Professional Documents

Culture Documents

U-S Return: Tentative Section of The Wall

U-S Return: Tentative Section of The Wall

Uploaded by

MohammedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

U-S Return: Tentative Section of The Wall

U-S Return: Tentative Section of The Wall

Uploaded by

MohammedCopyright:

Available Formats

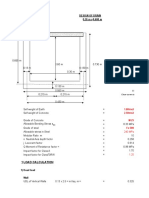

Design magui U-S Return

1.20 0.30 0.079 0.02 1.10

100.50

3

4

3.300 9 9

97.20 1 5

6

0.900 10

2

96.30 11 12

13 14

95.80 0.40 7 0.500 15 19.2 3.0 9.0

93.00 2.70 19.23 4.66 14

8

1.40

Assumptions

Weight of R.C.C. = 24.00 kN/m3

Weight of dry earth = 16.00 "

Weight of wet earth = 17.50 "

g of water

Weight = 10.00 "

Weight of saturated earth = 20.00 "

Weight of submerged earth = 10.00 "

Weight of foundation concrete = 22.50 "

Angle of repose of earth = 0.52

Ka = 0.33

2

Allowable bearing pressure of soil = 150.00 kN/m

Max. compressive stress in masonry = 1000.00 "

Co-efficient of friction between concrete & masonry = 0.65

C

Co-efficient

ffi i t off ffriction

i ti bbetween

t concrete

t & soil

il = 0.40

0 40

Earth top level = 100.50

Static Hydraulic Grade Level = 97.20

Floor level = 96.30

Foundation Level = 95.80 OK

Tentative section of the wall

Top width of wall = 0.30 m

Bottom width of wall = 0.40 m

Projection of concrete beyond heel = 1.10 m

Projection of concrete beyond toe = 1.20 m

Width of batter = 0.10 m

Adopt overall depth of wall sestion = 400 mm Revise

Provide at the spacing of 16 mm dia bar @ 150 mm c/c

% Reinforcement in wall 0.392 %

Depth modification factor according to tensile steel provided= 1.27 For minimum Required

Permissible shear stress with respect to tensile reinforcement percentage = 0.268

Shear stress = 0 159 N/mm2

0.159 <0 268 Hence Safe

<0.268

Check for bond 0.528 N/mm2 Hence safe

a) Factor of safety against Over Turning = 199.478 / 104.277 = 1.91 >=1.5 Hence Safe

b) Factor of safety against Sliding = 0.4 x 103.405 / 71.722 = 0.58 <1.5 Provide Key

c) Check against max. pressure on soil Ecentricity (e) = 1.779 - 2.7 / 2 = 0.4 < 2.7/6 Hence Safe

Adopt overall depth of sestion = Toe 400 mm

Provide at the spacing of 12 mm dia bar @ 200 mm c/c

% Reinforcement in 0.164 %

Permissible shear stress with respect to tensile reinforcement percentage = 0.22

Sh t

Shear stress = 0 163

0.163 N/

N/mm2 2 <0 22 H

0.22 Hence OK

Check for bond 0.972 N/mm2 < 1.28 Hence OK

Adopt overall depth of sestion = Heel 400 mm = Toe , Hence OK

Provide at the spacing of 16 mm dia bar @ 150 mm c/c

% Reinforcement in 0.392 %

Permissible shear stress with respect to tensile reinforcement percentage = 0.268

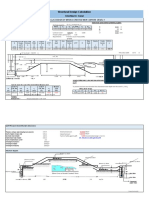

Design magui U-S Return

Shear stress = 0.2287 N/mm2 < 0.268 Hence OK

Check for bond 0.759 N/mm3 < 1.28 Hence OK

Adopt overall depth of sestion = Key 400 mm Provide at under-

Depth of key below bottom of bed slab (For design purpose) = 2.80 m Provide at weir side (m.) sluice side (m.)

Provide at the spacing of 16 mm dia bar @ 150 mm c/c 2.80 -41.30

% Reinforcement in 0.39 %

Modification factor = 1.74

Available d using 342 mm > 230 (Min. Req. for stiffness), Hence OK

Permissible shear stress with respect to tensile reinforcement percentage = 0 22

0.22

Shear stress = 0.194 N/mm2 < 0.22 Hence OK

Check for bond 0.643 N/mm2 < 1.28 Hence OK

Stability at Floor level

Item Unit wt. Area Force (kN) L Moments (kN-m)

3

wet earth pressure kN/m H arm Hm

section 9 1 31.733 31.733 2.000 63.466

section 10 1 17.309 17.309 0.450 7.789

submerged earth pressure

section 11 1 1.349 1.349 0.300 0.405

water pressure

section 12 1 4.050 4.050 0.300 1.215

Total 54.441 72.875

Total Horizontal moment = 72.875 KNm

Use Concrete M20 Steel Tor steel

cbc = 7 st = 230 using 20 mm and lower dia bars

modular ratio (m)= 280/(3xcbc) = 13.3

Neutral axis ratio (k) = (m x cbc) / (st+m x cbc) = 0.289

Leaver arm ratio (j) = 1 - k/3 = 0.904

Factor for moment of resistance (R) =1/2 x j x k x cbc = 0.9

0.5

Efective depth (d) of stem section = ( M / R/1000) = 283 mm

Available d using 16 mm f bars and 50 mm clear cover 342 mm

2

Area of steel required Ast= M/(sst x j x d ) = 1026 mm

Minimum steel = 0.12% of total sectional area = 480 mm2

2

Use 16 mm f bar = a= 201 mm P = 50 mm

Spacing of bar = 201x 1000 / 1026 196 mm

Provide at the spacing of 150 mm

2

Area of steel provided = 1000/150 x201= 1340 mm

Check for depth from stiffness / deflection consideration

% Ast = 100 x 1340 /(1000 x342)

342) = 0 3918

0.3918

Depth modification factor according to tensile steel provided= 1.27

Required effective depth of wall from stiffness / deflection consideration =

(3.3+0.9)/(7 x 1.27) x 1000 mm

= 472 mm

Check for shear

Total shear force = 54.441 KN = 54441 N

Permissible shear stress with respect to tensile reinforcement percentage = 0.268

Shear stress = 54441/(1000 x 342 ) = 0.1592 N/mm2 <0.268

0.268 Hence Safe

Check for bond Permissible bond stress = 1.28 N/mm2

2

sb = 54441 /(0.904x342x (1000/150)x50)= 0.5283947 N/mm Hence safe

Distribution bars

.12% of the section = 0.12/100 x 1000 x(400+300) /2 420 mm2

20% 0f main reinforcement = 20/100 x 1340= 268 mm2

2

P id

Provide 12 mm f b

bars a= 113 mm

Spacing = 113.1 x1000 / 420= 269.279

Provide at the spacing of 250 mm

Provide 12 mm dia bars @ 250mm c/c at water face as nominal reinforcement

Design magui U-S Return

Stability Foundation level

b = 2.700 m

Item Unit wt. Area Force (kN) L Moments (kN-m)

kN/m3 m2 V H arm Vm Hm

1 RCC

1.

section 1 24.00 1.26 30.24 1.35 40.824

section 2 24.00 0.21 5.04 1.53333333 7.728

2. Earth retained on back fac 0 0

wet soil 0 0

section 3 17.50 0.1296429 2.269 1.55238095 3.522

section 4 17.50 3.7007143 64.763 2.13928571 138.547

saturated soil 0 0

section 5 20.00 0.0096429 0.193 1.59285714 0.307

section

i 6 20

20.00

00 00.99

99 19

19.88 22.15

15 42

42.57

57

3. Uplift 0 0

section 8 10.00 1.89 -18.9 1.8 -34.02

4. Earth pressure

wet earth pressure

section 9 1 31.733079 31.733079 2.5 79.333

section 13 1 26.925037 26.925037 0.7 18.848

submerged earth pressure 0

section 14 1 3.2636409 3.2636409 0.46666667 1.523

water pressure 0

section 15 1 9.8 9.8 0.46666667 4.573

103.405 71.722 199.478 104.277

Height of C.G. Of total pressure from bottom of foundation slab = 104.277 / 71.722= 1.45391 m

Distance of C.G. Of total weight from toe of foundation slab = 199.478 / 103.405 = 1.92909 m

a) Factor of safety against Over Turning = 199.478 / 104.277 = 1.913 >=1.5 Hence Safe

b) Factor of safety against Sliding = 0.4 x 103.405 / 71.722 = 0.577 <1.5 Provide Key

Balance of sliding force = 1.5 x 71.722 - 103.405 x0.4 = 66.221 KN

c) Check against max. pressure on soil

71.72 Distance KL= 1.454x 71.722 / 103.405 = 1.01 m

Distance EL = 0.771 + 1.008 = 1.78 m

103.4 1.45 Ecentricity (e) = 1.779 - 2.7 / 2 = 0.4 < 2.7/6 Hence Safe m

L K E

Max. Pressure at the base = P/A + M/Z

1.93 0.77 = 103.405/2.7 +( 103.405 x 0.429) x 6 / (2.7 x 2.7)= 75 KN

2.70 Min. Pressure at the base = P/A - M/Z

103 405/2 7 -(( 103.405

103.405/2.7 103 405 x 00.429)

429) x 6 / (2.7

(2 7 x 2.7)=

2 7)= 18

1.8 KN

2.70

1.20 0.40 1.10

12 1.75844

30.358 42.4 31.53 29.7732

74.8 87.75 [17.5 x 3.3 + 20 x 0.9 + 24 x 0.5]

32.48 56.2184

Design of Toe Slab

Net upward pressure at toe = 74.838-12 = 62.838

Net upward pressure at junction of toe =

42.358-12 = 30.358

Moment at juncyion point due to rectangular part = 30.358 x 1.2 x 1.2 / 2 = 21.9

Moment at juncyion point due to triangular part = 32.48 /2 x 1.2 x 1.2 x2/ 3 = 15.6

Total 37.448 KNm = 37448160 Nmm

0.5

Efective depth (d) of stem section = ( M / R/1000) = 203 mm

Design magui U-S Return

Adopt overall depth of sestion = 400 mm

Available d using 12 mm f bars and 50 mm clear cover 344 mm

2

Area of steel required Ast= M/(sst x j x d ) = 524 mm

Minimum steel = 0.12 % of sectional area = 0.12 / 100 x 1000 x 400 =480 mm2

Use 12 mm f bar = a= 113 mm2 P = 37 mm

Spacing of bar = 113x 1000 / 524 215.65 mm

Provide at the spacing of 200 mm

Area of steel provided = 1000/200 x113

x113= 565 mm2

Percentage of steel = 0.164

Check for shear

Total shear force = [(74.838+42.358)/2 - 12] x 1.2 = 55.918 KN = 55917.6 N

2

Permissible shear stress (Adjusted according to % Tensile reinforcement) = 0.22 N/mm

2

Shear stress = 55917.6/(1000 x 344 ) = 0.16255116 N/mm < 0.22 Hence OK

Check for bond

2

Permissible bond stress = 1.28 N/mm

2

sb = 55917.6/(0.904x344x (1000 / 200 x 37)= 0.9721999 N/mm < 1.28 Hence OK

Distribution bars

.12 % of the section = 0.12/100 x 1000 x 400= 480

20% 0f main reinforcement = 20/100 x 565= 113

Provide 12 mm f bars a= 113 mm2

Spacing = 113.1 x1000 / 480= 235.619

p g of

Provide at the spacing 200 mm

Provide 12 mm dia bars @ 200mm c/c at water face as nominal reinforcement

Design of heel slab

Net downward pressure at heel = 87.75 - (1.758) = 85.992

Net downward pressure at junction of heel =

87.75 - 31.532 = 56.218

Moment at juncyion point due to rectangular part = 56.218 x 1.1 x 1.1 / 2 = 34

Moment at juncyion point due to triangular part = 29 773 /2 x 1.1

29.773 1 1 x 1.1

1 1 x2/ 3 = 12

Total 46 KNm

Efective depth (d) of stem section = ( M / R/1000)0.5= 225 mm

Available d using 16 mm f bars and 50 mm clear cover 342 mm

2

Area of steel required Ast= M/(sst x j x d ) = 648 mm

Minimum steel = 0.12 % of sectional area = 0.12 / 100 x 1000 x 400 =480 mm2

2

Use 16 mm f bar = a= 201 mm P = 50 mm

Spacing of bar = 201 1000 / 648

201x 310.19

310 19 mm

Provide at the spacing of 150 mm

Area of steel provided = 1000/150 x201= 1340 mm2

Percentage of steel = 0.392

Check for shear

Total shear force = 87.75 x 1.1 - (31.532 +(1.758) / 2) x 1.1 = 78.215 KN = 78215.48 N

1

Permissible shear stress (Adjusted according to % Tensile reinforcement) = 0.268 N/mm

Shear stress = 78215.485/(1000 x 342 ) = 0.2287 N/mm2 < 0.268 Hence OK

Check for bond

Permissible bond stress = 1.28 N/mm2

sb = 78215.485/(0.904x342x (1000 / 150 x 50)= 0.759 N/mm3 < 1.28 Hence OK

Distribution bars

.12 % of the section = 0.12/100 x 1000 x 400= 480 mm2

20% 0f main reinforcement = 20/100 x 1340= 268 mm2

2

Provide 12 mm f bars a= 113 mm

Spacing = 113.1 x1000 / 480= 235.619 mm

Provide at the spacing of 230 mm

Provide 12 mm dia bars @ 230mm c/c at water face as nominal reinforcement

Design magui U-S Return

Design for Key or heel beam

Balance of sliding force = 66.22 KN (As calculated earlier)

Permissible horizontal pressure = 70% of allowable bearing pressure = 0.7 x150

2

= 105 KN/m

Dx 105 = 66.2 96.30

From which D = 0 63 m

0.63

Provide Key Depth to be 2.8 m

BM= 66.221 X 2.8 / 2 = 92.7 KN m 400

d= (92.709 x1000000 / 0.913 / 1000) = mm D= 2.80 m

Provide Overall thickness of 300 mm

Available d = 300 - 50 = 250 mm

0.5

Efective depth (d) of stem section = ( M / R/1000) = 319 mm

g

Available d using 16 mm f bars and 50 mm clear cover 342 mm > 230 ((Min. Req.

q for stiffness),

), Hence OK

2

Area of steel required Ast= M/(sst x j x d ) = 1305 mm

2

Minimum Ast .12% of the section = 0.12/100 x 1000 x 400= 480 mm

2

Use 16 mm f bar = a= 201 mm P = 50 mm

Spacing of bar = 201x 1000 / 1305 154 mm

Provide at the spacing of 150 mm Check

2

Area of steel provided = 1000/150 x201= 1340 mm

Check for depth from stiffness / deflection consideration

% Ast = 100 x 1340 /(1000 x342) = 0 3918

0.3918

Frtom Chart Modification factor = 1.74

Required effective depth of wall from stiffness / deflection consideration = (2.8 /(7 x 1.74)) x 1000 mm

= 230 mm

Check for shear

Total shear force = 66.221 KN = 66221 N

1

Permissible shear stress (Adjusted according to % Tensile reinforcement) = 0.22 N/mm

2

Shear stress = 66221/(1000 x 342 ) = 0.1936 N/mm < 0.22 Hence OK

Check for bond

2

Permissible bond stress = 1.28 N/mm

sb = 66221 /(0.904x342x (1000/150)x50)= 0.643 N/mm2 < 1.28 Hence OK

Distribution bars

.12% of the section = 0.12/100 x 1000 x 342= 410.4

20% 0f main reinforcement = 20/100 x 1340= 268

2

Provide 12 mm f bars a= 113 mm

Spacing = 113.1 x1000 / 410.4= 275.578

Provide at the spacing of 250 mm

Provide 12 mm dia bars @ 250mm c/c at water face as nominal reinforcement

You might also like

- Database Technology Set 3Document13 pagesDatabase Technology Set 3TheOutsid3runNo ratings yet

- Design of Retaining Wall: 10 M Height 1.0Document30 pagesDesign of Retaining Wall: 10 M Height 1.0Executive Engineer DesignNo ratings yet

- ReportDocument17 pagesReportThrk TwrNo ratings yet

- Maharashtra Rail Insfrastructure Development Corporation LTDDocument17 pagesMaharashtra Rail Insfrastructure Development Corporation LTDThrk TwrNo ratings yet

- Toe Wall - 3m PDFDocument13 pagesToe Wall - 3m PDFsiddharth yadavNo ratings yet

- Retwall +14M - 3M - Total Hight 17M R0Document11 pagesRetwall +14M - 3M - Total Hight 17M R0Gunawan Prc2020No ratings yet

- Drain Design With Out SlabDocument4 pagesDrain Design With Out SlabANKESH SHRIVASTAVA100% (1)

- 1500D-6500 - High - Ret - Wall-Berm W03-W05Document23 pages1500D-6500 - High - Ret - Wall-Berm W03-W05munishant1No ratings yet

- Design of Raft FoundationDocument6 pagesDesign of Raft FoundationAshish GNo ratings yet

- 7+670 (1x10x5.8) R1Document55 pages7+670 (1x10x5.8) R1mayank007aggarwalNo ratings yet

- Design Retaining WallDocument98 pagesDesign Retaining WallAnkush SharmaNo ratings yet

- Counterfort Retaining Wall - Working Stress - SeismicDocument40 pagesCounterfort Retaining Wall - Working Stress - SeismicpsconsultantsNo ratings yet

- Retaining Wall - 4m-25t PDFDocument13 pagesRetaining Wall - 4m-25t PDFsiddharth yadavNo ratings yet

- Toe Wall - 4m PDFDocument13 pagesToe Wall - 4m PDFsiddharth yadavNo ratings yet

- RCC - Ret - Wall - Limit State - 26-01-12 - 4 - 3.5 - 15Document9 pagesRCC - Ret - Wall - Limit State - 26-01-12 - 4 - 3.5 - 15digvijay singhNo ratings yet

- Design of Drain 0.30 M X 0.600 M: 1 Load CalculationDocument68 pagesDesign of Drain 0.30 M X 0.600 M: 1 Load CalculationAnil SuryawanshiNo ratings yet

- Design of Retaining Wall For 1.5M HeightDocument1 pageDesign of Retaining Wall For 1.5M HeightManupriya KapleshNo ratings yet

- Government of Odisha National Highways: Rajlaxmi Constructions LimitedDocument4 pagesGovernment of Odisha National Highways: Rajlaxmi Constructions LimitedSaudagar Biswal100% (1)

- RCC Toe Wall - Total HT 3m To 5m PDFDocument40 pagesRCC Toe Wall - Total HT 3m To 5m PDFsiddharth yadavNo ratings yet

- Headworks Counterfort Wall 8mDocument19 pagesHeadworks Counterfort Wall 8mBishal PokharelNo ratings yet

- PCC Drain DesignDocument2 pagesPCC Drain DesignSharun ShajiNo ratings yet

- RCC Drain DesignDocument39 pagesRCC Drain DesignShubham AgrawalNo ratings yet

- (2/3H of Backfill) : Resultant Location Within BaseDocument1 page(2/3H of Backfill) : Resultant Location Within Basemark ignacioNo ratings yet

- Design of Retaining Wall For 1M HeightDocument1 pageDesign of Retaining Wall For 1M HeightManupriya KapleshNo ratings yet

- Drain Design FinalDocument4 pagesDrain Design FinalANKESH SHRIVASTAVA100% (1)

- Design of PCC WallDocument12 pagesDesign of PCC Wallfreelancer civilNo ratings yet

- Wing Wall (5.8m)Document49 pagesWing Wall (5.8m)Jack DoverNo ratings yet

- DBR-L2P9 2.5X2.5X.3 1000 Co-6Document1 pageDBR-L2P9 2.5X2.5X.3 1000 Co-6Rudra MehtaNo ratings yet

- Design of Valve Chamber 350mm Dia Pipe - 04112020Document6 pagesDesign of Valve Chamber 350mm Dia Pipe - 04112020Mukesh JangidNo ratings yet

- Top LVL of Landing SlabDocument3 pagesTop LVL of Landing SlabMuhammad HasanNo ratings yet

- Road Level 2.16m: 1.0 DiagramDocument16 pagesRoad Level 2.16m: 1.0 DiagramKrishna Dixit0% (1)

- Abutment Design For 30mDocument40 pagesAbutment Design For 30mManvendra NigamNo ratings yet

- Final Design of DrainDocument17 pagesFinal Design of Drainayan khan0% (1)

- Quarintine Office For Cattle QuaritineDocument84 pagesQuarintine Office For Cattle QuaritineAbudi KasahunNo ratings yet

- 500 Analisa Kolam Renang 2Document16 pages500 Analisa Kolam Renang 2ENG INKNo ratings yet

- 16-Oil Pit Tank Calc.Document8 pages16-Oil Pit Tank Calc.Omar SalahNo ratings yet

- BBS 105180Document32 pagesBBS 105180rajusk24No ratings yet

- PCC Return WallDocument19 pagesPCC Return Wallneeta rautelaNo ratings yet

- BridgeT BeamDocument18 pagesBridgeT BeamDinatal MamoriaNo ratings yet

- East WallDocument8 pagesEast WallKumar Atray100% (1)

- Qs 0 Kn/M2: Retaining Wall With Anchors Analysis & Design Iksapro V1.0 BetaDocument8 pagesQs 0 Kn/M2: Retaining Wall With Anchors Analysis & Design Iksapro V1.0 Betaedc1312No ratings yet

- Axial and Lateral Load Piles Fem v1.6Document60 pagesAxial and Lateral Load Piles Fem v1.6Shahab KhaledNo ratings yet

- 7 M Height Pressure Relief Shelf Retaining Wall DGNDocument10 pages7 M Height Pressure Relief Shelf Retaining Wall DGND.k. ChauhanNo ratings yet

- Desain Jembatan Beton ("T" Beam Type) : 1. Design DataDocument16 pagesDesain Jembatan Beton ("T" Beam Type) : 1. Design DataDwi100% (1)

- 357+388 Box Widening - 4Document1 page357+388 Box Widening - 4VivekNo ratings yet

- Perencanaan Jalan Bengkulu: Retainingwall Curup - Bts. Sumsel KM. 125+400 Tinggi 3MDocument29 pagesPerencanaan Jalan Bengkulu: Retainingwall Curup - Bts. Sumsel KM. 125+400 Tinggi 3MAhmadFauzanNo ratings yet

- WS Dawis Sur Carmen CebuDocument591 pagesWS Dawis Sur Carmen CebuShella May QuimpanNo ratings yet

- Extracted Pages From PCC Breast Wall 28-04-2021Document4 pagesExtracted Pages From PCC Breast Wall 28-04-2021Er navneet jassiNo ratings yet

- Stone Masonry Breast Wall - 2.0 MDocument6 pagesStone Masonry Breast Wall - 2.0 Mrahul sumanNo ratings yet

- Design of Box Type Line Drain of Size 0.6M and Height Upto 1.5MDocument66 pagesDesign of Box Type Line Drain of Size 0.6M and Height Upto 1.5Mrahul sumanNo ratings yet

- Annexure-Z. Design Calculations For FootingsDocument7 pagesAnnexure-Z. Design Calculations For Footingsprajjwal patidarNo ratings yet

- L-Type Ret WallDocument42 pagesL-Type Ret WallSiva SundarNo ratings yet

- Retaining Wall 12m Without Earth QuakeDocument17 pagesRetaining Wall 12m Without Earth QuakeKADALI RAVINDRANo ratings yet

- Design of Substructure Abutment Pile ch.44+801km, 2x30mDocument77 pagesDesign of Substructure Abutment Pile ch.44+801km, 2x30mLalit ChoudharyNo ratings yet

- Retaining Wall Design-ChDocument160 pagesRetaining Wall Design-Chanthropolozist entertainNo ratings yet

- Retaining Wall Design-ChDocument152 pagesRetaining Wall Design-Chanthropolozist entertainNo ratings yet

- Cropw Water RequirementDocument7 pagesCropw Water RequirementMohammedNo ratings yet

- Stability Calculation For Channel Wall: X SGM XBDocument4 pagesStability Calculation For Channel Wall: X SGM XBMohammedNo ratings yet

- 808.1 Jan Second Crop Command Area Ha Command Area % Total Command AreaDocument3 pages808.1 Jan Second Crop Command Area Ha Command Area % Total Command AreaMohammedNo ratings yet

- 808.1 Jan First Crop Command Area Ha Command Area % Total Command AreaDocument3 pages808.1 Jan First Crop Command Area Ha Command Area % Total Command AreaMohammedNo ratings yet

- FS Report Hafiz Bacha Canal Revised 7.21.2020 RevisedDocument34 pagesFS Report Hafiz Bacha Canal Revised 7.21.2020 RevisedMohammedNo ratings yet

- High Flood Discharge Calculation of Maguwai Khola: A Regional MethodDocument2 pagesHigh Flood Discharge Calculation of Maguwai Khola: A Regional MethodMohammedNo ratings yet

- Calculation ReportDocument1 pageCalculation ReportMohammedNo ratings yet

- Stabitlity Checks: 1 - Safety Against OverturningDocument2 pagesStabitlity Checks: 1 - Safety Against OverturningMohammedNo ratings yet

- Raft Slab Design For Head Works of Magui Khola Irrigation Project, Madi ChitwanDocument2 pagesRaft Slab Design For Head Works of Magui Khola Irrigation Project, Madi ChitwanMohammedNo ratings yet

- Head WorksDocument18 pagesHead WorksMohammedNo ratings yet

- Khoja M Hashim Canal Orifice DesignDocument6 pagesKhoja M Hashim Canal Orifice DesignMohammedNo ratings yet

- APPENDIX-1 Design Drawings For ConstructionDocument1 pageAPPENDIX-1 Design Drawings For ConstructionMohammedNo ratings yet

- Hydraulic Calculation: Dehpara Irrigation Canal #1, Badakhshan Province AbbreviationsDocument69 pagesHydraulic Calculation: Dehpara Irrigation Canal #1, Badakhshan Province AbbreviationsMohammedNo ratings yet

- Design of Vertical Drop Fall: Surface FlowDocument3 pagesDesign of Vertical Drop Fall: Surface FlowMohammed100% (1)

- CD G H Descrip Tion Chaina Ge Covera Ge in D Per Ha Rge Require Din A (Requi Red) MDocument2 pagesCD G H Descrip Tion Chaina Ge Covera Ge in D Per Ha Rge Require Din A (Requi Red) MMohammedNo ratings yet

- Hydraulic Design Calculation Sheet Mohammad Hashim Canal Based (Qmax)Document15 pagesHydraulic Design Calculation Sheet Mohammad Hashim Canal Based (Qmax)MohammedNo ratings yet

- Structural Design Calculation: Chechka Irr. CanalDocument2 pagesStructural Design Calculation: Chechka Irr. CanalMohammed100% (2)

- Construction Manager: Name of The Staff MembersDocument2 pagesConstruction Manager: Name of The Staff MembersMohammedNo ratings yet

- Hydraulic Calculation: As Per Crop Water RequirementDocument3 pagesHydraulic Calculation: As Per Crop Water RequirementMohammedNo ratings yet

- Bid Evaluation MatrixDocument143 pagesBid Evaluation MatrixMohammedNo ratings yet

- Design of Fall at RD 29.250 of RB Upper/Dy: (For Estimation Purpose Only)Document1 pageDesign of Fall at RD 29.250 of RB Upper/Dy: (For Estimation Purpose Only)MohammedNo ratings yet

- Mercy Corps, Afg Hanistan B Id Evaluation: Rehabilitation of Mullah Khail CanalDocument2 pagesMercy Corps, Afg Hanistan B Id Evaluation: Rehabilitation of Mullah Khail CanalMohammedNo ratings yet

- Kuliah Anum-2Document62 pagesKuliah Anum-2Jesse gioNo ratings yet

- RuggedDirector User GuideDocument38 pagesRuggedDirector User GuideBairon Alvira ManiosNo ratings yet

- LG 65uj670v 655V 701V Ud74q PDFDocument31 pagesLG 65uj670v 655V 701V Ud74q PDFady_gligor798771% (7)

- ServiceManual en E-Series V 1.1.6Document201 pagesServiceManual en E-Series V 1.1.6Nghia PhanNo ratings yet

- HP:081281836224 Jual Burner FBRDocument5 pagesHP:081281836224 Jual Burner FBRHabibie BoilerNo ratings yet

- Proposal Presentation by Pankaj and Team (2) 1Document25 pagesProposal Presentation by Pankaj and Team (2) 1Abhishek PantNo ratings yet

- Plunger Lift BrochureDocument4 pagesPlunger Lift BrochureCluis KeNo ratings yet

- Smart Freeze Drying: Basic Principles, Optimum Procedures and ApplicationsDocument56 pagesSmart Freeze Drying: Basic Principles, Optimum Procedures and Applicationssubarna_75No ratings yet

- PriDocument8 pagesPritubNo ratings yet

- 763 PDFDocument3 pages763 PDFइंजि कौस्तुभ पवारNo ratings yet

- The D LanguageDocument17 pagesThe D LanguageNtwari JoshuaNo ratings yet

- CGP 11plus Parents GuideDocument41 pagesCGP 11plus Parents GuidebakieNo ratings yet

- SM Adt+Small Mk+Vi Rev+3Document410 pagesSM Adt+Small Mk+Vi Rev+3Biswajit DasNo ratings yet

- Vitreous SubstitutesDocument17 pagesVitreous SubstitutesAnumeha JindalNo ratings yet

- Data Sheet For Oxygen Analyser (Hi Temp) : Project: North Karanpura 3 X 660Mw STPPDocument19 pagesData Sheet For Oxygen Analyser (Hi Temp) : Project: North Karanpura 3 X 660Mw STPPvishnu ANo ratings yet

- Osram XBO High Pressure Xenon Lamps Catalog 1977Document12 pagesOsram XBO High Pressure Xenon Lamps Catalog 1977Alan MastersNo ratings yet

- STR W6735 DatasheetDocument13 pagesSTR W6735 DatasheetloagerNo ratings yet

- TCP/IP Protocol Suite and IP AddressingDocument31 pagesTCP/IP Protocol Suite and IP AddressingHungry LadyNo ratings yet

- Fibrlok 2540 Data SheetDocument2 pagesFibrlok 2540 Data SheetSven BaeldenNo ratings yet

- Technical Batch Data Report: 001 Popular Concrete PVT LTD Plant 2, Kakati, BelgaumDocument1 pageTechnical Batch Data Report: 001 Popular Concrete PVT LTD Plant 2, Kakati, BelgaumAshwin PatilNo ratings yet

- Product Data Sheet: iPRD65r Modular Surge Arrester - 3P + N - 350V - With Remote TransfertDocument3 pagesProduct Data Sheet: iPRD65r Modular Surge Arrester - 3P + N - 350V - With Remote TransfertPasindu PriyankaraNo ratings yet

- Conbuildmat D 22 02274Document18 pagesConbuildmat D 22 02274PANAYIOTIS KAKAVASNo ratings yet

- Vibration Assessment Quiz To Determine Entry Vs Analysis IDocument2 pagesVibration Assessment Quiz To Determine Entry Vs Analysis IAhmad DanielNo ratings yet

- Femoral Triangle 1Document20 pagesFemoral Triangle 1USAMA AHMEDNo ratings yet

- Kahana RegressionsDocument10 pagesKahana RegressionsGiancarlo Coral LeonNo ratings yet

- Unit 3 Logarithms ExamplesDocument10 pagesUnit 3 Logarithms ExamplesAsghar Ali100% (3)

- Reference Manual: Updated For Version 2.7 of Capture PolarDocument33 pagesReference Manual: Updated For Version 2.7 of Capture PolarGangaNo ratings yet

- Day10 JavaDocument4 pagesDay10 JavaYaathriganNo ratings yet

- 2n3906 DatasheetDocument3 pages2n3906 DatasheetZain AliNo ratings yet