Professional Documents

Culture Documents

04 WPS Atp Asme 2012 (A312 304) (A312 310)

04 WPS Atp Asme 2012 (A312 304) (A312 310)

Uploaded by

lailatul kodriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

04 WPS Atp Asme 2012 (A312 304) (A312 310)

04 WPS Atp Asme 2012 (A312 304) (A312 310)

Uploaded by

lailatul kodriCopyright:

Available Formats

I

"I PT.Aditya Tangguh Perkasa

9'i Combustion Engineering and S11pp'°f

JI. Swatantra II Cluster The Swatantra B1

Jatiasih Bekasi Jawa Barat 17423

phone +62 21 82752239

email : erlangga1103@gmail.com

QW-482 WELDING PROCEDURE SPECIFICATION (WPS)

Company Name PT AdityaTangguh Perkasa

Welding Procedure Spec. No. 04/WPS/KCI/ASME/2012 Date Supporting PQR No. (s) 04/PQRIKCIIASME/2012

Revision No. Date

Welding Process(es) GTAW Type(s) Manual

(Automatic, Manual, Machine, or Semi Auto)

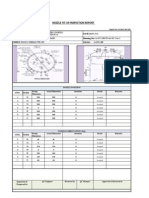

JOINTS (QW-402)

Detalls

Joint Design Single V Groove

Backing (Yes) (No) Details

- Backing Material (Type)

00'to6So

0 Metal 0 Nonfusing Metal

rl

0 Nonmetallic 0 Other

R

-:

Sketches, Production Drawing, Weld Symbols

or Written Description should show the general

,�

',c !

- �

arrangement of the parts to be welded. Where

applicable, the root spacing and the details of j_l

'

""�

weld groove maybe specified.

* BASE METALS (QW-403)

P-No. 8 Group No. 1 to P-No. 8 Group No. 2

OR

Specification type and grade SA-312 TP 304

to Specification type and grade SA-312 TP 310

OR

Chem. Analysis and Mech Prop.

to Chem. Analysis and Mech Prop.

'<, Thickness Range :

Base Metal: Groove 1 . 5 - 7.36 mm Fillet All

Pipe Dia. range Groove All Fillet All

Other

* FILLER METALS (QW-404)

(1"' layery

Spec. No. (SFA) A-5.9

AWS No. (Class) ER-308

F-No. 6

A-No. 8

Size of Filler Metals 2.4mm

Weld Metal

Thickness Range :

Groove 7.36 mm max

Fillet

Electrode-Flux (Class)

Consumable Insert

Other

Page1of2

No. Reg . / /.I

,&1 JJ '!&I jq/-R

Tanggal: 1 4 MAR 1011

.

111'1 PT.Aditya Tangguh Perkasa

l'9 Combu�ion Ertglneering and Supply

Jl.Swatantra II Cluster The Swatantra

B1Jatiasih Jawabarat 17423

phone : +62 21 82752239

email : erlangga1103@gmail.com

04/WPSIKCVASME/2012 RevO

POSITION (QW-405) POSTWELD HEAT TREATMENT (QW-107)

Position(s) of Groove ----�Al�--- Temperature Range NA

Welding Progression : ---------- Time Range _,

NA=----

Position(s) of Fillet - ""o�A�S�(

� Q�W�-<

� 0

8�)

- ------------�

PREHEAT (QW....06)

Percent Composition

Preheat Temp. Min. __:

-c._ _

Ga�es) (Mixture) Flow Rate

lnterpass Temp. Mex. Shielding 9990% 8-12 ltr

"'�

Preheat Maintenance during welding cycle Trailing -

-

(Continuous or special heating where appNcable Backing Ar�n 99,90% 6-121tr

should be recorderl\

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC ���DCc"--�_Polarity �--�DC

,;,;

EN7.e

- --

Amps (Range) 80-150 Volts(Range) �

(Amps and volts range should be recorded for each electrode size,

positions, and thickness, etc This information may be listed in

tabular form similar to that shown below.)

Tungsten Electrode Size and Type 02.4 mm and 2% Thoriated

Mode of Metal Transfer for GMAW _,,NcA�-------------

Electrode W1r

e feed speed range NA

TECHNIQUE (QW-410)

String or Wave Bead ----------'

"'""

"">

.O

C'•

"•'

cW�o

e"e

'cbo

e,•

edc_ _

Orifice or Gas Cup Size �-����---��-"N0A��---����-------

lnillal Imel lnterpass Cleaning (Brushing, Grinding, etc.) Brushing and Grindinff

Method of Back Gouging NA

Oscillation NA

C

ont

a

ctT

ube

- -

,,

-w�..,

� .,..

� -

- ,-""'---------""----_---------------

Multiple or Single Pass (per side) MuiiFle Pass

Multiple or Single Electrodes Sinnle Electrode

Trav�Speed (Range)�--------->'s'c-taOeOcmeml""'m";""---------------

Peening _

Ofuer-----------------------------�

F�ler Metal Coo-ent

Travel

Weld Volt

precess

Speed Remark

Layer(s) Type Amp. Range

Class Dia. Range

Pola, Range

1 GTAW ER-308 2.4mm DCEN 80-150 20-30 25-100

2 GTAW ER·308 2.4mm DCEN 80-150 20-30 25-100

3 GTAW ER-308 2.4mm DCEN 80-150 20-30 25-100

Preoared Bv · Review Bv.

��;' /A#s Ik//

,ffy� D ' '

��

\ ,. ...,, , M;g,s

Danar

l��i � ��b: nl _.......jl

L--------------------�.:,: B:987031002 Page2of2

PT.Aditya Tangguh Perkasa

1(1 Combustion Engineering and Supply

Jl.Swatantra II Cluster The Swatantra B1

Jatiasih Bekasi Jawa Barat 17423

phone : +62 21 82752239

email : erlangga1103@gmail.com

PROCEDURE QUALIFICATION RECORD ( PQR )

{ ASME IX BOILER ANO PRESSURE VESSEL CODE )

--- 1 of 2

PCR No. : 04/PQRIKCI/ASME/2012 Revision No Dato

WPS No. . 04M'PSIKCI/ASME/2012

Rl!YISIOl'I No Dato

Welding Process (es) : GTAW T yp e ( s )

BASE METAL

POST WELD HEAD TREATMENT :

. SA-312 SA-312 Temperature NA

""°""

Type of Grade . TP 304 TP 310 Time NA

NA

: 3 68 m m mm """"

-""""

3.68

Dillmeter : 1 5 inch

Deposit Weld Metal

""

Type of Gas

FILLER METAL Composition of Gas Mixture "'""

Analysm A

99 '°"

Weld Metal No : ANo.8 Flow Rate

8-12 ltr

/ min

Size of Electrode : z.amm

Flier Metal F No. : F No.6

ELETRIC CHARACTERSTIC :

SFA Specification : A5.9

Current DC Polarity : OCEN

AWS Classification : ER-308

Volt : 20-30

(Brand) : Kobe Steel Amp . 80-150

POSITION TECHNIQUE

'

'

Posttion ol Groove :6G String or Weave 6ead : String & Weave

Weld

=�

Progression : UphNI

--

Multiple Of Single

Multiple 0< Single Electrode

Paa

' NA

: Single Pasa

: Single Electrode

PREHEAT Initial and !nterpass Cleaniog : Brush and Grinding

'

Preheat Temperature : Ambient Methode of Back Gouging

' NA

.

-�

lnterpass Temperature Travel Speed Range ( mm I mnt) : 25-100

""""

FILLER METAL CURRENT Travel Speed

w,. w•• Electrode Ampere Voltage ...... Dtt,e�

•••

...,.,

'"""'

Class mm ..... ..... mm I mnt

1 GTAW ER-308 80-150 20-30 25-100

2'

2 GTAW ER-308 2.4 80-150 20-30 25-100

3 GTAW ER-308 2.4 80-1�0 20-30 25-100

No. Reg . ,,I,!/77ff/!fl;/.fY/�

Tanggal: 1 4 MAR 2012

PT.Aditya Tangguh Perkasa

1(1 Combustion Englne&rlng and Supply

Jl.Swatantra II Cluster The Swatantra B1

Jatiasih Bekasi Jawa Barat 17423

phone : +62 21 82752239

email : erlangga1103@gmail.com

PROCEDURE QUALIFICATION RECORD ( PQR )

( ASME IX BOILER AND PRESSURE VESSEL CODE )

TENSILE TEST ( QW - 150 )

Ultimate Ultlmate

Specimen Wldtt< Thickness AN• Total Load Unit Streu Type of Fa Hu re

No. mm mm mm2 Kg Kg/mmz and Location

T-1 12.4 3.0 37.20 2780 74.7 Weld Metal

T-2 12.5 3.0 37.50 2600 74.7 Weld Metal

GUit>E BEND TEST ( QW - 160 )

Typo Wldtt< Thlcklle5$ Pin Dia. Bending Angle Oe1'et

FB-1 19.0 3.0 • ,1 180 No defect

"'''"

Au

FB-2 19.0 3.0 • ,1 180 No defect Aco

RB-1 19.0 3.0 • ,1 180 No defect Aco

RB-1 19.0 3.0

."

180 No defect Aco

TOUGHNESS TEST ( QW 170 )

-

Specimen Noott< Noott< Tu1 Impact Lateral Drop Weight

No. L=oon Typo Tempe111b.Jre Values Break I No Break

•••

.

FILLET WELD TEST ( QW - 180 )

. NA

Result· Slltlsfacto,y P"'1Wation into Parent Metal

Macro - Result

OTHERS TEST

Type of Test · Radiography Report No. . 04/WPSIKCI

D11po&1111 Analysis

Welder Name : UU Bud Sebawan Stamp No.

Test Conducted by : S4T Bandung Laboratory Test No.

We certify that the statement 11 this record are correct and !hat the test welds were prepared, welded, and tested ti

accordance with the rlll(jtWements of sectiOn IX of the ASME Code.

Prepared By· Review By : Venlied By ·

Jl..t) Kementerian THE AGENCY FOR ASSESMENT OF POLICY BUSINESS ENVIRONMENT

,� Perindustrian AND QUALITY OF INDUSTRY

"W':.i M�UaLlll tNOONESIA

CENTER FOR MATERIAL AND TECHNICAL PRODUCTS

LP-007-lDN

Sangkuriang Street 14 Bandung, 40135 WEST JAVA- INDONESIA

Phone. 022 - 2504088, 2510682, 2504828 Fax. 022- 2502027

Website: www.b41.go id E-mail : b4t@b4tso.id

TEST REPORT

Repon No. : 7-01-12-1094 Testing machine : AMSLER 20 TON

max. capacity

Ciw1 Head Separation : 1.3 - 2.5 mm/minute

Commodity : WELDING PIPE SS 304 TO SS 3 1 0

0 IV, " SCH. 40 Temperature : 26'C (Room)

Executed for : PT. Aditya Tangguh Perkasa Test standard : ASME SECT IX - 2007

Jl.Swatantra II Cluster The Swatantra B1 ASME BOILER AND PRESSURE

Jatiasih Bekasi Jawa Barat 17423 VESSEL CODE

: Februruy 23, 2012 Acceptance cnteria : ASME SECT IX- 2007

Received on

ASME BOILER AND PRESSURE

VESSEL CODE

Tested on : February 24, 2012 Sheet no. :8ofll

TENSION TEST RESJ.iLT :

Samples Identification WPS N O . : 04 / WPS / K C I / A S M E / 2 0 1 2

Specimens No. T-1 T-2

0 mm/width x thickness. mm 12.4 x 3.0 12.5 x 3.0

2

Area section. mm 37.20 37.50

Gage length, mm - -

Yield !0<111 kizf -

1

Yield strenath k2Gmm (Mna) - -

Max.load kaf 2780 2800

1

Tensile strenath k1.d7mm fMrui\ 74.7 (733) 74.7 (732)

Lenath after fracture. mm - -

Elongation - , % - -

Diameter after fracture mm - -

1

Area after fracture mm - -

Reduction of area % -

Particularities WELD METAL WELD METAL

WITNESSED BY: w� ���

tro

.�<i •

.e; � �q,

� �

/

�

A/�

-P.,:sESAR "'

"

F.63a/08

Remark. I. This Laboratory is accroditaled by the National Accreditation Commitee (KAN), Reg. No. LP-007.IDN

2. The tcst(s) reported here in have been pcrfonned in accordance with its term of accreditation.

3. This report not for publicatioo and the result here in are f

or the submitted sample only.

4. This report shall not be reproduced except in full.

""-0

�"'-

Kementerian

Perindustrian

THE AGENCY FOR ASSESMENT OF POLICY BUSINESS ENVIRONMENT

AND QUALITY OF INDUSTRY

� llll!l'UBUK lltt>Ofrl!;:IHA

CENTER FOR MATERIAL AND TECHNICAL PRODUCTS

LP-007-IDN

Sangkuriang Street 14 Bandung, 40135 WEST JAVA- fNDONESIA

Phone. 022 - 2504088, 2510682, 2504828 Fax. 022 - 2502027

Website: WWW,b41 go.id E·mail : b4t@b4t go,jd

TEST REPORT

Report No. : 7-0)-12-!094 Testing machine : TOKYO TESTING

MACHINE

Commodity : WELDrNG PIPE SS 304 TO SS 3 1 0 Temperature : 26'C (Room)

0 I I>" SCH. 40

Executed for : PT.Aditya Tangguh Perkasa Test standard : ASME SECT lX - 2007

Jl. Swatantra II Cluster The Swatantra ASME BOILER AND PRESSURE

B1 Jatiasih Bekasi Jawa Barat 17423 VESSEL CODE

: February 23, 2012 Acceptance criteria : ASME SECT IX - 2007

Received on

ASME BOILER AND PRESSURE

VESSEL CODE

Tested on : February 24, 2012 Sheet no. :9ofll

BENDING TEST RESULT:

Samples Identification WPS NO.: 04 / WPS/ KCJ/ ASME/ 2 0 1 2

Specimens No. FB-1 FB-2 RB-I RB-2

mm/width x thickness, nun 19.0x3.0

Pin diameter of bending 4 x t

Bend angle 180'

-

Test result No Discontinuity No Discontinuity No Discontinuity No Discontinuity

WJTNESSED BY: 9-,u-01, s

/1¥� .. � f;� *

* �� l

ir''� \/ �,,,

;9,. �

F.62a/08 Tl!Kl'•

Remark . I. This Laboratory is accrcditated by the National Accreditation Commitee (KAN), Reg. No. LP.007-IDN

2. The tesl{1) reported here in have been performed in accordance with its term of accredit.alion.

3. This report DOI f

or publication and the result here in are for the submitted sample only.

4. This report shall not be reproduced except in full.

You might also like

- RT Film ReviewDocument1 pageRT Film Reviewpriti kumariNo ratings yet

- Equivalents of Carbon Steel QualitiesDocument6 pagesEquivalents of Carbon Steel QualitiesMarcos Fuller AlbanoNo ratings yet

- Mil-P-24503 Ic4Document5 pagesMil-P-24503 Ic4Russell Simano100% (1)

- Boq UpvcDocument2 pagesBoq UpvcAmit Singh100% (2)

- Asme Viii - Div.1 (2019) Appendix 4 RTDocument1 pageAsme Viii - Div.1 (2019) Appendix 4 RTionexchangeqcNo ratings yet

- Understanding API 1104 - Technical ToolboxesDocument2 pagesUnderstanding API 1104 - Technical Toolboxesinspector62No ratings yet

- Asme Sections ListDocument1 pageAsme Sections ListShreekanthKannathNo ratings yet

- ASME AcceptanceDocument46 pagesASME AcceptanceSteelera EngineersNo ratings yet

- Mechanical Testing Requirement As Per ASME BPVC Section IXDocument6 pagesMechanical Testing Requirement As Per ASME BPVC Section IXHary adiNo ratings yet

- 2-Asme BPVC Section Ix-2013Document2 pages2-Asme BPVC Section Ix-2013Reda ElsawyNo ratings yet

- OCS Prel WPS 007Document2 pagesOCS Prel WPS 007vinothNo ratings yet

- Asme Criteria For Welding PreheatingDocument2 pagesAsme Criteria For Welding PreheatingsauloctNo ratings yet

- Flange Face Surface FinishDocument2 pagesFlange Face Surface FinishJoel Ashley D'SouzaNo ratings yet

- Public-: Rev. D E English 03 / 2014Document33 pagesPublic-: Rev. D E English 03 / 2014xaviereduardoNo ratings yet

- Uhde Project-Reference-2020Document92 pagesUhde Project-Reference-2020sumit6singh100% (1)

- Astm A 450Document10 pagesAstm A 450Telmo VianaNo ratings yet

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad Pathan100% (1)

- 3LPE 1d44a0 PDFDocument33 pages3LPE 1d44a0 PDFHotnCrispy CrispyNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument7 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCTrường Tùng LýNo ratings yet

- Sa 450/sa 450MDocument13 pagesSa 450/sa 450MSaravana VelNo ratings yet

- Userguide For SSDocument26 pagesUserguide For SSehsan4uNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- 171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQDocument4 pages171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument38 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilNo ratings yet

- EGWDocument2 pagesEGWpratishgnairNo ratings yet

- Asme B31.3 2020Document4 pagesAsme B31.3 2020Tuugii OtgooNo ratings yet

- Qw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )Document2 pagesQw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )essnelsonNo ratings yet

- Acceptance Criteria For Weld Defects - Welding & NDTDocument11 pagesAcceptance Criteria For Weld Defects - Welding & NDTKevin ThomasNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEDocument18 pagesAcceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEEngineersEDGE CoimbatoreNo ratings yet

- P No QaDocument11 pagesP No QadhasdjNo ratings yet

- Welding Bevel Design 3.1 Bevels For Other Than GTAW Root PassDocument2 pagesWelding Bevel Design 3.1 Bevels For Other Than GTAW Root PassaezeadNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- Welding Procedure Specification: Material / Joints QualifiedDocument2 pagesWelding Procedure Specification: Material / Joints Qualifiedmurshid badshahNo ratings yet

- SB410 (JIS) - Worldwide Equivalent Grades 11Document1 pageSB410 (JIS) - Worldwide Equivalent Grades 11valli raju100% (1)

- Koc MP 018Document17 pagesKoc MP 018Subhajit BhattacharyaNo ratings yet

- Specification For Nickel and Nickel-Alloy Bare Welding Electrodes and RodsDocument19 pagesSpecification For Nickel and Nickel-Alloy Bare Welding Electrodes and RodsT arekiNo ratings yet

- WPS No. GT-SM-5B (F43) WPS No. GT-SM-5B (F43)Document4 pagesWPS No. GT-SM-5B (F43) WPS No. GT-SM-5B (F43)Amir Surya Hidayah100% (1)

- Is 7310 RequirementsDocument4 pagesIs 7310 RequirementsRavichandran Tirupattur SubramaniamNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- Aws B1.11Document40 pagesAws B1.11Bilel RebaiNo ratings yet

- Catalog Fabricante TechnipDocument9 pagesCatalog Fabricante Technipjimy GutiérrezNo ratings yet

- 188-Gmaw-Zug-Asme (Rivaldy Hendrawan-3g) - WPQDocument1 page188-Gmaw-Zug-Asme (Rivaldy Hendrawan-3g) - WPQMuhammad Fitransyah Syamsuar Putra100% (1)

- Astm A 516 Gr.60n Plate SpecificationDocument3 pagesAstm A 516 Gr.60n Plate Specificationharishbabuek100% (1)

- Aws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFDocument1 pageAws Form E-9 Stud Welding Procedure Specification (WPS) or Procedure Qualification Record (PQR) or Welder Qualification Record (WQR) 000 PDFrajNo ratings yet

- Nozzle Fit-Up Inspection Report: Inspected & Prepared byDocument9 pagesNozzle Fit-Up Inspection Report: Inspected & Prepared byDaison PaulNo ratings yet

- Narrow Gap Welding: By: Engy Ibrahim Khalil. Wesam Muhammed Sadek. Asmaa Muhammed Rabie. Omnia Ismail Abd-ElgawadDocument29 pagesNarrow Gap Welding: By: Engy Ibrahim Khalil. Wesam Muhammed Sadek. Asmaa Muhammed Rabie. Omnia Ismail Abd-ElgawadAhmed El MorsyNo ratings yet

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohNo ratings yet

- RT Standards NotesDocument4 pagesRT Standards NotesprabhuNo ratings yet

- MTC Er70s 2Document1 pageMTC Er70s 2Mirza BaigNo ratings yet

- Thickness Tolerance of API 5L ASTM A53 EN10219 StandardDocument2 pagesThickness Tolerance of API 5L ASTM A53 EN10219 StandardhungNo ratings yet

- CWB 178.1 CertificationDocument2 pagesCWB 178.1 Certificationmtor_scribdNo ratings yet

- Asme BPVC IxDocument7 pagesAsme BPVC IxNVTVNNo ratings yet

- Section 2Document31 pagesSection 2Mohd Farid OsmanNo ratings yet

- CV Hotrungtinh QC-NDT PDFDocument6 pagesCV Hotrungtinh QC-NDT PDFTrung Tinh HoNo ratings yet

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- Overview Fusion Welding StandardsDocument1 pageOverview Fusion Welding StandardspedroNo ratings yet

- Compare S235JR, E250BRDocument6 pagesCompare S235JR, E250BRGANESHNo ratings yet

- Chem-Wps - PQR - WPQ-004 CS-SS 08-08 GtawDocument5 pagesChem-Wps - PQR - WPQ-004 CS-SS 08-08 Gtawvijay padaleNo ratings yet

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocument2 pagesWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- DV 5Document20 pagesDV 5lailatul kodriNo ratings yet

- Daily Fit Up Work Order & Report: WO No.: Line No.: Foreman: FitterDocument1 pageDaily Fit Up Work Order & Report: WO No.: Line No.: Foreman: Fitterlailatul kodriNo ratings yet

- List PompaDocument1 pageList Pompalailatul kodriNo ratings yet

- Standard Response Upright Sprinkler VK598 (K25.2) : Technical DataDocument12 pagesStandard Response Upright Sprinkler VK598 (K25.2) : Technical Datalailatul kodriNo ratings yet

- Daily Fit Up Work Order & Report: WO No.: Date: Status Line No.: Remarks: Area Foreman: FitterDocument1 pageDaily Fit Up Work Order & Report: WO No.: Date: Status Line No.: Remarks: Area Foreman: Fitterlailatul kodriNo ratings yet

- List MatDocument1 pageList Matlailatul kodriNo ratings yet

- Daily Fit Up Work Order & Report: WO No.: Line No.: Foreman: FitterDocument1 pageDaily Fit Up Work Order & Report: WO No.: Line No.: Foreman: Fitterlailatul kodriNo ratings yet

- Spec Boomlift s-125Document2 pagesSpec Boomlift s-125lailatul kodriNo ratings yet

- Lifting PlanDocument1 pageLifting Planlailatul kodriNo ratings yet

- Lifting Plan Single Rafter Grid F-L1Document5 pagesLifting Plan Single Rafter Grid F-L1lailatul kodriNo ratings yet

- 68-De HM MRDocument6 pages68-De HM MRlailatul kodriNo ratings yet

- PT - Aditya Tangguh Perkasa: Flare Stack Inspection & Test Plan (Itp)Document3 pagesPT - Aditya Tangguh Perkasa: Flare Stack Inspection & Test Plan (Itp)lailatul kodriNo ratings yet

- Welding Procedure Specification: Wps 1'0. Oo-Wf'S-Kct-A.Sii.E.-1:01Document15 pagesWelding Procedure Specification: Wps 1'0. Oo-Wf'S-Kct-A.Sii.E.-1:01lailatul kodriNo ratings yet

- Astm A 941 PDFDocument7 pagesAstm A 941 PDFDouglas Rodrigues0% (1)

- Paper 3Document10 pagesPaper 3Umaibalan100% (2)

- Quality Control ReportDocument1 pageQuality Control ReportRahul TRNo ratings yet

- Cswip 3 1 Wis5 Handout 2009 PDFDocument196 pagesCswip 3 1 Wis5 Handout 2009 PDFravi00098No ratings yet

- Roomlogs 1122Document234 pagesRoomlogs 1122Rhona TaanNo ratings yet

- Welder and Procedure QualificationDocument25 pagesWelder and Procedure QualificationRamón G. Pacheco100% (3)

- 300+ TOP Construction Engineering Interview Questions and Answers 2021Document5 pages300+ TOP Construction Engineering Interview Questions and Answers 2021Irfan AwanNo ratings yet

- F11 - Tools (SMAW) NC IIDocument1 pageF11 - Tools (SMAW) NC IIFemee JisonNo ratings yet

- Pulp and Paper DictionaryDocument93 pagesPulp and Paper DictionaryHoang PhongNo ratings yet

- 0302 Brass Fittings CatalogueDocument59 pages0302 Brass Fittings CatalogueCHALERMKIAT JIRARUNGSATEAN0% (1)

- 4-Shaper, Planer & SlotterDocument43 pages4-Shaper, Planer & SlotterkaushiksoniNo ratings yet

- Primary Sedimentation TankDocument7 pagesPrimary Sedimentation TankKareen AmlosNo ratings yet

- AISI 4130 Alloy SteelDocument2 pagesAISI 4130 Alloy SteelSantosh IngaleNo ratings yet

- Technical Query Sheet Format - ColumnDocument8 pagesTechnical Query Sheet Format - ColumnChetan PatelNo ratings yet

- Practical Guidelines For The Fabrication of Duplex Stainless Steels (2nd Edition)Document64 pagesPractical Guidelines For The Fabrication of Duplex Stainless Steels (2nd Edition)sanketNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- Cidpex 2023Document8 pagesCidpex 2023chienk55husNo ratings yet

- 0STXOS-BOX BB xPIN SRGDocument1 page0STXOS-BOX BB xPIN SRGDinesh YkatilNo ratings yet

- Overall Recovery Efficiency - Pulp and Paper - Project ReportDocument109 pagesOverall Recovery Efficiency - Pulp and Paper - Project ReportLavanya Kumar Jain100% (4)

- WALL-ACCENT-RENDER-wall Accent 1.5 X 2 X 12 PDFDocument1 pageWALL-ACCENT-RENDER-wall Accent 1.5 X 2 X 12 PDFVaoughn Benedict Yolores BalderosaNo ratings yet

- Fulkrum Rates - Quality Third PartyDocument1 pageFulkrum Rates - Quality Third PartyJamesNo ratings yet

- Asme Boiler and Pressure Vessel Codes: SectionsDocument68 pagesAsme Boiler and Pressure Vessel Codes: Sectionsajay thomasNo ratings yet

- Types of Forging OperationsDocument6 pagesTypes of Forging OperationsAshutosh SinghNo ratings yet

- Steel-BS4360 43A PDFDocument1 pageSteel-BS4360 43A PDFscmNo ratings yet

- Barton Firtop Datasheet Pack Rev 4Document82 pagesBarton Firtop Datasheet Pack Rev 4Sajir ThiyamNo ratings yet

- Value Stream Mapping of APS Paper CompanyDocument4 pagesValue Stream Mapping of APS Paper CompanyAditya ChourasiaNo ratings yet

- LMT Belin 2015+ CATDocument68 pagesLMT Belin 2015+ CATShi SamNo ratings yet

- CHAMSADocument51 pagesCHAMSAGerson RamirezNo ratings yet

- Report FFFDocument2 pagesReport FFFamevaluacionesNo ratings yet