Professional Documents

Culture Documents

Rfi-00898 Welder Test

Rfi-00898 Welder Test

Uploaded by

Wahyudi MetrizaCopyright:

Available Formats

You might also like

- Keto Breads - Digital PDFDocument118 pagesKeto Breads - Digital PDFPP043100% (18)

- OptiBlend System Operation and Installation ManualDocument9 pagesOptiBlend System Operation and Installation ManualVijendra PanwarNo ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- PRPP-10-DW-PL-002 - Drawing For Road Crosing Detail Section B - 19-12-2018-River Crossing 1 - ABDocument1 pagePRPP-10-DW-PL-002 - Drawing For Road Crosing Detail Section B - 19-12-2018-River Crossing 1 - ABPer Bagus Handoko100% (1)

- Prpp-10-Dw-pl-002-02 - Drawing For Road Crosing Detail Section A - 19-12-2018-Detail River Crosing 3 - AbDocument1 pagePrpp-10-Dw-pl-002-02 - Drawing For Road Crosing Detail Section A - 19-12-2018-Detail River Crosing 3 - AbPer Bagus Handoko100% (1)

- Pipeline Alignment Sheets River Crossing 02 - AB ( - CIJERUK RIVER) KM 146+200Document1 pagePipeline Alignment Sheets River Crossing 02 - AB ( - CIJERUK RIVER) KM 146+200Per Bagus Handoko100% (1)

- JK Pipeline Welding & Installation Traceability Procedure CoDocument1 pageJK Pipeline Welding & Installation Traceability Procedure Cogst ajahNo ratings yet

- Ebs1 Fsfa00 HSGH Gdhs 1002 g01 Health Safety PlanDocument80 pagesEbs1 Fsfa00 HSGH Gdhs 1002 g01 Health Safety PlanAsaad AdnanNo ratings yet

- 3 Steel Structure Installation CLDocument2 pages3 Steel Structure Installation CLwhah11No ratings yet

- List Certificates of Werder QualificationDocument2 pagesList Certificates of Werder QualificationMuhammad FajarNo ratings yet

- Week6 Acomprehensiveillustration CompressDocument86 pagesWeek6 Acomprehensiveillustration CompressTariku0% (1)

- Inspection & Test Plan PT. Barata Indonesia: Fabrication DocumentDocument22 pagesInspection & Test Plan PT. Barata Indonesia: Fabrication DocumentmoddysNo ratings yet

- Refrigerated Pertamina Tanjung Sekong Merak Visual Examination Welding Repair ReportDocument2 pagesRefrigerated Pertamina Tanjung Sekong Merak Visual Examination Welding Repair ReportNauval Labiby N M100% (1)

- Class 1: Pttep International Limited (Myanmar) Zawtika Development ProjectDocument10 pagesClass 1: Pttep International Limited (Myanmar) Zawtika Development ProjectfajarNo ratings yet

- 2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IR PDFDocument22 pages2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IR PDFDadaso Baburao JamdarNo ratings yet

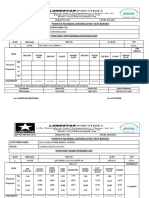

- NCT SCN 000 E10 00001 - A01 - Quality Requirements For Subcontractors (High Criticality)Document21 pagesNCT SCN 000 E10 00001 - A01 - Quality Requirements For Subcontractors (High Criticality)Charles KingNo ratings yet

- PO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDocument1 pagePO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDadaso Baburao JamdarNo ratings yet

- ITP Fuel Fillter (J-1001) Rev10+Document9 pagesITP Fuel Fillter (J-1001) Rev10+DjokoNo ratings yet

- Pipe Fit Up ReportDocument2 pagesPipe Fit Up ReportnguyenquanghiepNo ratings yet

- Procedure: Technical Bid Evaluation For Catodic ProtectionDocument6 pagesProcedure: Technical Bid Evaluation For Catodic ProtectionPer Bagus Handoko100% (1)

- B Qac Pro 210 39161 ADocument12 pagesB Qac Pro 210 39161 AZaidiNo ratings yet

- Updated Rigging and Lifting Plan GTG 2 OverhaulingDocument2 pagesUpdated Rigging and Lifting Plan GTG 2 OverhaulingHamzaNoumanNo ratings yet

- Welding Consumables Request Card: Client LogoDocument1 pageWelding Consumables Request Card: Client LogoZaidiNo ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- Dokumen - Tips - Project Packing and Preservation ProcedureDocument27 pagesDokumen - Tips - Project Packing and Preservation ProceduremohdfaridabubakarNo ratings yet

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocument2 pagesDuqm Refinery Project EPC Package 2 - Utilities and OffsitesDadaso Baburao JamdarNo ratings yet

- 26071-100-V28A-PX02-00005-001-Manufacturing Specification Procedure (MPS) For Cement Lined Pipe PDFDocument11 pages26071-100-V28A-PX02-00005-001-Manufacturing Specification Procedure (MPS) For Cement Lined Pipe PDFNaza Gavaputri100% (1)

- Test PDFDocument3 pagesTest PDFRyanNo ratings yet

- Itp - Inspection and Testing Plan (Creation and Management)Document11 pagesItp - Inspection and Testing Plan (Creation and Management)rohit12389No ratings yet

- Tle-02 Dossier.Document40 pagesTle-02 Dossier.suria qaqcNo ratings yet

- MAS FormatDocument2 pagesMAS FormatDebesh ChaudharyNo ratings yet

- Job Procedure For Cable TrayDocument5 pagesJob Procedure For Cable TrayNisith SahooNo ratings yet

- Pmi ReportDocument5 pagesPmi ReportMANIMARAN QCNo ratings yet

- DWR Piping Indosol1Document84 pagesDWR Piping Indosol1mizwarNo ratings yet

- Progress Summary CTR 059 - Engineering Design For Micro Turbine Generator (MTG) at Nui PlatformDocument14 pagesProgress Summary CTR 059 - Engineering Design For Micro Turbine Generator (MTG) at Nui PlatformRokan PipelineNo ratings yet

- Inspection and Test Plan: Piping Fabrication & InstallationDocument11 pagesInspection and Test Plan: Piping Fabrication & Installationmohd as shahiddin jafriNo ratings yet

- Pressure Transmitter Elec: Instrument Calibration ResultDocument2 pagesPressure Transmitter Elec: Instrument Calibration ResultIsaalexNo ratings yet

- 0468-Asom20-92p1-0006-001 - Flange Repair and Machining (Revised) PDFDocument11 pages0468-Asom20-92p1-0006-001 - Flange Repair and Machining (Revised) PDFDenny AgusNo ratings yet

- Occpl: Hydro & Pneumatic Test ProcedureDocument3 pagesOccpl: Hydro & Pneumatic Test ProcedureNupesh katreNo ratings yet

- Rab Pek. Pengecatan Ulang Meja KoridorDocument1 pageRab Pek. Pengecatan Ulang Meja KoridorJosep NapitupuluNo ratings yet

- IONE-AA00-MS-MS-0014 WMS FOR Levelling Pad InstallationDocument22 pagesIONE-AA00-MS-MS-0014 WMS FOR Levelling Pad InstallationYusufNo ratings yet

- VDRL PT. Alfa Valve Indonesia 22 Desember 2019Document8 pagesVDRL PT. Alfa Valve Indonesia 22 Desember 2019Yusri FakhrizalNo ratings yet

- Afcons - WPS LIST For E410C Updated (31.08.2019)Document1 pageAfcons - WPS LIST For E410C Updated (31.08.2019)Neem LalNo ratings yet

- Cold Tap Coating Report 2Document1 pageCold Tap Coating Report 2Jamal BakhtNo ratings yet

- NPK 000 Q0 in 6001 K Nonconformance Inspection Procedure Rev 3 ForDocument11 pagesNPK 000 Q0 in 6001 K Nonconformance Inspection Procedure Rev 3 ForDangolNo ratings yet

- 2021.12.13 ITP - Concreting (5244.009) V.0Document4 pages2021.12.13 ITP - Concreting (5244.009) V.0huot phirunNo ratings yet

- Approved By: Material Test Report Hydrotest Report Inspection CertificateDocument3 pagesApproved By: Material Test Report Hydrotest Report Inspection CertificateMohamed RaafatNo ratings yet

- Boq Pekerjaan Pondasi 500 KV Lot 1.: Foundation For 500 KV Two Circuit TowersDocument8 pagesBoq Pekerjaan Pondasi 500 KV Lot 1.: Foundation For 500 KV Two Circuit TowersErick SavrinaldoNo ratings yet

- 26071-100-GPP-GPX-00002 - Material Control and Handling Procedure - Rev.001 PDFDocument26 pages26071-100-GPP-GPX-00002 - Material Control and Handling Procedure - Rev.001 PDFSendal BodolNo ratings yet

- How02 - Z11 - Mec503 - C01 - Oss Piping Matr Class SpecDocument31 pagesHow02 - Z11 - Mec503 - C01 - Oss Piping Matr Class Speckristian100% (1)

- 02 - Ab-Pf1a-C000-B13-Spec-0007 - 02C2.1Document38 pages02 - Ab-Pf1a-C000-B13-Spec-0007 - 02C2.1Walid BdeirNo ratings yet

- List of Inspection Tools (Qaqc)Document7 pagesList of Inspection Tools (Qaqc)saffririzal4237No ratings yet

- Nde-1711-T393-F0005 Annular To Bottom Plate JointDocument1 pageNde-1711-T393-F0005 Annular To Bottom Plate Jointdada khalandar100% (1)

- Test Package: Pt. TTN (Tambang Tondano Nusajaya)Document18 pagesTest Package: Pt. TTN (Tambang Tondano Nusajaya)unto gunungNo ratings yet

- Punch List Report: Client Date Project No. Discipline Location Date of InspectionDocument1 pagePunch List Report: Client Date Project No. Discipline Location Date of InspectionHanuman RaoNo ratings yet

- NGWK PK 0001 VDQC Plit 0006Document7 pagesNGWK PK 0001 VDQC Plit 0006stdshopNo ratings yet

- NPK 000 Q2 in 6001 K Rev 3 Field Inspection and Test Procedure ADocument15 pagesNPK 000 Q2 in 6001 K Rev 3 Field Inspection and Test Procedure ADangolNo ratings yet

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- CE & EH WHP - Pressure Test & Test Pack Procedure: Block 5 - AL SHAHEEN FIELD DevelopmentDocument20 pagesCE & EH WHP - Pressure Test & Test Pack Procedure: Block 5 - AL SHAHEEN FIELD DevelopmentkristianNo ratings yet

- BGEP TETL B104 GENX PI 10 012 0023 D - Rev - 0 - Specification For Piping Fabrication, Erection and InstallationDocument26 pagesBGEP TETL B104 GENX PI 10 012 0023 D - Rev - 0 - Specification For Piping Fabrication, Erection and InstallationMitchel Fernandes100% (1)

- How02 Z01uab12&cdc112 Ga 117Document1 pageHow02 Z01uab12&cdc112 Ga 117Ajizul Rohim AkbarNo ratings yet

- 4384 QPD 9 TS H 0001 1 CDFDocument12 pages4384 QPD 9 TS H 0001 1 CDFamirNo ratings yet

- instaPDF - in Indian Grocery Items List 836Document16 pagesinstaPDF - in Indian Grocery Items List 836Namita BhattNo ratings yet

- Pyramis 58 489 Touch HobDocument46 pagesPyramis 58 489 Touch HobAndrás LeventeNo ratings yet

- Road Safety Training DocumentsDocument25 pagesRoad Safety Training DocumentsAbdullah Al BakyNo ratings yet

- MJMHS 0034Document3 pagesMJMHS 0034Alan MarshallNo ratings yet

- Dr. Reddy's Laboratories: Performance HighlightsDocument10 pagesDr. Reddy's Laboratories: Performance HighlightsAngel BrokingNo ratings yet

- Unit 2.2 Landforms and Landscape Processes Weathering and RiversDocument12 pagesUnit 2.2 Landforms and Landscape Processes Weathering and RiversifeNo ratings yet

- Basic Aviation Medicine: DR Firman Rachman Masjhur SPKP 17 November 2014Document43 pagesBasic Aviation Medicine: DR Firman Rachman Masjhur SPKP 17 November 2014sunarniNo ratings yet

- Reynolds, 2014Document8 pagesReynolds, 2014Joana ComiranNo ratings yet

- Application LetterDocument2 pagesApplication LetterTiara Larasati PriniartiNo ratings yet

- Otec SeminarDocument21 pagesOtec SeminarAbhishekSuman80% (5)

- May 2014Document48 pagesMay 2014debtwiggNo ratings yet

- EE311A 2021 AV Slides L23Document13 pagesEE311A 2021 AV Slides L23Ananya AgarwalNo ratings yet

- Exercise LMTDocument4 pagesExercise LMTapi-276845347No ratings yet

- Brochure - EPD - EN - EU RU - Float - Lami - Coated - 2021-2026 ENDocument31 pagesBrochure - EPD - EN - EU RU - Float - Lami - Coated - 2021-2026 ENNaseer KhanNo ratings yet

- PCPNDT AssignmentDocument5 pagesPCPNDT Assignmentricha ayengia100% (2)

- Bayesian-Statistics Final 20140416 3Document38 pagesBayesian-Statistics Final 20140416 3muralidharanNo ratings yet

- Work Schedule-Rfp Kinyona-NjabiniDocument1 pageWork Schedule-Rfp Kinyona-NjabiniEmily MuthigaNo ratings yet

- E-Cart ChecklistDocument6 pagesE-Cart ChecklistClarissa GuifayaNo ratings yet

- Chemistry Project File (Class-12th)Document20 pagesChemistry Project File (Class-12th)sanchitNo ratings yet

- Central Venous Pressure Monitoring.: DR Jyothsna Chairperson DR Sunil ChhabriaDocument24 pagesCentral Venous Pressure Monitoring.: DR Jyothsna Chairperson DR Sunil ChhabriaPriyanka MaiyaNo ratings yet

- Action Research On Students Misbehavior in ClassDocument4 pagesAction Research On Students Misbehavior in ClassAnalyn Girasol86% (7)

- Meaning of LeverageDocument5 pagesMeaning of LeverageAdeem AshrafiNo ratings yet

- Voucher (Pre-Paid Booking) : ST - Havel ResidenceDocument2 pagesVoucher (Pre-Paid Booking) : ST - Havel ResidenceAlena KolesnykNo ratings yet

- Swale (Landform) - WikipediaDocument2 pagesSwale (Landform) - WikipediaMohamedNo ratings yet

- Pengelolaan Kualitas Lingkungan Dengan Pemanfaatan Limbah Cair Dari Industri Tahu Sebagai BiogasDocument17 pagesPengelolaan Kualitas Lingkungan Dengan Pemanfaatan Limbah Cair Dari Industri Tahu Sebagai BiogasMuhammad Sadiqul ImanNo ratings yet

- Death Valley NP Historic Resource Study of Mining Vols 1 and 2Document982 pagesDeath Valley NP Historic Resource Study of Mining Vols 1 and 2Russell HartillNo ratings yet

- Becoming Acquainted With Statistical ConceptsDocument3 pagesBecoming Acquainted With Statistical ConceptsCorteza, Ricardo Danilo E. UnknownNo ratings yet

- G4 Chem BoilingDocument5 pagesG4 Chem BoilingNashwaAlinsangaoNo ratings yet

Rfi-00898 Welder Test

Rfi-00898 Welder Test

Uploaded by

Wahyudi MetrizaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rfi-00898 Welder Test

Rfi-00898 Welder Test

Uploaded by

Wahyudi MetrizaCopyright:

Available Formats

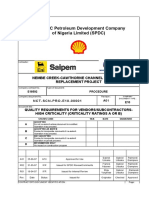

Request For Inspection

(RFI)

[IKAN] RDMP - Refinery Unit V

Project : Unit / Area : N/A

Balikpapan Project

RFI No : RFI-R-CH-MS-00898 Discipline : MS

Subcontractor : Cahaya Hidup Prima Karya Request Date : 2021-02-20

Inspection Detail

1. Inspection Date / Time 2021-02-22 / 08:30

2. Construction Activity Cahaya Hidup Prima Karya (R)

3. Inspection Activity Welder Qualification

4. Description Welder Test GMAW / FCAW Position 3G

26071-V3A-D-320-02-00002, 26071-V3A-D-320-02-00055, 26071-V3A

5. DWG No or Reference

-D-320-12-00002

6. Attachment (Inspection Item List) ㅁ YES ㅁ No

Remark

Welder Test GMAW / FCAW Position 3G

Contractor

Subcontractor IPMT

Construction QA/QC

Name DODY EDWIN

Signature

Date 22/02/2021 22/02/2021

DETAIL-A DETAIL "B"

note 3 to be updated as MDS R.002

will be shared later

add applicable project spec in

reference doc.

major document as per MDS R.002 shall be added latest allowable nozzle table for

N1, N2, N3, N4, N5, N14 shall be added to this GAD

General notes:

comment from Package Audit shall be absorbed

1. Update transtition phase data as per PDS and MDS

2. Update nozzle and flange as per latest conditon

3. Update Flange Foam Chamber from WNFF --> SOFF

4. Vortex Breaker attached to elbow may be added to N2 and N14 after

study from Process

5. Supply gauge hatch that can be act as emergency vent

6. Add applicable major spec as per MDS to the GAD

7. Add Allowable Nozzle Table that has been calculated as per Latest

Strength Calculation.ed.

update value as per latest strength calc.

wind moment: 43,328,179 Nm

wind shear force: 310, 475 N

design data: follow as per MDS R.002 will

be shared to vendor Seismic Ringwall moment: 163,322,966 Nm

Seismic Slab moment: 539,444,217 Nm

design temp: 210 degC Shear Force: 21,787,402

ope temp (transition): 85 degC

change the sch as per SG: 0.9002

purchased material. (sch 40) ELEVATION

add annex P

DESIGN DATA

update as per latest strength calc: Nominal: 61,123

empty: 1,417,222 Net Cap: 57,584

operation: 56,427,766 WEIGHT

ESTIMATED & CAPACITY

full water weight: 62,540,048

wind direction to be update as per TQ,

26071-PMC-JO-TQ-00434

Month

Oct - March North

Apr - Sep South South West

DETAIL-A DETAIL "B" update notes.

3. the value Shall be updated to latest value on MDS

R.002, will be shared later

4. The notes shall be change to

"Design Specification for Paint Spec shall refer to

Method Statement 26071-203-V3A-MTF5-00006"

latest allowable nozzle table for

N1, N2, N3, N4, N5, N14 shall be added to this GAD

refer to latest strength calc annex P section

add applicable project spec in General notes:

reference doc. comment from Package Audit shall be absorbed

major document as per MDS R.002 shall be added 1. Update transtition phase data as per PDS and MDS

2. Update nozzle and flange as per latest conditon

3. Update Flange Foam Chamber from WNFF --> SOFF

4. Vortex Breaker attached to elbow may be added to N2 and

N14 after study from Process

5. Supply gauge hatch that can be act as emergency vent

6. Add applicable major spec as per MDS to the GAD

7. Add Allowable Nozzle Table that has been calculated as per

Latest Strength Calculation.ed.

design data: follow as per MDS R.

002 will be shared to vendor

design temp: 210 degC

ope temp : 180 degC

ope temp (transition): 85 degC

SG: 0.9002

change the sch as per purchased update value as per latest strength calc.

material. (sch 40)

ELEVATION

API Standard 650 Edition 12Th (2018) + Annex E,F,M,P,V wind moment: 43,328,179 Nm

wind shear force: 310, 475 N

Seismic Ringwall moment: 163,322,966 Nm

DESIGN DATA Seismic Slab moment: 539,444,217 Nm

Shear Force: 21,787,402

update as per latest strength calc:

empty: 1,417,222 show color

Nominal: 61,123

operation: 56,427,766

Net Cap: 57,584

full water weight: 62,540,048 ESTIMATED WEIGHT & CAPACITY

update wind direction as per TQ

26071-PMC-JO-TQ-00434

Month

Oct - March North

Apr - Sep South South West

Note 3. to be updated as MDS R.002

will be shared later

Note 4. to be changed to

"Design Specification for Paint Schedule shall refer to

method statement 26071-203-V3A-MTF5-00006"

latest allowable nozzle table for

N1, N2, N3, N4, N5, N14 shall be added to this GAD

value refer to latest strength calc annex P

General notes:

comment from Package Audit shall be absorbed

1. Update transtition phase data as per PDS and MDS

2. Update nozzle and flange as per latest conditon

3. Update Flange Foam Chamber from WNFF --> SOFF

4. Vortex Breaker attached to elbow may be added to N2 and N14 after

study from Process

5. Supply gauge hatch that can be act as emergency vent

6. Add applicable major spec as per MDS to the GAD

7. Add Allowable Nozzle Table that has been calculated as per Latest

Strength Calculation.ed.

ELEVATION

put applicable project spec in reference

document as per MDS R.002

design data: follow as per MDS R.002 will be shared

to vendor

design temp: 210 degC

ope temp : 180 degC

API Standard 650 Edition 12th (2018) + Annex E,F,M,P, ope temp (transition): 85 degC

V SG: 0.9002

DESIGN DATA

update value as per latest strength calc.

wind moment: 21,703,523 Nm

wind shear force: 242,758 N

Seismic Ringwall moment: 123,866,580 Nm

Seismic Slab moment: 322,108,423 Nm

Shear Force: 16,619,632

nominal: 37,306

net work cap: 35,147

ESTIMATED WEIGHT & CAPACITY

You might also like

- Keto Breads - Digital PDFDocument118 pagesKeto Breads - Digital PDFPP043100% (18)

- OptiBlend System Operation and Installation ManualDocument9 pagesOptiBlend System Operation and Installation ManualVijendra PanwarNo ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- PRPP-10-DW-PL-002 - Drawing For Road Crosing Detail Section B - 19-12-2018-River Crossing 1 - ABDocument1 pagePRPP-10-DW-PL-002 - Drawing For Road Crosing Detail Section B - 19-12-2018-River Crossing 1 - ABPer Bagus Handoko100% (1)

- Prpp-10-Dw-pl-002-02 - Drawing For Road Crosing Detail Section A - 19-12-2018-Detail River Crosing 3 - AbDocument1 pagePrpp-10-Dw-pl-002-02 - Drawing For Road Crosing Detail Section A - 19-12-2018-Detail River Crosing 3 - AbPer Bagus Handoko100% (1)

- Pipeline Alignment Sheets River Crossing 02 - AB ( - CIJERUK RIVER) KM 146+200Document1 pagePipeline Alignment Sheets River Crossing 02 - AB ( - CIJERUK RIVER) KM 146+200Per Bagus Handoko100% (1)

- JK Pipeline Welding & Installation Traceability Procedure CoDocument1 pageJK Pipeline Welding & Installation Traceability Procedure Cogst ajahNo ratings yet

- Ebs1 Fsfa00 HSGH Gdhs 1002 g01 Health Safety PlanDocument80 pagesEbs1 Fsfa00 HSGH Gdhs 1002 g01 Health Safety PlanAsaad AdnanNo ratings yet

- 3 Steel Structure Installation CLDocument2 pages3 Steel Structure Installation CLwhah11No ratings yet

- List Certificates of Werder QualificationDocument2 pagesList Certificates of Werder QualificationMuhammad FajarNo ratings yet

- Week6 Acomprehensiveillustration CompressDocument86 pagesWeek6 Acomprehensiveillustration CompressTariku0% (1)

- Inspection & Test Plan PT. Barata Indonesia: Fabrication DocumentDocument22 pagesInspection & Test Plan PT. Barata Indonesia: Fabrication DocumentmoddysNo ratings yet

- Refrigerated Pertamina Tanjung Sekong Merak Visual Examination Welding Repair ReportDocument2 pagesRefrigerated Pertamina Tanjung Sekong Merak Visual Examination Welding Repair ReportNauval Labiby N M100% (1)

- Class 1: Pttep International Limited (Myanmar) Zawtika Development ProjectDocument10 pagesClass 1: Pttep International Limited (Myanmar) Zawtika Development ProjectfajarNo ratings yet

- 2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IR PDFDocument22 pages2037-PL-PL-0058-IR-T-015 Dated 18.12.19-IRN IR PDFDadaso Baburao JamdarNo ratings yet

- NCT SCN 000 E10 00001 - A01 - Quality Requirements For Subcontractors (High Criticality)Document21 pagesNCT SCN 000 E10 00001 - A01 - Quality Requirements For Subcontractors (High Criticality)Charles KingNo ratings yet

- PO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDocument1 pagePO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDadaso Baburao JamdarNo ratings yet

- ITP Fuel Fillter (J-1001) Rev10+Document9 pagesITP Fuel Fillter (J-1001) Rev10+DjokoNo ratings yet

- Pipe Fit Up ReportDocument2 pagesPipe Fit Up ReportnguyenquanghiepNo ratings yet

- Procedure: Technical Bid Evaluation For Catodic ProtectionDocument6 pagesProcedure: Technical Bid Evaluation For Catodic ProtectionPer Bagus Handoko100% (1)

- B Qac Pro 210 39161 ADocument12 pagesB Qac Pro 210 39161 AZaidiNo ratings yet

- Updated Rigging and Lifting Plan GTG 2 OverhaulingDocument2 pagesUpdated Rigging and Lifting Plan GTG 2 OverhaulingHamzaNoumanNo ratings yet

- Welding Consumables Request Card: Client LogoDocument1 pageWelding Consumables Request Card: Client LogoZaidiNo ratings yet

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- Dokumen - Tips - Project Packing and Preservation ProcedureDocument27 pagesDokumen - Tips - Project Packing and Preservation ProceduremohdfaridabubakarNo ratings yet

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDocument2 pagesDuqm Refinery Project EPC Package 2 - Utilities and OffsitesDadaso Baburao JamdarNo ratings yet

- 26071-100-V28A-PX02-00005-001-Manufacturing Specification Procedure (MPS) For Cement Lined Pipe PDFDocument11 pages26071-100-V28A-PX02-00005-001-Manufacturing Specification Procedure (MPS) For Cement Lined Pipe PDFNaza Gavaputri100% (1)

- Test PDFDocument3 pagesTest PDFRyanNo ratings yet

- Itp - Inspection and Testing Plan (Creation and Management)Document11 pagesItp - Inspection and Testing Plan (Creation and Management)rohit12389No ratings yet

- Tle-02 Dossier.Document40 pagesTle-02 Dossier.suria qaqcNo ratings yet

- MAS FormatDocument2 pagesMAS FormatDebesh ChaudharyNo ratings yet

- Job Procedure For Cable TrayDocument5 pagesJob Procedure For Cable TrayNisith SahooNo ratings yet

- Pmi ReportDocument5 pagesPmi ReportMANIMARAN QCNo ratings yet

- DWR Piping Indosol1Document84 pagesDWR Piping Indosol1mizwarNo ratings yet

- Progress Summary CTR 059 - Engineering Design For Micro Turbine Generator (MTG) at Nui PlatformDocument14 pagesProgress Summary CTR 059 - Engineering Design For Micro Turbine Generator (MTG) at Nui PlatformRokan PipelineNo ratings yet

- Inspection and Test Plan: Piping Fabrication & InstallationDocument11 pagesInspection and Test Plan: Piping Fabrication & Installationmohd as shahiddin jafriNo ratings yet

- Pressure Transmitter Elec: Instrument Calibration ResultDocument2 pagesPressure Transmitter Elec: Instrument Calibration ResultIsaalexNo ratings yet

- 0468-Asom20-92p1-0006-001 - Flange Repair and Machining (Revised) PDFDocument11 pages0468-Asom20-92p1-0006-001 - Flange Repair and Machining (Revised) PDFDenny AgusNo ratings yet

- Occpl: Hydro & Pneumatic Test ProcedureDocument3 pagesOccpl: Hydro & Pneumatic Test ProcedureNupesh katreNo ratings yet

- Rab Pek. Pengecatan Ulang Meja KoridorDocument1 pageRab Pek. Pengecatan Ulang Meja KoridorJosep NapitupuluNo ratings yet

- IONE-AA00-MS-MS-0014 WMS FOR Levelling Pad InstallationDocument22 pagesIONE-AA00-MS-MS-0014 WMS FOR Levelling Pad InstallationYusufNo ratings yet

- VDRL PT. Alfa Valve Indonesia 22 Desember 2019Document8 pagesVDRL PT. Alfa Valve Indonesia 22 Desember 2019Yusri FakhrizalNo ratings yet

- Afcons - WPS LIST For E410C Updated (31.08.2019)Document1 pageAfcons - WPS LIST For E410C Updated (31.08.2019)Neem LalNo ratings yet

- Cold Tap Coating Report 2Document1 pageCold Tap Coating Report 2Jamal BakhtNo ratings yet

- NPK 000 Q0 in 6001 K Nonconformance Inspection Procedure Rev 3 ForDocument11 pagesNPK 000 Q0 in 6001 K Nonconformance Inspection Procedure Rev 3 ForDangolNo ratings yet

- 2021.12.13 ITP - Concreting (5244.009) V.0Document4 pages2021.12.13 ITP - Concreting (5244.009) V.0huot phirunNo ratings yet

- Approved By: Material Test Report Hydrotest Report Inspection CertificateDocument3 pagesApproved By: Material Test Report Hydrotest Report Inspection CertificateMohamed RaafatNo ratings yet

- Boq Pekerjaan Pondasi 500 KV Lot 1.: Foundation For 500 KV Two Circuit TowersDocument8 pagesBoq Pekerjaan Pondasi 500 KV Lot 1.: Foundation For 500 KV Two Circuit TowersErick SavrinaldoNo ratings yet

- 26071-100-GPP-GPX-00002 - Material Control and Handling Procedure - Rev.001 PDFDocument26 pages26071-100-GPP-GPX-00002 - Material Control and Handling Procedure - Rev.001 PDFSendal BodolNo ratings yet

- How02 - Z11 - Mec503 - C01 - Oss Piping Matr Class SpecDocument31 pagesHow02 - Z11 - Mec503 - C01 - Oss Piping Matr Class Speckristian100% (1)

- 02 - Ab-Pf1a-C000-B13-Spec-0007 - 02C2.1Document38 pages02 - Ab-Pf1a-C000-B13-Spec-0007 - 02C2.1Walid BdeirNo ratings yet

- List of Inspection Tools (Qaqc)Document7 pagesList of Inspection Tools (Qaqc)saffririzal4237No ratings yet

- Nde-1711-T393-F0005 Annular To Bottom Plate JointDocument1 pageNde-1711-T393-F0005 Annular To Bottom Plate Jointdada khalandar100% (1)

- Test Package: Pt. TTN (Tambang Tondano Nusajaya)Document18 pagesTest Package: Pt. TTN (Tambang Tondano Nusajaya)unto gunungNo ratings yet

- Punch List Report: Client Date Project No. Discipline Location Date of InspectionDocument1 pagePunch List Report: Client Date Project No. Discipline Location Date of InspectionHanuman RaoNo ratings yet

- NGWK PK 0001 VDQC Plit 0006Document7 pagesNGWK PK 0001 VDQC Plit 0006stdshopNo ratings yet

- NPK 000 Q2 in 6001 K Rev 3 Field Inspection and Test Procedure ADocument15 pagesNPK 000 Q2 in 6001 K Rev 3 Field Inspection and Test Procedure ADangolNo ratings yet

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- CE & EH WHP - Pressure Test & Test Pack Procedure: Block 5 - AL SHAHEEN FIELD DevelopmentDocument20 pagesCE & EH WHP - Pressure Test & Test Pack Procedure: Block 5 - AL SHAHEEN FIELD DevelopmentkristianNo ratings yet

- BGEP TETL B104 GENX PI 10 012 0023 D - Rev - 0 - Specification For Piping Fabrication, Erection and InstallationDocument26 pagesBGEP TETL B104 GENX PI 10 012 0023 D - Rev - 0 - Specification For Piping Fabrication, Erection and InstallationMitchel Fernandes100% (1)

- How02 Z01uab12&cdc112 Ga 117Document1 pageHow02 Z01uab12&cdc112 Ga 117Ajizul Rohim AkbarNo ratings yet

- 4384 QPD 9 TS H 0001 1 CDFDocument12 pages4384 QPD 9 TS H 0001 1 CDFamirNo ratings yet

- instaPDF - in Indian Grocery Items List 836Document16 pagesinstaPDF - in Indian Grocery Items List 836Namita BhattNo ratings yet

- Pyramis 58 489 Touch HobDocument46 pagesPyramis 58 489 Touch HobAndrás LeventeNo ratings yet

- Road Safety Training DocumentsDocument25 pagesRoad Safety Training DocumentsAbdullah Al BakyNo ratings yet

- MJMHS 0034Document3 pagesMJMHS 0034Alan MarshallNo ratings yet

- Dr. Reddy's Laboratories: Performance HighlightsDocument10 pagesDr. Reddy's Laboratories: Performance HighlightsAngel BrokingNo ratings yet

- Unit 2.2 Landforms and Landscape Processes Weathering and RiversDocument12 pagesUnit 2.2 Landforms and Landscape Processes Weathering and RiversifeNo ratings yet

- Basic Aviation Medicine: DR Firman Rachman Masjhur SPKP 17 November 2014Document43 pagesBasic Aviation Medicine: DR Firman Rachman Masjhur SPKP 17 November 2014sunarniNo ratings yet

- Reynolds, 2014Document8 pagesReynolds, 2014Joana ComiranNo ratings yet

- Application LetterDocument2 pagesApplication LetterTiara Larasati PriniartiNo ratings yet

- Otec SeminarDocument21 pagesOtec SeminarAbhishekSuman80% (5)

- May 2014Document48 pagesMay 2014debtwiggNo ratings yet

- EE311A 2021 AV Slides L23Document13 pagesEE311A 2021 AV Slides L23Ananya AgarwalNo ratings yet

- Exercise LMTDocument4 pagesExercise LMTapi-276845347No ratings yet

- Brochure - EPD - EN - EU RU - Float - Lami - Coated - 2021-2026 ENDocument31 pagesBrochure - EPD - EN - EU RU - Float - Lami - Coated - 2021-2026 ENNaseer KhanNo ratings yet

- PCPNDT AssignmentDocument5 pagesPCPNDT Assignmentricha ayengia100% (2)

- Bayesian-Statistics Final 20140416 3Document38 pagesBayesian-Statistics Final 20140416 3muralidharanNo ratings yet

- Work Schedule-Rfp Kinyona-NjabiniDocument1 pageWork Schedule-Rfp Kinyona-NjabiniEmily MuthigaNo ratings yet

- E-Cart ChecklistDocument6 pagesE-Cart ChecklistClarissa GuifayaNo ratings yet

- Chemistry Project File (Class-12th)Document20 pagesChemistry Project File (Class-12th)sanchitNo ratings yet

- Central Venous Pressure Monitoring.: DR Jyothsna Chairperson DR Sunil ChhabriaDocument24 pagesCentral Venous Pressure Monitoring.: DR Jyothsna Chairperson DR Sunil ChhabriaPriyanka MaiyaNo ratings yet

- Action Research On Students Misbehavior in ClassDocument4 pagesAction Research On Students Misbehavior in ClassAnalyn Girasol86% (7)

- Meaning of LeverageDocument5 pagesMeaning of LeverageAdeem AshrafiNo ratings yet

- Voucher (Pre-Paid Booking) : ST - Havel ResidenceDocument2 pagesVoucher (Pre-Paid Booking) : ST - Havel ResidenceAlena KolesnykNo ratings yet

- Swale (Landform) - WikipediaDocument2 pagesSwale (Landform) - WikipediaMohamedNo ratings yet

- Pengelolaan Kualitas Lingkungan Dengan Pemanfaatan Limbah Cair Dari Industri Tahu Sebagai BiogasDocument17 pagesPengelolaan Kualitas Lingkungan Dengan Pemanfaatan Limbah Cair Dari Industri Tahu Sebagai BiogasMuhammad Sadiqul ImanNo ratings yet

- Death Valley NP Historic Resource Study of Mining Vols 1 and 2Document982 pagesDeath Valley NP Historic Resource Study of Mining Vols 1 and 2Russell HartillNo ratings yet

- Becoming Acquainted With Statistical ConceptsDocument3 pagesBecoming Acquainted With Statistical ConceptsCorteza, Ricardo Danilo E. UnknownNo ratings yet

- G4 Chem BoilingDocument5 pagesG4 Chem BoilingNashwaAlinsangaoNo ratings yet