Professional Documents

Culture Documents

FJS-727 SeriesChecklistandProceduresManual

FJS-727 SeriesChecklistandProceduresManual

Uploaded by

Dave91Copyright:

Available Formats

You might also like

- Across The Fence (John Stryker Meyer (Meyer, John Stryker) )Document340 pagesAcross The Fence (John Stryker Meyer (Meyer, John Stryker) )Dave91100% (2)

- STUDENT Logbook RevisedDocument36 pagesSTUDENT Logbook Reviseddickson muthomi100% (1)

- Waterbox 900Document28 pagesWaterbox 900cem jakartaNo ratings yet

- PR Oposed Land Use Map Planning Distr I CT: 25Document3 pagesPR Oposed Land Use Map Planning Distr I CT: 25Maruthi PrasadNo ratings yet

- Aerospace Standard AS4330: Custodian: Sae G-3/G-3BDocument2 pagesAerospace Standard AS4330: Custodian: Sae G-3/G-3BHenry100% (2)

- Public Opinion Does Not Exist Pierre Bourdieu 1972Document4 pagesPublic Opinion Does Not Exist Pierre Bourdieu 1972tristan138No ratings yet

- Validation of The Work-Life Balance Culture Scale (WLBCS)Document10 pagesValidation of The Work-Life Balance Culture Scale (WLBCS)Gunel JamaladdinovaNo ratings yet

- FJS-727 SeriesManouversManualDocument9 pagesFJS-727 SeriesManouversManualDave91No ratings yet

- Lighting Layout Avinash 25janDocument1 pageLighting Layout Avinash 25janSai SrimanthNo ratings yet

- Rationale This Document Has Been Reaffirmed To Comply With The Sae 5-Year Review PolicyDocument3 pagesRationale This Document Has Been Reaffirmed To Comply With The Sae 5-Year Review Policyvinoth67% (3)

- RJTT Tokyo INTL PDFDocument108 pagesRJTT Tokyo INTL PDF張允執No ratings yet

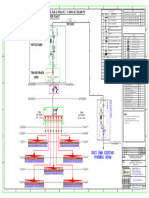

- Scraper Launcher at South Berri Wip For Details, See Plot PlanDocument1 pageScraper Launcher at South Berri Wip For Details, See Plot PlanMohamed HaleemNo ratings yet

- BGLR1207 DWGDocument1 pageBGLR1207 DWGMani CadNo ratings yet

- 3B-32-002 Pnid D-400-32-50-1010 - Rev - F1Document1 page3B-32-002 Pnid D-400-32-50-1010 - Rev - F1jk.jackycheokNo ratings yet

- Tribuna Sector Oriente: TUBERIA COLECTOR ADS N12 Ø 10" S 0.25% - 109 M TUBERIA COLECTOR ADS N12 Ø 10" S 0.25% - 109 MDocument4 pagesTribuna Sector Oriente: TUBERIA COLECTOR ADS N12 Ø 10" S 0.25% - 109 M TUBERIA COLECTOR ADS N12 Ø 10" S 0.25% - 109 MNicanor CarcaustoNo ratings yet

- Gift Map 022024Document1 pageGift Map 022024Rakesh T KanjniNo ratings yet

- Dhemaji District (Assam E-District Project) : CSC Name: Dhemaji, MADURI PATHARDocument1 pageDhemaji District (Assam E-District Project) : CSC Name: Dhemaji, MADURI PATHARkaminaladka72No ratings yet

- Issued For Construction: Continuation See Above Right Matchline Sta. 5+000 ForDocument1 pageIssued For Construction: Continuation See Above Right Matchline Sta. 5+000 ForMohamed HaleemNo ratings yet

- Guayas, Ecuador: Remodelacion Edificio Club Aerotecnicos FaeDocument1 pageGuayas, Ecuador: Remodelacion Edificio Club Aerotecnicos Faestalin vNo ratings yet

- Gate 4Document1 pageGate 4AMARNo ratings yet

- Foundation Details of Raft & Footing Details Key Plan: Scale - (NTS) Scale - (NTS)Document1 pageFoundation Details of Raft & Footing Details Key Plan: Scale - (NTS) Scale - (NTS)GUNJAN KUMBHARNo ratings yet

- Sector 76 Faridabad MapDocument1 pageSector 76 Faridabad MapVarun100% (1)

- Justos e SantosDocument1 pageJustos e SantosSxchutzs PankratzNo ratings yet

- SBXX Enrc-H1 Enrc 20181011Document1 pageSBXX Enrc-H1 Enrc 20181011edmarrodrigoNo ratings yet

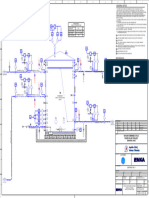

- Bepl BMR DWG El 410 SLD Rev00Document1 pageBepl BMR DWG El 410 SLD Rev00pavantirumala03No ratings yet

- Al-Ghanni Homes Rev3Document1 pageAl-Ghanni Homes Rev3Shahzaman SbNo ratings yet

- Cer ChasDocument1 pageCer ChasElvis Rodrigo Yana QuispeNo ratings yet

- Ugel Huancayo 2018Document1 pageUgel Huancayo 2018Alexander Julca ChavezNo ratings yet

- Especificaciones CVL Mobil - 160902Document1 pageEspecificaciones CVL Mobil - 160902Earlgrey 79No ratings yet

- G 104 Number Location1664004365260Document1 pageG 104 Number Location1664004365260Alaa Abo ShamaaNo ratings yet

- 0-8936-2 Golden Triangle Polymers Company LLCDocument1 page0-8936-2 Golden Triangle Polymers Company LLCLester MuscaNo ratings yet

- Detour ShiftDocument1 pageDetour ShiftinforumdocsNo ratings yet

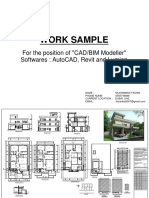

- Work Sample: For The Position of "Cad/Bim Modeller" Softwares: Autocad, Revit and LumionDocument26 pagesWork Sample: For The Position of "Cad/Bim Modeller" Softwares: Autocad, Revit and Lumionفیضان فیض حسینیNo ratings yet

- Plans For Engineer Quote DEC18Document10 pagesPlans For Engineer Quote DEC18Aziz H. AzizNo ratings yet

- FLR A9sn Ep 3810 PD Is 5605 08Document1 pageFLR A9sn Ep 3810 PD Is 5605 08Brandon C LoyolaNo ratings yet

- 24-FP Min Ad 24 Jan (2) - 240227 - 140231-1Document1 page24-FP Min Ad 24 Jan (2) - 240227 - 140231-1rzmajiahNo ratings yet

- General Notes:: 00ENB20BB001 Raw Co Storage TankDocument1 pageGeneral Notes:: 00ENB20BB001 Raw Co Storage Tankmustafa1989ocNo ratings yet

- E-200-Setting Out Plan Power LayoutDocument1 pageE-200-Setting Out Plan Power LayoutsadoonNo ratings yet

- Semw 2354 LP RF 001Document1 pageSemw 2354 LP RF 001zfrlNo ratings yet

- Produced by An Autodesk Student Version: Existing Repair & Maruti PointDocument1 pageProduced by An Autodesk Student Version: Existing Repair & Maruti PointAvinash SharmaNo ratings yet

- CJP (TYP.) : Sample TextDocument1 pageCJP (TYP.) : Sample TextGHULAM NABINo ratings yet

- Wh-1088pe DrawingDocument1 pageWh-1088pe Drawingom sai quality developmentNo ratings yet

- A13-L1e - Lower Ground - Part e (Finish Plan)Document1 pageA13-L1e - Lower Ground - Part e (Finish Plan)consultnadeem70No ratings yet

- A04-61 - Entrance PavillionDocument1 pageA04-61 - Entrance Pavillionconsultnadeem70No ratings yet

- Span Arrangementpackage-59 - P3L2 PDFDocument23 pagesSpan Arrangementpackage-59 - P3L2 PDFJ. Kumar Infraprojects LtdNo ratings yet

- Layout Current Drg-ModelDocument1 pageLayout Current Drg-ModelMuzzammil ShaikhNo ratings yet

- Residential AreaDocument1 pageResidential Areaits.nisshantNo ratings yet

- Irrigation Control Cable LayoutDocument4 pagesIrrigation Control Cable Layoutalivesince1091No ratings yet

- Chrysler Stratus 2.5 DohcDocument2 pagesChrysler Stratus 2.5 DohcErisvaldo Vital DA Silva100% (1)

- R02i16 Wsu XX ZZ DWG ST 33012 PDFDocument1 pageR02i16 Wsu XX ZZ DWG ST 33012 PDFSanjay LohodasanNo ratings yet

- No.20 - TBN Oil Piping 2of2Document1 pageNo.20 - TBN Oil Piping 2of2Adetunji Babatunde TaiwoNo ratings yet

- Nivel Acceso A-4Document1 pageNivel Acceso A-4Jesus Rafael Quijada AndradeNo ratings yet

- Issued For Construction: SandyDocument1 pageIssued For Construction: SandyMohamed HaleemNo ratings yet

- 250613DLDND2241 Exco00 01Document1 page250613DLDND2241 Exco00 01Mohammed HijaziNo ratings yet

- ODEC Ventilation Layout UKDocument1 pageODEC Ventilation Layout UKsondeepyadav4873No ratings yet

- FLR A9sn Ep 3810 PD Is 5605 03Document1 pageFLR A9sn Ep 3810 PD Is 5605 03Brandon C LoyolaNo ratings yet

- Podium Lev-2 (Amenity Floor)Document1 pagePodium Lev-2 (Amenity Floor)2059 ASHRAWI SHAIKHNo ratings yet

- Issued For Construction: Detail-1Document1 pageIssued For Construction: Detail-1Mohamed HaleemNo ratings yet

- MA2273Document3 pagesMA2273gagalunar789No ratings yet

- 3412 Shematic 4 PDFDocument2 pages3412 Shematic 4 PDFDmitry100% (2)

- QSC-PL1.8 Pwramp XtalDocument12 pagesQSC-PL1.8 Pwramp XtalAkhmad GuiNo ratings yet

- 24-01-2018 - MASTER PLAN - 19-04-2018-Model PDFDocument1 page24-01-2018 - MASTER PLAN - 19-04-2018-Model PDFTsukomaruNo ratings yet

- распределитель воздуха с лягушкамиDocument4 pagesраспределитель воздуха с лягушкамиИльнур СултановNo ratings yet

- Mig-17 Technical Description Manual-Part 1 PDFDocument56 pagesMig-17 Technical Description Manual-Part 1 PDFDave91No ratings yet

- Saab Gripen Handbook PDFDocument22 pagesSaab Gripen Handbook PDFJavi Moreno100% (2)

- MiG-29 v2.01 ChecklistsDocument7 pagesMiG-29 v2.01 ChecklistsDave91100% (1)

- Flight Rules and Procedures. It Establishes Employment Procedures For AFSOC AC-130H Aircraft and Aircrew. ItDocument26 pagesFlight Rules and Procedures. It Establishes Employment Procedures For AFSOC AC-130H Aircraft and Aircrew. ItDave91No ratings yet

- Joint Doctrine For Airspace Control in The Combat ZoneDocument93 pagesJoint Doctrine For Airspace Control in The Combat ZoneDave91No ratings yet

- What's New in Version: Custom 3D SoundDocument3 pagesWhat's New in Version: Custom 3D SoundDave91No ratings yet

- By Flightfactor and Steptosky For X-Plane 11.35+ (VR Compatable) Produced by VmaxDocument12 pagesBy Flightfactor and Steptosky For X-Plane 11.35+ (VR Compatable) Produced by VmaxDave91No ratings yet

- B757-767 Series: by Flightfactor and Steptosky For X-Plane 11.35+ (VR Compatable) Produced by VmaxDocument12 pagesB757-767 Series: by Flightfactor and Steptosky For X-Plane 11.35+ (VR Compatable) Produced by VmaxDave91No ratings yet

- B757-767 Series: by Flightfactor and Steptosky For X-Plane 11.35+ (VR Compatable) Produced by VmaxDocument12 pagesB757-767 Series: by Flightfactor and Steptosky For X-Plane 11.35+ (VR Compatable) Produced by VmaxDave91No ratings yet

- B757-767 Series: by Flightfactor and Steptosky For X-Plane 11.35+ Produced by VmaxDocument35 pagesB757-767 Series: by Flightfactor and Steptosky For X-Plane 11.35+ Produced by VmaxDave91No ratings yet

- FCOM FPDS AdditionDocument137 pagesFCOM FPDS AdditionDave91No ratings yet

- Bell 429 Throttle SetupDocument4 pagesBell 429 Throttle SetupDave91No ratings yet

- BMS Keystrokes - DefaultsDocument16 pagesBMS Keystrokes - DefaultsDave91No ratings yet

- FJS-727 SeriesManouversManualDocument9 pagesFJS-727 SeriesManouversManualDave91No ratings yet

- BMS Keystrokes - Old Vs NewDocument16 pagesBMS Keystrokes - Old Vs NewDave91No ratings yet

- Eries V Anual: For X-Plane Flight Simulator Flyjsim. All Rights ReservedDocument20 pagesEries V Anual: For X-Plane Flight Simulator Flyjsim. All Rights ReservedDave91No ratings yet

- Block Code/ Period Code Code Module Title Credits Exam CADocument9 pagesBlock Code/ Period Code Code Module Title Credits Exam CADublin City University, InternationalNo ratings yet

- The Latvian Is Cluster: Case of Industry - University CooperationDocument22 pagesThe Latvian Is Cluster: Case of Industry - University CooperationFARANo ratings yet

- Importance of Business Law For Business GraduatesDocument8 pagesImportance of Business Law For Business GraduatesAbdul AhadNo ratings yet

- Chapter 1Document4 pagesChapter 1aloktripathi19No ratings yet

- The Stony Brook Press - Volume 18, Issue 10Document20 pagesThe Stony Brook Press - Volume 18, Issue 10The Stony Brook PressNo ratings yet

- MST Call - Cover LetterDocument4 pagesMST Call - Cover LetterBryan RodgersNo ratings yet

- Business Communication - Study Material I MBADocument102 pagesBusiness Communication - Study Material I MBAPerumal DMNo ratings yet

- Recommendation Letter Ahsan IqbalDocument1 pageRecommendation Letter Ahsan IqbalAhsan IqbalNo ratings yet

- Sarav Preet Foods: DeclarationDocument9 pagesSarav Preet Foods: DeclarationCloxan India Pvt LtdNo ratings yet

- Mac 413Document216 pagesMac 413Thạch LêNo ratings yet

- Lesson Plan For Sonstitutional CompromiseDocument4 pagesLesson Plan For Sonstitutional CompromiseharcourtcNo ratings yet

- Newsletter May 2017 MinDocument119 pagesNewsletter May 2017 MinachuthathNo ratings yet

- Assignment On Prerogative MercyDocument17 pagesAssignment On Prerogative MercyMasudur Rahman RanaNo ratings yet

- Distributed Operating Systems: Unit - 2Document48 pagesDistributed Operating Systems: Unit - 2eyasuNo ratings yet

- The Motivation, Problems, and Perceived Success of Entrepreneurs in RomaniaDocument16 pagesThe Motivation, Problems, and Perceived Success of Entrepreneurs in RomaniaIrina AtudoreiNo ratings yet

- How Would You Like To Capture Your Past Memories? - Why Do People Write Diary? - Can You Name A Famous Book Which Is Actually ADocument8 pagesHow Would You Like To Capture Your Past Memories? - Why Do People Write Diary? - Can You Name A Famous Book Which Is Actually AAashi GuptaNo ratings yet

- India TourismDocument3 pagesIndia TourismPrakash ShekhawatNo ratings yet

- Civilizing The Native Educating The Nation 1Document22 pagesCivilizing The Native Educating The Nation 1rajesh dua50% (2)

- 21 Activity 3 Disruptive InnovationDocument4 pages21 Activity 3 Disruptive InnovationBright WritersNo ratings yet

- Top-Down Design With Autodesk® Inventor™ Using Skeletal ModelingDocument14 pagesTop-Down Design With Autodesk® Inventor™ Using Skeletal ModelingNOCHE3No ratings yet

- 6969-Aiga Dukate 2007 PDFDocument220 pages6969-Aiga Dukate 2007 PDFdarkaro_1039No ratings yet

- Kelompok 3 APBN Dan Peran PemerintahDocument34 pagesKelompok 3 APBN Dan Peran PemerintahYorda Satrio A WNo ratings yet

- Perdev q1wk2 Summative FP 1Document3 pagesPerdev q1wk2 Summative FP 1Khylie VaklaNo ratings yet

- Anti Corruption Notes.Document60 pagesAnti Corruption Notes.PrernaNo ratings yet

- Technician: Ojula David ThomasDocument4 pagesTechnician: Ojula David ThomasOjula davidNo ratings yet

- Chapter 1&2 Oral CommunicationDocument61 pagesChapter 1&2 Oral CommunicationKundan kumarNo ratings yet

- Booking Report 2-8-2021Document1 pageBooking Report 2-8-2021WCTV Digital TeamNo ratings yet

FJS-727 SeriesChecklistandProceduresManual

FJS-727 SeriesChecklistandProceduresManual

Uploaded by

Dave91Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FJS-727 SeriesChecklistandProceduresManual

FJS-727 SeriesChecklistandProceduresManual

Uploaded by

Dave91Copyright:

Available Formats

727 SERIES

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 1/67

727 SERIES

727

SERIES

CHECKLIST

AND

PROCEDURES

For

X-‐Plane

Flight

Simulator

version

10.11+

Copyright

©

2012

FlyJSim

LLC.

All

Rights

Reserved

NOT

TO

BE

USED

FOR

REAL

WORLD

OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 2/67

727 SERIES

NOTE:

This

aircraft

add-‐on

including

this

manual

are

only

for

use

in

X-‐Plane

®

10.10+

for

entertainment

and

enjoyment

purposes

only,

and

in

no

way

should

any

part

of

this

manual

or

product

be

used

for

real

world

navigation

or

operations

including

training.

For

real

world

operation

please

consult

the

official

Boeing

727

manuals.

Although

we

have

worked

hard

to

ensure

that

the

systems

modeled

are

as

accurate

as

possible,

any

operational

references

or

detail

are

only

for

operation

in

the

X-‐Plane

®

Flight

simulator.

This

simulation

may

not

be

used

in

any

public

display

for

which

users

are

charged

admission,

usage

fees

or

other

revenue

generating

charges.

Nor

may

the

simulation

be

used

in

any

manner

which

reflects

poorly

on

FlyJSim,

including

Jack

Skieczius

and

Joe

Vermeulen,

Armchair

Aviation,

Boeing,

or

customers

or

employees

of

the

aforementioned

entities.

LICENSE:

The

User

agrees

to

the

following

conditions

upon

purchase

and

download

and

installation:

1.

Not

to

distribute

any

part

of

the

product

including

this

manual,

scripts

or

support

files,

without

written

consent

of

the

author

(FlyJSim).

2.

To

copy

the

product

or

any

part

of

the

product

including

this

manual,

scripts

or

support

files

only

for

the

purpose

of

backing

up

said

product,

and

thence

only

to

re-‐install

the

product

onto

the

owner’s

personal

computer.

Users

will

be

required

to

make

their

own

back

up

copies.

The

author

and

distributor

will

not

be

liable

for

lost

files.

3. To install the aircraft on as many computers as the purchaser directly owns and controls.

4.

This

product

is

provided

“As

Is”,

and

copyright

holders

make

no

representation

or

warranties,

express

or

implied

with

regards

to

performance

on

your

computer,

any

possible

damage,

or

any

other

claim.

Further

copyright

holders

will

not

be

liable

for

any

direct,

indirect,

special

or

consequential

damages

arising

out

of

any

use

of

the

software

or

documentation.

5. This software product, manuals and support files are copyright © FlyJSim 2012. All rights reserved.

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 3/67

727 SERIES

727 SERIES NORMAL CHECKLIST

DO NOT USE FOR REAL WORLD FIGHT

BEFORE START

Cockpit Preparation Procedures..........COMPLETE

Antiskid.........................................................ON

Stall Warning.......................................CHECKED

Emergency Exit Lights.............................ARMED

Passenger Signs(If applicable)........................ON

Window Heat................................................ON

Anti-Ice.................................................CLOSED

Flight Instruments, Altimeters and

Flight directors...............SET AND X CHECKED

Compasses.......................SYNC AND X CHECKED

Radios, Radar, Transponder....SET AND STANDBY

Start Levers..........................................CUTOFF

Parking Brakes.............................................SET

Ruder and Aileron Trim...............FREE AND ZERO

Fuel................... LBS, SET FOR START

Hydraulics.................INTER CLOSED, PRESS AND

QTY NORMAL

Papers..............................................ON BOARD

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 4/67

727 SERIES

CLEARED FOR START

Beacon............................................................ON

Galley Power..................................................OFF

Packs............................................................OFF

Start Pressure........................................20+ PSI

Before Start Checklist........................COMPLETE

AFTER START

Ground Equipment................................CLEARED

Fuel.......................................SET FOR TAKEOFF

Doors..................................................CHECKED

After Start Checklist...........................COMPLETE

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 5/67

727 SERIES

BEFORE TAKEOFF

Anti Ice............................CLOSE/OPEN (As Rqd)

Pitot Heat.....................................................ON

Flight Instruments, FDS

and Radios.........................SET FOR DEPARTURE

Flight Controls.....................................CHECKED

Speedbrake............................CHECKED,DETENT

Stabilizer Trim.................................. UNITS

Flaps....................... , , GREEN LIGHT

Galley Power.................................................ON

Electrical................................NO LIGHTS, ESS 3

Fuel Heat......................................................OFF

Hydraulics....................PRESS AND QTY NORMAL

Elevator and Rudder Lights...........................OFF

APU...............................................................OFF

Flight/Ground Switch...............................FLIGHT

Air Cond and Press............ NO 2 BLEEDS CLOSED

SET FOR TO

Cockpit Door.........................................LOCKED

EPR and Airspeed Bugs........................BUGS SET

Take-off Briefing.............................COMPLETED

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 6/67

727 SERIES

CLEARED FOR TAKEOFF

Start Switches.......................................GUARDED

Transponder..........................................ON ALT

Landing Lights.............................................ON

Auto Pack Trip Switch.............NORMAL/CUTOUT

Before Takeoff Checklist....................COMPLETE

AFTER TAKEOFF

Start Switches.......................................GUARDED

Seat Belt..............................................OFF/ON

Anti Ice.........................................CLOSE/OPEN

Gear...............................................UP AND OFF

Flaps...........................................UP, NO LIGHTS

Auto Pack Trim Switch..........................CUTOUT

Hydraulics....................PRESS AND QTY NORMAL

Pressurization........................CHECKED AND SET

After Takeoff Checklist......................COMPLETE

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 7/67

727 SERIES

DESCENT- APPROACH

Seat Belt......................................................ON

Anti Ice.........................................CLOSE/OPEN

Landing Lights..............................................ON

Altimeters...........................SET AND X CHECKED

Radio Altimeter............................................SET

Flight Instruments, FDS

and Radios..........................SET AND X CHECKED

Go-Around EPR and Vref......................BUGS SET

Fuel.......................................SET FOR LANDING

Hydraulics........................PRESS & QTY NORMAL

Pressurization & Cooling Doors.....................SET

Descent-Approach Checklist...............COMPLETE

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 8/67

727 SERIES

LANDING

No Smoking....................................................ON

Gear...........................................DOWN, 3 GREEN

Flaps...................... , , GREEN LIGHT

Hydraulics........................PRESS & QTY NORMAL

Landing Checklist...............................COMPLETE

AFTER LANDING

Window Heat...............................................OFF

Anti Ice.................................................AS RQD

Pitot Heat...................................................OFF

Flaps...........................................UP, NO LIGHTS

Radar, Transponder.....................................OFF

Speed Break..........................................DETENT

Stabilizer Trim.................................ZERO UNITS

Galley Power...............................................OFF

Fuel...........................................1 PUMP/ENGINE

Hydraulics.....INTER OPEN, PRESS & QTY NORMAL

Flight/Ground Switch..............................GROUND

Air Conditioning...........................................SET

APU......................................................ON BUS

After Landing Checklist......................COMPLETE

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 9/67

727 SERIES

SHUTDOWN

Seat Belt.....................................................OFF

Beacon.......................................................OFF

Exterior Lights.......................................AS RQD

Start Levers..........................................CUTOFF

Parking Brakes.............................................SET

Electrical...................APU/EXTERNAL POWER ON

Fuel...........................................................OFF

Hydraulic B Pump Switches.....................ON/OFF

Air Cond...........4 BLEEDS OPEN, PACKS SET/OFF

Shutdown Checklist............................COMPLETE

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 10/67

727 SERIES

TERMINATING FLIGHT

Emergency Exit Lights..................................OFF

APU............................................................OFF

Battery.......................................................OFF

Shutdown Checklist............................COMPLETE

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 11/67

727 SERIES

Normal Procedures

General

The appropriate preflight procedures will be completed prior to

each flight. The required procedures are performed by recall

(Memory) and the checklists used to verify all items effecting

safety have been accomplished. The amplified procedures contain

detailed information for system checks and inspection

requirements.

Exterior Safety Inspection

This inspection is performed on each originating trip or crew change

before entering the airplane to ascertain that no obviously unsafe

conditions exist.

Wheel Chocks ... In Place

Landing Gear Doors ... Check

Flight Control Surfaces ... Clear

Ensure proper clearance of flight controls from all ground

equipment or other obstructions.

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 12/67

727 SERIES

Cockpit Safety Inspection

This inspection is performed on each originating trip or crew change

to ensure the airplane systems are configured so as to permit

electrical power to be safely applied to the airplane at the proper

time.

Flight Control Hydraulic Power Switches ... On guards closed

Alternate Flap Switches ... Off

Master Switch - Guard Closed and Safetied

Inboard and outboard switches - Off

Landing Gear Lever... Down

Radar ... Off

Transponder ... Off

Hydraulic System B Pump Switches ... Off

Air Conditioning Pack Switches ... Off

Fuel Dump Panel Cover ... Closed

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 13/67

727 SERIES

Preliminary Cockpit Preparation

All items on this inspection are to be accomplished on each

originating trip or crew change. Cockpit Systems, Controls and

Equipment are checked for operation, condition and availability and

the cockpit is configured for exterior inspection or engine start, as

appropriate.

Maintenance Status and Dispatch Deviations ... Check

Verify Maintenance status to ensure agreement with

authorized dispatch deviations

Circuit Breakers ... Check

Verify circuit breakers are in or collared in compliance with

dispatch requirements

External/APU Electrical Power ... Off

If electrical power is on the airplane, when conditions permit,

remove the electrical power until the Battery and Standby

Electrical System checks are completed. Prior to removing

power from the airplane check that the airplane is not being

fueled, the A/C packs are OFF, galley power is OFF and the B

Hydraulic pumps are OFF. If the airplane is being fueled, delay

the Battery and Standby Electrical System checks until after

fuelling is completed.

Battery Switch ... On

With AC electrical power removed from the airplane, check

the generator breaker lights and the essential power failure

warning lights illuminated. For through flight, check the

battery switch in the ON position, guard closed.

Battery...Check

DC Meters Selector - BAT

DC Meters - Check

Observe DC ammeter for negative indication and DC

Voltmeter reads at least 22.

NOT

TO

BE

USED

FOR

REAL

WORLD

OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 14/67

727 SERIES

Standby Electrical System ... Check

Essential Power Selector - Standby

Do not leave the switch in this position for more than 2

minutes without equipment cooling airflow.

DC Meters - Check

Observe DC Voltmeter indicates minimum of 22.

Instrument warning flag - Check

Observe a flag retract from view in either the captains

ADI, HSI or RMI.

Essential Power Selector - Any Engine Generator

External / APU Electrical Power…. Re Establish

APU Fire Warning System … Check (NOT SIMULATED)

APU Fire Switch - Push In

Automatic Fire Shutdown Switch - Armed Guard Closed

APU Fire warning test and reset switch - Test

Hold the switch in the test position (for not more than

60 seconds) until the APU fire warning light illuminates

and the fire warning bell rings.

APU fire warning test and reset switch - Reset

Fire warning bell silences. Observe the fire warning light

extinguish after a few seconds.

APU fire warning test and reset switch - reset again

APU(if required) … Start

AC Meters Selector – APU

Bus Tie Breaker switches – Closed

APU Field Switch - Closed

APU Master Switch - Start; release

Observe APU CRANK light illuminate, DC ammeter read

full scale negative, EGT shows a normal initial rise. After

a short delay observe the APU Crank light extinguish

followed by the DC Ammeter return to a normal

indication.

AC Meters - Check

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 15/67

727 SERIES

Observe the frequency stabilized

APU EGT- In Green Band

Electrical Power (APU or external) … on

AC Meters - Check applicable position.

Observe the frequency stabilized at 400+/-8 and

voltage stabilized at 115 +/-5.

APU (If desired) … ON

Close the APU Generator breaker switch and observe the

generator breaker light extinguish. Observe the voltage and

frequency are normal. Position the essential power selector to

APU and observe the essential power failure and master

WARN lights extinguished. Observe APU ammeter within

limit.

External Power (If desired) … ON (Not Simulated)

Observe the AC connected light illuminated and bus tie lights

extinguished. Position the external power selector to EXT

PWR and observe essential power failure and master warn

lights extinguished. Observe the APU ammeter within limit.

Pressurization system … Set

Mode selector - Auto

FLT/GRD switch - GRD

Air Conditioning (if required) … ON

Operate the APU for at least one minute before

switching the first A/C Pack switch to ON

APU EGT – In Green Band

Air Temperature indicator - Check

Rotate air temp selector to each position and observe

the approximate ambient temperature indications.

Air Temp Selector - Main Supply

Air mix valve position indicators – Full Cold

Cabin temperature Controls - Auto & Set

Duct overheat lights - Check

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 16/67

727 SERIES

Engine bleed air switches (4) - Open

Auto Pak Trip Armed light - Check

Pack TRIP OFF lights – Check

Duct Pressure – Normal for Source

Left and Right pack cooling doors posn indicators - Full Open

Cargo Heat Outflow switch – Normal

Left and right pack temperature indicators – Ambient

APU AMMETER - within limits for activating pack

If APU is power source observe maximum of 120 if

external power is power source observe maximum of

155.

Left pack switch – On

Observe apu ammeter within limit for power source.

Observe pack temperature, air mix valve position

indicator normal for conditions and main air temp

stabilizes below aprx 140f/60c. Repeat for right pack.

Gasper fan switch – As Desired

Cabin Air Distribution selector – As required

If rapid cabin temperature change is desired position

selector full up. Place in mid position to maintain

existing temperature.

Radio Master Switches … ON

Emergency exit lights … Check

Emergency exit light switch – On

Observe the emergency exit light above the cockpit

door illuminated

Emergency exit light switch - Off

Passenger signs … On

Window heat … Check

Window heat switches (4) – On

Observe all power on lights illuminated. If not all lights

illuminate position the test switch to power on test and

observe power on lights illuminated.

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 17/67

727 SERIES

Test switch - Overheat test

Observe overheat lights illuminated

Window heat switches - Off/ Reset

Observe all lights extinguish

Wing and engine anti ice systems … check

Duct Overheat light – Check

Duct Temperature indicator – check

Rotate duct temperature selector through all positions

observing approximate ambient temperature indication

in each position.

Duct Temperature selector – Engine 2

Engine inlet anti ice switches – Close

Valve Position light selector – L

Observe engine inlet valve position lights illuminated

Engine inlet anti ice switches – open

Observe engine inlet valve position lights extinguished

momentarily.

Valve Position light selector - Cowl

Observe all valve position lights remain illuminated

Valve position light selector – R

Observe all valve position lights remain illuminated

Wing anti ice stiches - Close

Valve position light selector - Wing

Observe engine inlet valve position lights extinguished

and the wing valve position lights illuminated.

Wing anti ice switches - Ground test

Observe wing valve position lights extinguished

momentarily.

Valve position selector – R

Observe wing valve position lights extinguished and

engine inlet valve position lights illuminated.

Engine inlet anti ice switches - close

Observe engine inlet valve position lights extinguished

momentarily

Valve position light selector – Cowl L

Observe all engine inlet valve position lights remain I

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 18/67

727 SERIES

illuminated in each position

Valve position light selector - off

Observe all engine inlet valve position lights

extinguished

Pitot static heat system … Check

Pitot static heat switches - On

Observe heater off light extinguish and increase in total

air temperature indication

Pitot static heat ammeter selector - All positions

Observe equal amperage readings in each position

except PROBE/AUX P where reading may be slightly

different

Pitot static heat switches - Off

Observe heater off light illuminate

Navigation, Wing illumination … On

Engine fire extinguisher system … Set

Engine fire switches - In

Bottle transfer switch - Left

Engine fire warning system - Check

Detector fault switches - AB

Detector Fault lights - Extinguished

Fire Test switch - TEST

Engine and wheel well fire warning and detector fault

lights- Illuminated

Fire alarm bell - Rings

Bell Cutout switch – Press (Not Simulated)

Fire warning bell silences. All fire warning lights and

detector fault remain illuminated.

Fire test Switch - Off

Fire warning lights – Extinguished

Forward engine instruments … Check

Observe indications consistent with conditions

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 19/67

727 SERIES

Landing Gear Annunciator lights … Check

Speed brake lever … Detent

Flap lever and indicators … Agree

Hydraulic brake pressure precharge … Check

Observing hydraulic brake pressure indicator,

repeatedly actuate brake pedals until pressure

indication stabilizes at approximately 1000

Parking brake … Set

Parking Brake warning light- Illuminated

Crew and Passenger oxygen pressure … Check

Passenger oxygen switch … Normal

Auto pack trip switch … Cutout

Zone temperature control indicator … Center

Overhead light … Check

Pressurization barometric setting … Set

Set departure airport barometric pressure

Strut and Lower aft body overheat … Check

Overheat detector test switch - Press

Overheat warning lights - Illuminated

Essential Power failure warning lights … check

Rotate essential power selector to any generator

position and observe essential power failure and master

warn lights illuminated. Rotate selector to original

position and observe lights extinguished.

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 20/67

727 SERIES

Galley power (if required) … On

APU Ammeter - Monitor

DC Meters … Check, On Ess Tr

DC Meters selector – Bat

DC Ammeter:

If external power source – Aprx 0

If APU power source - Aprx 0 or pulsing

DC Meters Selector - Ess TR, TR1, TR2

DC Voltmeter 24.5-29.0 in each position

DC Ammeter - Positive Amperage

DC Meters Selector - ESS TR

AC Electrical System … Checked, Set for start

Generator drive disconnect switch guards - Down

Generator drive low pressure lights - Illuminated

Generator drive oil temp switches - Rise

Generator drive oil temperature indicators - Normal range

Generator drive oil temperature switches - In

Generator drive oil temperature indicators – Ambient Temp

Bus tie breaker lights - Check

Field lights - Check

Kw/kvar meters – 0 kw

Fuel quantity indicators … Check

Fuel quantity indicator test switches- Press

Observe each tank quantity decrease and total quantity

indication increase and pointers return to original

position when test switch released.

Fuel system … check

Forward boost pump switches - On

Observe forward boost pump low pressure lights

extinguished and aft boost pump low pressure lights

illuminated

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 21/67

727 SERIES

Forward boost pump switches - Off

Observe forward boost pump low pressure lights

illuminated.

Repeat test procedures for aft boost pumps.

Engine 1 and engine 3 crossfuel selectors - Open; Close

Observe valve in transit light illuminate momentarily

Engine 2 crossfuel selector- Close; Open

Observe valve transit light illuminate momentarily.

Fuel shutoff switches - open

Fuel Heat System … Check

Fuel icing lights – Check

Fuel Heat Switches – On

Observe valve open lights illuminate

Fuel heat switches – Off

Valve open lights - Extinguished

Fuel Temperature Indicator … Check

Observe indicator displays appropriate temperature for

prevailing conditions.

Hydraulic Brake Interconnect … Check

Hydraulic brake Interconnect switch - Open; Close

Observe the hydraulic brake interconnect light

illuminated when the switch is open and

extinguished when close

Hydraulics system … Check

System A pump low pressure lights - On

System A pump switches – On

System A fluid shutoff switches - Open

System A overheat light - Extinguished

Ground Interconnect Switch - Closed

System A quantity indicator – Approximately 4.4

System B quantity indicator – ‘F’

System B overheat light- extinguished

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 22/67

727 SERIES

CAUTION: Obtain Ground Crew Clearance Before Activating Either

Pump.

NOTE: Normal system B hydraulic pressure is 2800-3100 PSI with

either pump on and system interconnect closed, or both pumps on

and interconnect open. System pressures under either condition

between 2400 and 2800 PSI are acceptable for flight through

normally scheduled revenue stops, to a maintenance base for

corrective action.

System B pump 1 switch - On

Observe pump 1 low pressure light extinguished, pump

2 low pressure light illuminated , and system B

hydraulic brake pressure indicators showing a minimum

of 2800psi.

System B pump 1 switch - Off

Observe pump 1 low pressure light illuminated and

pressure indication decreasing, Hydraulic brake

pressure remains steady.

System B pump 2 switch – On

Observe pump 2 low pressure light extinguished, pump

1 low pressure light illuminated and pressure indicating

a minimum of 2800psi.

Ground interconnect switch - Open

System B pump switches - Both on

System B pressure indicator- minimum 2800psi

A system pressure indicator - Check

Note: System A pressure may be 100 PSI lower than system B

System A and B quantity indicators – Remain normal

System A pump low pressure lights - Illuminated

System B overheat light - Extinguished

Flight controls low pressure annunciator Lights - Extinguished

Standby System Quantity indicator – F

Standby system overheat light - Extinguished

System A rudder switch- Off

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 23/67

727 SERIES

Standby rudder switch – On

Observe rudder system A low pressure annunciator and

standby system on lights illuminated, standby system

overheat light remains extinguished, and standby

system quantity remains normal.

Standby A rudder switch - On

Standby rudder switch - Off

Observe rudder system A low pressure annunciator

light extinguish followed by the standby system On

light after a short delay.

CSD Cooler switch … Normal

No Equip Cooling Light … Extinguished

Oxygen … On, 100%

Oxygen lever - 100%

Pneumatic brake pressure … Normal

Observe 1100-1400 lbs pressure

Door Warning Annunciators … Check

Engine instruments … Check

Oil Pressure - Zero

Oil temperature - Normal

Oil Quantity Indicators – Check

Test Switch - Press

Observe quantity indicators decrease. On release

observe indicators return to original position

Oil Quantity - Minimum for dispatch

Clock … Wind and Set (Knob Changes X-Planes system time)

Panel lights … Set

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 24/67

727 SERIES

Pressurization system … Check

Mode selector - Man AC

Observe AUTO FAIL and STANDBY lights extinguished

and MANUAL light illuminated. Hold Outflow valve

manual control switch to CLOSE then OPEN and

observe outflow valve pointer move left then right.

Mode Selector - Man DC

Repeat previous Steps

Mode Selector - Auto

Manual light- Extinguished

Pressurization system … Set

Mode Selector - Auto

Flight/Ground switch - GRD

Outflow valve - Full open (right)

All indicator lights - extinguished

Cabin Alt - Set

Set to value indicated by cabin flight altitude placard

Cabin rate selector - at index

LAND ALT - Set destination airport elevation

FLT ALT - Set flight planned cruise altitude

Cabin rate of climb - zero

Cabin pressure differential - Zero

Cabin Altitude - Field Elevation

Pneumatics … Check and set

Engine Bleed Air Switches – Open

Engine bleed air TRIP OFF lights - check

Engine no 2 High Temp light - Check

Duct Pressure - Normal

Air Conditioning … Check and Set

If Pack(s) are off:

Air Temperature Indicator - Check

Rotate air temp selector to each position and observe

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 25/67

727 SERIES

approximately ambient temperature indication

Air tem Selector - Main Supply

Air Mix Valve indicators - Full cold

Cabin temperature Controls - Auto and Set

Duct overheat lights - Check

Auto Pack trip Armed light - Check

Pack Trip Off lights - Check

Left and right pack cooling door position indicator - Full Open

Cargo heat outflow switch - Normal

Left and right pack temperature indictors - Ambient

Gasper Fan Switch - As desired

Fuel Dump Panel Lights …. Check (Not Simulated)

Leading edge devices position annunciators … Check

Test Switch- Light Test

Observe all leading edge devices light illuminated.

Test Switch - Position Test

Check for Proper position light indicator

Electrical fault annunciators … Check

Test Switch - Press

Observe all lights illuminated

Passenger oxygen system actuation handle … off

Cabin Air distribution lever… set

For rapid cabin heating or cooling select position 10.

Prior to passenger loading select position 4 or 5

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 26/67

727 SERIES

Prior to Before Start Checklist

Airplane Loading … Check via Weight and Balance Manger

Fuel - Check

Observe fuel quantity to agree with flight planned fuel

and distributed properly

Gross weight - Check

Observe the airplane gross weight to agree with flight

plan weight

Center of Gravity - Check

Observe airplane CG to be within limits.

Fuel System … Set for Start

Boost pump switches - One on Each Main Tank

Main Tanks Loaded Equally:

Cross feed selectors… No 2 open No 1/3 Closed.

No 2 main tank fuel greater than main tanks 1 or 3:

Cross feed selectors… All Open

Hydraulic Pressure and Quantities … Normal

Ground Interconnect Switch … Close

Hydraulic A pressure - Decreases

System B pump switch - One Off

Pump no 1 or 2 may be turned off. Observe system B

brake pressure – Normal

Elev feel diff press light and system A flight controls low pressure

annunciators - Illuminated

If flaps are up:

Rudder Load limiter light - Illuminated.

Pressurization Barometric Indicator… Check

Observe field pressure corrected to sea level QNH set

in barometric pressure indicator.

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 27/67

727 SERIES

Takeoff Data Card … Review

Windows … Check

Ensure that window opens and closes properly and are

clear and undamaged

Anti Skid Switches … Check, On

Anti Skid System … Check , On

Ensure airplane is chocked.

Parking brakes - Release

Main gear and nose gear anti skid switch guards - Closed

Main gear anti skid indicators - Blank

Nose gear anti skid indicator- Rel

Test Swtich - IMBD AND NOSE

Observe the IMBD and nose indicators BLANK, OUTBD

Indictors REL.

Test Switch - OTBD AND NOSE

Observe OUTBD and nose indicators BLANK, INBD

indicators REL

Stall Warning … Check

Observe off light extinguish, indictor rotating.

Emergency exit Lights … ARMED

Panel lights … Check

Exterior Lights … Check

Engine fail light … Extinguished

Instrument panels … Secured

Pneumatic brake Lever … Off and Safetied

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 28/67

727 SERIES

APD lights … Check

Flight instruments … Check

Yaw Damper Switches … ON

Yaw dampers … Check (Not fully simulated)

Ensure hydraulic Systems A and B are pressurized

Upper and lower rudder Y/D flags- Retracted

Test Switch – Lower (HOLD)

Observe lower indicator deflect right and return to

center.

Test switch – Release

Observe lower indicator deflect left and return to

center.

Test switch - Upper (Hold)

Observe upper indicator deflect left and return to

center

Test Switch - Release

Observe upper indicator deflect right and return to

center.

Passenger signs … On

Window heat … On

Total Air temperature indicator … Check

Altitude Alert … Set

Standby horizon … Check

Flap Position indicators … Check

Engine low oil pressure lights … Check

Radios, Flight Instruments, flight director … Set for Departure.

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 29/67

727 SERIES

Autopilot - Confirm disengaged

Mode Selector - As desired

Altitude Hold switch - Off

Pitch Command Control - Climb Attitude

Course selectors - As desired

Heading selector - Set runway heading

Departure VHF Frequency - Set

HIS Nav Warning Flag - Retracted

Observe correct station identification and RMI pointers

for proper bearing

Transponder … Set and standby

Radar … Standby

Engine Controls … Set for start

Reverse thrust levers full down, thrust levers closed,

start levers cutoff.

Parking Brake … Set

Stabilizer trim … Check and set for takeoff

Rudder Trim … Free and zero

Aileron Trim … Free and zero

Stabilizer brake release … Disengaged

Documents … Onboard

V2 and Takeoff EPR bugs … SET

Takeoff information … Check

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 30/67

727 SERIES

When cleared for Engine Start

Galley Power Switches … Off

Pack Switches … Off

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 31/67

727 SERIES

Amplified Before Start Checklist

When all appropriate preflight procedures are completed, the

captain will call for the Before Start checklist. The first officer will

read aloud each challenge and receive the appropriate response

from the designated crew member.

Cockpit Preparation Procedures..........COMPLETE

Antiskid..................................................ARMED

Stall Warning.......................................CHECKED

Emergency Exit Lights.............................ARMED

Passenger Signs(If applicable)........................ON

Window Heat................................................ON

Anti-Ice.................................................CLOSED

Verify all anti ice switches are positioned to closed

Flight Instruments, Altimeters and

Flight directors...............SET AND X CHECKED

Verify altimeters are set and cross checked, appropriate ADI and

HIS warning flags retracted, cross check HIS and RIM headings and

verify ADI set for takeoff

Compasses.......................SYNC AND X CHECKED

Verify all compass systems have been checked and are

synchronized

Radios, Radar, Transponder....SET AND STANDBY

Check radios set as desired for departure and observe radar and

transponder are set to standby

Start Levers..........................................CUTOFF

NOT

TO

BE

USED

FOR

REAL

WORLD

OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 32/67

727 SERIES

Parking Brakes.............................................SET

Ruder and Aileron Trim...............FREE AND ZERO

Fuel................... LBS, SET FOR START

Report total fuel on board; verify one fuel boost pump on in each

main tank. Verify cross feed selectors set according to fuel load

Hydraulics.................INTER CLOSED, PRESS AND

QTY NORMAL

Check ground interconnect switch Closed and all pressures and

quantities normal.

Papers..............................................ON BOARD

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 33/67

727 SERIES

CLEARED FOR START

After clearance for engine star has been received, the captain will

position the beacon switch to ON and the flight engineer will

position the galley power switch and both pack switches to off,

then verify the pneumatic duct pressure is within limits for engine

start (20 PSI). When directed the first officer will continue reading

the checklist.

Beacon...........................................................ON

Galley Power..................................................OFF

Packs............................................................OFF

Start Pressure........................................20+ PSI

Before Start Checklist........................COMPLETE

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 34/67

727 SERIES

Engine Start Procedure

To successfully start the engines the following procedure should be

used.

1. Normal starting procedure is to start engine 3 (Right) followed

by 2 and 1 (Center and Left).

2. To begin start, ensure all bleed air switches are open and all AC

Packs are off. Once Bleed air pressure is above 20PSI you can

continue with the procedure.

3. On the overhead panel open the guard over the ignition switch.

Click the switch once to commence engine start.

4. Monitor the engine instruments to ensure proper engine start.

You will be looking for the N2 Gauge to show between 17-

20%N2 and for the N1 Gauge to show N1 slowly increasing.

(You will probably have to look at the little needle in the gauge

to detect this motion since the large needle will not move

much.)

5. Once you reach the N2 and N1 values required, introduce fuel by

raising the lever at the aft end of the throttle section above the

Autopilot for the specific engine.

6. Continue to monitor the engine instruments to ensure that the

engine does not overheat.

7. Engine start procedure is complete when the low oil pressure

light extinguishes on the forward panel and the starter engaged

light extinguishes on the flight engineers panel.

8. Replace the guard on the ignition switch and carry out this

procedure for the other two engines.

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 35/67

727 SERIES

After Start Procedure

After the engines have been started and have stabilized, the

following tasks are performed to configure the airplane for taxing.

Electrical power… Transfer

If APU power source:

AC Meters selector - Gen 1, Gen 2, Gen 3

Verify voltage and frequency normal for each

generator.

No.1 generator breaker - Close

Observe no1 generator breaker light extinguished, the

APU generator breaker light illuminated.

No.2 Generator breaker - Close

Observe generator breaker light extinguished.

No.3 Generator breaker - Close

Observe generator breaker light extinguished.

Essential power selector - Gen1, Gen2, Gen3

Rotate the selector to each generator position and

observe essential power failure warning light

extinguished in each position. Leave in gen 3

If External Power is Power source: (Not Simulated)

AC Meters selector - Gen3, Gen 2, Gen 1

Verify voltage and frequency normal for each

generator.

Essential power selector - Gen 3

Observe essential power failure warning light

extinguished.

No 1 Generator breaker - CLOSE

Observe generator breaker light extinguished, external

power switch trip to OFF

No2 Generator breaker - Close

Observe generator breaker light extinguished.

Essential power selector - Gen 2, Gen 1

Rotate the selector to each generator position and

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 36/67

727 SERIES

observe the essential power failure warning light

extinguished in each position.

No 3 generator breaker - Close

Observe generator breaker light extinguished.

AC meters selector- Gen 3

Essential power selector- Gen 3

Ready for disconnect- announce

Galley power switches … ON

Fuel System … Set for Takeoff

All remaining main tank fuel boost pump switches - On

All low pressure lights - Extinguished

Hydraulic System A … Check

Hydraulic system A pump 1 switch … Off

Check that system A pressure indicates 2800-3100 psi

at idle thrust.

Hydraulic A pump 2 switch … Off

Check that A system pressure decreases

Hydraulic system A pump 1 switch … On

Check that system A pressure increases to 2800-3100

psi at idle thrust.

Hydraulic system A pump no 2 switch … On

Ground equipment … Disconnect

Doors … Check

Taxi Clearance … Obtain

Ground Equipment … Clear

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 37/67

727 SERIES

Amplified After Start Checklist

Prior to taxi and on the captains command the first officer will read

aloud each challenge and receive the appropriate response from the

designated crewmember.

Ground Equipment................................CLEARED

Fuel.......................................SET FOR TAKEOFF

Verify all main tank fuel boost pump switches are ON and low pressure

lights are extinguished. If tank quantities are equal verify system is tank

to engine configuration. If No2 tank quantity is greater verify all cross

feeds open.

Doors..................................................CHECKED

Verify all lights on the door annunciator panel except APU are

extinguished.

After Start Checklist...........................COMPLETE

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 38/67

727 SERIES

Taxi Out Procedure

Each crewmember may accomplish such action items in this procedure as

time and conditions permit prior to airplane movement.

Parking Brake … Release

Taxi … Begin

Flap Lever … Takeoff Setting

Observe green LE flaps light illuminated and both outbd and

inbd flap position indicators display takeoff setting.

Exterior lighting … Set

Outboard and inboard landing lights, taxi, runway turnoff

lights- as required

Wing anti ice switches … Check Close

Engine inlet anti ice switches … Close/Open

When icing conditions exist or are anticipated, position the

engine inlet anti ice switches to OPEN and verify the position

of the anti ice valves by accomplishing the appropriate steps

in the system check. When engine anti ice is not required,

observe all anti ice switches positioned to close, and valve

position light selector OFF.

Pitot Static Heat switches … On

Nav Instruments … Check

Observe HIS and RMI agree and reflect changes in airplane

heading.

Speedbrake/Flap Warning … Check (Not simulated)

Flight control warning test switch - Safety relay bypass

Speedbrake lever - Out of detent

Observe warning horn sound intermittently.

Speedbrake lever - Detent

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 39/67

727 SERIES

Observe warning horn silence

Flight control warning test switch - Release

Stabilizer trim … Set for takeoff

Flight controls … Check for freedom of movement

Engine operation … Check indicators normal lights extinguished

Fuel heat … As required

During taxi out if fuel temperature is 0 deg or below or any

fuel icing light illuminates.

Fuel heat switches … On

After one minute

Fuel heat switches … Off

Hydraulic systems … Set for flight

Other hydraulic system B pump switch - On

Pressure and quantities – Normal

Observe systems A and B overheat lights extinguished.

Elev feel diff press and rudder load limiter lights … Extinguished

No equip cooling light … Extinguished

Pneumatic system … Set for flight

Engine 2/ Apu Bleed air switches – Close

Left AC Pack switch… On

Right AC pack switch … ON

Pressurization system … Set for flight

Flight ground switch - FLT

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 40/67

727 SERIES

Observe outflow valve move toward close, cabin rate of climb

indicator deflect down momentarily and differential pressure

increase to approximately 01. Psi.

APU Master Switch … Off

Operate the APU a minimum of one minute with no pneumatic

load before positioning the APU Master switch to OFF. The

one-minute cooling period begins at starter cutout on the

last engine started. Observe EGT decrease, generator circuit

open light and apu annunciator light extinguished.

Prepare for takeoff announcement … Complete

Takeoff briefing … Conduct

When lining up on the runway:

Landing lights… On

Transponder… TA/RA

CSD Oil Cooler… OFF

Auto Pack Trip System… Normal

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 41/67

727 SERIES

Amplified Before Takeoff Checklist

When commanded by the pilot flying the airplane the flight engineer

with accomplish the following checklist items, announcing and

receiving the appropriate response for the items accomplished by

captain and first officer and reading and responding in a normal

voice those items accomplished by himself.

Anti Ice............................CLOSE/OPEN (As Rqd)

Verify engine anti ice switches are positioned as required, and

respond with the switch position.

Pitot Heat.....................................................ON

Flight Instruments, FDS

and Radios.....................SET FOR DEPARTURE

Flight Controls.....................................CHECKED

Speedbrake............................................ DETENT

Verify Speedbrake lever is in the detent position

Stabilizer Trim.................................. UNITS

Verify the stabilizer trim is set to agree with the takeoff data card

and respond with the indicated position.

Flaps....................... , , GREEN LIGHT

Verify the flap lever is positioned to agree with the takeoff data

card, both flap position indicators indicate flap setting as selected

and the green LE FLAPS light is illuminated.

Galley Power................................................ON

Electrical................................NO LIGHTS, ESS 3

Verify all lights on the electrical panel are extinguished and the

essential power selector is positioned to GEN3.

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 42/67

727 SERIES

Fuel Heat....................................................OFF

Hydraulics....................PRESS AND QTY NORMAL

Verify all pressures and quantities are normal

Elevator and Rudder Lights...........................OFF

Verify the ELEV FEEL DIF PRESS and RUDDER LOAD LIMITED lights

are extinguished

APU Annunciator..........................EXTINGUISHED

Flight/Ground Switch...............................FLIGHT

Air Cond and Press..... NO 2 BLEEDS CLOSED SET

FOR TO

Verify the L and R engine 2 APU Bleed air switches are positioned

closed, the flight alt and land alt are set, the cabin is pressurized

for takeoff.

EPR and Airspeed Bugs........................BUGS SET

Verify the airspeed index markers and the EPR counters and cursors

are set to the takeoff data card values.

Take-off Briefing.............................COMPLETED

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 43/67

727 SERIES

CLEARED FOR TAKEOFF

Complete the checklist as the following items are configured for

takeoff:

Start Switches....................................................GUARDED

Transponder..........................................................ON ALT

Landing Lights.............................................................ON

.

Auto Pack Trip Switch..........................NORMAL/CUTOUT

When takeoff performance is based on use of the Auto Pack Trip

system, place the switch to Normal. The normal position may be

used on all takeoffs to activate the engine fail lights and assist in

engine failure recognition

Before Takeoff Checklist...................................COMPLETE

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 44/67

727 SERIES

Amplified After Takeoff Checklist

When commanded by the Captain, The flight engineer will read

silently each challenge and verify that the appropriate action has

been accomplished. If any action has not been accomplished, he will

read aloud the challenge to the designated crew member and after

the action has been completed, receive the correct response. After

all actions have been completed and verified the flight engineer will

announce to the Captain: “After Takeoff Checklist Complete”

Seat Belt..............................................OFF/ON

Verify switches are OFF if conditions permit.

Anti Ice.........................................CLOSE/OPEN

Verify anti ice valves are positioned as required for conditions.

Gear...............................................UP AND OFF

Verify the landing gear indicates up and locked, tailskid retracted,

and the landing gear lever is positioned off

Flaps...........................................UP, NO LIGHTS

Verify the flaps are fully retracted and the green and amber le flaps

lights are extinguished

Auto Pack Trim Switch..........................CUTOUT

Hydraulics....................PRESS AND QTY NORMAL

Pressurization........................CHECKED AND SET

Verify the flt alt and cab alt are set to agree with the cruise

altitude, the cabin rate of climb is normal and the cabin pressure

differential is increasing.

After Takeoff Checklist......................COMPLETE

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 45/67

727 SERIES

Climb Procedures

Autopilot (If desired) … Engage

Radios … Set for navigation

VHF nav radios - Frequency tuned, flags retracted

Verify correct station identification and set course

cursor/counter as desired.

Autopilot (If desired) … Set for Navigation

With Autopilot engaged, position heading select switch

to HDG SEL, select desired heading, rotate mode

selector to NAV LOC and observe A/P VOR/LOC light

on approach progress display illuminate amber. Observe

the airplane turn to the selected heading and the A/P

VOR/LOC light illuminate green when radial is captured.

Observe airplane track the radial.

Flight Director (if desired) … Set for Navigation

Move Mode Selector from HDG to V/L. Observe the

APD F/D annunciator illuminate amber and roll

command bar follow selected heading. When radial is

captured, observe the roll command bar direct a bank

to track radial and the F/D annunciator illuminates

green.

Climb thrust … Set and monitor

Verify climb EPR as set agrees with the quick reference

data f or existing temperature and altitude.

Landing lights … Off

Inboard landing lights should be turned off when

passing through FL100.

Cooling doors … Adjust

Check the pack temperature indicators. If the

temperature is below 40 degrees C move the cooling

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 46/67

727 SERIES

doors towards close, continue closing the doors in

increments until the temperature reaches 40 degrees c

or the doors are fully closed, whichever occurs first.

Fuel usage ... Monitor

Altimeters … Set and Cross Checked

At transition altitude each pilot set altimeters to

1013MB/29.92 HG and crosscheck. F/E changes

pressurization barometric pressure to same value.

Operating systems … Monitor

Monitor following operating systems periodically as

flight conditions permit.

Crew and Passenger oxygen - Check normal

Aft cabin zone air supply overheat light - Check extinguished

Pressurization barometric pressure - Check

Engine no 1 and no 3 strut and body overheat lights - Check

extinguished

Generator voltage and frequency - Check Normal

Essential Power - Operating Generator

Observe essential power failure warning light

extinguished

Galley power switch - Check on

DC electrical system - Check normal

Rotate DC meters selector to ess tr, tr1 and tr2

positions observing DC volts of 24.5-29.- and positive

DC amp indication.

CSD units - Check normal

Observe all low-pressure lights extinguished. Position

generator drive switches to RISE and IN and observe

normal temperatures in each position.

All Generators - Check parallel

Observe all bustie breaker lights extinguished.

Generator power loads -Check Normal and within limits

Fuel usage - Check normal

Verify fuel quantity indicators are operative and fuel

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 47/67

727 SERIES

load is balanced within limits. Verify fuel is being

supplied under pressure to all engines.

Fuel heat system - Check normal

Observe all valve open lights extinguished and fuel heat

switches off.

Fuel tank temperature - Check Normal

Observe fuel temperatures at least 3 degrees c above

the freezing point of the fuel being used.

Hydraulic systems pressure and quantities - Check normal

Equipment cooling airflow - Check normal

Observe the NO EQUIP COOLING light extinguished.

Elevator feel differential pressure - Check normal

Observe elev feel diff pess light extinguished.

Rudder load limiter - Check normal

Observe RUDDER LOAD LIMITER light extinguished.

Door annunciator panel indications - Check Normal

Observe lights extinguished.

Clock - Check

Engine instruments – Check Within limits

Observe oil pressure and temperature within green

band and oil quantity not decreasing at a rate of

greater than .25 gallons per hour per engine.

Pressurization system - Check Normal

Observe cabin rate of climb normal, cabin altitude

changing to that consistent with FLT ALT set and cabin

differential pressure increasing. Observe AUTO FAIL and

OFF SCHED DESCENT lights extinguished.

Air conditioning system - Check normal

Rotate air temperature selector to AFT CABIN, FWD

CABIN and return to MAIN SUPPLY observing air

temperature indication in normal range in each position

and observe all lights extinguished. Observe gasper fan

switch as desired and cabin air distribution selector

between 1 and 4

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 48/67

727 SERIES

Cruise Procedure

Cruise thrust … Set

Autopilot (if desired) … SET FOR VOR/GPS NAVIGATION

Altitude hold - ON

Flight Director (If desired)… Set for VOR/GPS NAVIGATION

Altitude Hold - ON

Pressurization … Set

Observe Cabin Altitude in agreement with altitude

setting on cabin altitude selector, cabin rate of climb

stabilized on zero and cabin differential pressure

normal.

Fuel Usage … Monitor

Observe decrease in fuel quantity consistent with total

fuel flow and time.

Operating systems … Monitor

Continue monitoring operating systems for normal

indications

Fuel Temperature … Check

Observe Fuel Temperature to be at least 3 degrees

above the freezing point of the fuel being used.

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 49/67

727 SERIES

Descent Approach procedure

Standby pressurization … Set

Set CAB ALT 200 ft below destination airport

elevation. Observe standby cabin rate selector at the

index mark. Adjust thrust levers or close the cargo

heat outflow valve as necessary to maintain the desired

rate of change or altitude.

Descent … Initiate

Pack Cooling doors … Full Open

Fasten Seat Belts Switch … ON

Airplane gross weight and fuel load … Check (W+B Manager)

Wing and engine anti ice switches (as required) … Close/Open

Landing Lights … On

For collision avoidance turn on the inboard landing

lights when descending through Fl100.

Altimeters … Set and Cross Check

When descending through transition altitude each pilot

set current altimeter setting and cross check

instruments. F/E set pressurization barometric

pressure indicator to destination airport altimeter

setting (QNH)

Radio Altimeter … Set

Set MDA cursor at MDA altitude.

Autopilot(if desired) … Set for descent

Position mode selector to turn knob or NAV LOC as

desired and set heading cursor to desired heading.

Heading select switch may be engaged if desired (in

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 50/67

727 SERIES

Turn Knob mode) observe airplane track selected

heading or radial. Pitch control may be maintained by

adjusting the vertical speed control for desired descent

rate.

Flight director(If required) … Set for descent

Position mode selector to heading or V/L and altitude

hold switch OFF. Set heading cursor to desired heading.

Adjust pitch command control for desired descent

attitude. Observe ADI command bars direct flight on

selected heading or radial and pitch angle.

Landing data card … Complete/Reviewed

For flaps 30 landing increase VREF by 4 knots to obtain

bug speed

Go Around EPR and Vref … Bugs Set

Fuel systems … Set for landing

Position all main tank fuel boost pump switches ON and

observe all low pressure lights extinguished; with tanks

1,2 and 3 quantities equal set tank to engine

configuration. With tank 2 quantity greater than tank 1

or 3 position all cross-feed selectors open. Position fuel

heat switches OFF. Observe wing fuel balanced within

limits. If any tank contains 1000lbs or less establish

fuel system minimum fuel operating procedures.

Hydraulic systems … Pressure and quantities normal

ADF radios … Set for approach

VHF Nav radios … Set for approach

Course cursors/counters- Localizer course (Inbound

front course)

Autopilot … Set for Approach

NOT TO BE USED FOR REAL WORLD OPERATIONS

Copyright © 2012 FlyJSim LLC. All Rights Reserved 51/67

727 SERIES

With heading cursor on airplane heading place mode

selector to MAN and HDG SEL ON. Observe airplane

track selected heading.

Flight director… set

Mode selector - HDG

Observe command bars track selected heading

Flaps … Extend