Professional Documents

Culture Documents

Process Equipment Data Sheet: Operating Mechanical Data GAS Liquid Unit

Process Equipment Data Sheet: Operating Mechanical Data GAS Liquid Unit

Uploaded by

Audhinna ZuffyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Equipment Data Sheet: Operating Mechanical Data GAS Liquid Unit

Process Equipment Data Sheet: Operating Mechanical Data GAS Liquid Unit

Uploaded by

Audhinna ZuffyCopyright:

Available Formats

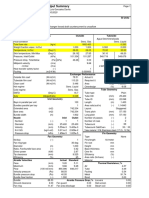

Doc No:

PROCESS EQUIPMENT

DATA SHEET

Rev : 0 Page : 1 of 1

Rev Date:

PROPRIETARY INFORMATION – For Authorized Company Use Only

1 P&ID No. Item No. Service No. Required

2 01-T-101 MEA Regenerator 1

3 OPERATING MECHANICAL DATA

4 GAS LIQUID UNIT

5 FLUID CO2 Rich MEA

6 INLET 4E+05 kg/h

7 OUTLET 2.45.E+04 3.52E+05 kg/h

8 PRESSURE 2.0 2.2 bar

9 TEMPERATURE 64 126 ºC

10 DENSITY 2.94 970.7 kg/m3

11 VISCOSITY 1.67E-02 0.4265 cP

12 MW 40.85 23.31

13 OPERATING TEMPERATURE 126 ºC

14 OPERATING PRESSURE 2.3 bar

15 DESIGN TEMPERATURE 141 ºC

16 DESIGN PRESSURE 2.53 bar

17 DIMENSION

18 HEIGHT 10 m

19 DIAMETER 4.2 m

20 MAWP 980 bar

21 THICKNESS 0.013 m

22 CORROSION ALLOWANCE 0.008 m

23 MATERIAL SS304

24 BED CHARACTERISTIC

25 SECTION 1

26 STAGE 1-10

27 PACKING TYPE MELLAPAK

28 PACKING HEIGHT 0.4 m

29 NOZZLE SCHEDULE (REVISE AS NECESSARY) PACKING MATERIAL SS304

30 MARKSize (in) Service Qty Class REMARK SECTION DIAMETER 4.2 m

31 N1 2 Temperature Transmiter Inlet 1 #150 HEAD AND BOTTOM

32 N2 2 Pressure Gauge 1 #150 HEAD TYPE Torispherical

33 N3 12 Oultet Pressure Gauge 1 #150 HEAD HEIGHT 0.7 m

34 N4 2 Vent 1 #150 HEAD THICKNESS 0.06 m

35 N5 2 Inbreathing/Outbreathing PSV Line 1 #150 HEAD MATERIAL SS304

36 N6A/B 2 Level Transmiter/ Gauge Manway 2 #150 PROCESS DATA

37 N7 12 Inlet PSV Line 1 #150 FUNCTION MEA Absorber

38 N8 2 Makeup Inlet Balancing Line 1 #150 OPERATION Continuous

39 M1 24 Manway Manway 1 #150 COLUMN TYPE Packed

40 PRESSURE DROP 0.019 bar

41

42 NOTES:

43 1

44 2

45 3

46

47

Doc No:

PROCESS EQUIPMENT

DATA SHEET

Rev : 0 Page : 1 of 1

Rev Date:

PROPRIETARY INFORMATION – For Authorized Company Use Only

1 P&ID No. Item No. Service No. Required

2 01-T-100 MEA Absorber 1

3 OPERATING MECHANICAL DATA

4 GAS LIQUID UNIT

5 FLUID Flue Gas Larutan MEA

6 INLET 1E+05 3.50E+05 kg/h

7 OUTLET 8E+04 3.72E+05 kg/h

8 PRESSURE 1.1 1.2 bar

9 TEMPERATURE 57 65 ºC

10 DENSITY 1.073 1082 kg/m3

11 VISCOSITY 1.82E-02 1.044 cP

12 MW 26.77 24.07

13 OPERATING TEMPERATURE 65 ºC

14 OPERATING PRESSURE 2 bar

15 DESIGN TEMPERATURE 80 ºC

16 DESIGN PRESSURE 2.2 bar

17 DIMENSION

18 HEIGHT 9.0 m

19 DIAMETER 3.8 m

MAWP 1100 bar

20 THICKNESS 0.012 m

21 CORROSION ALLOWANCE 0.008 m

22 MATERIAL SS304

23 BED CHARACTERISTIC

24 SECTION 1

25 STAGE 1

26 PACKING TYPE MELLAPAK

27 PACKING HEIGHT 0.4 m

28 NOZZLE SCHEDULE (REVISE AS NECESSARY) PACKING MATERIAL SS304

29 MARKSize (in) Service Qty Class REMARK SECTION DIAMETER 3.8 m

30 N1 2 Temperature Transmiter Inlet 1 #150 HEAD AND BOTTOM

31 N2 2 Pressure Gauge 1 #150 HEAD TYPE Torispherical

32 N3 12 Oultet Pressure Gauge 1 #150 HEAD HEIGHT 0.63 m

33 N4 2 Vent 1 #150 HEAD THICKNESS 0.04 m

34 N5 2 Inbreathing/Outbreathing PSV Line 1 #150 HEAD MATERIAL SS304

35 N6A/B 2 Level Transmiter/ Gauge Manway 2 #150 PROCESS DATA

36 N7 12 Inlet PSV Line 1 #150 FUNCTION MEA Absorber

37 N8 2 Makeup Inlet Balancing Line 1 #150 OPERATION Continuous

38 M1 24 Manway Manway 1 #150 COLUMN TYPE Packed

39 PRESSURE DROP 0.016 bar

40

41 NOTES:

42 1

43 2

44 3

45

46

Parameter unit 01-T-100 01-T-101

T operasi 65 126

P operasi (P) 2 2.3

T desain 80 141

P desain (Pi) MPa 2.2 2.53

Diameter m 3.8 4.2

crown radius (Rc) m 3.42 3.78

knuckle radius (Rk) 0.21 0.23

stress factor (Cs) 1.77 1.77

design stress (f) N/mm2 153 137.2

joint factor (J) 1 1

thickness (e) m 0.04 0.06

height (H) m 0.63 0.70

interpolasi

150 130

126 137.2

200 115

You might also like

- GAP-015 - Rev D (2015 - 06 - 02 18 - 24 - 57 UTC)Document2 pagesGAP-015 - Rev D (2015 - 06 - 02 18 - 24 - 57 UTC)Epuran Liviu100% (2)

- Model LibraryDocument119 pagesModel Librarydongjinzong2004No ratings yet

- Rate-Based NaOH ModelDocument21 pagesRate-Based NaOH Modelniawd100% (3)

- A Seminar Report On Rover Mission .1Document23 pagesA Seminar Report On Rover Mission .1monster gaming100% (1)

- Reconfirmation Notice: AS 1141.5-2000 (Reconfirmed) 2016-07-15Document9 pagesReconfirmation Notice: AS 1141.5-2000 (Reconfirmed) 2016-07-15Alexandru LetNo ratings yet

- Tower-Process-Data-Sheet - Ex (Version 1)Document1 pageTower-Process-Data-Sheet - Ex (Version 1)Abraham Burgos CelisNo ratings yet

- Mole Sieve Dehydration Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignDocument26 pagesMole Sieve Dehydration Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignMariana Michel0% (1)

- Enquiry Specification of OxidizerDocument28 pagesEnquiry Specification of OxidizerNikhileshkumarMishraNo ratings yet

- Gas Dehydration (ENGINEERING DESIGN GUIDELINE)Document23 pagesGas Dehydration (ENGINEERING DESIGN GUIDELINE)Tu Dang TrongNo ratings yet

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- 01 P&ID Nitrogen System - Building 2,3,5Document1 page01 P&ID Nitrogen System - Building 2,3,5MTT VIETPRONo ratings yet

- Typical PFD For Centrifugal Compressor SystemsDocument2 pagesTypical PFD For Centrifugal Compressor Systemsandres_old_condeNo ratings yet

- Pressure Relief Valves: Item Number Service SheetDocument14 pagesPressure Relief Valves: Item Number Service SheetMaura ApostolacheNo ratings yet

- PFD Unit 2000 - ReferenceDocument2 pagesPFD Unit 2000 - ReferenceAgravante JakeNo ratings yet

- PLC For The Pressure Swing Adsorption (PSA) SystemDocument4 pagesPLC For The Pressure Swing Adsorption (PSA) SystempintaratNo ratings yet

- MdeaDocument2 pagesMdeaVera MarsellaNo ratings yet

- Piping Class - AR75Document2 pagesPiping Class - AR75Дмитрий РыбаковNo ratings yet

- Control Valve Data Sheet Form S20 50 PDFDocument4 pagesControl Valve Data Sheet Form S20 50 PDFPanner2009No ratings yet

- Vertical KO Drum Sizing (Ver 1.0.0) : 1.0 DescriptionDocument21 pagesVertical KO Drum Sizing (Ver 1.0.0) : 1.0 Descriptionrameshkarthik810No ratings yet

- Qatar General Petroleum Corporation Ngl-1 Operating Manual: Vol: 1 Sec.: 8 1Document23 pagesQatar General Petroleum Corporation Ngl-1 Operating Manual: Vol: 1 Sec.: 8 1varatharajan g rNo ratings yet

- Mr. C.H.Park / Project Manager 03-May-06Document30 pagesMr. C.H.Park / Project Manager 03-May-06Ali YassineNo ratings yet

- Chapter 9 - Dynamic Behavior of Closed Loop SystemsDocument45 pagesChapter 9 - Dynamic Behavior of Closed Loop SystemsFakhrulShahrilEzanieNo ratings yet

- Engineering Solutions: KLM Technology GroupDocument27 pagesEngineering Solutions: KLM Technology Groupramadan rashadNo ratings yet

- P&ID For SRU-2Document1 pageP&ID For SRU-2Sukdeb MaityNo ratings yet

- GBH Enterprises, LTD.: Process Engineering GuideDocument15 pagesGBH Enterprises, LTD.: Process Engineering GuidePaul JamesonNo ratings yet

- E 106Document1 pageE 106Bith SMGNo ratings yet

- MC-001-DS-M-002-120 DS For Condensate Separator Rev ADocument4 pagesMC-001-DS-M-002-120 DS For Condensate Separator Rev AHeldiyan RamdhanNo ratings yet

- Production of Ethylene From Ethanol PDFDocument165 pagesProduction of Ethylene From Ethanol PDFWaleedChNo ratings yet

- Process Flow Diagram: NIOEC-SP-00-52Document6 pagesProcess Flow Diagram: NIOEC-SP-00-52Amirhossein DavoodiNo ratings yet

- ChEnected Example PIDs and Lead SheetsDocument5 pagesChEnected Example PIDs and Lead Sheetsrobirosa079No ratings yet

- Urmes-2019-Kinetic-study-of-the-selective-hydrogenation of AcetyleneDocument13 pagesUrmes-2019-Kinetic-study-of-the-selective-hydrogenation of AcetyleneRaian Yousuf Tanmoy100% (1)

- Promax: A Brief ReviewDocument27 pagesPromax: A Brief ReviewFreddy Reyes FalckNo ratings yet

- Att. 5-1 RAPID-P028B-CMI-MEC-TDS-1450-0402 - 0Document6 pagesAtt. 5-1 RAPID-P028B-CMI-MEC-TDS-1450-0402 - 0Ranjith Kumar100% (1)

- Line SizingDocument13 pagesLine Sizingadil alameenNo ratings yet

- B 84547 DY MM2 DSR ST 20 0001 - Rev.1A.MDS Inlet - Separator.IFUDocument10 pagesB 84547 DY MM2 DSR ST 20 0001 - Rev.1A.MDS Inlet - Separator.IFUYusri FakhrizalNo ratings yet

- PEPA3-11-MS-03-DS-005 - Tank Mechanical Datasheet For Tangki Prioritas 2 (Tambun SP) Rev ADocument30 pagesPEPA3-11-MS-03-DS-005 - Tank Mechanical Datasheet For Tangki Prioritas 2 (Tambun SP) Rev ARokan PipelineNo ratings yet

- Page 1 of 5 Compressor Blocked Discharge - Chemical EngineersDocument5 pagesPage 1 of 5 Compressor Blocked Discharge - Chemical EngineersKarthikeyan SivaNo ratings yet

- Volume 3-The Origins of ProtreatDocument2 pagesVolume 3-The Origins of ProtreatIbhar Santos MumentheyNo ratings yet

- Vessel Process Data Sheet1Document3 pagesVessel Process Data Sheet1AJAY1381No ratings yet

- Equipo Mayor (Major Equipment List)Document4 pagesEquipo Mayor (Major Equipment List)rondonjjNo ratings yet

- 09-05-Sulzer-Key To Success in Ethylene Plant-VFDocument23 pages09-05-Sulzer-Key To Success in Ethylene Plant-VFnktiah1207No ratings yet

- Instrument Process Datasheet Control Valves Section 100: Technologies TechnologiesDocument13 pagesInstrument Process Datasheet Control Valves Section 100: Technologies TechnologiesMohamedNo ratings yet

- Bunner ControlDocument19 pagesBunner ControlHai NguyenNo ratings yet

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadDocument7 pagesOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- Prico Process PDFDocument13 pagesPrico Process PDFcorkynhoNo ratings yet

- Dokumen - Tips - Gpsa 13 Ed Separation PDFDocument48 pagesDokumen - Tips - Gpsa 13 Ed Separation PDFNovi WulansariNo ratings yet

- ACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgDocument2 pagesACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgbaccour bilelNo ratings yet

- A-1 - Process - DescriptionDocument8 pagesA-1 - Process - DescriptionMuhammad KhurshidNo ratings yet

- InsulationDocument1 pageInsulationCesar Ricardo Lopez ValerioNo ratings yet

- Tema Datasheet: Ras Laffan Olefin ProjectDocument6 pagesTema Datasheet: Ras Laffan Olefin ProjectShaaban NoamanNo ratings yet

- Inert Gas Generators: Design Practices Fired Heaters Subsection L Exxon EngineeringDocument5 pagesInert Gas Generators: Design Practices Fired Heaters Subsection L Exxon EngineeringFRANKLIN REVILLANo ratings yet

- How To Calculate Glycol Circulation RateDocument1 pageHow To Calculate Glycol Circulation RateSameer MahmoudNo ratings yet

- Diseño Aeroenfriador para Agua Desmineralizada 66 Tubos - 2 PassesDocument25 pagesDiseño Aeroenfriador para Agua Desmineralizada 66 Tubos - 2 PassesLuis AlexanderNo ratings yet

- Basic Engineering Design Basis For Sour Water Stripper Unit (SWS) (UNIT 08)Document10 pagesBasic Engineering Design Basis For Sour Water Stripper Unit (SWS) (UNIT 08)mohsen ranjbarNo ratings yet

- PDS For Prewash Flash Column - R0Document8 pagesPDS For Prewash Flash Column - R0idilfitriNo ratings yet

- Amine Basic Practices Guideline PDFDocument64 pagesAmine Basic Practices Guideline PDFrajeshpillai26787No ratings yet

- CPS6 Choke GAsDocument19 pagesCPS6 Choke GAskarthikNo ratings yet

- Datasheet For Booster PumpDocument1 pageDatasheet For Booster PumpLe Anh DangNo ratings yet

- HE L-301 DesaireadorDocument1 pageHE L-301 DesaireadorAndrés SepúlvedaNo ratings yet

- IN-LIS-002 Rev. ADocument9 pagesIN-LIS-002 Rev. ALeon CardenasNo ratings yet

- Anexo 5 - Hoja de DatosDocument2 pagesAnexo 5 - Hoja de DatosCesar Ricardo Lopez ValerioNo ratings yet

- GV001-267-00-1A Datasheet Condensate TankDocument2 pagesGV001-267-00-1A Datasheet Condensate TankJUAN ORTEGANo ratings yet

- Design of An Air-Conditioning and Ventilation System in A 1,300 M Three-Storey HospitalDocument16 pagesDesign of An Air-Conditioning and Ventilation System in A 1,300 M Three-Storey HospitalSecret SecretNo ratings yet

- Wave On String - Exe With SolDocument76 pagesWave On String - Exe With SolArjun SabnisNo ratings yet

- CE ELECT 2S Requirement 2Document11 pagesCE ELECT 2S Requirement 2Jericho Alfred Rullog SapitulaNo ratings yet

- Nsf-Gov researchExperienceSitesDocument99 pagesNsf-Gov researchExperienceSitesManish MehraNo ratings yet

- Mini ProjectDocument7 pagesMini ProjectMolly KayeNo ratings yet

- IAL - Physics - SB2 - Teaching Plans - 11ADocument10 pagesIAL - Physics - SB2 - Teaching Plans - 11AsalmaNo ratings yet

- Laboratory Activity No. 1Document3 pagesLaboratory Activity No. 1Kent CatarinaNo ratings yet

- Experimental Literature Physics: Laboratory ExperimentsDocument10 pagesExperimental Literature Physics: Laboratory ExperimentsNetflix TagNo ratings yet

- Manual Nonlinear Time History AnalysisDocument18 pagesManual Nonlinear Time History AnalysisSOO愛.No ratings yet

- 441a PDFDocument1 page441a PDFabrar NihalNo ratings yet

- Pump CalcDocument8 pagesPump CalcMohamed FouadNo ratings yet

- Milos Ristic - Mere Bezbednosti I Zastite Zavarivaca Pri Gasnom Zavarivanju A571bDocument12 pagesMilos Ristic - Mere Bezbednosti I Zastite Zavarivaca Pri Gasnom Zavarivanju A571bVladan MitrovicNo ratings yet

- Types and Forms of EnergyDocument10 pagesTypes and Forms of EnergyPau PaguioNo ratings yet

- Direct Shear Test On Salt Range SampleDocument10 pagesDirect Shear Test On Salt Range Samplemuhammad irfanNo ratings yet

- Ophthamoscopes, Otoscopes and No. 20000 Otoscope/Throat IlluminatorDocument31 pagesOphthamoscopes, Otoscopes and No. 20000 Otoscope/Throat IlluminatorFélix EnríquezNo ratings yet

- Math 2023Document34 pagesMath 2023Muhammad AmmarNo ratings yet

- KISSsoft 2019 Tutorial 6-E-ShafteditorDocument18 pagesKISSsoft 2019 Tutorial 6-E-ShafteditorNguyễnVănLăngNo ratings yet

- SP23 MSE 2241 Homework - 239Document2 pagesSP23 MSE 2241 Homework - 239Bayejid Bin Zahid 1611942642No ratings yet

- Science: Modified Strategic Intervention MaterialsDocument26 pagesScience: Modified Strategic Intervention MaterialsFhien Garcia100% (2)

- Short Questions Chapter 14 FSC Physics Part 2Document1 pageShort Questions Chapter 14 FSC Physics Part 2anon_364604040100% (1)

- Open2023 OpenDocument13 pagesOpen2023 Openipsita lahiriNo ratings yet

- Syllabus For Soldier General Duty: Abbreviations Sports - Awards & Prizes - HistoryDocument3 pagesSyllabus For Soldier General Duty: Abbreviations Sports - Awards & Prizes - Historythegranddaddy3No ratings yet

- Din 2080-1-1978Document3 pagesDin 2080-1-1978tudorboulescuNo ratings yet

- Current Distribution and Metal Flow in An Electric Arc Furnace PDFDocument151 pagesCurrent Distribution and Metal Flow in An Electric Arc Furnace PDFOmar DiaaNo ratings yet

- Kalyan: Toll Infrastructure LTDDocument3 pagesKalyan: Toll Infrastructure LTDAKA RAIPURNo ratings yet

- Module 2Document64 pagesModule 2Hämźã ÃâmïrNo ratings yet

- An Experimental Study For In-Plane Cyclic Behavior of Low Aspect-Ratio Steel-Concrete Composite WallsDocument11 pagesAn Experimental Study For In-Plane Cyclic Behavior of Low Aspect-Ratio Steel-Concrete Composite Wallsci_balaNo ratings yet