Professional Documents

Culture Documents

Chapter4 Surcharge Angle

Chapter4 Surcharge Angle

Uploaded by

achmat0 ratings0% found this document useful (0 votes)

328 views10 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

328 views10 pagesChapter4 Surcharge Angle

Chapter4 Surcharge Angle

Uploaded by

achmatCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 10

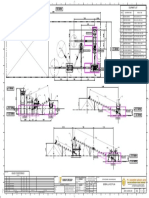

The attached sketch shows a typical burden surcharge gauge for a 900

min wide belt. For wider belts you will need a few more rods and a

longer cross member.

The loaded conveyor is stopped and isolated and then the gauge placed

on to the stringers. The rods are dropped down on to the burden and the

length of each rod below the cross member recorded together with the

distance from the edge of the belt to the tip of the wing roller and from

the edge of the belt to the edge of the burden on both sides. It is some

times worthwhile taking 2 or 3 readings at different locations on the

conveyor. If only taking one reading, do it just after the loading point.

This information together with the idler dimensions can then be drawn by

a draftsman. A single circular curve, that approximates to the measured

Surface profile, is superimposed on the drawing and the angle of this

Curve at the point of contact with the belt is measured to obtain the

surcharge angle.

\ Mite Boe ban

Wiel

PAP Ageless Jo |?

| Mio wut | |

1 yi was ro RAG

1 19x16~ oe 450 Love,

é

ti Souteve ~ i

| Acre! Clpat f

IT STenGces

joe] Bett Sods

Practical Belt Conveying Part I, Chapter 4 Page 1 of 7, Rev.2,

4.6

47

48

49

4.10

4.10.1

4.10.2

4.10.3

4.10.4

4.10.5

CHAPTER 4

URDEN SURCHARGE ANGLE

TABLE OF CONTENTS

INTRODUCTION

FULLNESS RATIO

LOADING CHUTE DESIGN

SLOPE REDUCTION FACTOR.

BELT VELOCITY

CONVEYOR LENGTH

BELT SAG

RIPPERS

HORIZONTAL CURVES

ESTIMATION OF SURCHARGE ANGLE

General

Material Reduction Allowance Kay

Slope/Velocity Reduction Allowance K,

Special Reduction Allowances K,

Examples of Surcharge Angle Calculations

Copyright

“ROM” MANUFACTURERS OF HIGH QUALITY CONVEYOR EQUIPMENT

BULK MATERIAL CHARACTERISTICS

Table 4.0

ty lek [fom © [fk | amon

MATERIAL siet, [emleeeel cx MATERIAL one, [aeetesiee| oan

om” | gees | eae Cn | sees | tages

‘ian tre rave02 835 | Genet, 102mm sip ‘64308 wa

‘ky. ain 35 Corea. 150rm snp tne 2405 | [ra

[ Riri 202-1082 | TO | 70:12 [Bara —| conn ove ~ | itzt acs 2

oa 7a 1603:3405

Asbestos sired 20401 aa a

Aah tick, goon i 7 ean 7a

‘Ashes, oly Si ae und |B -F 3075 1200 483

| Ashes coat di. Tenm ander S66 | ‘9 i608

rae | 25 | asa

73-808

earrei || 2095 fie

1250 D47T | ah, we casing cy 60317

-sphat binderfor peg 125.1980 645 | Felten tam eeronngs [22-89

Asta shed. Tm apd nda 724 535 | Feet 3 to Timm kenps | 440-4730

Begone i280 Easy] Fear 200 Mesh Pos 7

Ban, wed a ‘os20 | ad_| 27] eas —| Fish meas iw

Barey 09 10 Tose | Bren | Fou wheat apie

Bares, pondered 19878 [B26 | Five ae bie Fase dy “fava

Bante wound iy 1090 |_| 20826 | Fspar- Tar evenings [a 8 ce

ave mine vn faea-t4a3 | 15 |_| ost | Forpar, 3a Ton ngs 1TSE Tee |

12021363, 20_| 037 | Fey eth ry (ee he iia

BeL6H Da6x | Feary sar se (ene sane — | 8TH Bar

[Serine 10 mesh and ua e022 20_| Azexy — [Foun eke, od sand coves, 1121603 ‘MZ

B ESear ee Fuller ery ——fanteer [1e| ——| ms

| Bonerar ‘2 062 sits erty ~eee-1002-] B26

Borax, Som Ten ipa [oe 14 ‘ae Foe feat 26

Sora, 4010 50mm tps | 882 202 ‘B36 Fars enh en sereai [75 | -ao_| 78

Biews"s gn per dy ‘ovae0 || eas Farben. tise er “eave

[ Brewers gan pen wet azake | ~~ east —[ ease tren 12857609 wz [wee

Bick nd 2004 | ‘Darz | Granite tien sseeings | ans: ~ fea

rik sot a 47 [Grate 380m to Herm ps RS 1a [ba

Bucks oui.sr | Toa | was — | Cra beken ozs 1507 027]

‘Carbon nc potaeod 320401 15150 —| Gensel bank 4. t508 I

|"cardon. nk ower ea ~[=R36Y | Grnve sar nt | or

| Cerbonnrs. Sim aera 1603 ‘tavepebbie wa.¥609 bie

Cement Potand ‘so7 | Gypsum dst neared | HF

emer Poran seated [0621202 | Srosim dn eat 352-1 | a 76% —

‘Cemertock (68 imestns) | e088 “Gaps, fen srenings | 93 209 | 39 ce |

‘erm cnker = ane 23 ‘ps. For 2.1988 | 48 be

[Cement mor ise ieecensted ri || ~ [oe

Champ 12021965 Ire = —Trer

hak, 10 mesh nar | Toro 202 ‘ron or fi zc

‘cheer SEEM of evshad prises

‘hip, papr na 520404 Tron oie, pre [aos

‘his. per mil slinood—— aa ian ca Ton vd ier | 1010

| Gey tne aso Beni, irre wah flrs aah ain ~ Pain ne mos ara 88

hy clcned “a Ten Lead oes 206 4329

hy dy toes ont824 | 15 | BOB Timeton, are

Gay dy py wez i202 | 45 | 1820 Sire and one

[Got antec, vero cn, ——[tivestons. cused

2mm and undo 82 19_| ossty_[Umestore ait one

Coal antacid enzo 1026 | Wi nea aren

[Coa bri, ined Manganese ae 008 28s

0 mesh and under ones | 20 | 24 | seer | Nckatcobo subivie oe | war sane

Cosi, bominous, ined ad sind | 724 2 | 15 —F8 [rons mn

oa. baninni mined Paper pl aoak

tno nine revase | 20 | te | past _ | Phosphate; ne ete

onl Bs aa Sat ca Phosphate sine

mnedaect. nm ander lesse02 | zo | 2 | cast | gomsemce sone _| 20 | a0 | pose

Cos. bitrincus, Pression baie Ay frene Dea] 1s [eis [bas —|

stipeng rot lane 02962 ser | Phoepnin osk verses 20 | 35 |

Coal. Ugite ear rat {20 | ae | ast —| Pytes en ono Tor ang | se 2I05 Dorr

‘eke, 360.961 0 | paraVT | Pyles pees ‘224.2086 | | feast —

Coke, perioum cated | eexr2t 20 bev a ae | |r

| Cake trnre, ane and der [aor sot | 1590-| ao99 | CaF Toate | — core

Covet, Str simp 1643005 24-26 [098 | Outs Smo Fn tne | THEE TRE are

414

* May vary considerably

Practical Belt Conveying Part I, Chapter 4 Page 2 of 7, Rev.2

4,

44

BURDEN SURCHARGE ANGLE

INTRODUCTION

The burden surcharge angle is defined as ‘the angle between the top surface of the

material burden and the horizontal when measured at the edge of the burden.”

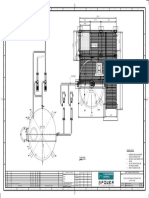

The idealised burden profile shown in Fig.4-1 is formed by a circular are, which is

tangential at its edges to the surcharge angle. ‘This idealised profile is used in ISO

5048, BS 2890 and CEMA. However the German Standard DIN 22 101 shows the

burden surcharge profile as a triangle, Fig.4-2. A note at the end of DIN 22 101

states that the angle of the surcharge triangle should be two thirds of the ISO angle.

The circular are profile is more representative of the actual burden profile and is

therefore recommended.

Fig.4-1 Fig.4-2

CEMA, ISO, BS DIN 22 101

COMPARISON OF SURCHARGE ANGLE REPRESENTATION

The surcharge angle of a given material is not only a function of the physical properties

of the material but itis also effected by various aspects of the conveyor design. It is not

therefore a true material property and it is possible to have a series of conveyors all

handling the same material at the same flow rate but due to different features of

conveyor, a different surcharge angle may be applicable to each conveyor

ch

‘The following factors will effect the surcharge angle and they should be taken into

consideration when selecting a suitable surcharge angle for the design of a new

conveyor or when evaluating the material surcharge angle on an existing conveyor:~

©The angle of repose of the material

* The internal friction angle of the conveyed material.

© The material particle size and the lump to fines ratio.

The moisture content of the material and the possible variations that could occur.

* The fullness ratio of the material on the belt.

The design of the loading chute.

* The angle of inclination of the conveyor at the loading point.

Copyright

of Bulk Materials

Mi

laterial Characteristi

‘The successful design of a belt conveyor must begin with an accurate appraisal of

the characteristics of the material to be transported. A few important characteristics

require definition.

‘The angle of repose of a material is the acute angle which the surface of a normal,

freely formed pile makes to the horizontal.

‘The angle of surcharge of a material is the angle to the horizontal which the su

face of the material assumes while the material is at rest on a moving conveyor belt,

This angle usually is 5 degrees to 15 degrees less than the angle of repose, though in

some materials it may be as much as 20 degrees less,

The flowability of a material, as measured by its angle of repose and angle of sur-

charge, determines the cross-section of the material load which safely ean he carried

(ona belt. Italso is an index of the safe angle of incline of the belt conveyor.

The flowability is determined by such material characteristics as: size and shape

of the fine particles and lumps, roughness or smoothness of the surface of the mate

rial particles, proportion of fines and lumps present, and moisture content of the

material,

Table 3-1 illustrates and defines the normal relationship of the foregoing proper:

ties and the general characteristics of materials,

Table 3-1, Flowability-angle of surcharge-angle of repose,

Flow fa

Very ree towing 1" | _ Free tlowing 2° Average flowing 3° Slugaish a

Angle of Surcharge

e io] 20° 2 30

e

ate

~T

if z Angle of Repose

019" 20-25" 30-34" 35-39° 40° up

Material Characteristics

[Uniform si very Rounded dorpok regular ramior | Type common | regular avg

Anal rounded part ished partes of | ortonny meriaeof | nmeriahsuchachita | firene inertcteg

des either very et or | metvm wight such | meium weight snch | sui cal sane, | meneal nce

verydry such asdry | aswholegrainand | asanthrate coal cat | mest mec re wood hips Fase

sien sand. cement, | beans tensed mea clay. ee tempered fry

wet coneet te cant et

*Code designations conform to hulk material characteristics chart, Table 3-2

Consideration should also be given to the weight per cubic foot of the material;

its dustiness, wetness, stickiness, abrasiveness; its chemically corrosive action; and its

temperature, Some general information concerning these properties of many mater

30

Practical Belt Conveying Part I, Chapter 4 Page 3 of 7. Rev.2

42

43

* The maximum angle of inclination of the conveyor.

+ The belt velocity

«The length of the conveyor.

‘©The belt sag between the idlers.

‘©The inclusion of a tripper in the conveyor.

© The inclus

- foarte

mn of one or more horizontal curves in the conveyor

‘The following subsections provide additional detdil orf sOme of these aspects and

their effect on the surcharge angle

FULLNESS RATIO. Ne E Guckage

‘The fullness ratio is defined as ‘the ratio of the cross sectional area of material on a

conveyor divided be the normal design cross sectional area.’ Generally, the fuller

the belt the greater the surcharge angle. a ~ fet

LOADING CHUTE DESIGN [faded

‘The design of the loading chute, particularly the amount of redirection of the

material stream in the direction of belt travel, can have a major effect on the

surcharge angle. Ideally the material stream at the loading point should have a

horizontal velocity component equal to the belt velocity. The use of *V" shaped

loading boots mounted close to the belt or curved chutes can also help to improve

the surcharge angle.

The angle of inclination of the conveyor at the loading point will also affect the

surcharge angle. Photo 4a shows a conveyor transporting fine iron ore, This

conveyor has a horizontal loading zone and the burden surcharge angle is in the order

of 10°. Photo 4b shows another conveyor handling similar material. In this case, the

loading zone is inclined at 15° and the burden surcharge angle is closer to 0°.

Photo 4b

15° loading point

Photo 4a

Horizontal loading point

Copyright

Practical Belt Conveying Part I, Chapter 4 Page 4 of 7, Rev.2

44

4.6

47

48

49

SLOPE REDUCTION FACTOR

Many conveyor design standards and manuals recommend a reduction in the cross

sectional area of the conveyed material where sections of the conveyor are inclined

(Refer ISO 5048 and DIN 22 101). This reduction in cross sectional area is based

n the assumption that the surcharge angle will change as the angle of the conveyor

increases. In practice, once the material has settled 10 its surcharge angle at the

Joading point, subsequent changes to the surcharge angle do not appear to occur on

inclined sections. A reduction in the surcharge angle is not therefore considered

necessary for normal conveying angles of up to 20 degrees, provided the material is

capable of being conveyed up the slope without slippage and provided the inclined

section of conveyor does not include the loading point.

BELT VELOCITY

Belt velocity can have an effect on the surcharge angle and generally higher belt

velocities will result in some loss of surcharge angle. This is particularly noticeable

on steeply inclined loading points.

CONVEYOR LEN

3TH

On long conveyors, the vibration caused by the belt passing over the idlers can

cause a reduction in the surcharge angle. However, the reduction in surcharge angle

is generally accompanied by consolidation of the conveyed material such that the

burden edge distance is not reduced.

BELT SAG

On conveyors with relatively low belt tensions, ic. belt sag between the idlers exceeding

1% of the idler spacing, the opening up of the burden at the mid span and the subsequent

bunching at the next idler set will have a detrimental effect on the surcharge angle. In

cases where the belt sag is excessive or where the centre roll of an idler is higher than

the adjacent sets, the material burden can actually become airborne as it passes up and

over the idler and this lifting of the burden also results in loss of surcharge angle.

TRIPPERS

In the approach curve to a tripper, the belt will lift off the idlers and flatten out.

When the belt is retroughed, the surcharge angle and the burden edge distance will

often be reduced and material spillage may occur. For this reason a reduction in the

nominal burden surcharge angle is recommended for conveyors fitted with trippers.

HORIZONTAL CURVES.

In horizontal curves, the conveyor belt is pulled towards the centre of the curve and

the idlers have to be banked (0 counter this effect. The effect of this idler banking

on the burden surcharge angle will depend on the material being handled and the

Copyright

Practical Belt Conveying Part I, Chapter 4 Page 5 of 7, Rev.2,

4.10

4.10.1

4.10.2

4.10.3

banking angle. It is generally prudent to use a reduced surcharge angle or

alternatively, an increased burden edge distance on horizontally curved conveyors.

ESTIMATION OF SURCHARGE ANGLE

General

If there is no reliable surcharge angle information available for similar materials on

similar conveyors, the following method offers a guide to the selection of a suitable

surcharge angle. The method is based on reducing the angle of repose to allow for

(a) the material properties, (b) the belt velocity and angle of inclination at the

loading point and (c) special allowance for trippers ete.

Nominal surcharge angle A= YW —Ky~K,—K, degrees

Where: y =angle of repose degrees

Ky, = material reduction allowance degrees

K, = slope/velocity reduction allowance degrees

K, = special reduction allowance degrees

Note: if the surcharge angle obtained is a negative value, a rethink on belt velocity

or the angle of the loading point may be necessary.

Material Reduction Allowance Kn,

For this allowance the following three reduction values are recommended:-

Material description Reduction allowance Ky,

Fine material with 5% moisture -

content o interlocking material

Dry material with low fines content, 10°

e.g. crushed rock

Dry, free flowing fine material 15°

Slope/Velocity Reduction Allowance K,

This allowance takes into consideration the belt velocity and also the angle of the

conveyor at the loading point. The following table gives surcharge angle reduction

values for a range of belt velocities and loading angles. These reduction values are

proportional to the time taken to accelerate the material at the loading point with an

assumed coefficient of friction between the belt and the material of 0.5.

‘These reduction values are for typical transfers where there is some material

redirection at the loading point. If the feed chute provides effective material

redirection, these values could be reduced. If the feed chute does not provide any

material redirection, these values should be increased,

Copyright

Practical Belt Conveying Part I, Chapter 4 Page 6 of 7, Rev.2

4.10.4

4.105

Conv. Angle Conveyor surcharge angle reduction allowance K,

at loading Belt velocity nvs

Point degrees 1 2 3 4 5 6

0 # £ & 8 10° 12°

1 2 £ & & 10° 12°

2 28 a oe 9 ie 13°

3 2 ¥ Pr xe ue 1°

4 2 = Ee e 12 1°

Hotes ae & 7 10° 12° 15°

6 Ey ¥ 8° 10° 13° 15°

7 = 5° 8° ue 13° 16°

8 3° e s ue 1 7

9 3% © ° 12° 15° 18°

10 = oF - Be 16° is

Ln al - 10° 13° via 20°

12 # Pr ue 1 ise [2°

3 ae Be ue 15° 19° 23°

See ila ae 8° 19° 16° me 25°

15 cm - 13° 18° 22° 27°

16 10° 15° 20° 24° 29°

Special Reduction Allowances Ky

The special reduction allowance for belt sag, trippers and horizontal curves will

depend in part on the design of these features of the conveyor and also the nominal

surcharge angle obtained from the other factors. If the nominal surcharge value is,

high, say greater than 15°, some additional reduction in the surcharge angle is

recommended to allow for the effect of these special features.

For conveyors with a tripper a K, value of 5° to 10° should be adequate.

If the belt sag is high, i.e. exceeding 1% of the idler centres, a special reduction

allowance of 5° should be made.

Examples of Surcharge Angle calculations

(a) Crushed rock

Angle of repose 37°

Belt velocity 2 m/s

Horizontal loading

High belt sag

37° - 10° 4° 5° = 18°

Copyright

Practical Belt Conveying Part I, Chapter 4

Page 7 of 7, Rev.2

(b) Fine iron ore, dry

Angle of repose 34°

Belt velocity 4 mis

15° inclined loading

Surcharge angle = 34° — 15° 18° = 1°

(©) Fine iron ore, 4% moisture

Angle of repose 37°

Belt velocity 4 m/s

15° inclined loading

Kn=5°

K, 8°

‘Surcharge angle = 37° — 5°-18° = 14°

(d)_ As for (c) but horizontal loading

Ks 5°

kK

Surcharge angle = 37° — 5° — 8° = 24°

Copyright

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tsl-Vdr-dw-st01-0008 - Gad Coal Crushing and Drying System - Rf-AppDocument6 pagesTsl-Vdr-dw-st01-0008 - Gad Coal Crushing and Drying System - Rf-AppachmatNo ratings yet

- TSL-VDR-DW-ST01-0025-01 Detail Darwing Rail For Hoist Coal Crushing and Drying Package - RA-APPDocument1 pageTSL-VDR-DW-ST01-0025-01 Detail Darwing Rail For Hoist Coal Crushing and Drying Package - RA-APPachmatNo ratings yet

- Crushing Plant Basir Group Rev.dDocument1 pageCrushing Plant Basir Group Rev.dachmatNo ratings yet

- HPU Radial Stacker-1Document1 pageHPU Radial Stacker-1achmatNo ratings yet

- HPU Radial StackerDocument1 pageHPU Radial StackerachmatNo ratings yet

- TSL VDR DW St01 0044 Sub Assembly Stack of Coal Crushing - RC AppDocument4 pagesTSL VDR DW St01 0044 Sub Assembly Stack of Coal Crushing - RC AppachmatNo ratings yet

- AJU-BMR-TNK-DWG-001 - 01 GA & NOZZLE ORIENTATION DETAIL Rev. BDocument2 pagesAJU-BMR-TNK-DWG-001 - 01 GA & NOZZLE ORIENTATION DETAIL Rev. BachmatNo ratings yet

- TSL-VDR-DW-ST01-0001 - Piping & Instrument Diagram (P & ID) Rev I-APPDocument6 pagesTSL-VDR-DW-ST01-0001 - Piping & Instrument Diagram (P & ID) Rev I-APPachmatNo ratings yet

- Skematik Hidrolik Radial StackerDocument1 pageSkematik Hidrolik Radial StackerachmatNo ratings yet

- Radial Bogie Travelling DriveDocument1 pageRadial Bogie Travelling DriveachmatNo ratings yet

- Feeder Load Force Calculation Inputs - Theoretical MethodDocument1 pageFeeder Load Force Calculation Inputs - Theoretical MethodachmatNo ratings yet

- AJU-BMR-TNK-DWG-001 - 01 Rev.C General Arrangement and Nozzle Orientation Detail Sulphuric Acid Storage Tank 01ABC Sheet 1of2Document1 pageAJU-BMR-TNK-DWG-001 - 01 Rev.C General Arrangement and Nozzle Orientation Detail Sulphuric Acid Storage Tank 01ABC Sheet 1of2achmatNo ratings yet

- Taper Lock® Pulleys For Z, SPZ, XPZ & QXPZ Belts: Friction Belt DrivesDocument8 pagesTaper Lock® Pulleys For Z, SPZ, XPZ & QXPZ Belts: Friction Belt DrivesachmatNo ratings yet

- BMR.00-MEC-004 - 0 - Flocullant Mixing Storage Tank - Elevation ViewDocument1 pageBMR.00-MEC-004 - 0 - Flocullant Mixing Storage Tank - Elevation ViewachmatNo ratings yet

- BMR.00-MEC-003 - 0 - Flocullant Mixing Storage Tank - Plan View DetailDocument1 pageBMR.00-MEC-003 - 0 - Flocullant Mixing Storage Tank - Plan View DetailachmatNo ratings yet

- Helix ZC01-FD001 24092020Document9 pagesHelix ZC01-FD001 24092020achmatNo ratings yet

- INABECDocument12 pagesINABECachmatNo ratings yet

- CamScanner 09-14-2022 15.23Document1 pageCamScanner 09-14-2022 15.23achmatNo ratings yet

- Triple Roll CrusherDocument6 pagesTriple Roll CrusherachmatNo ratings yet

- DRIVE GEARBOX ZC01-FD001-3.7 TPHDocument1 pageDRIVE GEARBOX ZC01-FD001-3.7 TPHachmatNo ratings yet

- Conveyor Design Summary: Pt. Siko TechnoDocument8 pagesConveyor Design Summary: Pt. Siko TechnoachmatNo ratings yet

- Chapter9 Belt Width and VelocityDocument9 pagesChapter9 Belt Width and VelocityachmatNo ratings yet

- Chapter5 Edge DistanceDocument6 pagesChapter5 Edge DistanceachmatNo ratings yet

- Chapter 11 Flooded Belt&Blocked Chute ConsiderationDocument18 pagesChapter 11 Flooded Belt&Blocked Chute ConsiderationachmatNo ratings yet

- Chapter 15 Conveyor ArrangementsDocument22 pagesChapter 15 Conveyor ArrangementsachmatNo ratings yet

- Chapter 13 Belt SagDocument4 pagesChapter 13 Belt SagachmatNo ratings yet

- Chapter 19 Conveyor PulleyDocument32 pagesChapter 19 Conveyor Pulleyachmat100% (1)