Professional Documents

Culture Documents

Specification For Low or Medium Voltage, High Resistance Type Grounding Resistors

Specification For Low or Medium Voltage, High Resistance Type Grounding Resistors

Uploaded by

Ichsan Rosidin0 ratings0% found this document useful (0 votes)

8 views1 pageThis document specifies requirements for low or medium voltage, high resistance type grounding resistors. It outlines that resistors must be made of stainless steel or nickel chromium and mounted rigidly. Enclosures must be made of galvanized steel for indoor use and structural steel for outdoor use, with stainless steel hardware. Terminals and connections must also be stainless steel. The document provides details on enclosure construction and covers based on voltage level to protect resistors from weather.

Original Description:

Original Title

NG201-07LowOrMediumVoltage_HRG

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document specifies requirements for low or medium voltage, high resistance type grounding resistors. It outlines that resistors must be made of stainless steel or nickel chromium and mounted rigidly. Enclosures must be made of galvanized steel for indoor use and structural steel for outdoor use, with stainless steel hardware. Terminals and connections must also be stainless steel. The document provides details on enclosure construction and covers based on voltage level to protect resistors from weather.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

0 ratings0% found this document useful (0 votes)

8 views1 pageSpecification For Low or Medium Voltage, High Resistance Type Grounding Resistors

Specification For Low or Medium Voltage, High Resistance Type Grounding Resistors

Uploaded by

Ichsan RosidinThis document specifies requirements for low or medium voltage, high resistance type grounding resistors. It outlines that resistors must be made of stainless steel or nickel chromium and mounted rigidly. Enclosures must be made of galvanized steel for indoor use and structural steel for outdoor use, with stainless steel hardware. Terminals and connections must also be stainless steel. The document provides details on enclosure construction and covers based on voltage level to protect resistors from weather.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

Download as doc, pdf, or txt

You are on page 1of 1

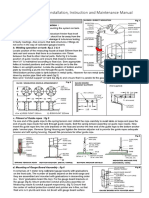

Specification for Low or Medium

Voltage, High Resistance Type

Grounding Resistors Enclosures

Scope Low Voltage (600 volts or less)

Enclosure shall be of heavy gauge Galvanneal cold rolled steel

This specification covers design, manufacture and testing of low- with baked enamel finish. All mounting hardware shall be

or medium-voltage, high-resistance type Neutral Grounding stainless steel.

Resistors (NGR) for installation indoors and outdoors onto a

Indoor enclosure shall have a screened cover with maximum

concrete pad or power transformer.

openings of 1/2".

Applicable Standards Outdoor enclosure shall have a solid heavy gauge top cover,

slightly overhung to prevent ingress of rain or sleet.

The NGR shall be designed, manufactured and tested as per the

latest revisions of IEEE-32. CSA Approved Low Voltage

Separate external terminal junction boxes shall be provided for

Resistors termination of the neutral conductor and the ground conductor.

All of the other requirements outlined above shall be met.

The resistive elements shall be low temperature coefficient,

resistor grade stainless steel or nickel chromium rigidly supported Medium Voltage (above 600 volts to 5,000 volts)

at each end to allow for expansion due to heating. The frame of the enclosure shall be made from structural steel

angles made from heavy gauge steel, welded together, or bolted

The resistors shall be mounted in corrosion resistant support together with stainless-steel hardware. The top of the enclosure

frames, using stainless-steel hardware. shall be solid, slightly overhung and sloped. It shall be embossed

with stiffening ribs. The enclosure shall have forged eyebolts in

For low voltage, continuous rated above 10 amp, and all medium

each corner for lifting purposes.

voltage applications, the entire resistor frame shall be mounted on

insulators rated for the system voltage. The bottom of the enclosure shall be screened with expanded or

perforated metal with openings of 1/2" or less. This screening

All resistor terminals and interconnections between units shall be

shall be welded or bolted in and is not removable. It shall be

stainless-steel, using stainless-steel hardware including lock

elevated 4 to 6 inches above the base of the unit.

washers. High current connections shall be spot or TIG welded as

appropriate. Bolt-on side covers on all four sides shall be used. Screened

covers may be furnished for certain applications. Stainless-steel

Connections between resistors and bushings or current

hardware shall be used. Louvered or screened openings shall not

transformers shall be solid copper or stainless steel bus or copper

exceed 1/2".

cables.

A durable nameplate, permanently attached to one side cover

shall show the manufacturer and the complete rating.

Painted enclosures shall be suitably sanded, cleaned, primed and

painted. Stainless-steel and aluminum enclosures (in particular)

shall be protected from scratching during manufacture, assembly

and shipment.

PGR Document #NG201-07

You might also like

- NGR PDFDocument4 pagesNGR PDFFerly AsriNo ratings yet

- Ami 335Document2 pagesAmi 335Daniel PaisNo ratings yet

- NG101-07 High Voltage LRGDocument1 pageNG101-07 High Voltage LRGIchsan RosidinNo ratings yet

- GT110-08 NGR Trans PDFDocument2 pagesGT110-08 NGR Trans PDFrexNo ratings yet

- Specification Sheet NGRDocument5 pagesSpecification Sheet NGRAghniaNurAnNisaNo ratings yet

- GT210-10 NGR W TransformerDocument2 pagesGT210-10 NGR W TransformerDeepen SharmaNo ratings yet

- 57-TMSS-01-R0 Neutral Grounding Resister - 11kV To 34.5kVDocument11 pages57-TMSS-01-R0 Neutral Grounding Resister - 11kV To 34.5kVsrifaceNo ratings yet

- Dhofar Power Company Saog: Mott MacdonaldDocument1 pageDhofar Power Company Saog: Mott Macdonald54045114No ratings yet

- SETFt RIP Transformer Outdoor BushingDocument12 pagesSETFt RIP Transformer Outdoor Bushingp m yadavNo ratings yet

- 11KV - 415V Overhead Line Specification (REC) - Electrical Notes & ArticlesDocument61 pages11KV - 415V Overhead Line Specification (REC) - Electrical Notes & ArticlesHemant KumarNo ratings yet

- 11KV - 415V Overhead Line Specification (REC) - Electrical Notes & ArticlesDocument64 pages11KV - 415V Overhead Line Specification (REC) - Electrical Notes & ArticlesPradeepKrYadavNo ratings yet

- NGRDocument2 pagesNGRAchint RajputNo ratings yet

- Gt110-08 NGR TransDocument2 pagesGt110-08 NGR TransRaviteja NowduruNo ratings yet

- Receptaculo Con Tapa y Caja Mod. ARE-6424Document7 pagesReceptaculo Con Tapa y Caja Mod. ARE-6424Rolando GilNo ratings yet

- Isolator TSDocument6 pagesIsolator TSanirban 007No ratings yet

- Avtron Neutral Grounding ResistorsDocument6 pagesAvtron Neutral Grounding ResistorsRaul CasperNo ratings yet

- Types of LV Switchboard: SwitchboardsDocument6 pagesTypes of LV Switchboard: SwitchboardscRi SocietyNo ratings yet

- Sla Eim 12 Week 4 Flexible Armored CableDocument2 pagesSla Eim 12 Week 4 Flexible Armored CableCandice Bolay-og100% (1)

- DO Fuse UnitDocument8 pagesDO Fuse UnitImran KhanNo ratings yet

- Neutral Grounding ResistorDocument4 pagesNeutral Grounding ResistorViswanathan VNo ratings yet

- RN - Transformer Spec.Document21 pagesRN - Transformer Spec.ddhar633No ratings yet

- Insulator of Overhead Transmission LineDocument13 pagesInsulator of Overhead Transmission LineElias BeyeneNo ratings yet

- CH-7 InsulatorDocument13 pagesCH-7 InsulatorMerera TaresaNo ratings yet

- liquidtight-flexible-metal-conduit-fittingsDocument24 pagesliquidtight-flexible-metal-conduit-fittingsGHOUSENo ratings yet

- Different Parameters of Overhead LinesDocument8 pagesDifferent Parameters of Overhead LinesRohan Sharma75% (4)

- Henghe Electrical Cutout-FuseDocument7 pagesHenghe Electrical Cutout-Fusejack wuNo ratings yet

- Specification NGRDocument7 pagesSpecification NGRPrasenjit MaityNo ratings yet

- TransformersDocument15 pagesTransformersAnonymous GRXy0TNo ratings yet

- 3na HRC Din FuseDocument20 pages3na HRC Din Fusesuresh kanchanaNo ratings yet

- Neutral Earthing ResistorsDocument4 pagesNeutral Earthing ResistorsjaytamijNo ratings yet

- Flange Insulation Brochure Rev3Document10 pagesFlange Insulation Brochure Rev3Gilberto YoshidaNo ratings yet

- Zigzag TransformerDocument2 pagesZigzag TransformerRaditya Wika BaskaraNo ratings yet

- Insulator of Overhead Transmission LineDocument13 pagesInsulator of Overhead Transmission LineElias BeyeneNo ratings yet

- Catalog Appleton WSR Interlocked Receptacle Cover en Us 178392Document3 pagesCatalog Appleton WSR Interlocked Receptacle Cover en Us 178392Eecol phone ParedesNo ratings yet

- CUTOUT Fuse Holders: (Standard)Document9 pagesCUTOUT Fuse Holders: (Standard)MadyNo ratings yet

- Techspec 8 Shalini - Gupta@dvc - Gov.inDocument19 pagesTechspec 8 Shalini - Gupta@dvc - Gov.inchetan42688No ratings yet

- D-73P Disconnect and D-73P3 Bypass Switches: Technical Data 328-10Document8 pagesD-73P Disconnect and D-73P3 Bypass Switches: Technical Data 328-10Benjamin HidalgoNo ratings yet

- ST44 Metal Roof Battens Steel - Product Brochure 44Document2 pagesST44 Metal Roof Battens Steel - Product Brochure 44frogknotNo ratings yet

- Junction BoxesDocument11 pagesJunction BoxesKhalil EbrahimNo ratings yet

- SBCT Sheet WebDocument2 pagesSBCT Sheet WebpitillinNo ratings yet

- Ohmicontrols Final BrochureDocument9 pagesOhmicontrols Final BrochureAnoop SaneNo ratings yet

- Distribution Boards & Protection DevicesDocument31 pagesDistribution Boards & Protection Devicessudhir raiNo ratings yet

- Sec-09 Electrical Works and InstallationDocument6 pagesSec-09 Electrical Works and InstallationOmer HayatNo ratings yet

- RGA750 G2 Product OverviewDocument2 pagesRGA750 G2 Product OverviewRiyadh ZakiNo ratings yet

- Electric Fence SpecificationsDocument4 pagesElectric Fence SpecificationsAb CNo ratings yet

- Neutral Grounding ResistorsDocument4 pagesNeutral Grounding ResistorsLong LeoNo ratings yet

- Tomacorriente 20amp Appleton CompletoDocument6 pagesTomacorriente 20amp Appleton CompletoFex FexNo ratings yet

- Appleton Serie Toma AeDocument7 pagesAppleton Serie Toma AeasssasasNo ratings yet

- SA01900005E 150dpiDocument2 pagesSA01900005E 150dpivaishgoa56No ratings yet

- IDE Electric Roller Shutter Product LeafletDocument2 pagesIDE Electric Roller Shutter Product LeafletLi ChianNo ratings yet

- Electrical Specification For Food CourtDocument13 pagesElectrical Specification For Food CourtIndraneel BhawoorjarNo ratings yet

- Ganztrans TransformersDocument13 pagesGanztrans TransformersaidedthunderNo ratings yet

- Catalog Appleton Efs Non Sealed Tumbler Switches en 1277652Document8 pagesCatalog Appleton Efs Non Sealed Tumbler Switches en 1277652jabrix09No ratings yet

- Alfa Standard. IPB Catalogue PDFDocument8 pagesAlfa Standard. IPB Catalogue PDFabes1234No ratings yet

- Technical Specification For 11 KV AB Switch 400ADocument8 pagesTechnical Specification For 11 KV AB Switch 400AdillehNo ratings yet

- Oskf-Ansi-Brochure-En (CT-245kV)Document4 pagesOskf-Ansi-Brochure-En (CT-245kV)Trương Quang SơnNo ratings yet

- Technical Information: Usi Concrete PolesDocument14 pagesTechnical Information: Usi Concrete PolesMahfuzur RahmanNo ratings yet

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- Sunflex OSD250Document1 pageSunflex OSD250Ichsan RosidinNo ratings yet

- Nov 2014 Monthly Hse Statistics ReportDocument6 pagesNov 2014 Monthly Hse Statistics ReportIchsan RosidinNo ratings yet

- TYCO - Quick Response Sprinkler, Pendent, K5.6Document4 pagesTYCO - Quick Response Sprinkler, Pendent, K5.6Ichsan RosidinNo ratings yet

- TYCO - High Velocity NozzleDocument6 pagesTYCO - High Velocity NozzleIchsan RosidinNo ratings yet

- OSD150 Oil Suction/Discharge Hose 150 PsiDocument1 pageOSD150 Oil Suction/Discharge Hose 150 PsiIchsan RosidinNo ratings yet

- CompotecLine HosesDocument2 pagesCompotecLine HosesIchsan RosidinNo ratings yet

- Worker Welfare - Labour Rights Country RiskDocument3 pagesWorker Welfare - Labour Rights Country RiskIchsan RosidinNo ratings yet

- OIL800 HD (FROM SIZE 3/4" TO 12") Oil Heavy Duty Suction & Discharge Hose 200 Psi EN 13765:2010 TYPE 3Document2 pagesOIL800 HD (FROM SIZE 3/4" TO 12") Oil Heavy Duty Suction & Discharge Hose 200 Psi EN 13765:2010 TYPE 3Ichsan RosidinNo ratings yet

- UNIHOSE Hydraulic Hose - 2SNDocument1 pageUNIHOSE Hydraulic Hose - 2SNIchsan RosidinNo ratings yet

- Altivar Process ATV600 - ATV630D37N4Document13 pagesAltivar Process ATV600 - ATV630D37N4Ichsan RosidinNo ratings yet

- Altivar Easy 610 - ATV610D37N4Document4 pagesAltivar Easy 610 - ATV610D37N4Ichsan RosidinNo ratings yet

- Sigmashield™ 880 / Amerlock® 880: Product Data SheetDocument5 pagesSigmashield™ 880 / Amerlock® 880: Product Data SheetIchsan RosidinNo ratings yet

- Lembar Data Produk: Circuit Breaker Compact NSX160F - TMD - 160 A - 3 Poles 3dDocument3 pagesLembar Data Produk: Circuit Breaker Compact NSX160F - TMD - 160 A - 3 Poles 3dIchsan RosidinNo ratings yet

- NG101-07 High Voltage LRGDocument1 pageNG101-07 High Voltage LRGIchsan RosidinNo ratings yet

- EasyPact EZC - EZC250F3160Document6 pagesEasyPact EZC - EZC250F3160Ichsan RosidinNo ratings yet

- OS-E1UF Armoured CableDocument1 pageOS-E1UF Armoured CableIchsan RosidinNo ratings yet

- Liquilevel: Installation, Instruction and Maintenance ManualDocument2 pagesLiquilevel: Installation, Instruction and Maintenance ManualIchsan RosidinNo ratings yet

- Nasional Anugrah Tama Saka Prima Sinar Sahabat Peno: Harga Tembaga Dapat Berubah Sewaktu-WaktuDocument1 pageNasional Anugrah Tama Saka Prima Sinar Sahabat Peno: Harga Tembaga Dapat Berubah Sewaktu-WaktuIchsan RosidinNo ratings yet

- Rubber Lining ProcedureDocument9 pagesRubber Lining ProcedureIchsan RosidinNo ratings yet

- No Description Type/ Specification I MaterialDocument2 pagesNo Description Type/ Specification I MaterialIchsan RosidinNo ratings yet

- VTP Version 3: Solution GuideDocument29 pagesVTP Version 3: Solution Guidejnichols1009No ratings yet

- PMIT Admission Brochure - Spring 2021Document3 pagesPMIT Admission Brochure - Spring 2021Shayekh Mohiuddin Ahmed NavidNo ratings yet

- Cable - Datasheet - (En) NSSHCÖU, Prysmian - 2013-06-10 - Screened-Power-CableDocument4 pagesCable - Datasheet - (En) NSSHCÖU, Prysmian - 2013-06-10 - Screened-Power-CableA. Muhsin PamungkasNo ratings yet

- BRKDCN 2035 PDFDocument117 pagesBRKDCN 2035 PDFJorge Alberto Largaespada GonzalezNo ratings yet

- Aec 001-Bacc 001 (Econ) - Week 4 ModuleDocument3 pagesAec 001-Bacc 001 (Econ) - Week 4 ModuleNicole ValentinoNo ratings yet

- NX Nastran Error ListDocument224 pagesNX Nastran Error ListAdriana Livadariu100% (3)

- Measures of Dispersion: Greg C Elvers, PH.DDocument27 pagesMeasures of Dispersion: Greg C Elvers, PH.Dorchuchi100% (1)

- Smart Home: An-Najah National University Faculty of EngineeringDocument27 pagesSmart Home: An-Najah National University Faculty of Engineeringمعتز بسام محمود مرداوي معتز بسام محمود مرداويNo ratings yet

- Production Line Resume SampleDocument2 pagesProduction Line Resume SampleadityadhimanNo ratings yet

- Fluke Bangladesh 368 FC Leakage Current Clamp MeterDocument4 pagesFluke Bangladesh 368 FC Leakage Current Clamp MeterFluke BangladeshNo ratings yet

- I LuxDocument24 pagesI LuxNirav M. BhavsarNo ratings yet

- Blaupunkt Chicago Ivdm 7002Document4 pagesBlaupunkt Chicago Ivdm 7002Onix AdiNo ratings yet

- Human Rights Term PaperDocument18 pagesHuman Rights Term Papersanjog DewanNo ratings yet

- User Exit in Batch ManagementDocument5 pagesUser Exit in Batch ManagementSameer BagalkotNo ratings yet

- Analysis of GATE 2010Document25 pagesAnalysis of GATE 2010aloo_12345No ratings yet

- Niranjan A Murthy 2018Document15 pagesNiranjan A Murthy 2018Tim KNo ratings yet

- ContinueDocument5 pagesContinueuWu uWuNo ratings yet

- Q4 Module 8.2Document14 pagesQ4 Module 8.2Derick0% (1)

- Pinpointer PetrapinDocument15 pagesPinpointer PetrapinNacer MezghicheNo ratings yet

- AnalogI PDFDocument48 pagesAnalogI PDFJerc ZajNo ratings yet

- NCOER GuideDocument34 pagesNCOER GuideSteve RichardsNo ratings yet

- 2024 Tutorial 8Document2 pages2024 Tutorial 8ksfksfdsfNo ratings yet

- Monitoring Neuromuskular Kuantitatif Pada Penggunaan Muscle RelaxantDocument17 pagesMonitoring Neuromuskular Kuantitatif Pada Penggunaan Muscle RelaxantWidi Yuli HariantoNo ratings yet

- Vernacular Architecture of Hills IndiaDocument12 pagesVernacular Architecture of Hills IndiaTushar JainNo ratings yet

- Impact of Compensation and Reward SystemDocument88 pagesImpact of Compensation and Reward SystemDhanshri KavatkarNo ratings yet

- XRAY NT1 Instruction Manual 6Document40 pagesXRAY NT1 Instruction Manual 6Vincent ManNo ratings yet

- Case Digest - Asset Builders Vs StrongholdDocument3 pagesCase Digest - Asset Builders Vs StrongholdDianaVillafuerteNo ratings yet

- ABMM2Document3 pagesABMM2QAISER IJAZNo ratings yet