Professional Documents

Culture Documents

Petora

Petora

Uploaded by

ForceField0 ratings0% found this document useful (0 votes)

56 views12 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

56 views12 pagesPetora

Petora

Uploaded by

ForceFieldCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 12

PET Compressor

People.

Ete

Performance.

cal (t-ye (eam

Pneumatic

QUALITY

ENERGY

EFFICIENT

f

INCREASED

PRODUCTIVITY

LOWCOST

OF OWNERSHIP

7 =

A YOUR PET

BUSINESS

PARTNER

Compressed air is a vital resource in

your PET blow moulding operation.

An interruption in the air supply leads to loss of

product, expensive delays and costly restarts. The

smallest contamination from unwanted particles

‘an corrupt your product quality and affect the

performance of products

On the other hand, you don't want to worry about

air It just has to be there, around the clock, in the

right flow, pressure and quality. You want to

concentrate on your business, and more

importantly, ona sound bottom line.

‘Asa leader in compressed air technology, Chicago

Pneumatic Compressors understands your needs:

and has put its experience of more than a century

towork for your profitability,

A professional service organization across the

globe will ensure your optimum productivity and

reliability of machines round the clock.

LESSDOWN

TIME

ee

SPARE

FLEXIBLEIN j

OPERATION =

RELIABLE AND

DURABLE

Oil free cylinders with PTFE

piston rings and bearings for

extended life.

Factory Fitted Air/Water

interconnection with Control

Panel

Proven Piston Technology,

Robust 3 stage compression

design

Extra Long Distance Piece,

ensure separation of Oil from

Compression chamber

In built Local Control Panel

& Integrated VSD

All Components on common

base plate

Highly power efficient, low reciprocating masses with lower inertia

joads and lesser friction

Compact, Small Foot Prints, Easy to Instal

Standardization of parts,

Easy & faster Availability

Easy maintenance and easy

access to every subpart

Trained & Experience

resources close to customer

High Level of Service Integrity

to optimize productivity of

customer

Energy Savings & Flexibility

with CP Tronic Mark IV controller

Integrated factory fitted VFD

+

come a

Constant Outlet Pressure

‘The output pressure is virtually constant over

wide capacity range (narrow pressure band

within 0.1 bar) orif your power supply is not

steady, This optimizes energy consumption

and ensures high process stability when the

airdemand fluctuates.

AHigh and Stable Power Factor

Regardless of the flow variation, the power

factor remains constant at a high value (Cos

Phi 0.99). This means that no additional

investment needs to be made to correct the

power factor, and penalties from the utility,

‘company can be avoided

Rey my

of wearing

parts

Low Starting Current

With VSD technology, there is no current

peak at start-up. The starting current is

equal to the nominal current during the

start-up phase. This eliminates the need

to oversize your equipment to absorb

peaks.

te yea cont comparison (LCC) ovr a prog ofS yar

“—- ”

— iment 1%

recent: 77% Mwy consump

Sng: 22 ot yu)

'35% savings on energy consumption

piston rings

1

Cp Valves -

Suited for

Annual One Time

Shut-down

Maintenance

a.

(SY,

Z

K )

=

Specifically designed and adopted exclusively for CP

compressors, they ensure uninterrupted operation and

long service life. As a result, you only need an annual

shut-down formaintenance.

Manufactured on computerised SPMs, the perfect

concentricity and flatness provides close tolerances and

ensures an aerodynamic flow for low resistance. All of

which means higher reliability, least valve losses & power

savings.

Light Weight

Pistons

Result in lesser inertia forces

resulting in increased power savings.

wes

Unique feature specially developed

for CP Compressors, eliminates the

need for a concrete foundation and

comes in a complete high duty

package unit with a Plug & play

solution,

Anti-Vibration

Mounts

One Piece Bearing

Suited for Near oe

Life Time Operation

Shrunk fit bearings ensure proper alignment & clearance

thereby reducing wear and tear. They have very high load

bearing capacity, Ideally suited for short stroke & higher

speed piston compressors. Very high reliability & hardly

needs replacement

Piston and

The ceramic filled teflon piston and rider rings are higher

wear resistant and hence have longer life. The endless

type construction for rider rings give it flexibility to rotate

in 120 degreesincreasing life by 200%,

Cross-slide

Crossheads with wide guidesto ensure

perfect guiding.

Chicago

reat {Hl

s to make maintena

giving prior indications of service requirements, a

to plan maintenance interventions in advance.

It also helps to assess the

tual load on the comp

to optimize your

npressor usage thus enablin

decide the right size of compressor for you

expansion plans.

Energy Saving Compressor Management

Full Integration with VSD

Fault history enable fast diagnosis

Programmable start and stop timer

Intelligent Protection

Warning and maintenance indications

Multilingual selection program

Pressure Dew Point of 3 Degree C

(25 Degree F)

Environment Friendly Refrigerant

Designed for nominal pressure

range of 25 to 42 Bar

High Efficiency Micro Filter

Filtration up to 0.01 micron

Air / Oil circuit

MAY (ec Mey elee

Chicago Pneumatic High Pressure Air Compressed system are specifically designed to suit applications requiring OIL

FREE COMPRESSED AIR delivering Capacity from 55 cfm to 1519 cfm at discharge pressure range of 25 bar to 42 Bar.

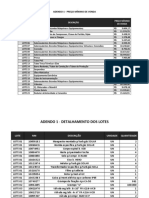

Ma CEng cies

ice

icc

30P03-25 24~32_ | 348 ~ 464 156 25

30P05-40 2-32 | 348-464 | 54 323 14 30 40

35P08-60 2-32 | 348-464 | 73 439 155 “5 60

40P05-50 35 ~ 42 508 ~ 609 54 3.23 114 37 50

40P10-60 35 ~ 42 508 ~ 609 73 439 155 45 60

4010-75, 35-42 | sos~609 | 93 555 196 55 B

4019-120 35-42 | s08-609 | 142 8.49 300 90 120

4020-180 35-42 | s0a-609 | 192 | 152 | 407 132 180

“4022-215 35-42 | 508-609 | 242 1450 siz 160 215

4027-270 35~42_| 508-609 | 340 | 2039 720 200 270

40P37-335, 35 ~ 42 508 ~ 609 453 27.18 960 250 335

4052-540 35-42 | sos-6oo | 717 | 4301 ‘| 1519 400 540

£) FAD an Pon orrn mpr BS 1571 at won

We Value

Good Service

To Ensure Customer

Satisfaction !!

‘At Chicago Pneumatic, it is our constant endeavour to provide

Peait aaa Nadie ect san Parl lverical ant eA

compressors are supported by a network of trained service

technicians and dealers who provide complete service iN

support and ensure spare parts availabilty. They are available

for any technical consultation to optimize the performance of

your equipment and ensure reliable operation, With a wide

network spread across the country, we are never too far away, to help you

solve your problems. Anytime, Anywhere.

We value your feedbacks and endeavour to

continuously improve our products and

services.

wis Aik

SR Re a eg

ee ea ae ee eee

ee ee ee ete eee

Peirce et ree ec eee cm et

Our people start every single day with a passion to research, develop,

manufacture and deliver new products that are meant to meet your needs

Pe a at ee

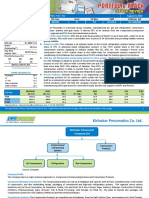

Chicago Pneumatic Compressors

Sveanagar, Mumbai Pune Highway, Dapodi

Pune - 411012 Maharashtra, India

Phone: + (91) 7030531199 / 9324175141

ws

eT al eT cel ey

Secret

West 98241 T4505 99956 36552

com /srvcn wastp.com

‘Tonty Plaza 2nd Foor, East Wing. 841A,

Tops Road, (South) Kolkata» 700 O48

Eost 322 90550 93072 91224

se

sasteep.com

South

793421 44480

©2010, chicago Preumatc lights reserves. All menoned.prodict names, co

‘ur pads re constant being Sovlope and improves. We ht raarve a

fener)

cacti

(>)

pany nara, rademarks and sence marks are the proper of he respective owners,

igh to modlyprosolspacifesbons wiht pornos

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cross Reference ListDocument1,079 pagesCross Reference ListForceField100% (1)

- Rivs Catalogue 2017Document153 pagesRivs Catalogue 2017ForceFieldNo ratings yet

- Mercedes / Knorr / Wabco / Bendix / Clayton / Volvo / RenualtDocument6 pagesMercedes / Knorr / Wabco / Bendix / Clayton / Volvo / RenualtForceFieldNo ratings yet

- Adend 1235Document22 pagesAdend 1235ForceFieldNo ratings yet

- Annex-I TG #2, MW-191 Gas Turbine Parts List For Disposal.: Sl. No. Part Name Quantity RemarksDocument55 pagesAnnex-I TG #2, MW-191 Gas Turbine Parts List For Disposal.: Sl. No. Part Name Quantity RemarksForceFieldNo ratings yet

- Rivs Catalogue 2017Document153 pagesRivs Catalogue 2017ForceFieldNo ratings yet

- Vendor Meet - Make in IndiaDocument6 pagesVendor Meet - Make in IndiaForceFieldNo ratings yet

- Naveen Kumar Singh: Knowledge PurviewDocument4 pagesNaveen Kumar Singh: Knowledge PurviewForceFieldNo ratings yet

- Very OldDocument36 pagesVery OldForceFieldNo ratings yet

- BC Imported Spares Price List NewDocument3 pagesBC Imported Spares Price List NewForceFieldNo ratings yet

- Ca Par CR 2019Document210 pagesCa Par CR 2019ForceFieldNo ratings yet

- KPDDocument27 pagesKPDForceFieldNo ratings yet

- Atlas Copco: High-Pressure Oil-Free Air Piston Compressors P 37 - P 275 / 25 To 40 Bar / 37 To 275 KWDocument12 pagesAtlas Copco: High-Pressure Oil-Free Air Piston Compressors P 37 - P 275 / 25 To 40 Bar / 37 To 275 KWForceFieldNo ratings yet

- Ingersoll Rand Type 40 Replacement Parts Repair Kits PDFDocument6 pagesIngersoll Rand Type 40 Replacement Parts Repair Kits PDFForceFieldNo ratings yet

- Kirloskar Pneumatic Co. Ltd. - CoMDocument4 pagesKirloskar Pneumatic Co. Ltd. - CoMForceFieldNo ratings yet

- SEPERATORDocument2 pagesSEPERATORForceFieldNo ratings yet

- Kirloskar Pneumatic Co-Ltd 505283 D 10 Rs.531.2 Rs. 563/348: Stock DataDocument5 pagesKirloskar Pneumatic Co-Ltd 505283 D 10 Rs.531.2 Rs. 563/348: Stock DataForceFieldNo ratings yet

- Req - No. Description Qty. Price/ Id Dinar 1241/2011 1169/2010 Spares For Compressors 11 Items 100 000Document7 pagesReq - No. Description Qty. Price/ Id Dinar 1241/2011 1169/2010 Spares For Compressors 11 Items 100 000ForceFieldNo ratings yet