesChapter 1AlecsisRoeEstañolFrasco100% (1)

- Steel Storage Tanks Excel Sheet (API 650-2009) Free-09122209467Document42 pagesSteel Storage Tanks Excel Sheet (API 650-2009) Free-09122209467Hamid Mansouri100% (6)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- PWHT Requirement As Per API-650Document1 pagePWHT Requirement As Per API-650hgagselim2012No ratings yet

- TANK DESIGN AWWA - 05 (2) - Final (106 M)Document29 pagesTANK DESIGN AWWA - 05 (2) - Final (106 M)hgagselim2012No ratings yet

- 14310A ch4 PDFDocument96 pages14310A ch4 PDFmiguelNo ratings yet

- 2014 Yang MaterialEffectonShrinkage WJ 2014 11 s421Document11 pages2014 Yang MaterialEffectonShrinkage WJ 2014 11 s421Abu Anas M.SalaheldinNo ratings yet

- Welded Lap Joints of Thin Steel Sheets With DiffeDocument11 pagesWelded Lap Joints of Thin Steel Sheets With DiffeRicardo HernandezNo ratings yet

- Powder Technology: Qing Shuai Cao, Yang Zhao, Li Xing, Ru Zhang, Ben Yue LiDocument11 pagesPowder Technology: Qing Shuai Cao, Yang Zhao, Li Xing, Ru Zhang, Ben Yue LiSohail ShaikhNo ratings yet

- Flexural-Torsional Buckling Tests of Cold-Formed Lipped Channel Beams Under Restrained Boundary ConditionsDocument10 pagesFlexural-Torsional Buckling Tests of Cold-Formed Lipped Channel Beams Under Restrained Boundary ConditionsPhạm Quang VinhNo ratings yet

- FEAnalysisof Buckling Behavior Causedby Weldingin Thin Platesof High Tensile Strength SteelDocument9 pagesFEAnalysisof Buckling Behavior Causedby Weldingin Thin Platesof High Tensile Strength SteelJose Marie Rmgrocks BatoNo ratings yet

- Prediction of Welding Distortion in Butt Joint of Thin Plates - Long-2009Document11 pagesPrediction of Welding Distortion in Butt Joint of Thin Plates - Long-2009DonatasNo ratings yet

- Author Manuscript: Microstructure and Thickness Effects On Impact Behavior and Separation Formation in X70 Pipeline SteelDocument20 pagesAuthor Manuscript: Microstructure and Thickness Effects On Impact Behavior and Separation Formation in X70 Pipeline Steelvijayaraman rajendranNo ratings yet

- Journal of Constructional Steel Research: V.K.R. Kodur, M.Z. NaserDocument12 pagesJournal of Constructional Steel Research: V.K.R. Kodur, M.Z. NasernnmmNo ratings yet

- 2019 A Review On Resistance Spot Welding of Steel MaterialDocument13 pages2019 A Review On Resistance Spot Welding of Steel Materialguravshubham7777No ratings yet

- Effect of Sequence and Stiffener Shape On Welding DistortionDocument12 pagesEffect of Sequence and Stiffener Shape On Welding DistortionRafi ZhaffNo ratings yet

- The Application of High Strength Steels For Fatigue Loaded StructuresDocument13 pagesThe Application of High Strength Steels For Fatigue Loaded StructuresmukulNo ratings yet

- Effect of Tempering Temperature, Plate Thickness and Presence of Holes On Ballistic Impact Behavior and ASB Formation of A High Strength SteelDocument13 pagesEffect of Tempering Temperature, Plate Thickness and Presence of Holes On Ballistic Impact Behavior and ASB Formation of A High Strength Steelm1601295No ratings yet

- Forgings For Low Temperature ApplicationsDocument1 pageForgings For Low Temperature ApplicationsTasmanijskaNemaNo ratings yet

- Martensitic Steel Sheets of 1300 and 1500mpa GradesDocument5 pagesMartensitic Steel Sheets of 1300 and 1500mpa Gradesmohamed ahmedNo ratings yet

- Effect of Welding Speed On The Microstructure and Texture Development in The Individual Weld Zone of Friction Stir Welded DP780 SteelDocument14 pagesEffect of Welding Speed On The Microstructure and Texture Development in The Individual Weld Zone of Friction Stir Welded DP780 SteelARUNPRAKASH SNo ratings yet

- Thin-Walled StructuresDocument13 pagesThin-Walled StructuresAnis SuissiNo ratings yet

- Qwerty PDFDocument2 pagesQwerty PDFNagalingaraja RnrNo ratings yet

- 6 PDFDocument2 pages6 PDFchtganduNo ratings yet

- Anch 003Document5 pagesAnch 003arun arunNo ratings yet

- Module 4 Lecture 5Document7 pagesModule 4 Lecture 5Silverio AcuñaNo ratings yet

- 2023 Turning - 230519 - 134402Document11 pages2023 Turning - 230519 - 134402Hassan LotfizadehNo ratings yet

- IRJET Distortional Buckling Study of ColDocument5 pagesIRJET Distortional Buckling Study of ColssierroNo ratings yet

- Forming Notes PDFDocument4 pagesForming Notes PDFMuthuKumarNo ratings yet

- BD C Candidate Handbook 2018 6.12.18 FINALDocument13 pagesBD C Candidate Handbook 2018 6.12.18 FINALmadhav sreekumarNo ratings yet

- Structures: Ahmad Siar Mahmood Shah, Saber Moradi TDocument13 pagesStructures: Ahmad Siar Mahmood Shah, Saber Moradi THAMID BOUDAGHINo ratings yet

- 2012-Fracture Toughness of Friction Hydro-Pillar Processing Welding in C-MN SteelDocument5 pages2012-Fracture Toughness of Friction Hydro-Pillar Processing Welding in C-MN SteelPedro CunhaNo ratings yet

- Influence of Process Parameters On Microstructure and Mechanical Properties in AA2024-T3 Friction Stir WeldingDocument10 pagesInfluence of Process Parameters On Microstructure and Mechanical Properties in AA2024-T3 Friction Stir WeldingYazid HelalNo ratings yet

- 10.1515 - JMBM 2022 0006Document12 pages10.1515 - JMBM 2022 0006jiji wangNo ratings yet

- Structural Performance of Corrosion-Damaged Concrete BeamsDocument13 pagesStructural Performance of Corrosion-Damaged Concrete BeamspublikgerNo ratings yet

- Study of Mach Inability in Boring Operation of Micro Alloyed and Heat Treated Alloy SteelsDocument10 pagesStudy of Mach Inability in Boring Operation of Micro Alloyed and Heat Treated Alloy SteelsmariotonNo ratings yet

- Lateral Torsion BucklingDocument11 pagesLateral Torsion BucklingkyleNo ratings yet

- Engineered Casting Solutions 2006 CastinDocument6 pagesEngineered Casting Solutions 2006 CastinMandeep SinghNo ratings yet

- Influence of Imperfections in The Buckling ResistaDocument6 pagesInfluence of Imperfections in The Buckling Resistahasan19994ggffNo ratings yet

- Design-of-Experiments Study To Examine The Effect of Polarity On Stud WeldingDocument8 pagesDesign-of-Experiments Study To Examine The Effect of Polarity On Stud WeldingtazzorroNo ratings yet

- 6.LII 2012 Residual-Stress SWDDocument12 pages6.LII 2012 Residual-Stress SWDDimitrios ManolakosNo ratings yet

- Sandwich Panels 2006 Special1Document4 pagesSandwich Panels 2006 Special1haidardiwantara83No ratings yet

- Materials and Design: G. Agarwal, A. Kumar, I.M. Richardson, M.J.M. HermansDocument12 pagesMaterials and Design: G. Agarwal, A. Kumar, I.M. Richardson, M.J.M. Hermanstolentino.jason1222No ratings yet

- Die Design ProgramDocument5 pagesDie Design ProgramSundar KaruppiahNo ratings yet

- Commentary On Highly Restrained Welded ConnectionsDocument13 pagesCommentary On Highly Restrained Welded ConnectionstrabajosicNo ratings yet

- Microstructure and Failure Behaviour ofDocument8 pagesMicrostructure and Failure Behaviour ofVipin MishraNo ratings yet

- The Effect of Anchorage On The Effectiveness of The Shear Reinforcement in The Punching ZoneDocument11 pagesThe Effect of Anchorage On The Effectiveness of The Shear Reinforcement in The Punching ZoneVinh LENo ratings yet

- Wang 2018Document12 pagesWang 2018n.salemizadehNo ratings yet

- Welding - SteelConstructionDocument19 pagesWelding - SteelConstructionsiroliver39No ratings yet

- Punching Shear of Thick Plates With and Without SHDocument12 pagesPunching Shear of Thick Plates With and Without SHShaikh ImranNo ratings yet

- Steel ConnectionsDocument29 pagesSteel ConnectionsSHRADDHA KADAM100% (1)

- Journal of Manufacturing Processes: Jastej Singh, A.S. ShahiDocument10 pagesJournal of Manufacturing Processes: Jastej Singh, A.S. ShahiSorabh SinghalNo ratings yet

- Tech Uddeholm Die Casting ENDocument24 pagesTech Uddeholm Die Casting ENSajal GoelNo ratings yet

- Resistance Welding of FeCrNiSi AlloyDocument18 pagesResistance Welding of FeCrNiSi Alloytqzw7p8m2kNo ratings yet

- Metals 13 00187 v2Document18 pagesMetals 13 00187 v2shatayu deshpandeNo ratings yet

- Design Guidelines - Spot Welding ChapterDocument11 pagesDesign Guidelines - Spot Welding ChapterJoel BrasilBorgesNo ratings yet

- Weld Overlaycladding of HSLA With ASSDocument11 pagesWeld Overlaycladding of HSLA With ASSUjjawal PathakNo ratings yet

- JSP1265SSWPAPERFeb O9Document19 pagesJSP1265SSWPAPERFeb O9Hussain AlsaadyNo ratings yet

- Experiment On The Flexural Functioning of Cold-Formed Steel Built-Up Complex Hat SectionDocument7 pagesExperiment On The Flexural Functioning of Cold-Formed Steel Built-Up Complex Hat SectionIJRASETPublicationsNo ratings yet

- Weld Joint DesignDocument21 pagesWeld Joint DesignKoushik SarkarNo ratings yet

- Guidance Note Plate Bending No. 5.04: ScopeDocument3 pagesGuidance Note Plate Bending No. 5.04: ScoperoldoguidoNo ratings yet

- Advances and Trends On Tube Bending Forming TechnoDocument12 pagesAdvances and Trends On Tube Bending Forming Techno1ere année ingNo ratings yet

- Welding Defects at Friction Stir Welding: P. Podržaj, B. Jerman, D. KlobčarDocument3 pagesWelding Defects at Friction Stir Welding: P. Podržaj, B. Jerman, D. Klobčarsanjay_dutta_5No ratings yet

- 1 s2.0 S0263823123002185 MainDocument14 pages1 s2.0 S0263823123002185 MainHari Om Tamrakar ce21d019No ratings yet

- Effect of Stiffeners On Shear Lag in Steel Box GirdersDocument14 pagesEffect of Stiffeners On Shear Lag in Steel Box Girderserky arkvathonejhNo ratings yet

- Ubc 2013 Fall Salem HayderDocument117 pagesUbc 2013 Fall Salem Hayderhgagselim2012No ratings yet

- Pipe Spool DWG List: Total Q'Ty 42Document2 pagesPipe Spool DWG List: Total Q'Ty 42hgagselim2012No ratings yet

- Design Calculation of Recycle Oil Injection Insert (Sheet-37)Document30 pagesDesign Calculation of Recycle Oil Injection Insert (Sheet-37)hgagselim2012No ratings yet

- Overview of Stainless Steel and Stainless Plate - Stainless Processing, Inc. - Coatesville, PennsylvaniaDocument7 pagesOverview of Stainless Steel and Stainless Plate - Stainless Processing, Inc. - Coatesville, Pennsylvaniahgagselim2012No ratings yet

- Open TankDocument27 pagesOpen Tankhgagselim2012No ratings yet

- Design of 5 Tons Capacity Cone Bottom STDocument26 pagesDesign of 5 Tons Capacity Cone Bottom SThgagselim2012No ratings yet

- Self-Supported Cone Roof Design Data: Design of Steel Storage Tanks As Per Api-650 (Diameter 3M)Document23 pagesSelf-Supported Cone Roof Design Data: Design of Steel Storage Tanks As Per Api-650 (Diameter 3M)hgagselim2012No ratings yet

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument14 pagesStorage Tank Design Calculation - Api 650: Close Floating Roofhgagselim2012No ratings yet

- Air Vessel (Final Sent To AI) - 1Document38 pagesAir Vessel (Final Sent To AI) - 1hgagselim2012No ratings yet

- Flate EndDocument3 pagesFlate Endhgagselim2012No ratings yet

- Desalinated Water TankDocument34 pagesDesalinated Water Tankhgagselim2012No ratings yet

- Ch02 PartIDocument44 pagesCh02 PartIgirm2002No ratings yet

- Compression EngineDocument15 pagesCompression EngineAlina RajputNo ratings yet

- DiaphragmsDocument26 pagesDiaphragmsHello WorldNo ratings yet

- Schematic SMPS-PFC Sheet-1 20190424001902 PDFDocument1 pageSchematic SMPS-PFC Sheet-1 20190424001902 PDFАлексей АндрияшNo ratings yet

- Stair Expert: User ManualDocument19 pagesStair Expert: User Manualcoc08No ratings yet

- RCC Drain 002Document1 pageRCC Drain 002GOMASH RCPNo ratings yet

- Thermal Energy Storage For Space CoolingDocument32 pagesThermal Energy Storage For Space CoolingAzim AdamNo ratings yet

- Esci341 Lesson11 Energy Minimum PrincipleDocument8 pagesEsci341 Lesson11 Energy Minimum PrincipleDilaraa AtılganNo ratings yet

- Carrier Frame PartsDocument40 pagesCarrier Frame PartsSales AydinkayaNo ratings yet

- pv5n6 2 PDFDocument112 pagespv5n6 2 PDFCharles SandersNo ratings yet

- Answer All Questions. Each Question Carries 2 MarksDocument2 pagesAnswer All Questions. Each Question Carries 2 MarksJaferNo ratings yet

- MSDS - CHIMEC 1038 - Gas Corr. InhibitorDocument6 pagesMSDS - CHIMEC 1038 - Gas Corr. InhibitorAnonymous LfeGI2hM0% (1)

- Subdivision Storm Sewers SampleDocument1 pageSubdivision Storm Sewers Sampleaggrey noahNo ratings yet

- Simple Data Types in C: Alan L. Cox Alc@rice - EduDocument44 pagesSimple Data Types in C: Alan L. Cox Alc@rice - EduDavinder SinghNo ratings yet

- CS 3853 Computer Architecture - Memory HierarchyDocument37 pagesCS 3853 Computer Architecture - Memory HierarchyJothi RamasamyNo ratings yet

- StressHead - Design Concept - 170223Document15 pagesStressHead - Design Concept - 170223Juan ManuelNo ratings yet

- Recce Checklist: Things To TakeDocument3 pagesRecce Checklist: Things To Takehsmedia16No ratings yet

- Aeci Mining Explosives Differentitated Products AccessoriesDocument11 pagesAeci Mining Explosives Differentitated Products AccessoriesMashudu MbulayeniNo ratings yet

- Activity Ans AssessmentDocument2 pagesActivity Ans AssessmentOhmark VeloriaNo ratings yet

- Akp Associates Event Profile FinalDocument27 pagesAkp Associates Event Profile FinalanupkpandaNo ratings yet

- U0 8801Document133 pagesU0 8801vicbalt07No ratings yet

- Short Literature Review On T5 Lighting SystemDocument2 pagesShort Literature Review On T5 Lighting SystemChing Wai YongNo ratings yet

- ME4447-ME6405 Course OutlineDocument13 pagesME4447-ME6405 Course OutlineAnonymous qTKCWlxNo ratings yet

- Clamping Force: Security and Safety in Application - by DesignDocument15 pagesClamping Force: Security and Safety in Application - by DesignIna IoanaNo ratings yet

- Mobile FTP Client - An Android ApplicationDocument41 pagesMobile FTP Client - An Android ApplicationOscar ParraNo ratings yet

- SCHEDULES - National Highways Authority of IndiaDocument101 pagesSCHEDULES - National Highways Authority of IndiaIrfanNo ratings yet

- AgileDocument4 pagesAgileSakriti VermaNo ratings yet

- Windows Sockets 2Document29 pagesWindows Sockets 2ntarylNo ratings yet