Professional Documents

Culture Documents

Full Automatic Integrated Sewing Series Manual V1.1: 1. Safety Instruction 4.operation Box Use

Full Automatic Integrated Sewing Series Manual V1.1: 1. Safety Instruction 4.operation Box Use

Uploaded by

Dinh NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Full Automatic Integrated Sewing Series Manual V1.1: 1. Safety Instruction 4.operation Box Use

Full Automatic Integrated Sewing Series Manual V1.1: 1. Safety Instruction 4.operation Box Use

Uploaded by

Dinh NguyenCopyright:

Available Formats

Full automatic integrated sewing series manual V1.

1

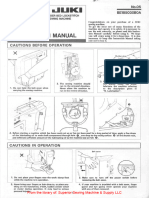

1. Safety instruction

Please read the operation manual and related sewing machinery datasheet carefully before correct use.

4.Operation box use

1.1 (1) Power voltage and frequence: please refer to motor and control box nameplate. Function Button Described

(2) Interference from electromagnetic wave:please keep far away strong magnetic or high radiation environment in order

to avoid obstructions and make to misoperation. Starting Execute starting reinforcing-sewing 2 times, to and fro.

(3) Grounding: to avoid the noise obstructions or leakage of electricity accident(inculding sewing machine,motor,control reinforcing

box and positioner. -sewing Execute starting reinforcing-sewing 1 times, to and fro.

1.2 Please make sure power off at least 1min and then can open control box cover, because there are dangerous high voltage.

1.3 Please turn off the power while repairing or wearing needle in order to protect operater’s safty. ending Execute ending reinforcing-sewing 2 times, to and fro.

1.4 Used where potential dangers exist. reinforcing

Used where high voltage and electric danger exist. -sewing Execute ending reinforcing-sewing 1 times, to and fro.

1.5 Product warranty period of one year on condition that this machine is operated correctly and no man-made damage. free-style

Press treadle ahead for normal sewing, stop in the middle, behind for thread-cutting and thread wiping.

sewing

1、Press treadle ahead for automatic sewing, to and fro, which is set at D and can reach 15times.(F)

2. System parameter table continuous

2、Continuous reinforcing-sewing is in trigger mode by default, treadle doesn’t need to be kept being pressed, and

reinforcing

corresponding trigger light of preset sewing is solid lit.

The -sewing

Setting Level 3、Previous ending reinforcing-sewing setting is invalid if this function is valid.

No Project Content range default

value 1.Press treadle ahead to execute sewing times set at E or E, F, G, H.

1 Sewing speed Set sewing speed 200~5000rpm 3500 I preset 2.Sewing will stop immediately if treadle is lifted; press treadle again, it will go on with the rest.

0: No soft-start function sewing 3.Ending reinforcing-sewing (if selected), thread-cutting and thread wiping will be automatically executed after sewing

2 Soft-start function 0~9 0 I is completed.

1~9: Soft start stitches

3 Ornamental bartacks 0: Invalid 1: Effective 0/1 0 I 1.For preset sewing. Trigger treadle and the system will automatically conduct sewing at E, F, G, H sections; the treadle

4 Fixed-length seam sewing speed Set fixed-length seam sewing speed 200~4000rpm 3000 I parameter

doesn’t need to be kept being pressed.2.Solid light for continuous reinforcing-sewing mode means that it is trigger mode

5 Simple sewing mode Settings 0: invalid 1: effectively 0/1 0 I setting

by default.

can keep needle from breaking while

9 Back stitch speed limitation 500~1500rpm 800 I thread-cutt

backstitching

Set or cancel thread-cutting function.

19 Solid after before sewing stop 0: unavailable 1: available 0/1 0 I ing

Reverse sewing switch mode selection

needle-lift Free sewing mode, can be based on the according to the length of time is different, complementary half needle,

0: Only reverse sewing ing/stitch a needle or continuous feeding half needle.

Setting of reverse sewing

20 1: Reverse sewing and fill needle 0/1/2 0 I

switch function compensatio

2: Only reverse sewing, standby without

operating nNeedle Set the needle position shortcut keys,Key is effective for needle,The cancel key function is set to stop pin。

21 soft start speed 1 speed of the 1

st

needle of soft start 100~3000rpm 600 I position

nd

22 soft start speed 2 speed of the 2 needle of soft start 100~3000rpm 1000 I The middle

rd th

23 soft start speed 3 speed of the 3 ~9 needle of soft start 100~3000rpm 1500 I presser Presser foot to set shortcut keys: set or cancel the presser foot function.

Presser foot soft lowering foot

24 0: unavailable 1: available 0/1 0 I

function

25 Presser foot lift function 0: unavailable 1: available 0/1 0 I Shear line

0: unavailable pressure The shear line and presser foot set shortcut keys: set or cancel trimmer and presser foot function.

26 Auto lift presser foot function 0/1 0 I foot

1:Auto presser foot lift when shut down

27 Power on and positioning 0: unavailable 1: available 0/1 1 I

Setting of signal mode of turn/lift Soft start Soft start to set shortcut keys: set or cancel the pedal soft start function.

signal mode for turn/lift switch of machine head

28 0/1/2 0 I

switch 0: always open

1.Implementation of this key, circulating switch display 3 pin number to set the display value

1: always close 2:forbid a protection

upper end:A、B、C、DPeriod of pin number,Light corresponding level;

To set presser foot soft lowering time

29 Presser foot soft lowering time The longer time the lower speed of the 50~500ms 300 II Middleend:E、FPeriod of pin number,Light corresponding level;

Pinnumberse

presser foot lower extreme:G、HPeriod of pin number,Light corresponding level;

t/check

Decorative bar-tacking dwell 2.Corresponding to A D period of pin number, can set range 0 ~ 15 needle, B paragraph C pin number, can set range 1 ~ 15

32 To set decorative bar-tacking dwell time 5~500ms 50 I choice

time needle, among them, the liquid crystal display A B C D E F on each for 10 11 12 13 14 15 stitches.

Standard bar-tacking pedal speed 3. To take the thread clamp function model, according to the buttons can show long thread clamp strength adjustment (3

To select standard bar-tacking

34 Mode selection 0/1 0 II bright lights and three, liquid crystal display [7]), again according to the key exit.

pedal speed mode

0:Auto bar-tacking speed ; 1:Pedal speed

0:No by-piece function 1.Entering different parameter level

35 By-piece rate setting 1~20:Plus 1 to by-piece value for each 0~20 1 I On the sewing setting interface, the user can press the button P to enter the Parameter Interface, then the Level I parameters

set thread trimming in the parameter list will display.

37 Thread wiping operation time Thread wiping operation time 0~800ms 40 II On the sewing setting interface, the user can keep pressing the button for a few seconds to enter the Password Entering

41 Low speed The lowest speed of pedal 100~400rpm 200 I Interface. After entering the right maintenance password, then the user can press the button P to enter the Parameter

Pedal speed adjustment 0:normal Interface, now the Level I and Level II parameters in the parameter list will display.

42 Pedal curve selection 1:Slow acceleration 0/1/2 0 I

2: Quick acceleration 2.Password setting

43 Dial the line that can set 0: unavailable 1: available 0/1 1 I On the sewing setting interface, the user can keep pressing the button P for a few seconds to enter the Password Entering

44 thread-cutting speed thread-cutting speed 100~400rpm 280 I parameter Interface, and press the button combination of “burst button + cutting button” to enter the Password Resetting Interface.

Reverse sewing speed limit switch setting The three indicators (respectively are Indicator S1, S2 and S3 from up to down, among which one is on) corresponding to

processing can prevent reverse sewing the button S indicates the current status. S1 lights up, old password input, ending the key combination trigger key + tangent

Reverse sewing speed limit

45 needle breakage 0/1 0 I key, if the correct password into the password reset interface (mistakes have stayed the S1 state), and at the same time

switch

0: infinite speed S2 light, prompting the input new password and click confirm S3 S key input again when the light is the new password, according

1: have the speed limit to S key after two input if consistent, then set success, return to parameter interfaceIf the new passwords entered are

pressor foot lifting delays not the same, the Indicator S1 will be on and the LC screen will be reset, and the user shall enter the old password again.

46 delay with pressor foot lowered 0~800ms 200 II

sewing If the user presses the button P, the user will be brought back to the interface parameters and no modification will be

output time of total pressure of output time of total pressure of pressor

47 0~800ms 150 II saved. You can choose from the numbers of 0 to 9 or the letters of A to F for every single character of the password. Please

pressor foot lifting foot lifting

do keep the new password in mind.

output duty cycle of pressor output duty cycle of pressor foot

foot lifting lifting Teaching

48

hold time of pressor foot forced shut-down after hold time of

0~100 30 II Set or cancel the teaching function. (for liquid crystal panel)

function

lifting pressor foot lifting

Speed down. Keeping pressing to lower speed, the display will automatically switch to speed set. Simple seam, free seam

output duty cycle of pressor output duty cycle of pressor foot

49 1~60(s) 12 II effective.(Application of liquid crystal panel)

foot lifting lifting speed key

output time of total pressure of output time of total pressure of Speed up. Keeping pressing to increase speed, the display will automatically switch to speed set.Simple seam, free seam

50 0~800ms 150 II

reverse-sewing reverse-sewing effective. (Application of liquid crystal panel)

output duty cycle of

51 output duty cycle of reverse-sewing 0~100 40 II Teaching function:

reverse-sewing

forced shut-down after hold time of In the long slot (a, four, program seam) mode, press "S" button to switch to the fixed needle number display interface, long press "T" one second,

52 hold time of reverse-sewing 1~60(s) 12 II you can enter the teaching interface, this interface has buttons: T key, two groups of add-substract key, fill needle key. Role is as follows:

reverse-sewing

starting reinforcing-sewing Add-substract key 12: change teaching segments, segment numerical only to accumulate (into the next section teaching automatically save the last needle

53 starting reinforcing-sewing speed 100~3000rpm 1800 I numerical reduction), '-' key is invalid. Note: when the pedal operation, the key is invalid;

speed

starting reinforcing-sewing parameter of starting Add-substract key 34: modify teaching pin number, to stop running when the adjust pin number. Fill needle keys: press can manually fill needle, needle

54 0~100 30 I

compensation 1 reinforcing-sewing stitch compensation change.

starting reinforcing-sewing parameter of starting T: exit show interface, complete the current segment number teaching (section numerical covering the original mode).

55 0~100 10 I

compensation 2 reinforcing-sewing stitch compensation After the pedal shear line, will directly from the show and save the needle numerical, before returning to the fixed length of stitch pattern.

ending reinforcing-sewing

56 ending reinforcing-sewing speed 100~3000rpm 1800 I

speed

ending reinforcing-sewing parameter of ending reinforcing-sewing

57

compensation 1 stitch compensation

0~100 30 I 5. Error codes

ending reinforcing-sewing parameter of ending reinforcing-sewing Error

58

compensation 2 stitch compensation

0~100 10 I Contents Possible reasons Checking and treatment

Code

ending reinforcing-sewing E011 If electric engine plug is well contacted;

59 ending reinforcing-sewing speed 100~3000rpm 1800 I

speed

E012 if electric engine signal detecting device has been

continuous reinforcing-sewing parameter of continuous Motor signal error Motor position sensor signal failure

60 0~100 30 I E013 broken;

compensation1 reinforcing-sewing stitch compensation

continuous reinforcing-sewing parameter of continuous E014 if sewing machine handwheel correctly installed.

61 0~100 10 I

compensation2 reinforcing-sewing stitch compensation Unable identify operating box model

Pedal position upon start 10~50 E015 Model type error Check operating box

62 Pedal travel upon start 25 II type

Travel relative to medium pedal (0.1°)

Pedal position upon start acceleration 10~100 If electric engine plug is well contacted;

63 Pedal travel upon acceleration 50 II E021 if machine head or thread-cutting mechanism has been

Travel relative to medium pedal (0.1°) motor stall

Pedal travel at highest Pedal position at highest rotating speed 10~150 E022 Motor overload blocked completely;f materials are too thick;

64 110 II motor overload

rotation speed Travel relative to medium pedal (0.1°) E023 Electrical signal detection signal whether the

Pedal travel upon presser foot Pedal position upon pedal lift -100~-10 normal.

65 -30 II

lift Travel relative to medium pedal (0.1°)

Pedal travel from presser foot lowering Current detection abnormal Current detection loop system is working

Pedal travel upon presser foot 5~50 E101 Hardware drivers fault

66 position to neutral position 10 II Driving hardware error properly;Whether the damage to the device driver.

lowering (0.1°)

Travel relative to medium pedal

System into line voltage is too high;

Pedal position upon start trimming High input voltage

Pedal travel 1 upon thread -100~-10 E111

67 without presser foot function -30 II Braking resistance are working properly;

trimming (0.1°) Voltage too high Brake circuit fault

Travel relative to medium pedal E112

Pedal position upon start thread System voltage detection circuit are working

Pedal travel 2 upon tread -100~-10 Voltage detection error

68 trimming with presser foot function -60 II properly.

trimming (0.1°)

Travel relative to medium pedal If the voltage on the inlet wire is too low Whether

Down needle positioning E121 Actual low voltage

69 To adjust down needle position 120~240 175 I Voltage too low the system voltage detection circuit the normal

position E122 Voltage detection is wrong

work.

Reversal of needle lift function after

70 Reverse needle lift function thread trimming 0: unavailable 0/1 0 I E131 Current circuit fault Current detection abnormal Current detection loop system is working properly.

1: available

71 Reversal of needle lift angle Reversal of needle lift angle 0~45° 20 I E133 Oz circuit fault Oz circuit fault Oz circuit system is working properly.

Adjust the thread clamp strength size If machine head magnet suffers short circuit

Thread clamp strength E151 Magnet circuit error Over current magnet circuit

72 0: Clip line function is invalid 0~9 7 I Electromagnet circuit is working properly.

adjustment

1~9: Three Intensity Adjustment

73 Thread pressing actuation angle Thread pressing actuation angle 10~150° 100 I Current detection loop system is working properly

E201 over current Current detection error

74 Thread pressing release angle Thread pressing release angle 160~300° 270 I Electrical signal is normal.

77 Clutch magnet actuation time Clutch magnet actuation delay time 0~2000ms 60 I E211 If electric engine plug is well contacted;

Abnormal motor operation Current or voltage detection error

Clutch magnet release delay time (set as E212 If electric engine signal is matched.

78 Clutch magnet release time 0~2000ms 300 I

0 no release) if operation box plug is well contacted;

5: restore the current level factory E301 Communication error Sci circuit error

parameters if operation box components are damaged.

79 return to factory-set parameter 8: restore the current level and sewing 0~15 0 I

factory parameter set E302 Operation inner failure Sci circuit error To check whether the operating box is damaged..

According to S button, select yES, then

press the S key execution E402 Pedal ID fault Pedal verification fault Pedal connection is loosen.

80 highest speed of sewing highest speed of sewing 300~5000spm 4000 II

The pedal is damaged or it is not under stop state

Needle wear through cloth when used E403 Pedal zero position fault The pedal zero position over range

83 Aggravating function 0~15 6 II when correction.

0: invalid; 1 ~ 15 strength regulation

85 Suction angle of shear line To set suction angle of shear line 150~200 175 II

86 Power angle of shear line To set power angle of shear line 200~300 260 II E501 Safety switch fault Safety switch effective Put down the head or check turned up switch.

87 Release angle of shear line To set release angle of shear line 300~360 340 II P.oFF Power off Display Power off Wait for power supply to resume.

Pedal presser foot lift confirm Note: 1. Sewing abnormal action (speed electromagnet work abnormal) : in the control interface view model is correct;

92 Pedal presser foot lift confirm time 10~300ms 80 II

time 2. Turn up E501 fault when: sure it is normal to switch detection, temporary use can change the P-28 parameters;

The neutral position of the Trimming the neutral position of the

93 -15~15(0.1) 0 II 3. If the above according to check the project cannot rule out fault, please seek technical support.

pedal pedal

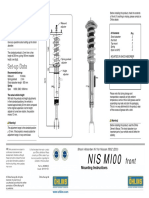

6.Accessories

Product

NO Product name Amount Confirm Remarks

3.System Info specification

Operation panel default mode, press the button at the same time in P made sewing needle trigger select key, enter the system Electric

1 1

monitoring state through the +-key choose need to look at the project, according to the S button to enter/exit the selected control box

projects such as the need to exit monitoring interface, according to P keys can be. Ball section

show frame show frame 2 1

Item Name unit Item Name unit connecting rod

numbers numbers

3 pedal 1 PL-302 with bracket

JJ Plan number piece U5 Mechanical Angle with limit

1 speed of motor control rpm U6 Motor initial Angle limit 4 screw 3 M5×25 screw

2 Motor Current 0.01A U7 Master control program version / The

U3 Motor Voltage V U8 Head type / 5 1

instructions

U4 Pedal voltage 0.01V vEr Operation box version of the program /

6 power cord 1

-1- -2-

You might also like

- Elna Elnita Sewing Machine Instruction ManualDocument9 pagesElna Elnita Sewing Machine Instruction Manualiliiexpugnans100% (1)

- DODGE V Belt IOM PDFDocument8 pagesDODGE V Belt IOM PDFSupervisorNo ratings yet

- Sunstar Fortuna AC Servo Motor VDocument85 pagesSunstar Fortuna AC Servo Motor Vsongdongemdem28No ratings yet

- Full Automatic Disconnect-Type Sewing Series Manual V1.1: 1. Safety InstructionDocument1 pageFull Automatic Disconnect-Type Sewing Series Manual V1.1: 1. Safety InstructionMichelNo ratings yet

- High Series Manual V1.0: 1. Safety InstructionDocument1 pageHigh Series Manual V1.0: 1. Safety InstructionThat TawooNo ratings yet

- Electronic Yarn Feeder: Constant or Remote Controlled Yarn TensionDocument2 pagesElectronic Yarn Feeder: Constant or Remote Controlled Yarn TensioncobaNo ratings yet

- Elect Eg-OcrDocument18 pagesElect Eg-OcrhelenosnetoNo ratings yet

- 杰克A4E-Q English 说明书VersionDocument13 pages杰克A4E-Q English 说明书Versionmajochepe25No ratings yet

- Panasonic Ey7440 Manual de Usuario Páginas 7 9Document3 pagesPanasonic Ey7440 Manual de Usuario Páginas 7 9Mr. Gonza M.No ratings yet

- SG8957AE4,0311E3,9310E4,9320E4,8751E3 Control Box ManualDocument8 pagesSG8957AE4,0311E3,9310E4,9320E4,8751E3 Control Box ManualAlex MedinaNo ratings yet

- Mini Sewing MachineDocument8 pagesMini Sewing MachineDannyNo ratings yet

- Guarantee TimeDocument12 pagesGuarantee TimeRene CamaraNo ratings yet

- For Safe Operation: Installation ManualDocument2 pagesFor Safe Operation: Installation ManualAmjad HossenNo ratings yet

- A4 B Electric Control ManualDocument14 pagesA4 B Electric Control ManualALFONSO GARCESNo ratings yet

- Preface: All-In-One Auto Trimmer and Suction Manual BookDocument16 pagesPreface: All-In-One Auto Trimmer and Suction Manual BookAl PoNo ratings yet

- Juki LK-1850 Instruction ManualDocument12 pagesJuki LK-1850 Instruction ManualOscar TorresNo ratings yet

- SD91 MG Manual enDocument1 pageSD91 MG Manual enAimielNo ratings yet

- Electric Vertical Machine ManualDocument3 pagesElectric Vertical Machine ManualHerdian PebiNo ratings yet

- Solar Controller User Manual - 20210729 - 0001Document2 pagesSolar Controller User Manual - 20210729 - 0001gohsaikitNo ratings yet

- Storage Feeder: Constant Yarn Tension, Fewer Knitting FaultsDocument2 pagesStorage Feeder: Constant Yarn Tension, Fewer Knitting FaultscobaNo ratings yet

- Construction Information ALPHA ClampDocument5 pagesConstruction Information ALPHA ClampSandro BeckerNo ratings yet

- Stripping Manual - (Update)Document22 pagesStripping Manual - (Update)Tecnico FiamNo ratings yet

- Welding Oscillator User ManualDocument7 pagesWelding Oscillator User Manualsandra morquechoNo ratings yet

- MVB 140 16530-CDocument62 pagesMVB 140 16530-CKevin Milla100% (2)

- curvadora hidráulico 液压打拱机说明书Document6 pagescurvadora hidráulico 液压打拱机说明书Alfredo BerrocalNo ratings yet

- Log Saw User ManualDocument28 pagesLog Saw User ManualAl Muqarram HygienicNo ratings yet

- P&S Tightening Instructions 07 GBDocument12 pagesP&S Tightening Instructions 07 GBaputraNo ratings yet

- Superbolt Instructions: Pretensioning SystemsDocument12 pagesSuperbolt Instructions: Pretensioning SystemscakhokheNo ratings yet

- For Safe Operation: Description of Error DetectedDocument1 pageFor Safe Operation: Description of Error DetectedAmjad HossenNo ratings yet

- Pac Man Smash Air Hockey Arcade Game Service Manual Namco GamesDocument214 pagesPac Man Smash Air Hockey Arcade Game Service Manual Namco GamesSofNo ratings yet

- LTJM 2099 Rice Polisher English ManualDocument5 pagesLTJM 2099 Rice Polisher English ManualWiwin LatifahNo ratings yet

- Hoist ManualDocument14 pagesHoist ManualgustavovicgarNo ratings yet

- Relative Volatility& Equlibrium DataDocument4 pagesRelative Volatility& Equlibrium DataAqib Amir HansuwNo ratings yet

- SMC Digital Manometer ManualDocument2 pagesSMC Digital Manometer ManualLily LabelsNo ratings yet

- U-508 Operation Manual: Sonic Belt Tension MeterDocument16 pagesU-508 Operation Manual: Sonic Belt Tension MeteripinNo ratings yet

- Synchronous Drive InstallationDocument4 pagesSynchronous Drive InstallationryanmackintoshNo ratings yet

- Hazard Sheet 23: Safety in The Use of Harnesses & Temporary LifelinesDocument6 pagesHazard Sheet 23: Safety in The Use of Harnesses & Temporary LifelinescerajibNo ratings yet

- M9930lu SM Sanyo en TextDocument15 pagesM9930lu SM Sanyo en TextgoNo ratings yet

- Information: 0. General RemarksDocument8 pagesInformation: 0. General RemarksmuhammedasifNo ratings yet

- Ahe58/59 Ac Servo System: Safely InstructionDocument8 pagesAhe58/59 Ac Servo System: Safely InstructionDinh Nguyen100% (1)

- Instruction Manual Zoje ZJ-5780A PDFDocument28 pagesInstruction Manual Zoje ZJ-5780A PDFMaskusyaniNo ratings yet

- Et500plus User ManualDocument8 pagesEt500plus User ManualLarry SausNo ratings yet

- Mi Nismi00Document4 pagesMi Nismi00Sr. PolestarNo ratings yet

- EG-112 ManualDocument14 pagesEG-112 ManualpetropaoNo ratings yet

- Electronic 7-Day Water - Heater Time Switches Models Eh10 and Eh40Document8 pagesElectronic 7-Day Water - Heater Time Switches Models Eh10 and Eh40ismael zelaya mendezNo ratings yet

- VERO-S - SPM-Fixacao - Por MembranaDocument6 pagesVERO-S - SPM-Fixacao - Por MembranaWilson DantasNo ratings yet

- K4-UT Operating ManualDocument51 pagesK4-UT Operating ManualCesar RiveroNo ratings yet

- MS-1261 MS-1261M: Instruction Manual Betriebsanleitung Manuel D'Utilisation Manual de Instrucciones Manuale D'IstruzioniDocument96 pagesMS-1261 MS-1261M: Instruction Manual Betriebsanleitung Manuel D'Utilisation Manual de Instrucciones Manuale D'IstruzioniShafikul IslamNo ratings yet

- Vibration Swicth 3171Document11 pagesVibration Swicth 3171Alexander Dominguez RamonNo ratings yet

- PFAFF Sewing MachineDocument21 pagesPFAFF Sewing MachineZeroNo ratings yet

- White W3300 Sewing Machine Instruction ManualDocument73 pagesWhite W3300 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- 5501E 绷缝单停针一体机电控说明书Document8 pages5501E 绷缝单停针一体机电控说明书JoseNo ratings yet

- Edda 1500 Kanepe PaketlemeDocument25 pagesEdda 1500 Kanepe PaketlemeEMRE KAAN USTA100% (1)

- LD-30FTA: Tension Controller Model Instruction ManualDocument26 pagesLD-30FTA: Tension Controller Model Instruction ManualSnrNo ratings yet

- (OM) Operation ManualDocument5 pages(OM) Operation ManualDennys GuizarNo ratings yet

- A7NETH-2P User's ManualDocument282 pagesA7NETH-2P User's ManualALEXNo ratings yet

- AEG HBS100 de PDFDocument32 pagesAEG HBS100 de PDFMaria MassanetNo ratings yet

- Zba 4 FDocument14 pagesZba 4 Faungp4142No ratings yet

- NV37MR Installation ManualDocument2 pagesNV37MR Installation ManualEdgar UlloaNo ratings yet

- Chopper Regulator Applications: Maximum RatingsDocument6 pagesChopper Regulator Applications: Maximum RatingsDinh NguyenNo ratings yet

- Isc 2SC3457: Silicon NPN Power TransistorDocument3 pagesIsc 2SC3457: Silicon NPN Power TransistorDinh NguyenNo ratings yet

- 700K/700L Split-Type Direct Drive Instruction: OverlockDocument7 pages700K/700L Split-Type Direct Drive Instruction: OverlockDinh NguyenNo ratings yet

- Audio Frequency Amplifier Applications: Absolute Maximum RatingsDocument5 pagesAudio Frequency Amplifier Applications: Absolute Maximum RatingsDinh NguyenNo ratings yet

- Ahe58/59 Ac Servo System: Safely InstructionDocument8 pagesAhe58/59 Ac Servo System: Safely InstructionDinh Nguyen100% (1)

- Preface: User ManualDocument16 pagesPreface: User ManualDinh NguyenNo ratings yet

- SPS/D BH3000Document2 pagesSPS/D BH3000Dinh NguyenNo ratings yet

- Operation Panel Setting Instruction ManualDocument16 pagesOperation Panel Setting Instruction ManualDinh NguyenNo ratings yet

- AHE27 User Manual: PrefaceDocument16 pagesAHE27 User Manual: PrefaceDinh NguyenNo ratings yet

- Error List: No. Error Message Description Alarm Pin NoDocument2 pagesError List: No. Error Message Description Alarm Pin NoDinh NguyenNo ratings yet

- LogDocument39 pagesLogTeguh VivoNo ratings yet

- DES-6322 ExamDocument16 pagesDES-6322 ExamEnes TaştanNo ratings yet

- Vmcore-Dmesg 1Document64 pagesVmcore-Dmesg 1LTI MaintenanceNo ratings yet

- Module 1 - 2-PSA2Document42 pagesModule 1 - 2-PSA2Naveen. N.JNo ratings yet

- AD9951 AppnoteDocument6 pagesAD9951 Appnoteshabaz_yousaf2734No ratings yet

- Karen Yeung, Martin Lodge - Algorithmic Regulation-Oxford University Press (2019)Document305 pagesKaren Yeung, Martin Lodge - Algorithmic Regulation-Oxford University Press (2019)Jhon Jairo Morales Vidal100% (1)

- Louis Braiotta Jr. - The Audit Committee HandbookDocument6 pagesLouis Braiotta Jr. - The Audit Committee HandbookShaneNo ratings yet

- Roblox Privacy Policy 2021-09-17Document45 pagesRoblox Privacy Policy 2021-09-17Katshiumy Strella Porras PaitanNo ratings yet

- Ele Emag Sadiku NelaturyDocument3 pagesEle Emag Sadiku NelaturyMylavarapu SriprithamNo ratings yet

- English II Mid Term TestDocument20 pagesEnglish II Mid Term TestEvelin MontenegroNo ratings yet

- Utility SoftwareDocument2 pagesUtility SoftwareTeddy Muleya SikabangaNo ratings yet

- ASU ToolboxDocument8 pagesASU ToolboxYanira ParraNo ratings yet

- Sweta Intern ReportDocument32 pagesSweta Intern ReportDhiraj JhaNo ratings yet

- OS6560 AOS 8.7.R01 Data Center Switching GuideDocument182 pagesOS6560 AOS 8.7.R01 Data Center Switching GuideAsnake TegenawNo ratings yet

- Tutorial 1.2Document5 pagesTutorial 1.2nurin afiqahNo ratings yet

- Extrusion Software (Presentation)Document30 pagesExtrusion Software (Presentation)Mahmoud KassabNo ratings yet

- Wireline Xy enDocument4 pagesWireline Xy enJuanNo ratings yet

- Lampiran R StudioDocument25 pagesLampiran R StudioSkripsi GorontaloNo ratings yet

- NetworkDocument3 pagesNetworkNikhil kushwahaNo ratings yet

- BBAS4103 Accounting Information System IDocument270 pagesBBAS4103 Accounting Information System IAnnie100% (3)

- Expedition XP106W Cutsheet - 2Document1 pageExpedition XP106W Cutsheet - 2RaymundNo ratings yet

- "Patna Dairy Project (PDP) " Was Started at 1st October, 1981 Through The NationalDocument5 pages"Patna Dairy Project (PDP) " Was Started at 1st October, 1981 Through The NationalMansi ChandNo ratings yet

- 10 ACT Practice Tests 2Document14 pages10 ACT Practice Tests 2Jihyun YeonNo ratings yet

- Canopen: Cia Draft Standard Proposal 305Document17 pagesCanopen: Cia Draft Standard Proposal 305Виктор АлимовNo ratings yet

- Maths Grade 9 Assignment Gauteng Term 1 2022 QP and MemoDocument11 pagesMaths Grade 9 Assignment Gauteng Term 1 2022 QP and MemosayamengaweNo ratings yet

- 4 Management of ComputersDocument10 pages4 Management of ComputersWilliam BisayiNo ratings yet

- LC700 Overview March2000 EaiDocument101 pagesLC700 Overview March2000 EaiCezardeBarrosNo ratings yet

- Gludo - Rubrics - Profed 7Document2 pagesGludo - Rubrics - Profed 7rosearianne.taboraNo ratings yet

- (InCompany 3.0 Pre-Intermediate) End-Of-Course TestDocument5 pages(InCompany 3.0 Pre-Intermediate) End-Of-Course TestelcidessanabNo ratings yet

- Project Management Unit-1 - New SyllabusDocument21 pagesProject Management Unit-1 - New Syllabusvivek singhNo ratings yet