Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

11 viewsPaper 4

Paper 4

Uploaded by

Sana ZahidThis document discusses the effectiveness of direct safety regulations for industrial machines in South Korea. It finds that:

1) Despite efforts, South Korea's industrial accident and fatality rates remain higher than developed countries due to ineffective safety policies and regulations.

2) An analysis of industrial accident causes found that over 76% were due to technical failures of machines, lacking or malfunctioning safety devices.

3) Current safety device regulations have limited indirect impact on users. Safety regulations need to shift focus to complement certification and compliance declarations to better regulate both manufacturers and users.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Value Creation: Q4. How Would You Explain IKEA's Business Model in Terms of Value Creation, Configuration and Capture?Document1 pageValue Creation: Q4. How Would You Explain IKEA's Business Model in Terms of Value Creation, Configuration and Capture?Sana Zahid100% (3)

- Q3 Explain How IKEA Tries To Ensure That TheirDocument1 pageQ3 Explain How IKEA Tries To Ensure That TheirSana ZahidNo ratings yet

- Detailed Lesson Plan in Health (Final Demo)Document4 pagesDetailed Lesson Plan in Health (Final Demo)Maria Gizella Valencia Paa80% (71)

- Q2 Identify How IKEA Have Achieved Differentiation From Their CompetitorsDocument1 pageQ2 Identify How IKEA Have Achieved Differentiation From Their CompetitorsSana Zahid100% (2)

- Ikea CaseDocument2 pagesIkea CaseSana ZahidNo ratings yet

- English Class A2+ Unit 6 Tests Answer Key: Vocabulary Check 6Document5 pagesEnglish Class A2+ Unit 6 Tests Answer Key: Vocabulary Check 6Julia SobierajNo ratings yet

- Chapter 4: Socializing The IndividualDocument24 pagesChapter 4: Socializing The IndividualSana ZahidNo ratings yet

- P-985-SH-AHA-005, AHA For Earthwork (General Excavation)Document5 pagesP-985-SH-AHA-005, AHA For Earthwork (General Excavation)Patrick Bibila Ndansi75% (4)

- An Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleFrom EverandAn Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleNo ratings yet

- Paper 6Document1 pagePaper 6Sana ZahidNo ratings yet

- Machine Safety Directions in Australia 581659296Document6 pagesMachine Safety Directions in Australia 581659296lucas.ck.liaoNo ratings yet

- X Paper 19Document17 pagesX Paper 19mohdfirdausNo ratings yet

- Electrical Safety AuditDocument19 pagesElectrical Safety AuditXozan100% (2)

- 1 s2.0 S2093791116302669 Main PDFDocument9 pages1 s2.0 S2093791116302669 Main PDFmanoj hawaleNo ratings yet

- Bulzacchelli 2007Document6 pagesBulzacchelli 2007Haniatul HidayahNo ratings yet

- The Management of Mechanical Integrity Inspections at Small-SizedDocument6 pagesThe Management of Mechanical Integrity Inspections at Small-SizedTadeu SantanaNo ratings yet

- Identifying and Eliminating Industrial Hazards in RMG Industries: A Case StudyDocument8 pagesIdentifying and Eliminating Industrial Hazards in RMG Industries: A Case StudyijsretNo ratings yet

- 001-A Comparative Analysis of Process Safety Management (PSM) Systems in The Process IndustryDocument14 pages001-A Comparative Analysis of Process Safety Management (PSM) Systems in The Process IndustryMiningSafety185No ratings yet

- 2017t12z3 05Document8 pages2017t12z3 0518rosa18No ratings yet

- Designing Instrumentation and Control For Process SafetyDocument7 pagesDesigning Instrumentation and Control For Process SafetyAdebamboAinaNo ratings yet

- Overview SiraDocument2 pagesOverview SiraIndranil HatuaNo ratings yet

- Human Failure Capitulo 3Document42 pagesHuman Failure Capitulo 3Fernando Alberto Sanguino ArellanoNo ratings yet

- Electrical Safety AuditDocument27 pagesElectrical Safety AuditM Alim Ur Rahman100% (1)

- 3-Industrial ACTSelecting EquipmentDocument16 pages3-Industrial ACTSelecting EquipmentMesafint kassieNo ratings yet

- Integration of Safety in Machine DesignDocument13 pagesIntegration of Safety in Machine DesignronfrendNo ratings yet

- Risk Based Maintanance PDFDocument9 pagesRisk Based Maintanance PDFRafaelPachecoNo ratings yet

- Risk Management in The Oil and Gas Industry-LevsonDocument10 pagesRisk Management in The Oil and Gas Industry-LevsonlizuttNo ratings yet

- 1077-2618/03/$17.00©2003 IeeeDocument6 pages1077-2618/03/$17.00©2003 Ieeegirish19No ratings yet

- Executive Diploma in Project Management Occupational Safety and Environmental Parameters Lt. Kol. Ahmad Zubir JX78946HP702 Feb 23, 2009Document24 pagesExecutive Diploma in Project Management Occupational Safety and Environmental Parameters Lt. Kol. Ahmad Zubir JX78946HP702 Feb 23, 2009Mohamad SyafiqNo ratings yet

- A Root Cause Analysis Method For Industrial Plant - Reliability Improvement and Engineering Design FeedbackDocument6 pagesA Root Cause Analysis Method For Industrial Plant - Reliability Improvement and Engineering Design FeedbackXiang LiuNo ratings yet

- Health and Safety Training Standards and Requirements For Personnel in The Offshore Wind Power IndustryDocument5 pagesHealth and Safety Training Standards and Requirements For Personnel in The Offshore Wind Power IndustryIQPC GmbHNo ratings yet

- MACD Promo EmersonZoneSafety WP JR 08202019Document5 pagesMACD Promo EmersonZoneSafety WP JR 08202019Khor Tze MingNo ratings yet

- Safety Engineering: Felipe A. Arnejo Ii Sheila Marie C. Cagadas Jamelee S. Marzonia John Henry V. MoratallaDocument11 pagesSafety Engineering: Felipe A. Arnejo Ii Sheila Marie C. Cagadas Jamelee S. Marzonia John Henry V. MoratallaSheila Marie CagadasNo ratings yet

- Guide To Safety Machinery SICKDocument128 pagesGuide To Safety Machinery SICKdayglis100% (1)

- Collection of Best Quotation From Many SourcesDocument5 pagesCollection of Best Quotation From Many SourcesabsahkahNo ratings yet

- Implementing OSHA in The Construction Industry - A ReviewDocument24 pagesImplementing OSHA in The Construction Industry - A Reviewz969862100% (4)

- Faut Analysis 2006-EbrahimipourDocument11 pagesFaut Analysis 2006-EbrahimipourAlana RamalhoNo ratings yet

- Functional Safety in Process IndustryDocument10 pagesFunctional Safety in Process Industry59wilchesNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- A Vehicle Bi-Fuel Petrol Engine Condition Prognosis in Service Based On Combined Vibrational and Exhaust Emission SignalsDocument17 pagesA Vehicle Bi-Fuel Petrol Engine Condition Prognosis in Service Based On Combined Vibrational and Exhaust Emission SignalsMohamed N.MansyNo ratings yet

- The Role of Process Safety Management in The Manufacturing Engineering Technology CurriculumDocument6 pagesThe Role of Process Safety Management in The Manufacturing Engineering Technology CurriculumDrakzNo ratings yet

- CHP 1Document6 pagesCHP 1ToniNo ratings yet

- Validating A Safety Critical Railway Application Using Fault InjectionDocument20 pagesValidating A Safety Critical Railway Application Using Fault Injectionwoof1800No ratings yet

- Mmscience - 2015 12 - Machine Tool Health and Usage Monitoring System An Intitial Analyses PDFDocument5 pagesMmscience - 2015 12 - Machine Tool Health and Usage Monitoring System An Intitial Analyses PDFOscarNo ratings yet

- Risk Assessment Reduction Machine Safety Case - Chinniah - 1007Document8 pagesRisk Assessment Reduction Machine Safety Case - Chinniah - 1007Helton OliveiraNo ratings yet

- Work Accidents Investigation Technique WAIT-part IDocument18 pagesWork Accidents Investigation Technique WAIT-part IRajiv NavadiyaNo ratings yet

- Aircraft Reliability ThesisDocument6 pagesAircraft Reliability Thesisfjfcww51100% (2)

- Journal of Accidents and PreventionDocument15 pagesJournal of Accidents and PreventionvnietospereiraNo ratings yet

- Approaches To Safety Engineering ESSAYDocument7 pagesApproaches To Safety Engineering ESSAYChristian D. AllanaNo ratings yet

- Safety and The EnvironmentDocument10 pagesSafety and The EnvironmentYong Kai MingNo ratings yet

- SIL Project In: Slovnaft Bratislava RefineryDocument4 pagesSIL Project In: Slovnaft Bratislava RefineryLuis SantosNo ratings yet

- Aramco Safety ManaementDocument50 pagesAramco Safety Manaementmuthuswamy77No ratings yet

- Safety AuditDocument8 pagesSafety AuditS VashishtaNo ratings yet

- SEMINARDocument11 pagesSEMINARCssusnejwhsNo ratings yet

- Elevated WatchDocument16 pagesElevated Watchpm69kf4rmmNo ratings yet

- 10 Technical Guide Functional SafetyDocument44 pages10 Technical Guide Functional SafetyAlejandro MárquezNo ratings yet

- Benchmarking Industry Practices For The Use of Alarms As Safeguards and Layers of ProtectionDocument30 pagesBenchmarking Industry Practices For The Use of Alarms As Safeguards and Layers of Protectionkirandevi1981No ratings yet

- Sauf SIL Paper 4-99 (Public)Document13 pagesSauf SIL Paper 4-99 (Public)Ahmad AzabNo ratings yet

- Assessment of Safety Management System Implementation in An Approved Maintenance Organization: A Case StudyDocument10 pagesAssessment of Safety Management System Implementation in An Approved Maintenance Organization: A Case Studyalibaba1888No ratings yet

- Industrial Safety and Health ManagementDocument5 pagesIndustrial Safety and Health ManagementAssignmentLab.comNo ratings yet

- SPE - DescriptionDocument5 pagesSPE - DescriptionJuan VelasquezNo ratings yet

- Hazard Identification and Evalution in Construction IndustryDocument10 pagesHazard Identification and Evalution in Construction IndustryIJSTENo ratings yet

- Mansur 2016 IOP Conf. Ser. Mater. Sci. Eng. 105 012033Document10 pagesMansur 2016 IOP Conf. Ser. Mater. Sci. Eng. 105 012033Fahmi MatarangNo ratings yet

- Hazard Identification SKYbrary Aviation SafetyDocument13 pagesHazard Identification SKYbrary Aviation SafetyToto SubagyoNo ratings yet

- Practical Control of Electric Machines: Model-Based Design and SimulationFrom EverandPractical Control of Electric Machines: Model-Based Design and SimulationNo ratings yet

- Challenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsFrom EverandChallenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsNo ratings yet

- Application of Probabilistic Methods for the Safety Assessment and the Reliable Operation of Research ReactorsFrom EverandApplication of Probabilistic Methods for the Safety Assessment and the Reliable Operation of Research ReactorsNo ratings yet

- Religious InstitutionsDocument19 pagesReligious InstitutionsSana Zahid100% (1)

- HRM in A Changing Environment: Fundamentals of Human Resource Management, 10/E, Decenzo/RobbinsDocument12 pagesHRM in A Changing Environment: Fundamentals of Human Resource Management, 10/E, Decenzo/RobbinsSana ZahidNo ratings yet

- Organizational BehaviorDocument34 pagesOrganizational BehaviorSana ZahidNo ratings yet

- Power: A Capacity That A Has To Influence The Behavior of B So That B Acts in Accordance With A's WishesDocument20 pagesPower: A Capacity That A Has To Influence The Behavior of B So That B Acts in Accordance With A's WishesSana ZahidNo ratings yet

- The Valuation of Long-Term SecuritiesDocument54 pagesThe Valuation of Long-Term SecuritiesSana ZahidNo ratings yet

- Investment FunctionDocument18 pagesInvestment FunctionSana ZahidNo ratings yet

- Business Model of Hotel IndustryDocument1 pageBusiness Model of Hotel IndustrySana ZahidNo ratings yet

- Family:: Partner Taking, People Making, and Contract BreakingDocument14 pagesFamily:: Partner Taking, People Making, and Contract BreakingSana ZahidNo ratings yet

- Do Personality and Organizational Politics Predict Workplace Victimization? A Study Among Ghanaian EmployeesDocument1 pageDo Personality and Organizational Politics Predict Workplace Victimization? A Study Among Ghanaian EmployeesSana ZahidNo ratings yet

- Paper 6Document1 pagePaper 6Sana ZahidNo ratings yet

- Point B An - Fabie Reza 12Document14 pagesPoint B An - Fabie Reza 12Ahmad Syaifudin Geming IndonesiaNo ratings yet

- Research DefendDocument4 pagesResearch DefendRian Hanz AlbercaNo ratings yet

- Job Hahards Analysis (Jha) For Preventive Maintenance: Project Name: Preventive Maintenace Client: EHS LENSDocument2 pagesJob Hahards Analysis (Jha) For Preventive Maintenance: Project Name: Preventive Maintenace Client: EHS LENSRaniel NecesitoNo ratings yet

- Safety SlogansDocument3 pagesSafety Slogansthomas alphoNo ratings yet

- Forensic Science Project.Document13 pagesForensic Science Project.poojaNo ratings yet

- Child Abuse Prevention and Reporting PlanDocument4 pagesChild Abuse Prevention and Reporting Planapi-544915903No ratings yet

- Tradução e Validação Do Questionário FAOS - Foot and Ankle Outcome Score para Língua PortuguesaDocument5 pagesTradução e Validação Do Questionário FAOS - Foot and Ankle Outcome Score para Língua PortuguesaRogéria RibeiroNo ratings yet

- General Instructions For Canine Trauma Combat Casualty Care Card (CTCCC)Document3 pagesGeneral Instructions For Canine Trauma Combat Casualty Care Card (CTCCC)Felix WinklerNo ratings yet

- Cuboid FractureDocument9 pagesCuboid FractureSilvia AlexandraNo ratings yet

- CDI 2 Module 3 Script 3Document14 pagesCDI 2 Module 3 Script 3Jezronzamri Peral SasoNo ratings yet

- Chapter 2 Softtissueinjuries 05 Apr 09Document7 pagesChapter 2 Softtissueinjuries 05 Apr 09K49B Y sỹ đa khoaNo ratings yet

- Ergonomics CIHDocument13 pagesErgonomics CIHHinalNo ratings yet

- Man Chapter 4 MCQDocument5 pagesMan Chapter 4 MCQAkash RathodNo ratings yet

- A.15 Project Completion Health and Safety ReviewDocument2 pagesA.15 Project Completion Health and Safety ReviewSami AjNo ratings yet

- 7.5 Statistical Data-Safety RecordsDocument2 pages7.5 Statistical Data-Safety RecordsKlemens SuhartonoNo ratings yet

- Effects of Camping First Aid Awareness Program On Short-Term Knowledge of Individuals at Al-Quryyat CityDocument13 pagesEffects of Camping First Aid Awareness Program On Short-Term Knowledge of Individuals at Al-Quryyat Cityindex PubNo ratings yet

- Hazard Identification, Risk Assessment, and Risk Control RegisterDocument2 pagesHazard Identification, Risk Assessment, and Risk Control RegisterFaisal JailaniNo ratings yet

- Back Injuries in ConstructionDocument3 pagesBack Injuries in ConstructionNurNo ratings yet

- Workplace Fire - Risk AssessmentDocument10 pagesWorkplace Fire - Risk AssessmentdeusNo ratings yet

- Report Format Conditions Unsafe Acts and IncidentsDocument3 pagesReport Format Conditions Unsafe Acts and IncidentsScribdTranslationsNo ratings yet

- Physical Activity and Active RecreationDocument38 pagesPhysical Activity and Active Recreationivan hernandezNo ratings yet

- HOPE 12 ModuleDocument27 pagesHOPE 12 ModuleNannah IbrahimNo ratings yet

- Concrete Pouring, Rebar, Formwork (Approved)Document2 pagesConcrete Pouring, Rebar, Formwork (Approved)Jixtha SaintNo ratings yet

- Ergonomics PPT v-03!01!17Document54 pagesErgonomics PPT v-03!01!17Ajeet TiwariNo ratings yet

- My Vampire 661-670 ChapterDocument48 pagesMy Vampire 661-670 ChapterLargu George DanielNo ratings yet

- Safety Alert Finger PinchDocument1 pageSafety Alert Finger PinchAadil HaroonNo ratings yet

- Level 2 Risk Assessment Form - UTTM - Rev0Document2 pagesLevel 2 Risk Assessment Form - UTTM - Rev0Raznan RamliNo ratings yet

Paper 4

Paper 4

Uploaded by

Sana Zahid0 ratings0% found this document useful (0 votes)

11 views1 pageThis document discusses the effectiveness of direct safety regulations for industrial machines in South Korea. It finds that:

1) Despite efforts, South Korea's industrial accident and fatality rates remain higher than developed countries due to ineffective safety policies and regulations.

2) An analysis of industrial accident causes found that over 76% were due to technical failures of machines, lacking or malfunctioning safety devices.

3) Current safety device regulations have limited indirect impact on users. Safety regulations need to shift focus to complement certification and compliance declarations to better regulate both manufacturers and users.

Original Description:

paper 4

Original Title

paper 4

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses the effectiveness of direct safety regulations for industrial machines in South Korea. It finds that:

1) Despite efforts, South Korea's industrial accident and fatality rates remain higher than developed countries due to ineffective safety policies and regulations.

2) An analysis of industrial accident causes found that over 76% were due to technical failures of machines, lacking or malfunctioning safety devices.

3) Current safety device regulations have limited indirect impact on users. Safety regulations need to shift focus to complement certification and compliance declarations to better regulate both manufacturers and users.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

11 views1 pagePaper 4

Paper 4

Uploaded by

Sana ZahidThis document discusses the effectiveness of direct safety regulations for industrial machines in South Korea. It finds that:

1) Despite efforts, South Korea's industrial accident and fatality rates remain higher than developed countries due to ineffective safety policies and regulations.

2) An analysis of industrial accident causes found that over 76% were due to technical failures of machines, lacking or malfunctioning safety devices.

3) Current safety device regulations have limited indirect impact on users. Safety regulations need to shift focus to complement certification and compliance declarations to better regulate both manufacturers and users.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

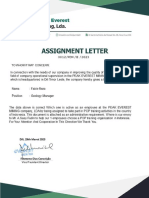

Effectiveness of Direct Safety Regulations on Manufacturers and Users

of Industrial Machines: Its Implications on Industrial Safety Policies in

Republic of Korea

Gi Heung Choi*

Department of Mechanical Systems Engineering, Hansung University, Seoul, Republic of Korea

articleinfo

Article history:

Received 3 November 2015

Received in revised form

21 September 2016

Accepted 23 September 2016

Available online 3 November 2016

Keywords:

direct regulation

safety certification

self-declaration of conformity

safety device regulation

safety inspection

abstract

Background: Despite considerable efforts made in recent years, the industrial accident rate and the fatality

rate in the Republic of Korea are much higher than those in most developed countries in Europe

and North America. Industrial safety policies and safety regulations are also known to be ineffective and

inefficient in some cases.

Methods: This study focuses on the quantitative evaluation of the effectiveness of direct safety regulations

such as safety certification, self-declaration of conformity, and safety inspection of industrial machines

in the Republic of Korea. Implications on safety policies to restructure the industrial safety system

associated with industrial machines are also explored.

Results: Analysis of causes in industrial accidents associated with industrial machines confirms that

technical causes need to be resolved to reduce both the frequency and the severity of such industrial

accidents. Statistical analysis also confirms that the indirect effects of safety device regulation on users

are limited for a variety of reasons. Safety device regulation needs to be shifted to complement safety

certification and self-declaration of conformity for more balanced direct regulations on manufacturers

and users. An example of cost-benefit analysis on conveyor justifies such a transition.

Conclusion: Industrial safety policies and regulations associated with industrial machines must be

directed towards eliminating the sources of danger at the stage of danger creation, thereby securing the

safe industrial machines. Safety inspection further secures the safety of workers at the stage of danger

use. The overall balance between such safety regulations is achieved by proper distribution of industrial

machines subject to such regulations and the intensity of each regulation. Rearrangement of industrial

machines subject to safety certification and self-declaration of conformity to include more movable

industrial machines and other industrial machines with a high level of danger is also suggested.

_ 2016, Occupational Safety and Health Research Institute. Published by Elsevier. This is an open access

article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/).

1. Introduction

Despite considerable efforts made in recent years, the industrial

accident rate (defined as the number of injuries and deaths per 100

workers or employees) and the fatality rate (defined as the number

of deaths per 100,000 workers or employees) in the Republic of

Korea are much higher than those in most developed countries in

Europe and North America [1]. Statistical analysis further revealed

that 76.92% of all industrial accidents associated with industrial

machines (hereafter referred to as “items”) were caused by technical

reasons in the Republic of Korea. For ease of interpretation, the

term “industrial accidents” was used to indicate all industrial accidents

that involved injuries or deaths or both in this study.

Fig. 1 depicts a flow chart for cause analysis of industrial accidents

associated with items. Causes of industrial accidents are first

classified into technical ones, managerial ones, and educational

ones at the highest level. These causes are further classified at

subsequent levels. In 2009, 28,441 cases of industrial accidents

associated with items were analyzed to classify their causes according

to the flow chart in Fig. 1. Most of the industrial accidents

caused by technical reasons were mainly due to defects of items,

items without safety devices, or malfunctioning of safety devices

attached to them, as shown in Table 1. Malfunction or defects of

personal protection equipment account for only a small portion of

those cases. Statistical analysis also showed that 59.66% (16,968

cases) among them were preventable. Managerial causes and dhsgfhsj fbsfshuf fhbsjfhujs

You might also like

- Value Creation: Q4. How Would You Explain IKEA's Business Model in Terms of Value Creation, Configuration and Capture?Document1 pageValue Creation: Q4. How Would You Explain IKEA's Business Model in Terms of Value Creation, Configuration and Capture?Sana Zahid100% (3)

- Q3 Explain How IKEA Tries To Ensure That TheirDocument1 pageQ3 Explain How IKEA Tries To Ensure That TheirSana ZahidNo ratings yet

- Detailed Lesson Plan in Health (Final Demo)Document4 pagesDetailed Lesson Plan in Health (Final Demo)Maria Gizella Valencia Paa80% (71)

- Q2 Identify How IKEA Have Achieved Differentiation From Their CompetitorsDocument1 pageQ2 Identify How IKEA Have Achieved Differentiation From Their CompetitorsSana Zahid100% (2)

- Ikea CaseDocument2 pagesIkea CaseSana ZahidNo ratings yet

- English Class A2+ Unit 6 Tests Answer Key: Vocabulary Check 6Document5 pagesEnglish Class A2+ Unit 6 Tests Answer Key: Vocabulary Check 6Julia SobierajNo ratings yet

- Chapter 4: Socializing The IndividualDocument24 pagesChapter 4: Socializing The IndividualSana ZahidNo ratings yet

- P-985-SH-AHA-005, AHA For Earthwork (General Excavation)Document5 pagesP-985-SH-AHA-005, AHA For Earthwork (General Excavation)Patrick Bibila Ndansi75% (4)

- An Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleFrom EverandAn Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleNo ratings yet

- Paper 6Document1 pagePaper 6Sana ZahidNo ratings yet

- Machine Safety Directions in Australia 581659296Document6 pagesMachine Safety Directions in Australia 581659296lucas.ck.liaoNo ratings yet

- X Paper 19Document17 pagesX Paper 19mohdfirdausNo ratings yet

- Electrical Safety AuditDocument19 pagesElectrical Safety AuditXozan100% (2)

- 1 s2.0 S2093791116302669 Main PDFDocument9 pages1 s2.0 S2093791116302669 Main PDFmanoj hawaleNo ratings yet

- Bulzacchelli 2007Document6 pagesBulzacchelli 2007Haniatul HidayahNo ratings yet

- The Management of Mechanical Integrity Inspections at Small-SizedDocument6 pagesThe Management of Mechanical Integrity Inspections at Small-SizedTadeu SantanaNo ratings yet

- Identifying and Eliminating Industrial Hazards in RMG Industries: A Case StudyDocument8 pagesIdentifying and Eliminating Industrial Hazards in RMG Industries: A Case StudyijsretNo ratings yet

- 001-A Comparative Analysis of Process Safety Management (PSM) Systems in The Process IndustryDocument14 pages001-A Comparative Analysis of Process Safety Management (PSM) Systems in The Process IndustryMiningSafety185No ratings yet

- 2017t12z3 05Document8 pages2017t12z3 0518rosa18No ratings yet

- Designing Instrumentation and Control For Process SafetyDocument7 pagesDesigning Instrumentation and Control For Process SafetyAdebamboAinaNo ratings yet

- Overview SiraDocument2 pagesOverview SiraIndranil HatuaNo ratings yet

- Human Failure Capitulo 3Document42 pagesHuman Failure Capitulo 3Fernando Alberto Sanguino ArellanoNo ratings yet

- Electrical Safety AuditDocument27 pagesElectrical Safety AuditM Alim Ur Rahman100% (1)

- 3-Industrial ACTSelecting EquipmentDocument16 pages3-Industrial ACTSelecting EquipmentMesafint kassieNo ratings yet

- Integration of Safety in Machine DesignDocument13 pagesIntegration of Safety in Machine DesignronfrendNo ratings yet

- Risk Based Maintanance PDFDocument9 pagesRisk Based Maintanance PDFRafaelPachecoNo ratings yet

- Risk Management in The Oil and Gas Industry-LevsonDocument10 pagesRisk Management in The Oil and Gas Industry-LevsonlizuttNo ratings yet

- 1077-2618/03/$17.00©2003 IeeeDocument6 pages1077-2618/03/$17.00©2003 Ieeegirish19No ratings yet

- Executive Diploma in Project Management Occupational Safety and Environmental Parameters Lt. Kol. Ahmad Zubir JX78946HP702 Feb 23, 2009Document24 pagesExecutive Diploma in Project Management Occupational Safety and Environmental Parameters Lt. Kol. Ahmad Zubir JX78946HP702 Feb 23, 2009Mohamad SyafiqNo ratings yet

- A Root Cause Analysis Method For Industrial Plant - Reliability Improvement and Engineering Design FeedbackDocument6 pagesA Root Cause Analysis Method For Industrial Plant - Reliability Improvement and Engineering Design FeedbackXiang LiuNo ratings yet

- Health and Safety Training Standards and Requirements For Personnel in The Offshore Wind Power IndustryDocument5 pagesHealth and Safety Training Standards and Requirements For Personnel in The Offshore Wind Power IndustryIQPC GmbHNo ratings yet

- MACD Promo EmersonZoneSafety WP JR 08202019Document5 pagesMACD Promo EmersonZoneSafety WP JR 08202019Khor Tze MingNo ratings yet

- Safety Engineering: Felipe A. Arnejo Ii Sheila Marie C. Cagadas Jamelee S. Marzonia John Henry V. MoratallaDocument11 pagesSafety Engineering: Felipe A. Arnejo Ii Sheila Marie C. Cagadas Jamelee S. Marzonia John Henry V. MoratallaSheila Marie CagadasNo ratings yet

- Guide To Safety Machinery SICKDocument128 pagesGuide To Safety Machinery SICKdayglis100% (1)

- Collection of Best Quotation From Many SourcesDocument5 pagesCollection of Best Quotation From Many SourcesabsahkahNo ratings yet

- Implementing OSHA in The Construction Industry - A ReviewDocument24 pagesImplementing OSHA in The Construction Industry - A Reviewz969862100% (4)

- Faut Analysis 2006-EbrahimipourDocument11 pagesFaut Analysis 2006-EbrahimipourAlana RamalhoNo ratings yet

- Functional Safety in Process IndustryDocument10 pagesFunctional Safety in Process Industry59wilchesNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- A Vehicle Bi-Fuel Petrol Engine Condition Prognosis in Service Based On Combined Vibrational and Exhaust Emission SignalsDocument17 pagesA Vehicle Bi-Fuel Petrol Engine Condition Prognosis in Service Based On Combined Vibrational and Exhaust Emission SignalsMohamed N.MansyNo ratings yet

- The Role of Process Safety Management in The Manufacturing Engineering Technology CurriculumDocument6 pagesThe Role of Process Safety Management in The Manufacturing Engineering Technology CurriculumDrakzNo ratings yet

- CHP 1Document6 pagesCHP 1ToniNo ratings yet

- Validating A Safety Critical Railway Application Using Fault InjectionDocument20 pagesValidating A Safety Critical Railway Application Using Fault Injectionwoof1800No ratings yet

- Mmscience - 2015 12 - Machine Tool Health and Usage Monitoring System An Intitial Analyses PDFDocument5 pagesMmscience - 2015 12 - Machine Tool Health and Usage Monitoring System An Intitial Analyses PDFOscarNo ratings yet

- Risk Assessment Reduction Machine Safety Case - Chinniah - 1007Document8 pagesRisk Assessment Reduction Machine Safety Case - Chinniah - 1007Helton OliveiraNo ratings yet

- Work Accidents Investigation Technique WAIT-part IDocument18 pagesWork Accidents Investigation Technique WAIT-part IRajiv NavadiyaNo ratings yet

- Aircraft Reliability ThesisDocument6 pagesAircraft Reliability Thesisfjfcww51100% (2)

- Journal of Accidents and PreventionDocument15 pagesJournal of Accidents and PreventionvnietospereiraNo ratings yet

- Approaches To Safety Engineering ESSAYDocument7 pagesApproaches To Safety Engineering ESSAYChristian D. AllanaNo ratings yet

- Safety and The EnvironmentDocument10 pagesSafety and The EnvironmentYong Kai MingNo ratings yet

- SIL Project In: Slovnaft Bratislava RefineryDocument4 pagesSIL Project In: Slovnaft Bratislava RefineryLuis SantosNo ratings yet

- Aramco Safety ManaementDocument50 pagesAramco Safety Manaementmuthuswamy77No ratings yet

- Safety AuditDocument8 pagesSafety AuditS VashishtaNo ratings yet

- SEMINARDocument11 pagesSEMINARCssusnejwhsNo ratings yet

- Elevated WatchDocument16 pagesElevated Watchpm69kf4rmmNo ratings yet

- 10 Technical Guide Functional SafetyDocument44 pages10 Technical Guide Functional SafetyAlejandro MárquezNo ratings yet

- Benchmarking Industry Practices For The Use of Alarms As Safeguards and Layers of ProtectionDocument30 pagesBenchmarking Industry Practices For The Use of Alarms As Safeguards and Layers of Protectionkirandevi1981No ratings yet

- Sauf SIL Paper 4-99 (Public)Document13 pagesSauf SIL Paper 4-99 (Public)Ahmad AzabNo ratings yet

- Assessment of Safety Management System Implementation in An Approved Maintenance Organization: A Case StudyDocument10 pagesAssessment of Safety Management System Implementation in An Approved Maintenance Organization: A Case Studyalibaba1888No ratings yet

- Industrial Safety and Health ManagementDocument5 pagesIndustrial Safety and Health ManagementAssignmentLab.comNo ratings yet

- SPE - DescriptionDocument5 pagesSPE - DescriptionJuan VelasquezNo ratings yet

- Hazard Identification and Evalution in Construction IndustryDocument10 pagesHazard Identification and Evalution in Construction IndustryIJSTENo ratings yet

- Mansur 2016 IOP Conf. Ser. Mater. Sci. Eng. 105 012033Document10 pagesMansur 2016 IOP Conf. Ser. Mater. Sci. Eng. 105 012033Fahmi MatarangNo ratings yet

- Hazard Identification SKYbrary Aviation SafetyDocument13 pagesHazard Identification SKYbrary Aviation SafetyToto SubagyoNo ratings yet

- Practical Control of Electric Machines: Model-Based Design and SimulationFrom EverandPractical Control of Electric Machines: Model-Based Design and SimulationNo ratings yet

- Challenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsFrom EverandChallenges and Approaches for Selecting, Assessing and Qualifying Commercial Industrial Digital Instrumentation and Control Equipment for Use in Nuclear Power Plant ApplicationsNo ratings yet

- Application of Probabilistic Methods for the Safety Assessment and the Reliable Operation of Research ReactorsFrom EverandApplication of Probabilistic Methods for the Safety Assessment and the Reliable Operation of Research ReactorsNo ratings yet

- Religious InstitutionsDocument19 pagesReligious InstitutionsSana Zahid100% (1)

- HRM in A Changing Environment: Fundamentals of Human Resource Management, 10/E, Decenzo/RobbinsDocument12 pagesHRM in A Changing Environment: Fundamentals of Human Resource Management, 10/E, Decenzo/RobbinsSana ZahidNo ratings yet

- Organizational BehaviorDocument34 pagesOrganizational BehaviorSana ZahidNo ratings yet

- Power: A Capacity That A Has To Influence The Behavior of B So That B Acts in Accordance With A's WishesDocument20 pagesPower: A Capacity That A Has To Influence The Behavior of B So That B Acts in Accordance With A's WishesSana ZahidNo ratings yet

- The Valuation of Long-Term SecuritiesDocument54 pagesThe Valuation of Long-Term SecuritiesSana ZahidNo ratings yet

- Investment FunctionDocument18 pagesInvestment FunctionSana ZahidNo ratings yet

- Business Model of Hotel IndustryDocument1 pageBusiness Model of Hotel IndustrySana ZahidNo ratings yet

- Family:: Partner Taking, People Making, and Contract BreakingDocument14 pagesFamily:: Partner Taking, People Making, and Contract BreakingSana ZahidNo ratings yet

- Do Personality and Organizational Politics Predict Workplace Victimization? A Study Among Ghanaian EmployeesDocument1 pageDo Personality and Organizational Politics Predict Workplace Victimization? A Study Among Ghanaian EmployeesSana ZahidNo ratings yet

- Paper 6Document1 pagePaper 6Sana ZahidNo ratings yet

- Point B An - Fabie Reza 12Document14 pagesPoint B An - Fabie Reza 12Ahmad Syaifudin Geming IndonesiaNo ratings yet

- Research DefendDocument4 pagesResearch DefendRian Hanz AlbercaNo ratings yet

- Job Hahards Analysis (Jha) For Preventive Maintenance: Project Name: Preventive Maintenace Client: EHS LENSDocument2 pagesJob Hahards Analysis (Jha) For Preventive Maintenance: Project Name: Preventive Maintenace Client: EHS LENSRaniel NecesitoNo ratings yet

- Safety SlogansDocument3 pagesSafety Slogansthomas alphoNo ratings yet

- Forensic Science Project.Document13 pagesForensic Science Project.poojaNo ratings yet

- Child Abuse Prevention and Reporting PlanDocument4 pagesChild Abuse Prevention and Reporting Planapi-544915903No ratings yet

- Tradução e Validação Do Questionário FAOS - Foot and Ankle Outcome Score para Língua PortuguesaDocument5 pagesTradução e Validação Do Questionário FAOS - Foot and Ankle Outcome Score para Língua PortuguesaRogéria RibeiroNo ratings yet

- General Instructions For Canine Trauma Combat Casualty Care Card (CTCCC)Document3 pagesGeneral Instructions For Canine Trauma Combat Casualty Care Card (CTCCC)Felix WinklerNo ratings yet

- Cuboid FractureDocument9 pagesCuboid FractureSilvia AlexandraNo ratings yet

- CDI 2 Module 3 Script 3Document14 pagesCDI 2 Module 3 Script 3Jezronzamri Peral SasoNo ratings yet

- Chapter 2 Softtissueinjuries 05 Apr 09Document7 pagesChapter 2 Softtissueinjuries 05 Apr 09K49B Y sỹ đa khoaNo ratings yet

- Ergonomics CIHDocument13 pagesErgonomics CIHHinalNo ratings yet

- Man Chapter 4 MCQDocument5 pagesMan Chapter 4 MCQAkash RathodNo ratings yet

- A.15 Project Completion Health and Safety ReviewDocument2 pagesA.15 Project Completion Health and Safety ReviewSami AjNo ratings yet

- 7.5 Statistical Data-Safety RecordsDocument2 pages7.5 Statistical Data-Safety RecordsKlemens SuhartonoNo ratings yet

- Effects of Camping First Aid Awareness Program On Short-Term Knowledge of Individuals at Al-Quryyat CityDocument13 pagesEffects of Camping First Aid Awareness Program On Short-Term Knowledge of Individuals at Al-Quryyat Cityindex PubNo ratings yet

- Hazard Identification, Risk Assessment, and Risk Control RegisterDocument2 pagesHazard Identification, Risk Assessment, and Risk Control RegisterFaisal JailaniNo ratings yet

- Back Injuries in ConstructionDocument3 pagesBack Injuries in ConstructionNurNo ratings yet

- Workplace Fire - Risk AssessmentDocument10 pagesWorkplace Fire - Risk AssessmentdeusNo ratings yet

- Report Format Conditions Unsafe Acts and IncidentsDocument3 pagesReport Format Conditions Unsafe Acts and IncidentsScribdTranslationsNo ratings yet

- Physical Activity and Active RecreationDocument38 pagesPhysical Activity and Active Recreationivan hernandezNo ratings yet

- HOPE 12 ModuleDocument27 pagesHOPE 12 ModuleNannah IbrahimNo ratings yet

- Concrete Pouring, Rebar, Formwork (Approved)Document2 pagesConcrete Pouring, Rebar, Formwork (Approved)Jixtha SaintNo ratings yet

- Ergonomics PPT v-03!01!17Document54 pagesErgonomics PPT v-03!01!17Ajeet TiwariNo ratings yet

- My Vampire 661-670 ChapterDocument48 pagesMy Vampire 661-670 ChapterLargu George DanielNo ratings yet

- Safety Alert Finger PinchDocument1 pageSafety Alert Finger PinchAadil HaroonNo ratings yet

- Level 2 Risk Assessment Form - UTTM - Rev0Document2 pagesLevel 2 Risk Assessment Form - UTTM - Rev0Raznan RamliNo ratings yet