Professional Documents

Culture Documents

Catalyst and Chemical Summary Sulfur Recovery Unit (SRU Unit #169)

Catalyst and Chemical Summary Sulfur Recovery Unit (SRU Unit #169)

Uploaded by

Jeroan AyamCopyright:

Available Formats

You might also like

- Citric Acid BiotechnologyDocument200 pagesCitric Acid BiotechnologyNechifor Manuela-Iuliana100% (3)

- TCMSC4Document39 pagesTCMSC4Eco Defense100% (3)

- Simulation of Dehydration - Regeneration Plant For Natural Gas Processing Using Aspen HysysDocument7 pagesSimulation of Dehydration - Regeneration Plant For Natural Gas Processing Using Aspen HysyseduryuNo ratings yet

- Pure Blue H2o Replacement GuideDocument16 pagesPure Blue H2o Replacement GuideupinderNo ratings yet

- AcetoneDocument14 pagesAcetoneAddison JuttieNo ratings yet

- Cembinder 8 TDSDocument1 pageCembinder 8 TDSkbkshanakaNo ratings yet

- Test Method - AlumDocument9 pagesTest Method - AlumAqmar Aqeem Bin Azhar100% (2)

- National Oil Corporation: Rev Date Description Checked ApprovedDocument17 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- PFD Unit 2000 - ReferenceDocument2 pagesPFD Unit 2000 - ReferenceAgravante JakeNo ratings yet

- Production of Ethylene From Ethanol PDFDocument165 pagesProduction of Ethylene From Ethanol PDFWaleedChNo ratings yet

- Surge Vessel Testing: (Update As of 30th April 2015)Document2 pagesSurge Vessel Testing: (Update As of 30th April 2015)Syed AliNo ratings yet

- Plano de SaturadorDocument6 pagesPlano de SaturadorRodrigo Andres CeledonNo ratings yet

- Engineering Standard: IPS-E-PR-410Document19 pagesEngineering Standard: IPS-E-PR-410محمد نصیریNo ratings yet

- VMS PDFDocument1 pageVMS PDFritoh8657No ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument18 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument23 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Flash Vessel Spirax Sarco FV-FINALDocument3 pagesFlash Vessel Spirax Sarco FV-FINALkawkatr100% (1)

- National Oil Corporation: Rev Date Description Checked ApprovedDocument30 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Diesel Catalytic CrackingDocument28 pagesDiesel Catalytic CrackingAdyNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument28 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Types Packing of Distillation Column by Huda ShahDocument7 pagesTypes Packing of Distillation Column by Huda ShahHuda ShahNo ratings yet

- Tech1 20190430 112222Document472 pagesTech1 20190430 112222rengapsNo ratings yet

- IPS-MBD21907-In-511A-Data Sheet of Level Gauge (Side Mounted) - ADocument3 pagesIPS-MBD21907-In-511A-Data Sheet of Level Gauge (Side Mounted) - ANikhil KarkeraNo ratings yet

- Vp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineDocument4 pagesVp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineRicardo NapitupuluNo ratings yet

- Example Shutdown Key PDFDocument1 pageExample Shutdown Key PDFsvnaik14No ratings yet

- Acetone Reactor Design Complete Project PDFDocument29 pagesAcetone Reactor Design Complete Project PDFKarliita LomNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument15 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- PT Cirebon Energi Prasarana: Issue For ApprovalDocument6 pagesPT Cirebon Energi Prasarana: Issue For ApprovalSiriepathi SeetharamanNo ratings yet

- Random Packing: From Competitive Products To Advanced SolutionsDocument16 pagesRandom Packing: From Competitive Products To Advanced SolutionsiazcuzcNo ratings yet

- UBL3&4 E 0 G0 ES AA0 002P - R3 - Color Schedule For Power PlantDocument12 pagesUBL3&4 E 0 G0 ES AA0 002P - R3 - Color Schedule For Power PlantAdvent ManurungNo ratings yet

- 26.380lvi.3.pm - Ts.0.a - Data Sheet Loading ArmsDocument9 pages26.380lvi.3.pm - Ts.0.a - Data Sheet Loading ArmsAntonio Stalin Marin0% (1)

- Process Description Part 1 of 2 32618-196-06-DB-001Document13 pagesProcess Description Part 1 of 2 32618-196-06-DB-001waheedNo ratings yet

- Attachment For FireDocument8 pagesAttachment For FireElias EliasNo ratings yet

- l2cm 4 0202 RQ Tsos Rev BDocument16 pagesl2cm 4 0202 RQ Tsos Rev BidilfitriNo ratings yet

- Process Gas Compressors: Comprehensive Api 618 Compressor PortfolioDocument20 pagesProcess Gas Compressors: Comprehensive Api 618 Compressor PortfolioaliakbarNo ratings yet

- Process Courses and Seminars March 21Document1 pageProcess Courses and Seminars March 21svnaik14No ratings yet

- Enquiry Specification of OxidizerDocument28 pagesEnquiry Specification of OxidizerNikhileshkumarMishraNo ratings yet

- Ips I in 115Document39 pagesIps I in 115hrmoeziNo ratings yet

- Trays and Packing Random & Structured PDFDocument9 pagesTrays and Packing Random & Structured PDFAsifNo ratings yet

- Column & HE Sizing - PresentationDocument76 pagesColumn & HE Sizing - PresentationRaihan FuadNo ratings yet

- Instructions: Landing Loss EmissionsDocument15 pagesInstructions: Landing Loss Emissionssunildubey02No ratings yet

- PP Aaa PP1 113Document15 pagesPP Aaa PP1 113Rabah AmidiNo ratings yet

- C 3031 Ih 8-F TSP002 Att00Document21 pagesC 3031 Ih 8-F TSP002 Att00Joseph Samir Eshak100% (1)

- CompressorDocument33 pagesCompressorfvaefaNo ratings yet

- Maamoura and Baraka Development ProjectDocument12 pagesMaamoura and Baraka Development ProjectAHMED AMIRANo ratings yet

- Engineering Standard: IPS-E-PR-790Document36 pagesEngineering Standard: IPS-E-PR-790Anonymous M4BGwOkIpNo ratings yet

- Integrated PFD Rev.0Document138 pagesIntegrated PFD Rev.0saifi khanNo ratings yet

- A8ij 300 25 BD 0006 - 1Document34 pagesA8ij 300 25 BD 0006 - 1becpavanNo ratings yet

- Inspection & Test Plan For Storage Tanks Work: ITP NO.:-9560/SITE/QAC/022/ITP-13Document6 pagesInspection & Test Plan For Storage Tanks Work: ITP NO.:-9560/SITE/QAC/022/ITP-13Shubham ShuklaNo ratings yet

- VBU Manual U-37 Chapter 1-13 PDFDocument86 pagesVBU Manual U-37 Chapter 1-13 PDFSanthana Kumar AnnamalaiNo ratings yet

- Iso-Propanol Production Report: Student Name: Course Name: Submission DateDocument18 pagesIso-Propanol Production Report: Student Name: Course Name: Submission DateAmir Javed official100% (1)

- Air ComprDocument118 pagesAir ComprMoaaz KhanNo ratings yet

- Dokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsDocument28 pagesDokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsCorne SalcedoNo ratings yet

- Id Number Title Year OrganizationDocument12 pagesId Number Title Year Organizationdeyanshu7No ratings yet

- Praj Industries PVTDocument10 pagesPraj Industries PVTanoopisbs0911No ratings yet

- Ips M PM 200 Reciprocating Compressors For Process ServicesDocument25 pagesIps M PM 200 Reciprocating Compressors For Process ServicesSeyedAli TabatabaeeNo ratings yet

- 2004 Methanol Steam Reforming Over CuZnOAl2O3 Catalyst Kinetics and Effectiveness FactorDocument11 pages2004 Methanol Steam Reforming Over CuZnOAl2O3 Catalyst Kinetics and Effectiveness FactorChauNo ratings yet

- T-0702 - P&idDocument2 pagesT-0702 - P&idPriyam KmNo ratings yet

- l2cm 4 0202 RQ Tsos RaDocument16 pagesl2cm 4 0202 RQ Tsos RaidilfitriNo ratings yet

- Mds HPH 1 - Skoda PowerDocument3 pagesMds HPH 1 - Skoda PoweridilfitriNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument33 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- DS RotDocument1 pageDS RotYENDRU LALITHAKUMARINo ratings yet

- Air Valve & Isolation Sluice Valve For Intake & CWR (32006-Lwss-Me-Ds-0009) Rev. ADocument4 pagesAir Valve & Isolation Sluice Valve For Intake & CWR (32006-Lwss-Me-Ds-0009) Rev. ASouvik DaluiNo ratings yet

- 220Kv Gss at Sanchore S/S: A24/25 KOILA BAZAR, VARANASI 221001Document1 page220Kv Gss at Sanchore S/S: A24/25 KOILA BAZAR, VARANASI 221001Vibhor ChourasiyaNo ratings yet

- Inspection & Test Plan: For Non Slam Check Valve (Axial Type)Document4 pagesInspection & Test Plan: For Non Slam Check Valve (Axial Type)Jeroan AyamNo ratings yet

- Material Requisition For Copper Nickel Piping: Doc. No.: 26071-100-MRA-PB01-00001 Job No.: 26071Document24 pagesMaterial Requisition For Copper Nickel Piping: Doc. No.: 26071-100-MRA-PB01-00001 Job No.: 26071Jeroan AyamNo ratings yet

- Itp: Acidification Vessel: Tag: A-325-02-01-C3Document8 pagesItp: Acidification Vessel: Tag: A-325-02-01-C3Jeroan AyamNo ratings yet

- FS01 Forged Steel Gate ValveDocument12 pagesFS01 Forged Steel Gate ValveJeroan AyamNo ratings yet

- Migas Jurlas Data Batch#2Document4 pagesMigas Jurlas Data Batch#2Jeroan AyamNo ratings yet

- 26071-203-M6-315-00005 - Piping and Instrumentation Diagram Fuel Oil and Fuel Gas System (Unit 315) Fuel Gas KO DrumDocument1 page26071-203-M6-315-00005 - Piping and Instrumentation Diagram Fuel Oil and Fuel Gas System (Unit 315) Fuel Gas KO DrumJeroan AyamNo ratings yet

- 26071-203-V66A-MTFR-20044 - Rev00D - Welding Map and NDE Map (D-320-06AB)Document11 pages26071-203-V66A-MTFR-20044 - Rev00D - Welding Map and NDE Map (D-320-06AB)Jeroan AyamNo ratings yet

- Att#3 - (Form) 26071 100 GQI GAQ 00007 02 Attendance RegisterDocument1 pageAtt#3 - (Form) 26071 100 GQI GAQ 00007 02 Attendance RegisterJeroan AyamNo ratings yet

- Inspection Report: 1. GeneralDocument33 pagesInspection Report: 1. GeneralJeroan AyamNo ratings yet

- TDS-US-ParaWeb M, Nov15Document1 pageTDS-US-ParaWeb M, Nov15Ammarah AzmatNo ratings yet

- Factors Affecting CO2 Absorption Efficiency in Packed Column: A ReviewDocument12 pagesFactors Affecting CO2 Absorption Efficiency in Packed Column: A ReviewARYAN_FATHONI_AMRINo ratings yet

- Co PP02032020Document12 pagesCo PP02032020Aashish SinghalNo ratings yet

- Salt 2 - Lead NitrateDocument2 pagesSalt 2 - Lead NitrateaaravNo ratings yet

- LSD-NEERI - Water Quality AnalysisDocument8 pagesLSD-NEERI - Water Quality Analysisneel721507No ratings yet

- GATE MT 2019 Paper With Solution - AskmemetallurgyDocument39 pagesGATE MT 2019 Paper With Solution - AskmemetallurgySivanujaNo ratings yet

- BASF in Malaysia Backgrounder-2021Document2 pagesBASF in Malaysia Backgrounder-2021Muhammad Umer FarooqNo ratings yet

- Jarabe de Coco MP May 2018Document1 pageJarabe de Coco MP May 2018Raul PerezNo ratings yet

- Module 2 HydrocarbonsDocument19 pagesModule 2 HydrocarbonsGabrielle TomoNo ratings yet

- 215215Document5 pages215215Chandan V ChanduNo ratings yet

- MAK Oil SpecDocument8 pagesMAK Oil SpecAnonymous alQXB11EgQNo ratings yet

- Intermolecular Forces of Liquids and Solids Solids and Their PropertiesDocument39 pagesIntermolecular Forces of Liquids and Solids Solids and Their PropertiesSTANNo ratings yet

- Science: Quarter 2 Types of Compounds Based On Their PropertiesDocument9 pagesScience: Quarter 2 Types of Compounds Based On Their PropertiesAriel Lomugdang PatricioNo ratings yet

- Valbruna UK LTD - Stainless Steels - Nickel Alloys and Titaniums - Round Bar Tolerances (DIN 1013)Document7 pagesValbruna UK LTD - Stainless Steels - Nickel Alloys and Titaniums - Round Bar Tolerances (DIN 1013)hamid razaNo ratings yet

- Flowchart of Palm Oil Mill ProcessingDocument15 pagesFlowchart of Palm Oil Mill ProcessingAndy Tander100% (5)

- Erowid LSD (Acid) Vault - ChemistryDocument1 pageErowid LSD (Acid) Vault - ChemistryAdam BruhNo ratings yet

- Kinetics Problem Set AnswersDocument2 pagesKinetics Problem Set AnswersMikey MadRat100% (1)

- Laboratory Activity 8 Wet Lab 025132 1Document3 pagesLaboratory Activity 8 Wet Lab 025132 1Ryan Carlo IbayanNo ratings yet

- Welding TerminologiesDocument11 pagesWelding TerminologiesPankajabhangNo ratings yet

- General Chemistry 1 Module 17Document9 pagesGeneral Chemistry 1 Module 17Sitti Rohima Marajan100% (1)

- Module - Naming Writing Compounds MoleculesDocument6 pagesModule - Naming Writing Compounds MoleculesMaricris MoralesNo ratings yet

- Libro de NN de Plata y BCDocument229 pagesLibro de NN de Plata y BCDaniella CelisNo ratings yet

- Chem September 2013Document84 pagesChem September 2013Orlando BarriosNo ratings yet

- Astm D2119-24Document3 pagesAstm D2119-24Giancarlo MenachoNo ratings yet

- CTO FullDocument98 pagesCTO FullsohailNo ratings yet

- Melting of Steel Scrap and Casting of WheelDocument51 pagesMelting of Steel Scrap and Casting of WheelVineet SinhaNo ratings yet

Catalyst and Chemical Summary Sulfur Recovery Unit (SRU Unit #169)

Catalyst and Chemical Summary Sulfur Recovery Unit (SRU Unit #169)

Uploaded by

Jeroan AyamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Catalyst and Chemical Summary Sulfur Recovery Unit (SRU Unit #169)

Catalyst and Chemical Summary Sulfur Recovery Unit (SRU Unit #169)

Uploaded by

Jeroan AyamCopyright:

Available Formats

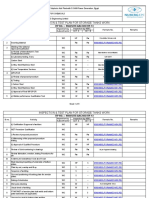

RDMP RU-V BALIKPAPAN PROJECT

Doc. No. : 26071-625-M2-169-00001

Job No : 26071

Location : EPC ISBL AND OSBL FOR RDMP PROJECT RU V BALIKPAPAN

CATALYST AND CHEMICAL SUMMARY

SULFUR RECOVERY UNIT

(SRU Unit #169)

000 27-Jan-21 ISSUED FOR CONSTRUCTION H.J.YUN/Y.H.HWANG Y.N.JOO/D.KOO Y.D.KIM

00A 23-Jul-20 ISSUED FOR REVIEW H.J.YUN/Y.H.HWANG Y.N.JOO/D.KOO Y.D.KIM

REV. DATE DESCRIPTION PREPARED CHECKED APPROVED

Doc. No. : 26071-625-M2-169-00001

Job No. : 26071 Rev.000

REVISION LOG

REV. NO. DATE PAGE DESCRIPTION

00A 23-Jul-20 ALL Document format is changed for EPC stage.

Manufacturer's type number, size, active compound

000 27-Jan-21 4, 5, 6, 7, 8, 9

are updated as per 26071-100-MRA-MVPC-00005.

Note is added as the word of 'No applicable on every

000 27-Jan-21 4, 5, 6, 7, 8, 9

page'.

000 27-Jan-21 9 Total volume is updated and Note 12 is added.

Injection rate, injection dosage, annual consumption

000 27-Jan-21 10

are updated.

Injection rate, Injection dosage are separated for

000 27-Jan-21 10

each location of injection point.

Frequency of Amine, Phosphate are changed from

000 27-Jan-21 10

'continuous' to 'Intermittent'.

Source of NaOH 40% Solution is added on Remark

000 27-Jan-21 10

section.

000 27-Jan-21 10 Powder Sulfur for commissioning is added.

000 27-Jan-21 10 Note 4,5 is added.

Phosphate injection rate and Annual consumption

000 27-Jan-21 10

are updated.

Doc. No. : 26071-625-M2-169-00001

Job No. : 26071 Rev.000

HOLD LIST

No. PARAGRAPH HOLD CONTENT

1 Job Number 26071

CATALYST AND CHEMICAL SUMMARY

2 Document Number 26071-625-M2-169-00001

3 EPC ISBL AND OSBL FOR RDMP PROJECT RU V BALIKPAPAN Revision Number 000

4 Rev. PROCESS DESIGN DATA

5 EQUIPMENT NO. C-169A/B-14

6 000 EQUIPMENT NAME 1st and 2nd Catalytic Reactor

7 CATALYST

8 CATALYST TYPE Activated Alumina Catalyst

9 MANUFACTURER Axens Eurosupport BASF(ALCOA) POROCELL

10 000 MANUFACTURER'S TYPE NO. CR 3S Ball S2001 DD-431 Balls Maxcell 725 Balls

11 000 SIZE 3~6mm (3) 3/16" 3~6mm

12 000 ACTIVE COMPOUND Al2O3 Al2O3 Al2O3 Al2O3

13 BULK DENSITY KG/M3 (3) (3) (3) (3)

14 TOTAL BULK VOLUME M3 43 (2)

15 TOTAL BULK WEIGHT KG (3) (3) (3) (3)

16 ESTIMATED CATALYST LIFE YEARS (4) (4) (4) (4)

17 CATALYST CONSUMPTION

18 ANNUAL CONSUMPTION RATE KG/YR

19 MATERIAL SAFETY DATA SHEET NO. (3) (3) (3) (3)

20 EQUIPMENT REFERENCE DRAWING NO.

21 000 PACKING (9)

22 PACKING TYPE

23 MANUFACTURER

24 MANUFACTURER'S TYPE NO.

25

26

SIZE - DIAMETER

SIZE - EXTERNAL DIAMETER -mm / AVERAGE LENGTH -mm

Contractor shall up-

27 BULK DENSITY KG/M

3

date all vendor re-

28 TOTAL BULK VOLUME M3

29 TOTAL BULK WEIGHT KG

lated information in

30 ANNUAL CONSUMPTION RATE KG/YR this document once

31 EQUIPMENT REFERENCE DRAWING NO. available.

32 NOTES

33 1. This Catalyst Summary shown for two trains.

34 2. Estimated handling loss 5% is included.

35 3. To be confirmed by vendor

36 4. Useful life is expected to be 4 years by Licensor.

37 5. Catalyst shall be supplied in drums or big bags suitable for long distance transportation by ship and trucks,

38 in accordance with Vendor instruction and recommendation.

39 6. Catalyst storage requirements at site shall be defined by Vendor.

40 7. Vendor shall state catalyst bulk density, catalyst shall be purchased on a volume (not weight) basis.

41 8. Vendor shall state expected pressure drop of fouled condition.

42 000 9. No applicable on every page.

43

44

45

46

47 General Comment: Contractor shall ensure actual pressure drop in catalyst bed

48

49

shall not exceed allowable pressure drop.

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

1 Job Number 26071

CATALYST AND CHEMICAL SUMMARY

2 Document Number 26071-625-M2-169-00001

3 EPC ISBL AND OSBL FOR RDMP PROJECT RU V BALIKPAPAN Revision Number 000

4 Rev. PROCESS DESIGN DATA

5 EQUIPMENT NO. C-169A/B-14

6 000 EQUIPMENT NAME 1st and 2nd Catalytic Reactor

7 CATALYST

8 CATALYST TYPE Hydrolysis Catalyst

9 MANUFACTURER Axens Eurosupport BASF POROCELL

10 000 MANUFACTURER'S TYPE NO. CRS-31 TL or CRS-31 Balls S7001 DD-831 or Ti-1100e Balls Maxcell 777 Balls

11 000 SIZE 3~6mm (3) 3/16" 3~6mm

12 000 ACTIVE COMPOUND TiO2 TiO2 TiO2 TiO2

3

13 BULK DENSITY KG/M (3) (3) (3) (3)

14 TOTAL BULK VOLUME M3 14 (2)

15 TOTAL BULK WEIGHT KG (3) (3) (3) (3)

16 ESTIMATED CATALYST LIFE YEARS (4) (4) (4) (4)

17 CATALYST CONSUMPTION

18 ANNUAL CONSUMPTION RATE KG/YR

19 MATERIAL SAFETY DATA SHEET NO. (3) (3) (3) (3)

20 EQUIPMENT REFERENCE DRAWING NO.

21 000 PACKING (9)

22 PACKING TYPE

23 MANUFACTURER

24 MANUFACTURER'S TYPE NO.

25

26

SIZE - DIAMETER

SIZE - EXTERNAL DIAMETER -mm / AVERAGE LENGTH -mm

Contractor shall up-

27 BULK DENSITY KG/M

3

date all vendor re-

28 TOTAL BULK VOLUME M3

29 TOTAL BULK WEIGHT KG

lated information in

30 ANNUAL CONSUMPTION RATE KG/YR this document once

31 EQUIPMENT REFERENCE DRAWING NO. available.

32 NOTES

33 1. This Catalyst Summary shown for two trains.

34 2. Estimated handling loss 5% is included.

35 3. To be confirmed by vendor

36 4. Useful life is expected to be 4 years by Licensor.

37 5. Catalyst shall be supplied in drums or big bags suitable for long distance transportation by ship and trucks,

38 in accordance with Vendor instruction and recommendation.

39 6. Catalyst storage requirements at site shall be defined by Vendor.

40 7. Vendor shall state catalyst bulk density, catalyst shall be purchased on a volume (not weight) basis.

41 8. Vendor shall state expected pressure drop of fouled condition.

42 000 9. No applicable on every page.

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

1 Job Number 26071

CATALYST AND CHEMICAL SUMMARY

2 Document Number 26071-625-M2-169-00001

3 EPC ISBL AND OSBL FOR RDMP PROJECT RU V BALIKPAPAN Revision Number 000

4 Rev. PROCESS DESIGN DATA

5 EQUIPMENT NO. C-169A/B-14

6 000 EQUIPMENT NAME 1st and 2nd Catalytic Reactor

7 CATALYST

8 CATALYST TYPE Catalyst Support

9 MANUFACTURER

10 MANUFACTURER'S TYPE NO. Inert Balls

11 000 SIZE 5~10mm

12 000 ACTIVE COMPOUND Al2O3-SiO2

13 BULK DENSITY KG/M3 (3)

14 TOTAL BULK VOLUME M3 5.8 (2)

15 TOTAL BULK WEIGHT KG (3)

16 ESTIMATED CATALYST LIFE YEARS (4)

17 CATALYST CONSUMPTION

18 ANNUAL CONSUMPTION RATE KG/YR

19 MATERIAL SAFETY DATA SHEET NO. (3)

20 EQUIPMENT REFERENCE DRAWING NO.

21 000 PACKING (9)

22 PACKING TYPE

23 MANUFACTURER

24 MANUFACTURER'S TYPE NO.

25

26

SIZE - DIAMETER

SIZE - EXTERNAL DIAMETER -mm / AVERAGE LENGTH -mm

Contractor shall up-

27 BULK DENSITY KG/M

3

date all vendor re-

28 TOTAL BULK VOLUME M3

29 TOTAL BULK WEIGHT KG

lated information in

30 ANNUAL CONSUMPTION RATE KG/YR this document once

31 EQUIPMENT REFERENCE DRAWING NO. available.

32 NOTES

33 1. This Catalyst Summary shown for two trains.

34 2. Estimated handling loss 5% is included.

35 3. Name and dimension to be provided / confirmed by vendor

36 4. Useful life is expected to be 4 years by Licensor.

37 5. Catalyst shall be supplied in drums or big bags suitable for long distance transportation by ship and trucks,

38 in accordance with Vendor instruction and recommendation.

39 6. Catalyst storage requirements at site shall be defined by Vendor.

40 7. Vendor shall state catalyst bulk density, catalyst shall be purchased on a volume (not weight) basis.

41 8. Vendor shall state expected pressure drop of fouled condition.

42 000 9. No applicable on every page.

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

1 Job Number 26071

CATALYST AND CHEMICAL SUMMARY

2 Document Number 26071-625-M2-169-00001

3 EPC ISBL AND OSBL FOR RDMP PROJECT RU V BALIKPAPAN Revision Number 000

4 Rev. PROCESS DESIGN DATA

5 EQUIPMENT NO. C-169A/B-15

6 EQUIPMENT NAME Hydrogenation Reactor

7 CATALYST

8 CATALYST TYPE Catalyst Support(Top) Hydrogenation Catalyst (3) Hydrogenation Catalyst (3) Catalyst Support (Bottom)

9 MANUFACTURER Axens Criterion

10 000 MANUFACTURER'S TYPE NO. Ceramic Balls (4) TG 107 234 TL Ceramic Balls (4)

11 SIZE 6.35mm (5) (5) 12.7mm

12 000 ACTIVE COMPOUND Al2O3-SiO2 CoMo CoMo Al2O3-SiO2

13 BULK DENSITY KG/M3 (5) (5) (5) (5)

14 TOTAL BULK VOLUME M3 1.6 21 1.6

15 TOTAL BULK WEIGHT KG (5) (5) (5) (5)

16 ESTIMATED CATALYST LIFE YEARS (6) (6) (6) (6)

17 CATALYST CONSUMPTION

18 ANNUAL CONSUMPTION RATE KG/YR

19 MATERIAL SAFETY DATA SHEET NO. (5) (5) (5) (5)

20 EQUIPMENT REFERENCE DRAWING NO.

21 000 PACKING (12)

22 PACKING TYPE

23 MANUFACTURER

24 MANUFACTURER'S TYPE NO.

25

26

SIZE - DIAMETER

SIZE - EXTERNAL DIAMETER -mm / AVERAGE LENGTH -mm

Contractor shall up-

27 BULK DENSITY KG/M

3

date all vendor re-

28 TOTAL BULK VOLUME M3

29 TOTAL BULK WEIGHT KG

lated information in

30 ANNUAL CONSUMPTION RATE KG/YR this document once

31 EQUIPMENT REFERENCE DRAWING NO. available.

32 NOTES

33 1. This Catalyst Summary shown for two trains.

34 2. Estimated handling loss 5% is included.

35 3. Catalyst shall be hydrotreating type, based on Alumina oxides and Co-Mo oxides as active metals.

36 4. DENSTONE 57 or equivalent (To be confirmed by vendor)

37 5. To be confirmed by vendor.

38 6. Useful life is expected to be 4 years by Licensor.

39 7. Catalyst shall be supplied in drums or big bags suitable for long distance transportation by ship and trucks,

40 in accordance with Vendor instruction and recommendation.

41 8. Catalyst storage requirements at site shall be defined by Vendor.

42 9. Vendor shall state catalyst bulk density, catalyst shall be purchased on a volume (not weight) basis.

43 10. Vendor shall state expected pressure drop of fouled condition.

44 11. Vendor to confirm COS, CS2 conversion at SOR and EOR condition.

45 000 12. No applicable on every page.

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

1 Job Number 26071

CATALYST AND CHEMICAL SUMMARY

2 Document Number 26071-625-M2-169-00001

3 EPC ISBL AND OSBL FOR RDMP PROJECT RU V BALIKPAPAN Revision Number 000

4 Rev. PROCESS DESIGN DATA

5 EQUIPMENT NO. C-169A/B-10

6 EQUIPMENT NAME Degassing Column

7 CATALYST

8 CATALYST TYPE Activated Alumina Catalyst Catalyst Support

9 000 MANUFACTURER Axens

10 MANUFACTURER'S TYPE NO. CR 3S Balls Ceramic or Alumina Balls (4)

11 SIZE 3~6mm 10~12mm

12 000 ACTIVE COMPOUND Al2O3 Al2O3-SiO2

13 BULK DENSITY KG/M3 (8) (8)

14 TOTAL BULK VOLUME M3 6.68 0.76

15 TOTAL BULK WEIGHT KG (8) (8)

16 ESTIMATED CATALYST LIFE YEARS (8) (8)

17 CATALYST CONSUMPTION

18 ANNUAL CONSUMPTION RATE KG/YR

19 MATERIAL SAFETY DATA SHEET NO. (8) (8)

20 EQUIPMENT REFERENCE DRAWING NO.

21 000 PACKING (10)

22 PACKING TYPE

23 MANUFACTURER

24 MANUFACTURER'S TYPE NO.

25

26

SIZE - DIAMETER

SIZE - EXTERNAL DIAMETER -mm / AVERAGE LENGTH -mm

Contractor shall up-

27 BULK DENSITY KG/M

3

date all vendor re-

28 TOTAL BULK VOLUME M3

29 TOTAL BULK WEIGHT KG

lated information in

30 ANNUAL CONSUMPTION RATE KG/YR this document once

31 EQUIPMENT REFERENCE DRAWING NO. available.

32 NOTES

33 1. This Catalyst Summary shown for two trains.

34 2. Estimated handling loss 5% is included.

35 000 3. Deleted.

36 4. DENSTONE 57 or equivalent (To be confirmed by vendor).

37 5. Catalyst shall be supplied in drums or big bags suitable for long distance transportation by ship and trucks,

38 in accordance with Vendor advise.

39 6. Catalyst storage requirements at site shall be defined by Vendor.

40 7. Vendor shall state catalyst bulk density, catalyst shall be purchased on a volume (not weight) basis.

41 8. To be confirmed by vendor.

42 9. Vendor shall state expected pressure drop of fouled condition.

43 000 10. No applicable on every page.

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

1 Job Number 26071

CATALYST AND CHEMICAL SUMMARY

2 Document Number 26071-625-M2-169-00001

3 EPC ISBL AND OSBL FOR RDMP PROJECT RU V BALIKPAPAN Revision Number 000

4 Rev. PROCESS DESIGN DATA

5 EQUIPMENT NO. S-169A/B-03

6 EQUIPMENT NAME Carbon Filter

7 CATALYST

8 CATALYST TYPE Activated Carbon Catalyst Support

9 MANUFACTURER

10 MANUFACTURER'S TYPE NO. (3) Ceramic inert Balls(4)

11 SIZE (3) 3mm

12 000 ACTIVE COMPOUND Carbon Bed Al2O3-SiO2

13 BULK DENSITY KG/M3 (5) (5)

14 000 TOTAL BULK VOLUME M3 19(12) 1.4(12)

15 TOTAL BULK WEIGHT KG (5) (5)

16 ESTIMATED CATALYST LIFE YEARS (5) (5)

17 CATALYST CONSUMPTION

18 ANNUAL CONSUMPTION RATE KG/YR

19 MATERIAL SAFETY DATA SHEET NO. (5) (5)

20 EQUIPMENT REFERENCE DRAWING NO.

21 000 PACKING (11)

22 PACKING TYPE

23 MANUFACTURER

24 MANUFACTURER'S TYPE NO.

25 SIZE - DIAMETER

26 SIZE - EXTERNAL DIAMETER -mm / AVERAGE LENGTH -mm

3

27 BULK DENSITY KG/M

28 TOTAL BULK VOLUME M3

29 TOTAL BULK WEIGHT KG

30 ANNUAL CONSUMPTION RATE KG/YR

31 EQUIPMENT REFERENCE DRAWING NO.

32 Contractor

NOTES shall up-

33 1. This Catalyst Summary shown for two trains. date all vendor re-

34 2. Estimated handling loss 5% is included.

35 000 lated information in

3. The Carbon bed shall remove traces of entrained hydrocarbons and heavy ends formed by thermal degradation of MDEA.

36

37

Granulometry (ASTM D 2.862-67) : 8*30

> 8 mesh (2.38mm) : 15% max

this document once

38 < 30 mesh (0.59mm) : 4% max available.

39 Mean particle diameter : 1.6mm

40 Above criteria are based on KT experience.

41 4. DENSTONE 57 or equivalent (To be confirmed by vendor).

42 5. To be confirmed by vendor.

43 6. Catalyst shall be supplied in drums or big bags suitable for long distance transportation by ship and trucks,

44 in accordance with Vendor advise.

45 7. Carbon Vendor shall define minimum storage requirements in site.

46 8. Vendor shall state carbon bulk density.

47 9. Catalyst guaranteed lifetime is 2years.

48 10. Vendor shall state expected pressure drop of fouled condition.

49 000 11. No applicable on every page.

50 000 12. The total volume of the carbon filter is considered up to the amount that will be used after 2 years of catalyst lifetime.

51 000 The initial filling amount of one filter is 4.52m3.

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

Job Number 26071

CATALYST AND CHEMICAL SUMMARY Document Number 26071-625-M2-169-00001

EPC ISBL AND OSBL FOR RDMP PROJECT RU V BALIKPAPAN Revision Number 000

INJECTION RATE

DILUTION INJECTION ANNUAL DENSITY INITIAL TYPICAL

LOCATION OF PACKAGE (l/h) (1)

Rev. CHEMICAL APPLICATION FREQUENCY DOSAGE CONSUMPTION (kg/m3) CHARGE CHEMICAL / REMARKS

INJECTION POINT NUMBER

Concentration (1) (ton) (2) (1) (m3) (2) MATERIAL

Yes/No min. nor. max.

(wt%)

000 Amine Solution H2S Removal Intermittent Yes 45 N/A N/A N/A N/A N/A 1038 ~ 1041 42 Formulated MDEA

Absorber

000 Antifoam (C-169A/B-04) Lean A-169A/B-01 Foam removal Intermittent Yes - - 0.18 0.3 5ppm

Amine inlet

Lean Amine Pump

1.58

000 Antifoam (G-169A/B-06A/B) A-169A/B-01 Foam removal Intermittent Yes - - 0.18 0.3 5ppm 1000 1.06 EC9079A Based on Nalco information to be confirmed later.

(4)

Lean Amine inlet

Reflux Drum

000 Antifoam (C-169A/B-12) A-169A/B-01 Foam removal Intermittent Yes - - 0.18 0.3 5ppm

Sour Water outlet

WHB Steam Drum

Note 2 is not applica-

000 Phosphate (C-169A/B-07) BFW

inlet,

A-169A/B-02 Water Treatment Intermittent Yes - - 0.20 0.33 10ppm

ble for Sulphur pow-

Incinerator WHB

1.87

(4)

der. Please confirm.

Steam Drum (C-

000 Phosphate 169A/B-13) A-169A/B-02 Water Treatment Intermittent Yes - - 0.20 0.33 10ppm 1070 1.05 Nalco 7208 Based on Nalco information to be confirmed later.

Preheated BFW

inlet.

Sulfur Condenser

0.19

000 Phosphate (E-169A/B-02) BFW A-169A/B-02 Water Treatment Intermittent Yes - 0.02 0.03 7ppm

(4)

inlet,

Quench Tower

(C-169A/B-03) 40% NaOH to be supplied by portable container from

000 NaOH 40% Solution PH Control Intermittent Yes 40 80 NaOH 40% Solution

Quench Water U325.

outlet

Sulfur Hydraulic

5.5 Powder Sulfur is considered commissioning

000 Powder Sulfur Seal (TR-169A- Initial start-up for commissioning One Time No - N/A N/A N/A N/A N/A - Powder Sulfur

(5) consumable.

01~06)

GENERAL NOTES:

• Annual consumption is based on 365 operating days per year.

•

•

Contractor shall con-

•

SPECIFIC NOTES:

firm applicability of

1. To

1. To be

be confirmed

confirmed by

by vendor.

vendor. Note 1

2. It shows the requirement for one train. Multiply by 2 to have the total amount of 2 trains.

000 3. Deleted.

000 4. Annual consumption is based on assumption that injection is continuous.

000 5. Considering total volume of seal with leakage margin.

You might also like

- Citric Acid BiotechnologyDocument200 pagesCitric Acid BiotechnologyNechifor Manuela-Iuliana100% (3)

- TCMSC4Document39 pagesTCMSC4Eco Defense100% (3)

- Simulation of Dehydration - Regeneration Plant For Natural Gas Processing Using Aspen HysysDocument7 pagesSimulation of Dehydration - Regeneration Plant For Natural Gas Processing Using Aspen HysyseduryuNo ratings yet

- Pure Blue H2o Replacement GuideDocument16 pagesPure Blue H2o Replacement GuideupinderNo ratings yet

- AcetoneDocument14 pagesAcetoneAddison JuttieNo ratings yet

- Cembinder 8 TDSDocument1 pageCembinder 8 TDSkbkshanakaNo ratings yet

- Test Method - AlumDocument9 pagesTest Method - AlumAqmar Aqeem Bin Azhar100% (2)

- National Oil Corporation: Rev Date Description Checked ApprovedDocument17 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- PFD Unit 2000 - ReferenceDocument2 pagesPFD Unit 2000 - ReferenceAgravante JakeNo ratings yet

- Production of Ethylene From Ethanol PDFDocument165 pagesProduction of Ethylene From Ethanol PDFWaleedChNo ratings yet

- Surge Vessel Testing: (Update As of 30th April 2015)Document2 pagesSurge Vessel Testing: (Update As of 30th April 2015)Syed AliNo ratings yet

- Plano de SaturadorDocument6 pagesPlano de SaturadorRodrigo Andres CeledonNo ratings yet

- Engineering Standard: IPS-E-PR-410Document19 pagesEngineering Standard: IPS-E-PR-410محمد نصیریNo ratings yet

- VMS PDFDocument1 pageVMS PDFritoh8657No ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument18 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument23 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Flash Vessel Spirax Sarco FV-FINALDocument3 pagesFlash Vessel Spirax Sarco FV-FINALkawkatr100% (1)

- National Oil Corporation: Rev Date Description Checked ApprovedDocument30 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Diesel Catalytic CrackingDocument28 pagesDiesel Catalytic CrackingAdyNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument28 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- Types Packing of Distillation Column by Huda ShahDocument7 pagesTypes Packing of Distillation Column by Huda ShahHuda ShahNo ratings yet

- Tech1 20190430 112222Document472 pagesTech1 20190430 112222rengapsNo ratings yet

- IPS-MBD21907-In-511A-Data Sheet of Level Gauge (Side Mounted) - ADocument3 pagesIPS-MBD21907-In-511A-Data Sheet of Level Gauge (Side Mounted) - ANikhil KarkeraNo ratings yet

- Vp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineDocument4 pagesVp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineRicardo NapitupuluNo ratings yet

- Example Shutdown Key PDFDocument1 pageExample Shutdown Key PDFsvnaik14No ratings yet

- Acetone Reactor Design Complete Project PDFDocument29 pagesAcetone Reactor Design Complete Project PDFKarliita LomNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument15 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- PT Cirebon Energi Prasarana: Issue For ApprovalDocument6 pagesPT Cirebon Energi Prasarana: Issue For ApprovalSiriepathi SeetharamanNo ratings yet

- Random Packing: From Competitive Products To Advanced SolutionsDocument16 pagesRandom Packing: From Competitive Products To Advanced SolutionsiazcuzcNo ratings yet

- UBL3&4 E 0 G0 ES AA0 002P - R3 - Color Schedule For Power PlantDocument12 pagesUBL3&4 E 0 G0 ES AA0 002P - R3 - Color Schedule For Power PlantAdvent ManurungNo ratings yet

- 26.380lvi.3.pm - Ts.0.a - Data Sheet Loading ArmsDocument9 pages26.380lvi.3.pm - Ts.0.a - Data Sheet Loading ArmsAntonio Stalin Marin0% (1)

- Process Description Part 1 of 2 32618-196-06-DB-001Document13 pagesProcess Description Part 1 of 2 32618-196-06-DB-001waheedNo ratings yet

- Attachment For FireDocument8 pagesAttachment For FireElias EliasNo ratings yet

- l2cm 4 0202 RQ Tsos Rev BDocument16 pagesl2cm 4 0202 RQ Tsos Rev BidilfitriNo ratings yet

- Process Gas Compressors: Comprehensive Api 618 Compressor PortfolioDocument20 pagesProcess Gas Compressors: Comprehensive Api 618 Compressor PortfolioaliakbarNo ratings yet

- Process Courses and Seminars March 21Document1 pageProcess Courses and Seminars March 21svnaik14No ratings yet

- Enquiry Specification of OxidizerDocument28 pagesEnquiry Specification of OxidizerNikhileshkumarMishraNo ratings yet

- Ips I in 115Document39 pagesIps I in 115hrmoeziNo ratings yet

- Trays and Packing Random & Structured PDFDocument9 pagesTrays and Packing Random & Structured PDFAsifNo ratings yet

- Column & HE Sizing - PresentationDocument76 pagesColumn & HE Sizing - PresentationRaihan FuadNo ratings yet

- Instructions: Landing Loss EmissionsDocument15 pagesInstructions: Landing Loss Emissionssunildubey02No ratings yet

- PP Aaa PP1 113Document15 pagesPP Aaa PP1 113Rabah AmidiNo ratings yet

- C 3031 Ih 8-F TSP002 Att00Document21 pagesC 3031 Ih 8-F TSP002 Att00Joseph Samir Eshak100% (1)

- CompressorDocument33 pagesCompressorfvaefaNo ratings yet

- Maamoura and Baraka Development ProjectDocument12 pagesMaamoura and Baraka Development ProjectAHMED AMIRANo ratings yet

- Engineering Standard: IPS-E-PR-790Document36 pagesEngineering Standard: IPS-E-PR-790Anonymous M4BGwOkIpNo ratings yet

- Integrated PFD Rev.0Document138 pagesIntegrated PFD Rev.0saifi khanNo ratings yet

- A8ij 300 25 BD 0006 - 1Document34 pagesA8ij 300 25 BD 0006 - 1becpavanNo ratings yet

- Inspection & Test Plan For Storage Tanks Work: ITP NO.:-9560/SITE/QAC/022/ITP-13Document6 pagesInspection & Test Plan For Storage Tanks Work: ITP NO.:-9560/SITE/QAC/022/ITP-13Shubham ShuklaNo ratings yet

- VBU Manual U-37 Chapter 1-13 PDFDocument86 pagesVBU Manual U-37 Chapter 1-13 PDFSanthana Kumar AnnamalaiNo ratings yet

- Iso-Propanol Production Report: Student Name: Course Name: Submission DateDocument18 pagesIso-Propanol Production Report: Student Name: Course Name: Submission DateAmir Javed official100% (1)

- Air ComprDocument118 pagesAir ComprMoaaz KhanNo ratings yet

- Dokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsDocument28 pagesDokumen - Tips Gas Filtration Products Absolute 2015-09-04 Gas Filtration ProductsCorne SalcedoNo ratings yet

- Id Number Title Year OrganizationDocument12 pagesId Number Title Year Organizationdeyanshu7No ratings yet

- Praj Industries PVTDocument10 pagesPraj Industries PVTanoopisbs0911No ratings yet

- Ips M PM 200 Reciprocating Compressors For Process ServicesDocument25 pagesIps M PM 200 Reciprocating Compressors For Process ServicesSeyedAli TabatabaeeNo ratings yet

- 2004 Methanol Steam Reforming Over CuZnOAl2O3 Catalyst Kinetics and Effectiveness FactorDocument11 pages2004 Methanol Steam Reforming Over CuZnOAl2O3 Catalyst Kinetics and Effectiveness FactorChauNo ratings yet

- T-0702 - P&idDocument2 pagesT-0702 - P&idPriyam KmNo ratings yet

- l2cm 4 0202 RQ Tsos RaDocument16 pagesl2cm 4 0202 RQ Tsos RaidilfitriNo ratings yet

- Mds HPH 1 - Skoda PowerDocument3 pagesMds HPH 1 - Skoda PoweridilfitriNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument33 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- DS RotDocument1 pageDS RotYENDRU LALITHAKUMARINo ratings yet

- Air Valve & Isolation Sluice Valve For Intake & CWR (32006-Lwss-Me-Ds-0009) Rev. ADocument4 pagesAir Valve & Isolation Sluice Valve For Intake & CWR (32006-Lwss-Me-Ds-0009) Rev. ASouvik DaluiNo ratings yet

- 220Kv Gss at Sanchore S/S: A24/25 KOILA BAZAR, VARANASI 221001Document1 page220Kv Gss at Sanchore S/S: A24/25 KOILA BAZAR, VARANASI 221001Vibhor ChourasiyaNo ratings yet

- Inspection & Test Plan: For Non Slam Check Valve (Axial Type)Document4 pagesInspection & Test Plan: For Non Slam Check Valve (Axial Type)Jeroan AyamNo ratings yet

- Material Requisition For Copper Nickel Piping: Doc. No.: 26071-100-MRA-PB01-00001 Job No.: 26071Document24 pagesMaterial Requisition For Copper Nickel Piping: Doc. No.: 26071-100-MRA-PB01-00001 Job No.: 26071Jeroan AyamNo ratings yet

- Itp: Acidification Vessel: Tag: A-325-02-01-C3Document8 pagesItp: Acidification Vessel: Tag: A-325-02-01-C3Jeroan AyamNo ratings yet

- FS01 Forged Steel Gate ValveDocument12 pagesFS01 Forged Steel Gate ValveJeroan AyamNo ratings yet

- Migas Jurlas Data Batch#2Document4 pagesMigas Jurlas Data Batch#2Jeroan AyamNo ratings yet

- 26071-203-M6-315-00005 - Piping and Instrumentation Diagram Fuel Oil and Fuel Gas System (Unit 315) Fuel Gas KO DrumDocument1 page26071-203-M6-315-00005 - Piping and Instrumentation Diagram Fuel Oil and Fuel Gas System (Unit 315) Fuel Gas KO DrumJeroan AyamNo ratings yet

- 26071-203-V66A-MTFR-20044 - Rev00D - Welding Map and NDE Map (D-320-06AB)Document11 pages26071-203-V66A-MTFR-20044 - Rev00D - Welding Map and NDE Map (D-320-06AB)Jeroan AyamNo ratings yet

- Att#3 - (Form) 26071 100 GQI GAQ 00007 02 Attendance RegisterDocument1 pageAtt#3 - (Form) 26071 100 GQI GAQ 00007 02 Attendance RegisterJeroan AyamNo ratings yet

- Inspection Report: 1. GeneralDocument33 pagesInspection Report: 1. GeneralJeroan AyamNo ratings yet

- TDS-US-ParaWeb M, Nov15Document1 pageTDS-US-ParaWeb M, Nov15Ammarah AzmatNo ratings yet

- Factors Affecting CO2 Absorption Efficiency in Packed Column: A ReviewDocument12 pagesFactors Affecting CO2 Absorption Efficiency in Packed Column: A ReviewARYAN_FATHONI_AMRINo ratings yet

- Co PP02032020Document12 pagesCo PP02032020Aashish SinghalNo ratings yet

- Salt 2 - Lead NitrateDocument2 pagesSalt 2 - Lead NitrateaaravNo ratings yet

- LSD-NEERI - Water Quality AnalysisDocument8 pagesLSD-NEERI - Water Quality Analysisneel721507No ratings yet

- GATE MT 2019 Paper With Solution - AskmemetallurgyDocument39 pagesGATE MT 2019 Paper With Solution - AskmemetallurgySivanujaNo ratings yet

- BASF in Malaysia Backgrounder-2021Document2 pagesBASF in Malaysia Backgrounder-2021Muhammad Umer FarooqNo ratings yet

- Jarabe de Coco MP May 2018Document1 pageJarabe de Coco MP May 2018Raul PerezNo ratings yet

- Module 2 HydrocarbonsDocument19 pagesModule 2 HydrocarbonsGabrielle TomoNo ratings yet

- 215215Document5 pages215215Chandan V ChanduNo ratings yet

- MAK Oil SpecDocument8 pagesMAK Oil SpecAnonymous alQXB11EgQNo ratings yet

- Intermolecular Forces of Liquids and Solids Solids and Their PropertiesDocument39 pagesIntermolecular Forces of Liquids and Solids Solids and Their PropertiesSTANNo ratings yet

- Science: Quarter 2 Types of Compounds Based On Their PropertiesDocument9 pagesScience: Quarter 2 Types of Compounds Based On Their PropertiesAriel Lomugdang PatricioNo ratings yet

- Valbruna UK LTD - Stainless Steels - Nickel Alloys and Titaniums - Round Bar Tolerances (DIN 1013)Document7 pagesValbruna UK LTD - Stainless Steels - Nickel Alloys and Titaniums - Round Bar Tolerances (DIN 1013)hamid razaNo ratings yet

- Flowchart of Palm Oil Mill ProcessingDocument15 pagesFlowchart of Palm Oil Mill ProcessingAndy Tander100% (5)

- Erowid LSD (Acid) Vault - ChemistryDocument1 pageErowid LSD (Acid) Vault - ChemistryAdam BruhNo ratings yet

- Kinetics Problem Set AnswersDocument2 pagesKinetics Problem Set AnswersMikey MadRat100% (1)

- Laboratory Activity 8 Wet Lab 025132 1Document3 pagesLaboratory Activity 8 Wet Lab 025132 1Ryan Carlo IbayanNo ratings yet

- Welding TerminologiesDocument11 pagesWelding TerminologiesPankajabhangNo ratings yet

- General Chemistry 1 Module 17Document9 pagesGeneral Chemistry 1 Module 17Sitti Rohima Marajan100% (1)

- Module - Naming Writing Compounds MoleculesDocument6 pagesModule - Naming Writing Compounds MoleculesMaricris MoralesNo ratings yet

- Libro de NN de Plata y BCDocument229 pagesLibro de NN de Plata y BCDaniella CelisNo ratings yet

- Chem September 2013Document84 pagesChem September 2013Orlando BarriosNo ratings yet

- Astm D2119-24Document3 pagesAstm D2119-24Giancarlo MenachoNo ratings yet

- CTO FullDocument98 pagesCTO FullsohailNo ratings yet

- Melting of Steel Scrap and Casting of WheelDocument51 pagesMelting of Steel Scrap and Casting of WheelVineet SinhaNo ratings yet