Professional Documents

Culture Documents

MIL-PRF-25732 REV. D (MIL-P-25732) - Part4

MIL-PRF-25732 REV. D (MIL-P-25732) - Part4

Uploaded by

David WongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MIL-PRF-25732 REV. D (MIL-P-25732) - Part4

MIL-PRF-25732 REV. D (MIL-P-25732) - Part4

Uploaded by

David WongCopyright:

Available Formats

MIL-PRF-25732D

exemption has been obtained.

3. REQUIREMENTS

3.1 Qualification.

The packings furnished under this specification shall be products that are authorized by the

qualifying activity for listing on the applicable qualified products list before contract award (see

4.2 and 6.2). Qualification testing shall be performed every three years.

3.2 Compound.

Shall be prepared from ingredients as shall be necessary to achieve the requirements detailed in

this specification and shall be a compound, based on butadiene-acrylonitrile (NBR) elastomer,

fully cured to produce product meeting the requirements of 3.4. Material used shall be 100

percent virgin NBR elastomer. No reprocessed or non-NBR polymer is acceptable.

3.3 Dimensions and tolerances.

The dimensions and tolerances of standard size O-rings procured to this specification shall

conform to SAE AS28775. Non-standard parts shall conform to applicable design drawings.

3.4 Physical properties.

The physical properties of the rubber shall conform to the values given in Table I. Material shall

be tested on the O-ring SAE AS28775-214 pertaining to this material specification. Calculations

of tensile strength and elongation may be made in accordance with SAE AIR851.

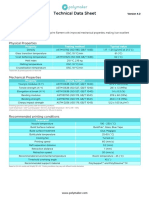

TABLE I. Physical properties.

Original Properties Requirements Test Method

As Received

Specific gravity ±0.02 of qualification ASTM D1414 and ASTM D297

value

Hardness Durometer Type A, points 73, ±5 ASTM D1414 and ASTM D2240

Tensile strength, psi, min. 1350 ASTM D1414

Elongation, percent, min 160 (may not be lower ASTM D1414

than 160 percent in

production)

Tensile Stress, min, psi 500 ASTM D1414

Temperature retraction, TR-10, 50 -49 °F (-45 °C) ASTM D1414 and ASTM D1329

percent elongation and 10 percent

return, °F (°C), max

Glass transition (Tg) Mid-Point, °F -49 °F (-45 °C) ASTM D7426

(°C), max

Short-term compression set, ASTM D1414 and ASTM D395

percent, max Method B

Temp: 75 ±5 ˚F (23.9 ±2.8 °C)

Time: 70 ±0.5 hours

ASTM D1414 and ASTM D395

Long-term Compression set, percent,

Method B

max

Temp: 75 ±5 ˚F (23.9 ±2.8 °C)

Time: 336 ±0.5 hours

4

Source: http://assist.dla.mil -- Downloaded: 2021-03-01T13:29Z

Check the source to verify that this is the current version before use.

You might also like

- CDU DesignDocument8 pagesCDU DesignAnonymous DcE7fcjSwNo ratings yet

- MIL-PRF-25732 REV. D (MIL-P-25732) - Part8Document1 pageMIL-PRF-25732 REV. D (MIL-P-25732) - Part8David WongNo ratings yet

- Ams 7259Document1 pageAms 7259chulhanNo ratings yet

- (AdvanSix) (TDS) Aegis H135ZPDocument3 pages(AdvanSix) (TDS) Aegis H135ZPMarcos KodairaNo ratings yet

- TABLE I. Physical Properties - Continued. Fluid MIL-PRF-5606 Resistance ASTM D471Document1 pageTABLE I. Physical Properties - Continued. Fluid MIL-PRF-5606 Resistance ASTM D471David WongNo ratings yet

- Raise3D Premium ABS Technical Data Sheet: Physical PropertiesDocument3 pagesRaise3D Premium ABS Technical Data Sheet: Physical PropertiesdeepNo ratings yet

- Z70B I2 R4 EnglishDocument1 pageZ70B I2 R4 English阿康No ratings yet

- 400 00030953en Engage 8180 TdsDocument3 pages400 00030953en Engage 8180 TdsSIDDHARTH BHASNEYNo ratings yet

- 400 00119895en Infuse 9500 TdsDocument2 pages400 00119895en Infuse 9500 TdsJorge CamargoNo ratings yet

- KOPA® KN333G40SIBL: Properties Measurement Condition Test Method Unit Typical ValueDocument2 pagesKOPA® KN333G40SIBL: Properties Measurement Condition Test Method Unit Typical Valuehugo santiago chavez godoyNo ratings yet

- Raise3d Premium PETG TDS V3Document3 pagesRaise3d Premium PETG TDS V3Faris AlmarshadNo ratings yet

- 3M™ Adhesive Transfer Tape 950 - 20240112Document8 pages3M™ Adhesive Transfer Tape 950 - 20240112qualityNo ratings yet

- 400 00125587en Dow Hdpe Dmda8920 Health TdsDocument3 pages400 00125587en Dow Hdpe Dmda8920 Health Tdshumberto.ramirezNo ratings yet

- TDS Engage 8200Document3 pagesTDS Engage 8200afernandezNo ratings yet

- Pmma-Lg Pmma Ih 830a (Natural)Document1 pagePmma-Lg Pmma Ih 830a (Natural)AVLight AutomotivesNo ratings yet

- TDS - Acrylic V045 - From TrinseoDocument3 pagesTDS - Acrylic V045 - From TrinseoVio AmarieiNo ratings yet

- 3M™ Adhesive Transfer Tape 966 - 20231209Document10 pages3M™ Adhesive Transfer Tape 966 - 20231209Son NguyenNo ratings yet

- Chloroprene (Neoprene) 70 Sha: Astm D2000 M2 Bc714 A14 B14 Eo14 Eo34 F17Document1 pageChloroprene (Neoprene) 70 Sha: Astm D2000 M2 Bc714 A14 B14 Eo14 Eo34 F17clarenceNo ratings yet

- CPVC PipesDocument24 pagesCPVC Pipeschaudhary osamaNo ratings yet

- Solvay - Halar 513 LCDocument3 pagesSolvay - Halar 513 LCRenan GadioliNo ratings yet

- Unival™ Dmdg-6200 NT 7: High Density Polyethylene ResinDocument3 pagesUnival™ Dmdg-6200 NT 7: High Density Polyethylene Resinyesenia flores rosadoNo ratings yet

- Gasoil Specification SPC 2016Document1 pageGasoil Specification SPC 2016Mohamed GasimNo ratings yet

- New XP9020 - TDSDocument1 pageNew XP9020 - TDSabuciodelgadoNo ratings yet

- Bitumen 80-100 Pen EcDocument1 pageBitumen 80-100 Pen EcsamirNo ratings yet

- Z85B I1 R4 EnglishDocument1 pageZ85B I1 R4 English阿康No ratings yet

- 3M™ Adhesive Transfer Tape 9471 - 20231201Document8 pages3M™ Adhesive Transfer Tape 9471 - 20231201dsfasdfafsNo ratings yet

- Z75L I2 R2 EnglishDocument1 pageZ75L I2 R2 English阿康No ratings yet

- PORON 4701-50 Firm - Supported MaterialsDocument2 pagesPORON 4701-50 Firm - Supported MaterialsLayeeq AhmedNo ratings yet

- Properties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCDocument1 pageProperties of PVC & CPVC PIPE Fitting: Item Test Method SI Unit Unit PVC CPVCsidsaleemNo ratings yet

- TDS HDPE DMDD 6200,Document2 pagesTDS HDPE DMDD 6200,Compras 2 BioinNo ratings yet

- Lexan™ 8010 Uncoated Polished Film DatasheetDocument3 pagesLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanNo ratings yet

- Hdpe Dmda-8920 NT 7 DowDocument2 pagesHdpe Dmda-8920 NT 7 DowEric Mahonri PereidaNo ratings yet

- Pellethane 5863-82AE TPU: Technical Data SheetDocument2 pagesPellethane 5863-82AE TPU: Technical Data SheetaNo ratings yet

- CYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetDocument2 pagesCYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetJoseNo ratings yet

- Green Cast Setacryl UKDocument4 pagesGreen Cast Setacryl UKgillestalbotNo ratings yet

- XIAMETER™ RBB-2030-40 Base: Features & Benefits ApplicationsDocument3 pagesXIAMETER™ RBB-2030-40 Base: Features & Benefits ApplicationsDaniela Alejandra Daza LancherosNo ratings yet

- Technical Datasheet: Properties Unit Value Test Method Value Test Method Test Specimen O-RingDocument2 pagesTechnical Datasheet: Properties Unit Value Test Method Value Test Method Test Specimen O-RingDacetIronForceNo ratings yet

- Material 75 Simriz 495: BlackDocument1 pageMaterial 75 Simriz 495: Blackmarco SimonelliNo ratings yet

- SABIC Cycolac MG47FDocument3 pagesSABIC Cycolac MG47FChu ChuNo ratings yet

- TDS Engage 8100Document3 pagesTDS Engage 8100afernandezNo ratings yet

- Halene - H : Technical Data SheetDocument1 pageHalene - H : Technical Data SheetIshah KaziNo ratings yet

- Polymax PC Tds v4Document2 pagesPolymax PC Tds v4Hector GarciaNo ratings yet

- White NBR PDFDocument1 pageWhite NBR PDFNik Danial Aiman Nik HassanNo ratings yet

- 400 00285217en Hdpe 6200 TdsDocument2 pages400 00285217en Hdpe 6200 TdsOriana Gudiño GaliñoNo ratings yet

- Pao 100Document2 pagesPao 100Антон СтепураNo ratings yet

- Penetration Grade Bitumens SpecsDocument1 pagePenetration Grade Bitumens Specsaegean227No ratings yet

- Physical Properties of PVC CPVC PipeDocument1 pagePhysical Properties of PVC CPVC PipeBimal DeyNo ratings yet

- Technical Data SheetDocument3 pagesTechnical Data SheetAbdul BasithNo ratings yet

- DK 3.0mm HDPE Geomembrane Mill CertificateDocument2 pagesDK 3.0mm HDPE Geomembrane Mill CertificatemikeNo ratings yet

- ELITE 5400G: Blown Film ResinDocument2 pagesELITE 5400G: Blown Film ResinEndayenew MollaNo ratings yet

- EPDM - Test by Romac Inc PDFDocument2 pagesEPDM - Test by Romac Inc PDFRajendra Kumar SharmaNo ratings yet

- Ss sn70Document4 pagesSs sn70Manoj MakholiyaNo ratings yet

- NBR 70.10-02Document3 pagesNBR 70.10-02titi suryaniNo ratings yet

- DOWLEX™ 2038.68G: Polyethylene ResinDocument3 pagesDOWLEX™ 2038.68G: Polyethylene ResinJosé PalmaNo ratings yet

- PolyMax PLA TDS V4Document2 pagesPolyMax PLA TDS V4fNo ratings yet

- Filament Specifications Unit ValueDocument4 pagesFilament Specifications Unit ValueRoberto Gonzalo PelazNo ratings yet

- Virgin PTFE Datasheet: Property Method Units ValuesDocument2 pagesVirgin PTFE Datasheet: Property Method Units ValuesMuhammad Ejaz QureshiNo ratings yet

- Filament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinDocument4 pagesFilament Specifications Unit Value: All 3D Printed Parts Printed at 100% Infill and Annealed at 110ºC/20 MinRoberto Gonzalo PelazNo ratings yet

- Plasticstestingstandards 160629115139Document12 pagesPlasticstestingstandards 160629115139FERNANDO JOSE NOVAESNo ratings yet

- ASTM E1444-E1444M (2021) - Part6Document1 pageASTM E1444-E1444M (2021) - Part6David WongNo ratings yet

- ASTM E1444-E1444M (2021) - Part9Document1 pageASTM E1444-E1444M (2021) - Part9David WongNo ratings yet

- An924 Rev. 14Document8 pagesAn924 Rev. 14David WongNo ratings yet

- ASTM E1444-E1444M (2021) - Part1Document1 pageASTM E1444-E1444M (2021) - Part1David WongNo ratings yet

- ASTM E1444-E1444M (2021) - Part4Document1 pageASTM E1444-E1444M (2021) - Part4David WongNo ratings yet

- An565 Rev. 7Document4 pagesAn565 Rev. 7David WongNo ratings yet

- ASTM E1444-E1444M (2021) - Part5Document1 pageASTM E1444-E1444M (2021) - Part5David WongNo ratings yet

- AN924Document8 pagesAN924David WongNo ratings yet

- ASTM E1444-E1444M (2021) - Part2Document1 pageASTM E1444-E1444M (2021) - Part2David WongNo ratings yet

- AN924 REV. 14 - Part5Document1 pageAN924 REV. 14 - Part5David WongNo ratings yet

- AN924 REV. 14 - Part6Document1 pageAN924 REV. 14 - Part6David WongNo ratings yet

- AN924 REV. 14 - Part2Document1 pageAN924 REV. 14 - Part2David WongNo ratings yet

- MIL-W-22759 Rev E - Part41Document1 pageMIL-W-22759 Rev E - Part41David WongNo ratings yet

- AN924 REV. 14 - Part7Document1 pageAN924 REV. 14 - Part7David WongNo ratings yet

- AN924 REV. 14 - Part4Document1 pageAN924 REV. 14 - Part4David WongNo ratings yet

- MIL-PRF-25732 REV. D (MIL-P-25732) - Part11Document1 pageMIL-PRF-25732 REV. D (MIL-P-25732) - Part11David WongNo ratings yet

- AN924 REV. 14 - Part3Document1 pageAN924 REV. 14 - Part3David WongNo ratings yet

- MIL-PRF-25732 REV. D (MIL-P-25732) - Part12Document1 pageMIL-PRF-25732 REV. D (MIL-P-25732) - Part12David WongNo ratings yet

- A-A-52081 REV.B - Part4Document1 pageA-A-52081 REV.B - Part4David WongNo ratings yet

- MIL-PRF-25732 REV. D (MIL-P-25732) - Part14Document1 pageMIL-PRF-25732 REV. D (MIL-P-25732) - Part14David WongNo ratings yet

- MIL-W-22759 Rev E - Part38Document1 pageMIL-W-22759 Rev E - Part38David WongNo ratings yet

- MIL-PRF-25732 REV. D (MIL-P-25732) - Part13Document1 pageMIL-PRF-25732 REV. D (MIL-P-25732) - Part13David WongNo ratings yet

- MIL-W-22759 Rev E - Part42Document1 pageMIL-W-22759 Rev E - Part42David WongNo ratings yet

- MIL-W-22759 Rev E - Part40Document1 pageMIL-W-22759 Rev E - Part40David WongNo ratings yet

- Optimization of Ultrasound-Assisted Extraction of Natural Antioxidants From The Flower of Jatropha Integerrima by Response Surface MethodologyDocument12 pagesOptimization of Ultrasound-Assisted Extraction of Natural Antioxidants From The Flower of Jatropha Integerrima by Response Surface MethodologyDreyden HaloNo ratings yet

- WoodDocument24 pagesWoodAhmed LahhamNo ratings yet

- 4211 Slides 1Document37 pages4211 Slides 1Roy VeseyNo ratings yet

- Composite Aircraft Structures - A Design Perspective - GM KamathDocument38 pagesComposite Aircraft Structures - A Design Perspective - GM KamathTarik Hassan ElsonniNo ratings yet

- Defects of HPDC With BifilmDocument22 pagesDefects of HPDC With BifilmdocphantomNo ratings yet

- Thermodynamics: Ideal Gas Practice Problems SolutionsDocument3 pagesThermodynamics: Ideal Gas Practice Problems SolutionsMuqeem Uddin100% (1)

- Checklist Maintenance Alat 2022Document9 pagesChecklist Maintenance Alat 2022rsud abadiNo ratings yet

- Viscosity of Liquid Water in The Range 8 °C To 150 °C: Articles You May Be Interested inDocument9 pagesViscosity of Liquid Water in The Range 8 °C To 150 °C: Articles You May Be Interested inAnandhu Mohan MNo ratings yet

- System: Naphthalene + Carbon Dioxide At 35°C, 13 Data Points Experimental Data File: Nfcd35Sr.Da3 For Α = 4.451; Β = 5.79 Plots (Sample Calculation In Mathcad In Next Pages)Document4 pagesSystem: Naphthalene + Carbon Dioxide At 35°C, 13 Data Points Experimental Data File: Nfcd35Sr.Da3 For Α = 4.451; Β = 5.79 Plots (Sample Calculation In Mathcad In Next Pages)Fredy Colpas CastilloNo ratings yet

- Lecture 17: Advanced Processing of Metastable MaterialsDocument22 pagesLecture 17: Advanced Processing of Metastable MaterialsJeremy TohNo ratings yet

- VETASSESS List of General Professional OccupationsDocument27 pagesVETASSESS List of General Professional OccupationsVignesh AsokNo ratings yet

- Metals and Some Aspects of Corrosion: ObjectivesDocument6 pagesMetals and Some Aspects of Corrosion: ObjectivesFree AcxNo ratings yet

- Quantitative Analysis of The Substrate Specificity of Human Rhinovirus 3C Protease and Exploration of Its Substrate Recognition MechanismsDocument14 pagesQuantitative Analysis of The Substrate Specificity of Human Rhinovirus 3C Protease and Exploration of Its Substrate Recognition MechanismsLuís MiguelNo ratings yet

- Rainwater Drainage 221017Document28 pagesRainwater Drainage 221017Yong QingNo ratings yet

- GM5340PRK enUS ASTMDocument2 pagesGM5340PRK enUS ASTMDuongthithuydungNo ratings yet

- Physical Science Module 4Document37 pagesPhysical Science Module 4klynth23No ratings yet

- Spectrophotometric Determination of Ascorbic Acid and Dehydroascorbic AcidDocument5 pagesSpectrophotometric Determination of Ascorbic Acid and Dehydroascorbic AcidmfhfhfNo ratings yet

- Ethyl Acetate: - Technical Data SheetDocument2 pagesEthyl Acetate: - Technical Data SheetFX Alan DarmasaputraNo ratings yet

- Thermal Analysis: Dr. Jyoti Prakash DhalDocument59 pagesThermal Analysis: Dr. Jyoti Prakash DhalBhagyashree PaniNo ratings yet

- 11 Physics Test PapersDocument261 pages11 Physics Test Papersnikochu100% (3)

- Experiment 11 1213Document8 pagesExperiment 11 1213MAYANKNo ratings yet

- User Defined Functions: Fluent Software Training TRN-99-003Document114 pagesUser Defined Functions: Fluent Software Training TRN-99-003VladJNo ratings yet

- The Polarization of Light: Experiment 3Document4 pagesThe Polarization of Light: Experiment 3Mujeeb UllahNo ratings yet

- FlotationDocument3 pagesFlotationtrabajosicNo ratings yet

- Concrete Limitting Values For Exposure Grade Pages From en 206Document1 pageConcrete Limitting Values For Exposure Grade Pages From en 206Ahmed Mostafa AL-AboudyNo ratings yet

- Removal of Chromium (VI) and Dye Alizarin Red S (ARS) Using Polymer-Coated Iron Oxide (Fe O) Magnetic Nanoparticles by Co-Precipitation MethodDocument15 pagesRemoval of Chromium (VI) and Dye Alizarin Red S (ARS) Using Polymer-Coated Iron Oxide (Fe O) Magnetic Nanoparticles by Co-Precipitation MethodDavid AriasNo ratings yet

- S ProcessDocument3 pagesS ProcessPraveen VsNo ratings yet

- Chemistry:: Exploring Life Through ScienceDocument11 pagesChemistry:: Exploring Life Through ScienceJay SajoNo ratings yet

- Diapham Valve PDFDocument8 pagesDiapham Valve PDFthouche007No ratings yet