Professional Documents

Culture Documents

Section 3 Fault Finding Procedures: All Rights Reserved

Section 3 Fault Finding Procedures: All Rights Reserved

Uploaded by

Diep NguyentuanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 3 Fault Finding Procedures: All Rights Reserved

Section 3 Fault Finding Procedures: All Rights Reserved

Uploaded by

Diep NguyentuanCopyright:

Available Formats

Service Manual BV Family R1.

2 Section 3

Fault finding procedures

Section 3 FAULT FINDING PROCEDURES

Contents

1. INTRODUCTION .....................................................................................................................................3

1.1. BV Family R1.2 System fault finding .......................................................................................................3

1.2. Fault finding philosophy ...........................................................................................................................3

1.3. Recommended fault finding procedures..................................................................................................3

2. ERROR MESSAGES ..............................................................................................................................4

2.1. Reaction on error messages....................................................................................................................4

2.1.1. Error messages on the monitor............................................................................................................4

2.1.2. Error messages on the C-arm stand display........................................................................................4

2.2. DFI error messages .................................................................................................................................7

2.3. SUCO error messages ..........................................................................................................................18

3. LIST OF MECHANICAL FUNCTIONS..................................................................................................28

4. FLOWCHART ‘SYSTEM DOES NOT START’.....................................................................................29

5. FLOWCHART ‘NO IMAGE ON THE MONITOR’..................................................................................31

6. FLOWCHART ‘IMAGE OF BAD QUALITY’ .........................................................................................33

6.1. System self tests....................................................................................................................................35

7. DFI FAULT FINDING PROCESS AND REPLACEMENTS ..................................................................36

7.1. Status LED indicators ............................................................................................................................36

7.2. Video input/output signal check .............................................................................................................37

7.3. Service menu monitoring & logging .......................................................................................................38

7.4. Self tests ................................................................................................................................................38

7.5. Swapping the DFI II unit. .......................................................................................................................38

8. SUCO FAULT FINDING PROCESS AND REPLACEMENTS .............................................................39

8.1. Status LED indicators ............................................................................................................................39

8.2. Service menu logging ............................................................................................................................40

8.3. SUCO fault finding and [PCB] replacements.........................................................................................41

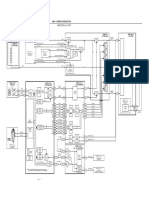

8.3.1. Back panel..........................................................................................................................................41

8.3.2. Midas board........................................................................................................................................43

BV Family R1.2 / Volume 1 (04.0) SM-CM 3 - 1

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Section 3 Service Manual BV Family R1.2

Fault finding procedures

8.3.3. Pulse Master board [SHA 3]...............................................................................................................46

8.3.4. XGC Pulse board [BV Pulsera X-ray generator control, SHA 4]........................................................48

8.3.5. XGC board [BV Endura/Libra X-ray generator control, SHA4] ..........................................................50

8.3.6. X-ray beam collimator board [SHA 5] ................................................................................................52

8.4. Power supply BV Endura / BV Pulsera..................................................................................................54

8.5. Power supply BV Libra ..........................................................................................................................56

SM-CM 3 - 2 (04.0) BV Family R1.2 / Volume 1

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Service Manual BV Family R1.2 Section 3

Fault finding procedures

1 INTRODUCTION

1.1 BV FAMILY R1.2 SYSTEM FAULT FINDING

This section describes activities on fault finding with a corrective nature only. Performance checks are dealt

with in the System Manual Installation and/or in the Preventive Maintenance manual. Image quality

performance checks are dealt with in this System Manual Corrective Maintenance section 6.

1.2 FAULT FINDING PHILOSOPHY

The faultfinding process is of major importance for corrective maintenance and could be approached as

follows. Any user should like to have a system availability up to 100%, without any discontinuity or even an

interruption. With technical systems this is not possible and even a try to achieve this goal would be a major

operation and would cost too much. For this reason planned- and corrective maintenance and (after sales)

service are necessities.

Troubleshooting and faultfinding and consequently system corrections and/or parts replacements and/or

adjustment & verification, are essential elements in this process. For optimal continuity and cost

effectiveness in the operation of the system, the 80-20 rule will be used.

Approximately 80% of the problems should be solved by field service. This should be done by the field

service engineer himself with the help of the available BV Family service documentation.

Approximately 20% of the system faults are not solvable and/or can not be allocated within a limited period.

These faults can only be allocated together with the dedicated support and/or assistance of specialists, of

which the X-ray HelpDesk should be the entrance.

NOTE

Faults can only be identified and resolved by competent and trained field service personnel; in the case an

individual problem cannot be identified, field service is strongly advised to contact the centralized X-ray

HelpDesk for the BV Family Systems. For communication with the HelpDesk, refer to section “General

introduction”.

________________

1.3 RECOMMENDED FAULT FINDING PROCEDURES

To find the causes of problems, a number of flow-charts and lists have been made. The idea is that in case

of a problem one will be triggered by one of the following points:

One of the system displays shows error messages (the C-arm stand display or MVS monitor), see

chapter 2.

The LED indicators light up in an unusual combination see chapter 7.1.

A mechanical function of the system does not work properly, see chapter 3.

The system does not start, see chapter 4.

No image appears on the monitor, see chapter 5.

The image on the monitor is of bad quality, see chapter 6.

Go to the flow-chart or list corresponding to your problem and follow the systematic steps. The flow-charts

have been set up carefully with people of several departments.

BV Family R1.2 / Volume 1 (04.0) SM-CM 3 - 3

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Section 3 Service Manual BV Family R1.2

Fault finding procedures

2 ERROR MESSAGES

2.1 REACTION ON ERROR MESSAGES

Error messages can appear on the display of the C-arm stand and on the left monitor of the Mobile Viewing

Station.

Messages generated by the SUCO processor will appear on the display of the C-arm stand.

Messages generated by the DFI processor will appear on the display on the left monitor of the MVS.

2.1.1 ERROR MESSAGES ON THE MONITOR

These messages have been generated by the DFI processor.

The fastest way is to consult the lists of error messages of the DFI (see chap. 2.2). However, an error

message can be the result of another error. Therefore is it advised to follow the procedure below.

1. Connect the service PC to the central service port.

2. In BV-Scope choose: Faultfinding - Logging - Logfile Complete System. The log file appears.

3. Save the log file, or copy and paste it in WordPad (or Notepad).

4. Place the cursor in the log file some minutes before the error message occurred.

5. Search for the phrase ‘ N ’ (so: space N space) with the ‘Find’-function of WordPad or Notepad.

(Use the ‘Match case’ function).

6. If ‘ N ’ has been found without an error code of 4, 5 or 6 digits, use the ‘Find next’ function until you find

the phrase ‘ N ’ with an error code of 4, 5 or 6 digits. (For example: File 003002).

7. Read the remarks below the error.

8. Take note of the point of time the error has been generated.

9. Use the ‘Find next’ function until you find the phrase ‘ N ’ with an error code of 4, 5 or 6 digits.

10. When the point of time of the found error is within one of two seconds of the first error, the 2nd error is

probably a result of the first error. For the time being: neglect the 2nd error.

11. Perform the actions in the remarks below the first error.

12. For each error message on the monitor of the viewing station: start again with step 2.

2.1.2 ERROR MESSAGES ON THE C-ARM STAND DISPLAY

These messages have been generated by the SUCO processor.

1. Push the info button on the C-arm stand. A list appears of errors, which occurred around the same point

in time.

2. The first error in the list is probably the cause of the other errors.

3. See if the first error is mentioned in one of the flow-charts below. If not, look up the error in the list of

error messages of the SUCO (see chapter 2.3) and perform the specified actions. You can find the

specified actions also in the log file.

SM-CM 3 - 4 (04.0) BV Family R1.2 / Volume 1

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Service Manual BV Family R1.2 Section 3

Fault finding procedures

'No ' means in the table below: continue with the cell right to the current cell.

'Yes ' means in the table below: continue with the cell below the current cell.

Error 053 Error 041

START START

Restart the complete Error 041 appears? Problem solved.

system. System starts up No

properly? Yes

No

Yes

If error 053 occurs often, see Check communication cable between SUCO and DFI. Check cables and

in the logging of the DFI the Check for bent pins in Burndy connector. replace the defect

messages at the Set on ‘power monitor on’ (see software manual). part.

corresponding point of time Restart the system.

(there can be a delay Does the system start up with the MIDAS board error

between the system time of message

the PCs on which the two No

loggings run). Yes

Replace MIDAS board of C-arm stand.

Error 341 (Pulsera only)

START

Connect the D-connector to SHA4 LED of power supply lights up? Check power supply

contact X2 point 19. No

Is 15 s after system start the Yes

result between 10 and 15 V?

No

Yes

Replace SHA4 Replace generator

Error 342 (Pulsera only)

START

Is the current on SEA3 to low Is the current on SEA3 to high

according to the lower LED indicator? according to the upper LED

No indicator?

Yes Yes

Connect D-connector to SHA4 contact Replace SHA4

X2 between point 1 and 25.

Is the result between 1.3 and 5.2 V?

No

Yes

Replace the generator

BV Family R1.2 / Volume 1 (04.0) SM-CM 3 - 5

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Section 3 Service Manual BV Family R1.2

Fault finding procedures

Error 350

START

Problem occurs during system Via stand: adjust to 100 Choose in BV-Scope:

start? kV and 3 mA. Install > Adjustment >

No Is the result between X-ray tube >

Yes +HVT and –HVT 350 V Fluoroscopy

1 V and during radiating

346 1 V? and follow the

No instructions

Yes

Check cabling between SHA4 Check cabling between Solve cabling problem

and the generator SHA4 connector X1 and

the tank.

Cabling ok?

No

Yes

Replace SHA4

Cabling ok? Solve cabling problem.

No

Yes

Measure SEA1 on contact Replace SHA4.

MAC.

Result between –1 and 3 V?

No

Yes

Measure VDC voltage on Is VDC > 18 V? Is VDC = 0 V? Replace tank.

SEA1 No No

Result between 10 and 18 V? Yes Yes

No Replace SEA1.

Yes

Replace the tank Measure Filcom current Check cabling

with oscilloscope. between the tank and

Oscilloscope picture is the generator

straight line?

No

Yes

Replace the tank.

Error 351

START

Problem occurs Does the problem Measure SEA1 on Check cabling between generator and

during system occur during contact MAC. tank.

start? radiology only? Result between > 3 V?

No No No

Yes Yes Yes

Replace SHA4

Check cabling Calibrate tube See log file of SUCO:

between SHA4 current. chapter 2.1.2.

and generator SE Is calibration

unit successful?

No

SM-CM 3 - 6 (04.0) BV Family R1.2 / Volume 1

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Service Manual BV Family R1.2 Section 3

Fault finding procedures

2.2 DFI ERROR MESSAGES

For how to react on error messages, see chapter 2.1.

DFI error messages: LOG filetext and remarks (co_error.c):

error no. and mnemonic

4 CC_E_LIMIT This error is possibly caused by other errors. Check the System logfile for further errors.

Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

17 CC_E_EXIST This error is possibly caused by other errors. Check the System logfile for further errors.

Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

79 CC_E_TIMEOUT This error is possibly caused by other errors. Check the System logfile for further errors.

Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

1000 CC_E_CANCEL This error is possibly caused by other errors. Check the System logfile for further errors.

Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

1001 CC_E_EMPTY This error is possibly caused by other errors. Check the System logfile for further errors.

Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

1002 CC_E_ERROR This error is possibly caused by other errors. Check the System logfile for further errors.

Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

1003 CC_E_SMALLER This error is possibly caused by other errors. Check the System logfile for further errors.

Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

1004 CC_E_LARGER This error is possibly caused by other errors. Check the System logfile for further errors.

Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

1005 CC_E_NOTRECV This error is possibly caused by other errors. Check the System logfile for further errors.

Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

1006 CC_E_CANCELLED This error is possibly caused by other errors. Check the System logfile for further errors.

Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

1007 CC_E_MEM Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

1008 CC_E_TIMER This error is possibly caused by other errors. Check the System logfile for further errors.

Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

2000 INIT_E_MEM Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

3001 Restart the MVS. If this problem remains, please sent a problem report with the System

IPDR_E_UNKNOWN_MOD logfile to the PMS helpdesk. Reload the software. See service manual for more information.

E

3002 IPDR_E_TIMEOUT DFI hardware failure. Start the DFI and check the selftest result on the selftest LED. See

service manual for more solutions.

3003 DFI hardware failure. Start the DFI and check the selftest result on the selftest LED. See

IPDR_E_TEST_FAILED service manual for more solutions.

3004 One of the fuses of the TRUIF power supply is blown. The fuses restore automatically after

IPDR_E_FUSE_BLOWN power off and on. Check TRUIF and cabling if problem is persistent.

3005 IPDR_E_MEM Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

3006 DFI hardware failure. Start the DFI and check the selftest result on the selftest LED. See

IPDR_E_SWAP_TIMEOUT service manual for more solutions.

3007 DFI hardware failure. Start the DFI and check the selftest result on the selftest LED. See

IPDR_E_TRANSPORT_TIM service manual for more solutions.

EOUT

BV Family R1.2 / Volume 1 (04.0) SM-CM 3 - 7

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Section 3 Service Manual BV Family R1.2

Fault finding procedures

DFI error messages: LOG filetext and remarks (co_error.c):

error no. and mnemonic

3008 Restart the MVS. If this problem remains, please sent a problem report with the System

IPDR_E_ILLEGAL_DISKTA logfile to the PMS helpdesk. Reload the software. See service manual for more information.

P

3009 DFI hardware failure. Start the DFI and check the selftest result on the selftest LED. See

IPDR_E_TB_STATE_TIME service manual for more solutions.

OUT

3010 Restart the MVS. If this problem remains, please sent a problem report with the System

IPDR_E_ILLEGAL_ARGUM logfile to the PMS helpdesk. Reload the software. See service manual for more information.

ENT

3011 IPDR_E_FILE The image-processor driver failed to access configuration files. Reload the software if this

problem is persistent.

3012 IPDR_E_HW_CONFIG DFI hardware failure. Start the DFI and check the selftest result on the selftest LED. See

service manual for more solutions.

4001 Communication error between DFI and MVS console (TRUIF). Restart the MVS. If this

RSDR_E_COMMUNICATIO problem remains, check the cabling between the DFI and the MVS console. See service

N manual for more solutions.

4002 Restart the MVS. If this problem remains, please sent a problem report with the System

RSDR_E_ILLEGAL_ACTIO logfile to the PMS helpdesk. Reload the software. See service manual for more information.

N_REQUEST

4003 Restart the MVS. If this problem remains, please sent a problem report with the System

RSDR_E_DOUBLE_ACTIO logfile to the PMS helpdesk. Reload the software. See service manual for more information.

N_REQUEST

4004 RSDR_E_STATUS Communication error between DFI and MVS console (TRUIF). Restart the MVS. If this

problem remains, check the cabling between the DFI and the MVS console. See service

manual for more solutions.

4005 Communication error between DFI and MVS console (TRUIF). Restart the MVS. If this

RSDR_E_HW_BOARD problem remains, check the cabling between the DFI and the MVS console. See service

manual for more solutions.

4006 Communication error between DFI and MVS console (TRUIF). Restart the MVS. If this

RSDR_E_ILLEGAL_SIGNA problem remains, check the cabling between the DFI and the MVS console. See service

L manual for more solutions.

4007 Communication error between DFI and MVS console (TRUIF). Restart the MVS. If this

RSDR_E_NO_VERSION problem remains, check the cabling between the DFI and the MVS console. See service

manual for more solutions.

4008 RSDR_E_TIMEOUT Communication error between DFI and MVS console (TRUIF). Restart the MVS. If this

problem remains, check the cabling between the DFI and the MVS console. See service

manual for more solutions.

4010 Communication error between DFI and MVS console (TRUIF). Restart the MVS. If this

RSDR_E_NO_STATUS problem remains, check the cabling between the DFI and the MVS console. See service

manual for more solutions.

4009 RSDR_E_LIMIT Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

5001 SCSI_E_READ DFI disk failure. CAUTION: After the following actions the PATIENT DATA, DFI

CONFIGURATION DATA and DFI IP SETS are LOST. Start the DFI power-up service menu

and low-level format the DFI disk. Re-install the DFI. See service for more solutions.

5002 SCSI_E_WRITE DFI disk failure. CAUTION: After the following actions the PATIENT DATA, DFI

CONFIGURATION DATA and DFI IP SETS are LOST. Start the DFI power-up service menu

and low-level format the DFI disk. Re-install the DFI. See service for more solutions.

5003 SCSI_E_FORMAT DFI disk failure. CAUTION: After the following actions the PATIENT DATA, DFI

CONFIGURATION DATA and DFI IP SETS are LOST. Start the DFI power-up service menu

and low-level format the DFI disk. Re-install the DFI. See service for more solutions.

5004 Restart the MVS. If this problem remains, please sent a problem report with the System

SCSI_E_ILLEGAL_START_ logfile to the PMS helpdesk. Reload the software. See service manual for more information.

SECTOR

5005 Restart the MVS. If this problem remains, please sent a problem report with the System

SCSI_E_ILLEGAL_SIZE logfile to the PMS helpdesk. Reload the software. See service manual for more information.

5006 Restart the MVS. If this problem remains, please sent a problem report with the System

SCSI_E_ILLEGAL_DISK_ID logfile to the PMS helpdesk. Reload the software. See service manual for more information.

5007 Restart the MVS. If this problem remains, please sent a problem report with the System

SCSI_E_ILLEGAL_PARAM logfile to the PMS helpdesk. Reload the software. See service manual for more information.

SM-CM 3 - 8 (04.0) BV Family R1.2 / Volume 1

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Service Manual BV Family R1.2 Section 3

Fault finding procedures

DFI error messages: LOG filetext and remarks (co_error.c):

error no. and mnemonic

S

5008 SCSI_E_INIT_FAILED DFI disk failure. CAUTION: After the following actions the PATIENT DATA, DFI

CONFIGURATION DATA and DFI IP SETS are LOST. Start the DFI power-up service menu

and low-level format the DFI disk. Re-install the DFI. See service for more solutions.

5009 Restart the MVS. If this problem remains, please sent a problem report with the System

SCSI_E_LOCK_FAILED logfile to the PMS helpdesk. Reload the software. See service manual for more information.

5010 SCSI_E_MEM Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

5011 DFI disk failure. CAUTION: After the following actions the PATIENT DATA, DFI

SCSI_E_TEST_FAILED CONFIGURATION DATA and DFI IP SETS are LOST. Start the DFI power-up service menu

and low-level format the DFI disk. Re-install the DFI. See service for more solutions.

6001 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_ILLEGAL_PARAM logfile to the PMS helpdesk. Reload the software. See service manual for more information.

6002 IMPR_E_ILLEGAL_ID Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

6003 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_SET_ACTIVE logfile to the PMS helpdesk. Reload the software. See service manual for more information.

6004 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_SET_IN_USE logfile to the PMS helpdesk. Reload the software. See service manual for more information.

6005 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_DEVICE_DOES_N logfile to the PMS helpdesk. Reload the software. See service manual for more information.

OT_EXIST

6006 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_ROUTING_NOT_P logfile to the PMS helpdesk. Reload the software. See service manual for more information.

OSSIBLE

6007 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_SCRIPT_CONFLI logfile to the PMS helpdesk. Reload the software. See service manual for more information.

CT

6008 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_WRONG_DEVICE logfile to the PMS helpdesk. Reload the software. See service manual for more information.

6009 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_SCRIPT_ACTIVE logfile to the PMS helpdesk. Reload the software. See service manual for more information.

6010 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_SAME_OUTPUT logfile to the PMS helpdesk. Reload the software. See service manual for more information.

6011 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_OUTPUT_IN_USE logfile to the PMS helpdesk. Reload the software. See service manual for more information.

6012 IMPR_E_MEM Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

6013 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_ILLEGAL_NR_OF logfile to the PMS helpdesk. Reload the software. See service manual for more information.

_OUTPUT_DEVICES

6014 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_ROUTING_NOT_ logfile to the PMS helpdesk. Reload the software. See service manual for more information.

CONCURRENT

6015 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_CHANGE_NOT_A logfile to the PMS helpdesk. Reload the software. See service manual for more information.

LLOWED

6016 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_SET_NOT_IN_SC logfile to the PMS helpdesk. Reload the software. See service manual for more information.

RIPT

6017 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_MAXIMUM_REGIS logfile to the PMS helpdesk. Reload the software. See service manual for more information.

TERED

6018 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_SAME_DEVICES logfile to the PMS helpdesk. Reload the software. See service manual for more information.

6019 Restart the MVS. If this problem remains, please sent a problem report with the System

IMPR_E_MASK_NOT_LOA logfile to the PMS helpdesk. Reload the software. See service manual for more information.

DED

BV Family R1.2 / Volume 1 (04.0) SM-CM 3 - 9

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Section 3 Service Manual BV Family R1.2

Fault finding procedures

DFI error messages: LOG filetext and remarks (co_error.c):

error no. and mnemonic

7001 USR_E_ILLEGAL_NR Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

7002 Restart the MVS. If this problem remains, please sent a problem report with the System

USR_E_DOUBLE_REQUES logfile to the PMS helpdesk. Reload the software. See service manual for more information.

TED_ACTION

7003 The SuCo hardware and or software failed. Restart the stand. If this problem remains,

USR_E_NO_SUCO_AVAIL please sent a problem report with the System logfile to the PMS helpdesk. See service

ABLE manual for more solutions.

7004 Communication error between DFI and MVS console (TRUIF). Restart the MVS. If this

USR_E_NO_TRUIF_AVAIL problem remains, check the cabling between the DFI and the MVS console. See service

ABLE manual for more solutions.

7005 USR_E_PROTOCOL Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

7006 USR_E_MEM Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

7007 The DFI found errors in the APF parameters received from the SuCo. Use BV-Scope,

USR_E_ILLEGAL_APF_PA program automatic, SUCO, examination to install the default APF parameters. See service

RAMETERS manual for more information.

7008 The DFI found errors in the system type, video frequency or free space time limit received

USR_E_ILLEGAL_CALIBRA from the SuCo. The SuCo hardware and or software failed. Restart the stand. If this problem

TION_DATA remains, please sent a problem report with the System logfile to the PMS helpdesk. See

service manual for more solutions.

7009 The DFI found errors in the clean circle parameters received from the SuCo. The SuCo

USR_E_ILLEGAL_CLEAN_ hardware and or software failed. Restart the stand. If this problem remains, please sent a

CIRCLE_RADIUS problem report with the System logfile to the PMS helpdesk. See service manual for more

solutions.

7010 The DFI found errors in the camera rotation parameters received from the SuCo. The SuCo

USR_E_ILLEGAL_CAMERA hardware and or software failed. Restart the stand. If this problem remains, please sent a

_ROTATION problem report with the System logfile to the PMS helpdesk. See service manual for more

solutions.

7011 The DFI found errors in the flip mode received from the SuCo. Use BV-Scope, program

USR_E_ILLEGAL_FLIP_MO automatic, SUCO, examination to install the default APF parameters. See service manual

DE for more information.

7012 The DFI found errors in the frame rate received from the SuCo. Use BV-Scope, program

USR_E_ILLEGAL_FRAME_ automatic, SUCO, examination to install the default APF parameters. See service manual

RATE for more information.

7013 The DFI found errors in the II format received from the SuCo. The SuCo hardware and or

USR_E_ILLEGAL_II_FORM software failed. Restart the stand. If this problem remains, please sent a problem report with

AT the System logfile to the PMS helpdesk. See service manual for more solutions.

7014 The DFI found errors in the fluoro time received from the SuCo. The SuCo hardware and or

USR_E_ILLEGAL_INT_FLU software failed. Restart the stand. If this problem remains, please sent a problem report with

ORO_TIME the System logfile to the PMS helpdesk. See service manual for more solutions.

7015 The DFI found errors in the iris settings received from the SuCo. The SuCo hardware and or

USR_E_ILLEGAL_IRIS_SE software failed. Restart the stand. If this problem remains, please sent a problem report with

TTINGS the System logfile to the PMS helpdesk. See service manual for more solutions.

7016 The DFI found errors in the LAT cross request from the SuCo. The SuCo hardware and or

USR_E_ILLEGAL_LAT software failed. Restart the stand. If this problem remains, please sent a problem report with

the System logfile to the PMS helpdesk. See service manual for more solutions.

7017 The DFI found errors in the fluoro mode received from the SuCo. The SuCo hardware and

USR_E_ILLEGAL_FLUORO or software failed. Restart the stand. If this problem remains, please sent a problem report

_MODE with the System logfile to the PMS helpdesk. See service manual for more solutions.

7018 The DFI found errors in the X-ray lamp request from the SuCo. The SuCo hardware and or

USR_E_ILLEGAL_XRAY software failed. Restart the stand. If this problem remains, please sent a problem report with

the System logfile to the PMS helpdesk. See service manual for more solutions.

7019 The DFI found errors in the dose data received from the SuCo. The SuCo hardware and or

USR_E_ILLEGAL_PATIENT software failed. Restart the stand. If this problem remains, please sent a problem report with

_DOSE the System logfile to the PMS helpdesk. See service manual for more solutions.

SM-CM 3 - 10 (04.0) BV Family R1.2 / Volume 1

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Service Manual BV Family R1.2 Section 3

Fault finding procedures

DFI error messages: LOG filetext and remarks (co_error.c):

error no. and mnemonic

7020 The DFI found errors in the dose effective area received from the SuCo. The SuCo

USR_E_ILLEGAL_EFF_RA hardware and or software failed. Restart the stand. If this problem remains, please sent a

D_AREA problem report with the System logfile to the PMS helpdesk. See service manual for more

solutions.

7021 The DFI found errors in the shutter settings received from the SuCo. The SuCo hardware

USR_E_ILLEGAL_SHUTTE and or software failed. Restart the stand. If this problem remains, please sent a problem

R_SETTINGS report with the System logfile to the PMS helpdesk. See service manual for more solutions.

7022 The DFI found errors in the status received from the SuCo. The SuCo hardware and or

USR_E_ILLEGAL_STATUS software failed. Restart the stand. If this problem remains, please sent a problem report with

the System logfile to the PMS helpdesk. See service manual for more solutions.

7023 The DFI found errors in the error code received from the SuCo. The SuCo hardware and or

USR_E_ILLEGAL_ERROR software failed. Restart the stand. If this problem remains, please sent a problem report with

the System logfile to the PMS helpdesk. See service manual for more solutions.

7024 The DFI found errors in the examination names received from the SuCo. Use BV-Scope,

USR_E_ILLEGAL_EXAM_T program automatic, SUCO, examination to install the default examination names. Use BV-

YPE_DATA Scope, program manual, SUCO, examination names to enter unique examination names.

See service manual for more information.

7025 The DFI found errors in the pulsed mode received from the SuCo. The SuCo hardware and

USR_E_ILLEGAL_PULSED or software failed. Restart the stand. If this problem remains, please sent a problem report

_MODE with the System logfile to the PMS helpdesk. See service manual for more solutions.

7026 The DFI found errors in the exam type index received from the SuCo. The SuCo hardware

USR_E_ILLEGAL_EXAM_T and or software failed. Restart the stand. If this problem remains, please sent a problem

YPE report with the System logfile to the PMS helpdesk. See service manual for more solutions.

8002 Restart the MVS. If this problem remains then perform the following. CAUTION: After the

FILE_E_NOT_INITIALIZED following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

8003 FILE_E_IMAGENR Restart the MVS. If this problem remains then perform the following. CAUTION: After the

following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

8004 FILE_E_IMAGEID Restart the MVS. If this problem remains then perform the following. CAUTION: After the

following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

8005 FILE_E_GROUPID Restart the MVS. If this problem remains then perform the following. CAUTION: After the

following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

8006 FILE_E_DISK_FULL Restart the MVS. If this problem remains then perform the following. CAUTION: After the

following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

8007 Restart the MVS. If this problem remains then perform the following. CAUTION: After the

FILE_E_BUFFER_FULL following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

8008 Restart the MVS. If this problem remains then perform the following. CAUTION: After the

FILE_E_NO_CAPACITY following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

8009 FILE_E_CORRUPT Restart the MVS. If this problem remains then perform the following. CAUTION: After the

following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

8010 FILE_E_RECOVERED The DFI detected an inconsistent image administration. This was recovered, but action

needed if problem is persistent Restart the MVS. If this problem remains then perform the

following. CAUTION: After the following actions ALL IMAGES on the DFI disk are LOST.

Initialize the image disk via: BV-Scope, program manual, DFI configuration. See service

manual for more information.

8011 Restart the MVS. If this problem remains, please sent a problem report with the System

FILE_E_ILLEGAL_IMG_SIZ logfile to the PMS helpdesk. Reload the software. See service manual for more information.

E

8012 Restart the MVS. If this problem remains then perform the following. CAUTION: After the

FILE_E_NOT_ENOUGH_E following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

NTRIES Scope, program manual, DFI configuration. See service manual for more information.

8013 Restart the MVS. If this problem remains, please sent a problem report with the System

FILE_E_ILLEGAL_SPEED logfile to the PMS helpdesk. Reload the software. See service manual for more information.

BV Family R1.2 / Volume 1 (04.0) SM-CM 3 - 11

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Section 3 Service Manual BV Family R1.2

Fault finding procedures

DFI error messages: LOG filetext and remarks (co_error.c):

error no. and mnemonic

8014 FILE_E_MEM Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

8015 Restart the MVS. If this problem remains, please sent a problem report with the System

FILE_E_WRITE_NOT_ACTI logfile to the PMS helpdesk. Reload the software. See service manual for more information.

VE

8016 FILE_E_UNSTABLE The DFI detected an inconsistent image administration. This can be recovered, but action

needed if problem is persistent Restart the MVS. If this problem remains then perform the

following. CAUTION: After the following actions ALL IMAGES on the DFI disk are LOST.

Initialize the image disk via: BV-Scope, program manual, DFI configuration. See service

manual for more information.

8017 Restart the MVS. If this problem remains then perform the following. CAUTION: After the

FILE_E_UNABLE_TO_RES following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

TORE Scope, program manual, DFI configuration. See service manual for more information.

8018 Restart the MVS. If this problem remains, please sent a problem report with the System

FILE_E_ILLEGAL_PARAME logfile to the PMS helpdesk. Reload the software. See service manual for more information.

TER

8019 Restart the MVS. If this problem remains, please sent a problem report with the System

FILE_E_WRONG_TRANSP logfile to the PMS helpdesk. Reload the software. See service manual for more information.

ORT_MODE

9000 DB_E_RESET Reload the software. See service manual for more solutions.

9001 DB_E_LIMIT Restart the MVS. If this problem remains then perform the following. CAUTION: After reset

database the PATIENT DATA, DFI CONFIGURATION DATA and IP SETS are LOST.

Reset the database via BV Scope service menu. Re-configure the System and reload

application data. See service manual for more information.

9002 DB_E_MEDIUM Restart the MVS. If this problem remains then perform the following. CAUTION: After reset

database the PATIENT DATA, DFI CONFIGURATION DATA and IP SETS are LOST.

Reset the database via BV Scope service menu. Re-configure the System and reload

application data. See service manual for more information.

9003 DB_E_CONNECTION Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

9004 DB_E_CONNECTED Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

9005 DB_E_SIZE Restart the MVS. If this problem remains then perform the following. CAUTION: After reset

database the PATIENT DATA, DFI CONFIGURATION DATA and IP SETS are LOST.

Reset the database via BV Scope service menu. Re-configure the System and reload

application data. See service manual for more information.

9006 DB_E_EXIST Restart the MVS. If this problem remains then perform the following. CAUTION: After reset

database the PATIENT DATA, DFI CONFIGURATION DATA and IP SETS are LOST.

Reset the database via BV Scope service menu. Re-configure the System and reload

application data. See service manual for more information.

9007 DB_E_LEVEL Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

9008 DB_E_TREENAME Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

9009 DB_E_TREE Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

9010 DB_E_RECORDS Restart the MVS. If this problem remains then perform the following. CAUTION: After reset

database the PATIENT DATA, DFI CONFIGURATION DATA and IP SETS are LOST.

Reset the database via BV Scope service menu. Re-configure the System and reload

application data. See service manual for more information.

9011 DB_E_INSERT Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

9012 DB_E_MEM Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

9013 DB_E_DIFF Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

9014 DB_E_CHECKSUM Restart the MVS. If this problem remains then perform the following. CAUTION: After reset

database the PATIENT DATA, DFI CONFIGURATION DATA and IP SETS are LOST.

Reset the database via BV Scope service menu. Re-configure the System and reload

application data. See service manual for more information.

SM-CM 3 - 12 (04.0) BV Family R1.2 / Volume 1

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Service Manual BV Family R1.2 Section 3

Fault finding procedures

DFI error messages: LOG filetext and remarks (co_error.c):

error no. and mnemonic

9015 DB_E_GENERAL Restart the MVS. If this problem remains then perform the following. CAUTION: After reset

database the PATIENT DATA, DFI CONFIGURATION DATA and IP SETS are LOST.

Reset the database via BV Scope service menu. Re-configure the System and reload

application data. See service manual for more information.

9016 DB_E_FULL Restart the MVS. If this problem remains then perform the following. CAUTION: After reset

database the PATIENT DATA, DFI CONFIGURATION DATA and IP SETS are LOST.

Reset the database via BV Scope service menu. Re-configure the System and reload

application data. See service manual for more information.

9017 DB_E_TIMESTAMP Restart the MVS. If this problem remains then perform the following. CAUTION: After reset

database the PATIENT DATA, DFI CONFIGURATION DATA and IP SETS are LOST.

Reset the database via BV Scope service menu. Re-configure the System and reload

application data. See service manual for more information.

11000 Restart the MVS. If this problem remains, please sent a problem report with the System

ADMI_E_ILLEGAL_MODE logfile to the PMS helpdesk. Reload the software. See service manual for more information.

11001 ADMI_E_DATA Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

11002 Restart the MVS. If this problem remains, please sent a problem report with the System

ADMI_E_ACTIVATOR_ID logfile to the PMS helpdesk. Reload the software. See service manual for more information.

11003 ADMI_E_ACTION Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

11004 Restart the MVS. If this problem remains, please sent a problem report with the System

ADMI_E_NO_SIGNAL logfile to the PMS helpdesk. Reload the software. See service manual for more information.

11005 Restart the MVS. If this problem remains, please sent a problem report with the System

ADMI_E_TABLE_FULL logfile to the PMS helpdesk. Reload the software. See service manual for more information.

11006 Restart the MVS. If this problem remains, please sent a problem report with the System

ADMI_E_TABLE_POSITION logfile to the PMS helpdesk. Reload the software. See service manual for more information.

11007 Restart the MVS. If this problem remains then perform the following. CAUTION: After reset

ADMI_E_PAT_NO_EXAM database the PATIENT DATA, DFI CONFIGURATION DATA and IP SETS are LOST.

Reset the database via BV Scope service menu. Re-configure the System and reload

application data. See service manual for more information.

11008 Restart the MVS. If this problem remains then perform the following. CAUTION: After reset

ADMI_E_ILLEGAL_PAT database the PATIENT DATA, DFI CONFIGURATION DATA and IP SETS are LOST.

Reset the database via BV Scope service menu. Re-configure the System and reload

application data. See service manual for more information.

11009 ADMI_E_MEM Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

12001 GUI_E_MEM Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

12002 GUI_E_RESET Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

12003 Restart the MVS. If this problem remains, please sent a problem report with the System

GUI_E_DOUBLE_ACTION_ logfile to the PMS helpdesk. Reload the software. See service manual for more information.

REQUEST

12004 Restart the MVS. If this problem remains, please sent a problem report with the System

GUI_E_ACTION_REQUEST logfile to the PMS helpdesk. Reload the software. See service manual for more information.

12005 GUI_E_SIGNAL Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

12006 Restart the MVS. If this problem remains, please sent a problem report with the System

GUI_E_SIGNAL_INFO logfile to the PMS helpdesk. Reload the software. See service manual for more information.

12007 Restart the MVS. If this problem remains, please sent a problem report with the System

GUI_E_UPDATE_INFO logfile to the PMS helpdesk. Reload the software. See service manual for more information.

12008 GUI_E_UPDATE Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

12009 GUI_E_OPERATION Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

12010 GUI_E_DIR Reload the software. See service manual for more solutions.

12011 GUI_E_DIR_INFO Reload the software. See service manual for more solutions.

12012 GUI_E_RESOURCE Reload the software. See service manual for more solutions.

12013 Reload the software. See service manual for more solutions.

BV Family R1.2 / Volume 1 (04.0) SM-CM 3 - 13

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Section 3 Service Manual BV Family R1.2

Fault finding procedures

DFI error messages: LOG filetext and remarks (co_error.c):

error no. and mnemonic

GUI_E_REQUEST_BITMAP

12014 GUI_E_LAST_EXP Error not used anymore. Restart the MVS. If this problem remains, please sent a problem

report with the System logfile to the PMS helpdesk. Reload the software. See service

manual for more information.

13000 Restart the MVS. If this problem remains, please sent a problem report with the System

VIEW_E_ILLEGAL_START_ logfile to the PMS helpdesk. Reload the software. See service manual for more information.

MODE

13001 Restart the MVS. If this problem remains, please sent a problem report with the System

VIEW_E_ILLEGAL_STATE_ logfile to the PMS helpdesk. Reload the software. See service manual for more information.

TRANSITION

13002 Restart the MVS. If this problem remains, please sent a problem report with the System

VIEW_E_NO_FUNCTION_ logfile to the PMS helpdesk. Reload the software. See service manual for more information.

DEFINED

13003 Restart the MVS. If this problem remains, please sent a problem report with the System

VIEW_E_NO_DATA_DEFIN logfile to the PMS helpdesk. Reload the software. See service manual for more information.

ED

13004 VIEW_E_ID_LOST Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

13005 VIEW_E_MEM Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

13006 Restart the MVS. If this problem remains then perform the following. CAUTION: After the

VIEW_E_NO_MOSAIC_MA following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

SK Scope, program manual, DFI configuration. See service manual for more information.

13007 Error not used anymore. Restart the MVS. If this problem remains, please sent a problem

VIEW_E_CALIBRATION report with the System logfile to the PMS helpdesk. Reload the software. See service

manual for more information.

13008 VIEW_E_VHCU_LUT The DFI configuration data contains invalid vhcuLut data.

14000 Restart the MVS. If this problem remains, please sent a problem report with the System

LIVE_E_ILLEGAL_MODE logfile to the PMS helpdesk. Reload the software. See service manual for more information.

14001 LIVE_E_ACTION Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

14002 LIVE_E_ACTIVATOR Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

14003 LIVE_E_STATE Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

14004 LIVE_E_RESET Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

14005 LIVE_E_DATA Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

14006 Restart the MVS. If this problem remains, please sent a problem report with the System

LIVE_E_RUNBUFFER logfile to the PMS helpdesk. Reload the software. See service manual for more information.

14007 LIVE_E_MEM Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

14008 LIVE_E_EXIST Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

14009 LIVE_E_FREQ DFI video frequency and SuCo detected video frequency do not match. Use BV-Scope,

Install, Program Manual, System Configuration to select the correct video frequency.

14010 LIVE_E_SYSTYPE DFI SW licence key and SuCo detected system type do not match. Use BV-Scope, Install,

Program Manual, System Configuration to enter the correct SW licence key.

15000 SERV_E_ERROR Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

15001 A cold restart was requested via service PC. No further actions needed.

SERV_E_COLD_RESTART

_REQUEST

15002 System config data is modified by service actions. Continuing functions can lead to

SERV_E_DFI_INCONSISTE unpredictable results, Restart needed.

NT

SM-CM 3 - 14 (04.0) BV Family R1.2 / Volume 1

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Service Manual BV Family R1.2 Section 3

Fault finding procedures

DFI error messages: LOG filetext and remarks (co_error.c):

error no. and mnemonic

15003 The software license key does not match with installed hardware. More hardware needed to

SERV_E_DFI_HARDWARE satisfy software license key requirements. Check software license key and hardware

_INCOMPLETE configuration.

16001 Restart the MVS. If this problem remains, please sent a problem report with the System

SYS_E_STARTUP_FAILUR logfile to the PMS helpdesk. Reload the software. See service manual for more information.

E

16002 Restart the MVS. If this problem remains, please sent a problem report with the System

SYS_E_ILLEGAL_FC_RES logfile to the PMS helpdesk. Reload the software. See service manual for more information.

P

16003 Restart the MVS. If this problem remains, please sent a problem report with the System

SYS_E_WARMRESTART logfile to the PMS helpdesk. Reload the software. See service manual for more information.

16004 Restart the MVS. If this problem remains, please sent a problem report with the System

SYS_E_COLDRESTART logfile to the PMS helpdesk. Reload the software. See service manual for more information.

16005 Restart the MVS. If this problem remains, please sent a problem report with the System

SYS_E_WRONG_PARAME logfile to the PMS helpdesk. Reload the software. See service manual for more information.

TER

17000 LOG_E_INIT Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

17001 LOG_E_INIT_BUF Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

17002 LOG_E_INIT_FILE Reload the software. See service manual for more solutions.

17003 LOG_E_FLUSH Reload the software. See service manual for more solutions.

17004 Reload the software. See service manual for more solutions.

LOG_E_FLUSH_PERM

17005 LOG_E_FREEZE Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

17006 Reload the software. See service manual for more solutions.

LOG_E_FREEZE_READ

17007 Reload the software. See service manual for more solutions.

LOG_E_FREEZE_WRITE

17008 Restart the MVS. If this problem remains, please sent a problem report with the System

LOG_E_FREEZE_CLOSED logfile to the PMS helpdesk. Reload the software. See service manual for more information.

17009 Reload the software. See service manual for more solutions.

LOG_E_FREEZE_OPEN

17010 LOG_E_READ_FILE Reload the software. See service manual for more solutions.

17011 Reload the software. See service manual for more solutions.

LOG_E_READ_SELECTIO

N

17012 Reload the software. See service manual for more solutions.

LOG_E_READ_TYPE

17013 Reload the software. See service manual for more solutions.

LOG_E_READ_NO_FILE

17014 Reload the software. See service manual for more solutions.

LOG_E_READ_END_OF_FI

LE

17015 LOG_E_MEM Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

17016 LOG_E_WRITE Reload the software. See service manual for more solutions.

17017 Restart the MVS. If this problem remains, please sent a problem report with the System

LOG_E_WRITE_TYPE logfile to the PMS helpdesk. Reload the software. See service manual for more information.

17018 LOG_E_WRITE_ID Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

17019 Restart the MVS. If this problem remains, please sent a problem report with the System

LOG_E_WRITE_BUF_FULL logfile to the PMS helpdesk. Reload the software. See service manual for more information.

17020 LOG_E_CLOSE Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

17021 Reload the software. See service manual for more solutions.

LOG_E_CLOSE_READ

17022 Reload the software. See service manual for more solutions.

BV Family R1.2 / Volume 1 (04.0) SM-CM 3 - 15

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Section 3 Service Manual BV Family R1.2

Fault finding procedures

DFI error messages: LOG filetext and remarks (co_error.c):

error no. and mnemonic

LOG_E_CLOSE_OPEN

17023 Reload the software. See service manual for more solutions.

LOG_E_CLOSE_FIND

17111 LOG_E_EXCEPTION Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

17112 Reload the software. See service manual for more solutions.

LOG_E_CORRUPT_LOG_F

ILE

19000 Restart the MVS. If this problem remains then perform the following. CAUTION: After the

RB_E_NOT_INITIALIZED following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

19001 RB_E_MEM Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

19002 RB_E_RECOVERED Restart the MVS. If this problem remains then perform the following. CAUTION: After the

following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

19003 RB_E_IMAGEID Restart the MVS. If this problem remains then perform the following. CAUTION: After the

following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

19004 RB_E_KEEP Restart the MVS. If this problem remains then perform the following. CAUTION: After the

following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

19005 RB_E_UNKEEP Restart the MVS. If this problem remains then perform the following. CAUTION: After the

following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

19006 RB_E_EXAM Restart the MVS. If this problem remains then perform the following. CAUTION: After the

following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

19007 Restart the MVS. If this problem remains then perform the following. CAUTION: After the

RB_E_EXAM_EMPTY following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

19008 RB_E_FILE Restart the MVS. If this problem remains then perform the following. CAUTION: After the

following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

19009 RB_E_LIMIT Restart the MVS. If this problem remains then perform the following. CAUTION: After the

following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

19010 Restart the MVS. If this problem remains then perform the following. CAUTION: After the

RB_E_FREE_SPACE following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

19011 RB_E_ILL_PARAM Restart the MVS. If this problem remains then perform the following. CAUTION: After the

following actions ALL IMAGES on the DFI disk are LOST. Initialize the image disk via: BV-

Scope, program manual, DFI configuration. See service manual for more information.

20001 HPI_E_FAIL The DICOM export device failed. Restart the MVS. If this problem remains, see service

manual for more solutions.

20003 The DICOM export device failed. Restart the MVS. If this problem remains, see service

HPI_E_RESPONSE_TIMEO manual for more solutions.

UT

20004 The DICOM export device failed. Restart the MVS. If this problem remains, see service

HPI_E_ACKNOWLEDGE_TI manual for more solutions.

MEOUT

20005 Restart the MVS. If this problem remains, please sent a problem report with the System

HPI_E_ALREADY_INITIALI logfile to the PMS helpdesk. Reload the software. See service manual for more information.

ZED

20006 Restart the MVS. If this problem remains, please sent a problem report with the System

HPI_E_NOT_INITIALIZED logfile to the PMS helpdesk. Reload the software. See service manual for more information.

20007 The DICOM export device failed. Restart the MVS. If this problem remains, see service

HPI_E_UNEXPECTED_EO manual for more solutions.

M

SM-CM 3 - 16 (04.0) BV Family R1.2 / Volume 1

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Service Manual BV Family R1.2 Section 3

Fault finding procedures

DFI error messages: LOG filetext and remarks (co_error.c):

error no. and mnemonic

20008 The DICOM export device failed. Restart the MVS. If this problem remains, see service

HPI_E_UNEXPECTED_RE manual for more solutions.

SPONSE

20009 The DICOM export device failed. Restart the MVS. If this problem remains, see service

HPI_E_MESSAGE_TOO_L manual for more solutions.

ONG

20011 The DICOM export device failed. Restart the MVS. If this problem remains, see service

HPI_E_ILLEGAL_MESSAG manual for more solutions.

E

20012 Restart the MVS. If this problem remains, please sent a problem report with the System

HPI_E_OUT_OF_MEMORY logfile to the PMS helpdesk. Reload the software. See service manual for more information.

20013 Restart the MVS. If this problem remains, please sent a problem report with the System

HPI_E_INVALID_CALL logfile to the PMS helpdesk. Reload the software. See service manual for more information.

20014 Restart the MVS. If this problem remains, please sent a problem report with the System

HPI_E_ILLEGAL_ARGUME logfile to the PMS helpdesk. Reload the software. See service manual for more information.

NT

20015 Restart the MVS. If this problem remains, please sent a problem report with the System

HPI_E_NOT_CONCURREN logfile to the PMS helpdesk. Reload the software. See service manual for more information.

T

20016 HPI_E_ERROR Restart the MVS. If this problem remains, please sent a problem report with the System

logfile to the PMS helpdesk. Reload the software. See service manual for more information.

BV Family R1.2 / Volume 1 (04.0) SM-CM 3 - 17

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Section 3 Service Manual BV Family R1.2

Fault finding procedures

2.3 SUCO ERROR MESSAGES

For how to react on error messages, see chapter 2.1.

error displayed STUIF texts LOG file text and remarks (co_error.c):

mnemonic: (dismsg.c):

019 X-ray generator not available Invalid error id or no error message defined !!!

Switch system off/on. Call

service if problem is

persistent

020 Warning: system parameters All DATABASE data has been reset or new DATABASE has

are reset. Call service been installed. Calibrated BV-scope data has been removed

and replaced with the default settings. Perform the following

actions: Perform Program Automatic install configuration and

examination. Check the program manual functions. Perform the

adjustments X-ray tube: Filament and Dose output. Perform the

adjustments Image processor. Perform the adjustments

Collimator (excluding laser alignment). Perform the adjustment

II/TV: Electrical-Dose rate.

021 Warning: system parameters Configuration data has been reset. The default settings are now

are reset. Call service used. Perform the following action: Using the Program

Automatic function, install Configuration.

022 Warning: system parameters No BV-scope calibration has been performed, or calibration

are reset. Call service data has been reset. The default settings are now used.

Perform the following actions: Perform the adjustments X-ray

tube: Dose output. Perform the adjustments Image processor.

Perform adjustments Collimator (excluding laser alignment).

Perform the adjustment II/TV: Electrical-Dose rate.

023 Warning: system parameters The APF data has been reset. The default settings are now

are reset. Call service used. Perform the following action: Using the Program

Automatic function, install Examination. Check program manual

functions: Examination names and APF settings.

024 Warning: system parameters The heat integrator data has been reset. This will correct itself

are reset. Call service automatically within 5 minutes - no further action required.

025 Warning: system parameters The current patient dose data has been reset. No action

are reset. Call service required.

026 Warning: system parameters Annabelle DATABASE data has been reset. The default

are reset. Call service settings are now used. No action required.

027 Warning: system parameters The dose output calibration data has been reset. Perform the

are reset. Call service adjustment for the X-ray tube: Dose output.

028 Warning: system parameters The tank history data has been reset. NOTE: The old tank

are reset. Call service history data has been deleted. No action required.

029 Warning: system parameters The energy storage history data has been reset. NOTE: The

are reset. Call service old energy storage history data has been deleted. No action

required.

030 Warning: system parameters NOTE: The dose report of the current acquisition patient is

are reset. Call service suspect. No action required.

031 Warning: system parameters NOTE: The filament adjustment data has been reset. Perform

are reset. Call service the filament adjustment procedure.

<none> Mobile Viewing Station not <none>

available. Switch system

off/on. Call service if problem

is persistent

SM-CM 3 - 18 (04.0) BV Family R1.2 / Volume 1

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Service Manual BV Family R1.2 Section 3

Fault finding procedures

error displayed STUIF texts LOG file text and remarks (co_error.c):

mnemonic: (dismsg.c):

<none> Mobile Viewing Station in <none>

service mode. Switch off/on

to enter normal mode

050 System initialisation problem A system startup problem occurred. Switch the system off and

Switch system off/on. Call on. If the problem persists, check if the Mobile Viewing Station

service if problem is and the Stand are correctly connected. Check the Stand-Mobile

persistent Viewing Station cable.

051 Software version mismatch The software version installed on the stand is not compatible

Call service with the version installed on the mobile viewing station. Install

the latest version of the software on either the stand or the DFI.

052 System not available The video frequency of the stand is not compatible with the

Switch system off/on video frequency of the mobile viewing station. Call PMS

Call service if problem is helpdesk.

persistent

053 Subsystem error, system still The DFI is not responding within the allowed time, causing a

available. It's possible to timeout. Switch the system off and on. Check the DFI unit for

continue errors.

054 APF parameters not The APF data is invalid due to a incompatibility between the

accepted. The settings for APF data and the IP set. Perform Program Automatic Install

current selection are invalid Examination.

Call service

055 APF parameters not Unknown IP set. Check the application data for errors. Load

accepted. The settings for DFI IP sets.

current selection are invalid

Call service

<none> Storage speed not accepted The selected frame speed is not acceptable during X-ray

Storage speed not

selectable during X-ray

056 Subsystem error, system still The collimator control board is not responding within the

available. It's possible to allowed time, causing a timeout. Check the collimator device,

continue board and cabling. If the problems persists, replace the SHA5

collimator board.

057 Subsystem error, system still The generator control board is not responding within the

available. It's possible to allowed time, causing a timeout. Check the generator device,

continue board and cabling. Check if the Stand software is operational. If

the problems persists, replace the SHA4 generator board.

058 Subsystem error, system still The TVI sub-system is not responding within the allowed time,

available. It's possible to causing a timeout. Check the II, the camera, pulse master

continue board and cabling. Check if the Stand software is operational. If

the problems persists, replace the pulse master board (SHA3).

059 Subsystem error, system still The pulse master control is not responding within the allowed

available. It's possible to time, causing a timeout. Check the board, the cabling and

continue Stand software. If the problems persists, replace the board

(SHA3).

060 HIP time exceeded, low Maximum hip time reached so hip switched off.

dose fluoro activated.

061 Warning: wrong Viewing Incorrect DFI connected with the SUCO. Find the correct DFI

Station connected. and connect this with the SUCO.

Connect the matching

Viewing Station

062 Image synchronisation No sync detected between XTV and DFI. Check XTV camera

problem. Call service if and the stand-mobile viewing station cable.

problem is persistent

BV Family R1.2 / Volume 1 (04.0) SM-CM 3 - 19

Copyright © 2004 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED