Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

65 viewsConstruction Materials IT2

Construction Materials IT2

Uploaded by

Elizzabeth HZThis document provides an overview of common construction materials used in building projects. It discusses earthwork materials like aggregates which are used as subbases or fill. Concrete is described as a mixture of cement, sand, gravel and water that hardens over time. Reinforced concrete uses rebar for strength. Masonry uses smaller units like brick and block with mortar. Common metals in construction include steel, aluminum, copper and brass used for windows, doors, beams and more.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Brick&Bolt Quality Assessment System - QASCONDocument24 pagesBrick&Bolt Quality Assessment System - QASCONPulkit ChawlaNo ratings yet

- Kuala Lumpur and Selangor Chinese Assembly HallDocument25 pagesKuala Lumpur and Selangor Chinese Assembly HallZacharyTay100% (2)

- B+G+2 Boq - (367-625)Document116 pagesB+G+2 Boq - (367-625)Amy Fitzpatrick100% (3)

- (Art of Woodworking 16) Time-Life Books-Classic American Furniture - Time Life Education (1995)Document148 pages(Art of Woodworking 16) Time-Life Books-Classic American Furniture - Time Life Education (1995)cosmelli100% (2)

- 2-1 Building MaterialsDocument64 pages2-1 Building MaterialsVũ Thị Hà TrangNo ratings yet

- Construction Material and Their ApplicationsDocument17 pagesConstruction Material and Their ApplicationsMay Myat Mon KyawNo ratings yet

- Building Design System: Submitted By: Hafiz Uzair Naeem Ud DinDocument15 pagesBuilding Design System: Submitted By: Hafiz Uzair Naeem Ud DinUzair SiddiqueNo ratings yet

- Types of Building Materials - Be Assignment-Shreya PDFDocument12 pagesTypes of Building Materials - Be Assignment-Shreya PDFShreya SinghNo ratings yet

- Stone MasonryDocument2 pagesStone MasonryPRIYA KUMARINo ratings yet

- MCM Assignment 1Document5 pagesMCM Assignment 1arnabgogoiNo ratings yet

- Unit Ii Construction Practices: MasonryDocument16 pagesUnit Ii Construction Practices: MasonryDarius CardozaNo ratings yet

- Basic Construction MaterialsDocument15 pagesBasic Construction MaterialsMark Angelo SuperalesNo ratings yet

- Masonry For Construction PDFDocument46 pagesMasonry For Construction PDFRando ClintonNo ratings yet

- 1622I - 2nd Semester - Mechanical EngineeringDocument21 pages1622I - 2nd Semester - Mechanical EngineeringReshab DeyNo ratings yet

- Research 4Document3 pagesResearch 4jacobsimon navarroNo ratings yet

- Unit 2Document142 pagesUnit 2srikarryettapu.ai22No ratings yet

- Building MaterialsDocument16 pagesBuilding MaterialsgloryyotlelyNo ratings yet

- BCM ReportDocument24 pagesBCM ReportPiyush ThakurNo ratings yet

- Boq DefinitionsDocument1 pageBoq DefinitionsRita AbdallahNo ratings yet

- Walls: Presented By: Manoj Kader Vengatesh DeekshiDocument24 pagesWalls: Presented By: Manoj Kader Vengatesh DeekshiDEEKSHI MNo ratings yet

- Specification, Estimation and Costing MODULE I (12 Hours)Document2 pagesSpecification, Estimation and Costing MODULE I (12 Hours)NITHIN A V100% (1)

- HW5 Ce100Document12 pagesHW5 Ce100Prince KJNo ratings yet

- Types of Building Materials Used in ConstructionDocument4 pagesTypes of Building Materials Used in ConstructionNurmaizatul HawaNo ratings yet

- Geological Materials Used in Construction:: Metamorphic RocksDocument3 pagesGeological Materials Used in Construction:: Metamorphic RocksMuhammadRohanAfzalNo ratings yet

- Paolo Fabugais Dain Casalta Chelsa Tapis: Construction Materials A. ConcreteDocument9 pagesPaolo Fabugais Dain Casalta Chelsa Tapis: Construction Materials A. ConcretePaolo Miguel FabugaisNo ratings yet

- Metal: Common Metals in The Construction Industry Carbon SteeDocument3 pagesMetal: Common Metals in The Construction Industry Carbon SteeChris Michelle JapinNo ratings yet

- Introduction To Masonry StructuresDocument65 pagesIntroduction To Masonry StructuresPRATIBHA AGRAWALNo ratings yet

- HW1Document2 pagesHW1Cyrille's ThoughtsNo ratings yet

- Ce102-W6-Masonry and Its Types: Engr. Caroline A. Asuncion 1 Semester A.Y. 2021-2022 La Concepcion CollegeDocument46 pagesCe102-W6-Masonry and Its Types: Engr. Caroline A. Asuncion 1 Semester A.Y. 2021-2022 La Concepcion CollegeRomel BernardoNo ratings yet

- ARC 3201 CANTOS LUISE ISABELLE M. BT 4 Research Work No. 1Document12 pagesARC 3201 CANTOS LUISE ISABELLE M. BT 4 Research Work No. 1Ivana Joyce VillalobosNo ratings yet

- Types of Construction Materials in Civil EngineeringDocument2 pagesTypes of Construction Materials in Civil EngineeringAssyifa FitrianiNo ratings yet

- Week 2 Types of Building Materials (Concrete and Masonry) 1Document68 pagesWeek 2 Types of Building Materials (Concrete and Masonry) 1spy0161No ratings yet

- Building MaterialsDocument5 pagesBuilding MaterialsNiranjana Karandikar100% (1)

- BCE 1st ModuleDocument17 pagesBCE 1st ModuleAdii100% (1)

- Installation of LintelsDocument3 pagesInstallation of LintelsJustine Noel De CastroNo ratings yet

- Buildig MaterialsDocument5 pagesBuildig MaterialsJoedel CapillanNo ratings yet

- Classification of Architectural MaterialsDocument33 pagesClassification of Architectural Materialsfernandez arar67% (3)

- Unit 2 Building MaterialsDocument4 pagesUnit 2 Building MaterialsHoàng NamNo ratings yet

- Furniture Production Materials - 2Document9 pagesFurniture Production Materials - 2Pitz Shady ShinNo ratings yet

- Module 1 NotesDocument38 pagesModule 1 Notesakshatanandvs2005No ratings yet

- Construction Materials DescriptionDocument69 pagesConstruction Materials DescriptionAlejandra De LeonNo ratings yet

- Part 1 MetalsDocument14 pagesPart 1 MetalsLenard UsonNo ratings yet

- Faculty of Engineering Tech. & Research.: Name Pen NoDocument70 pagesFaculty of Engineering Tech. & Research.: Name Pen NoBIJAYKUMAR MAJHI( CIVIL-1 2017 )No ratings yet

- BTLE 107 Chapter 1Document13 pagesBTLE 107 Chapter 1Lorenzo RamosNo ratings yet

- CM 01 - IntroductionDocument31 pagesCM 01 - IntroductionVijayNo ratings yet

- Al Tahadi UnivesityDocument19 pagesAl Tahadi UnivesityPadma SundarNo ratings yet

- Faculty of Engineering Tech. & Research.: Name Pen NoDocument70 pagesFaculty of Engineering Tech. & Research.: Name Pen NoKatherineCaayohanNo ratings yet

- Building Materials English For Civil EngDocument17 pagesBuilding Materials English For Civil EngDipendra AwasthiNo ratings yet

- Properties of Ferro-Cement: CopperDocument3 pagesProperties of Ferro-Cement: CopperCh-47JDZNo ratings yet

- 5 - Building MaterialsDocument86 pages5 - Building MaterialsZynb AlhlalNo ratings yet

- Materials Used in Civil EngineeringDocument18 pagesMaterials Used in Civil EngineeringMohsen TennichNo ratings yet

- UNIT-1 Reinforced BrickworkDocument24 pagesUNIT-1 Reinforced BrickworkKarnalPreethNo ratings yet

- Lec-1 - CE 201 - Bricks@CE-22 - 2021Document33 pagesLec-1 - CE 201 - Bricks@CE-22 - 2021Rj 30No ratings yet

- Construction MaterialsDocument4 pagesConstruction MaterialssateeshNo ratings yet

- CE 201 - Bricks@CE-21 - 2020Document54 pagesCE 201 - Bricks@CE-21 - 2020Nahid SultanNo ratings yet

- Pangilinan, Koryne E. Bs-Architecture 2-1Document7 pagesPangilinan, Koryne E. Bs-Architecture 2-1Koryne Escauriaga PangilinanNo ratings yet

- DIFFERENT TYPES OF BUILDING MATERIALSDocument10 pagesDIFFERENT TYPES OF BUILDING MATERIALSmohdmaazkhan025No ratings yet

- Composite Masonry1Document17 pagesComposite Masonry1Bibek Basnet0% (1)

- Stone MasonryDocument2 pagesStone MasonryDavid PascualNo ratings yet

- Assignment 2Document11 pagesAssignment 2Amit ChopraNo ratings yet

- TRAINING REPORT - Rate AnalysisDocument28 pagesTRAINING REPORT - Rate AnalysisvarshaNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Mainpuri Circle S.O.R 2020 PDFDocument101 pagesMainpuri Circle S.O.R 2020 PDFVikas KumarNo ratings yet

- Geotechnical Engineering: Hernandez, Gene Bryant V. Pangdan, Katherine Mae P. Pascual, John Casimir TDocument15 pagesGeotechnical Engineering: Hernandez, Gene Bryant V. Pangdan, Katherine Mae P. Pascual, John Casimir TKenneth RepasNo ratings yet

- DP 1Document1 pageDP 1MridulHasanNo ratings yet

- Dea-Report of Baridhara Dohs Building - 02 July 2019Document66 pagesDea-Report of Baridhara Dohs Building - 02 July 2019CEG BangladeshNo ratings yet

- Foundation Plan Second Floor Framing Plan Roof Framing Plan: C1F1 C1F1 C1F1 RB RBDocument1 pageFoundation Plan Second Floor Framing Plan Roof Framing Plan: C1F1 C1F1 C1F1 RB RBDanica Mae Amicay100% (1)

- Bill of QuantitiesDocument5 pagesBill of QuantitiesUlquiorra Garcia0% (1)

- Boq Schedule A DSR ItemesDocument22 pagesBoq Schedule A DSR ItemeskkodgeNo ratings yet

- Training - Guiding Principles For Design and Construction of Flood, Cyclone and Storm Surge Resilient House A CDMP Approach PDFDocument25 pagesTraining - Guiding Principles For Design and Construction of Flood, Cyclone and Storm Surge Resilient House A CDMP Approach PDFCDMP BangladeshNo ratings yet

- Low Cost Construction TechniquesDocument6 pagesLow Cost Construction TechniquesXahid UsmanNo ratings yet

- Labour Requirement For Various Building WorksDocument4 pagesLabour Requirement For Various Building WorksArun Chandra Babu100% (1)

- Renaissance ArchitectureDocument26 pagesRenaissance ArchitectureMiroslav Šilić100% (1)

- Column Structural Design TemplateDocument10 pagesColumn Structural Design TemplateJelal EdrisNo ratings yet

- Mountain Park Brochure FinalDocument77 pagesMountain Park Brochure FinalMostafa ElghifaryNo ratings yet

- Gothic ArchitectureDocument41 pagesGothic ArchitectureTrisha Marie Bustria MartinezNo ratings yet

- Nordlund HandoutDocument12 pagesNordlund HandoutmybestloveNo ratings yet

- TME522-Chapter 2-ApplicationsDocument33 pagesTME522-Chapter 2-ApplicationsFiras Abu talebNo ratings yet

- Your Energy Audit ChecklistDocument6 pagesYour Energy Audit ChecklistAnthony DavidNo ratings yet

- Punchlist: Area Comments / Remarks Contractor Fig. No. Completion Date ItemsDocument10 pagesPunchlist: Area Comments / Remarks Contractor Fig. No. Completion Date ItemsJan Lawrence AlbertoNo ratings yet

- May2012 - Renovating and Revamping Your Home PDFDocument45 pagesMay2012 - Renovating and Revamping Your Home PDFKapil RampalNo ratings yet

- Lafarge Interior Building Solutions BrochureDocument24 pagesLafarge Interior Building Solutions BrochuretwinpixtwinpixNo ratings yet

- ShaftWall 0Document30 pagesShaftWall 0VictorNo ratings yet

- Steel ExampleDocument177 pagesSteel Examplelomo2002No ratings yet

- History of Architecture (ALE Review 3)Document2 pagesHistory of Architecture (ALE Review 3)Jehan MohamadNo ratings yet

- KPI Precast Reinforced Conc. BlockDocument27 pagesKPI Precast Reinforced Conc. BlockArchie Joseph LlanaNo ratings yet

- Brutalism & Metabolism in ArchitectureDocument10 pagesBrutalism & Metabolism in ArchitectureMaira NoorNo ratings yet

- Key Notes: Wall SystemDocument1 pageKey Notes: Wall SystemMyo Min ThuNo ratings yet

Construction Materials IT2

Construction Materials IT2

Uploaded by

Elizzabeth HZ0 ratings0% found this document useful (0 votes)

65 views19 pagesThis document provides an overview of common construction materials used in building projects. It discusses earthwork materials like aggregates which are used as subbases or fill. Concrete is described as a mixture of cement, sand, gravel and water that hardens over time. Reinforced concrete uses rebar for strength. Masonry uses smaller units like brick and block with mortar. Common metals in construction include steel, aluminum, copper and brass used for windows, doors, beams and more.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an overview of common construction materials used in building projects. It discusses earthwork materials like aggregates which are used as subbases or fill. Concrete is described as a mixture of cement, sand, gravel and water that hardens over time. Reinforced concrete uses rebar for strength. Masonry uses smaller units like brick and block with mortar. Common metals in construction include steel, aluminum, copper and brass used for windows, doors, beams and more.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

65 views19 pagesConstruction Materials IT2

Construction Materials IT2

Uploaded by

Elizzabeth HZThis document provides an overview of common construction materials used in building projects. It discusses earthwork materials like aggregates which are used as subbases or fill. Concrete is described as a mixture of cement, sand, gravel and water that hardens over time. Reinforced concrete uses rebar for strength. Masonry uses smaller units like brick and block with mortar. Common metals in construction include steel, aluminum, copper and brass used for windows, doors, beams and more.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 19

Construction Materials

Introduction

It takes many different kinds of

materials to construct a building

project.

The purpose of this section is to get an

overview of the most common

materials used in building construction.

The materials will be discussed as they

relate to the Construction Specifications

Institute (CSI) specification categories.

Earthwork

Aggregates (gravel): In building construction, they

are typically used as subbase support under

concrete slabs, foundation and underground

drainage, fill around pipes , and as one of the three

basic concrete ingredients.

Aggregates start out as solid rock in the earth’s

crust, and over many thousands of years, are

broken down by freeze/thaw cycles and other

natural action into pieces of various sizes. The larger

pieces are called coarse aggregates or gravel; the

smaller pieces are usually referred to as sand or fine

aggregates.

Earthwork

There are various kinds of aggregates,

such as:

Pea gravel: small rounded pieces ranging

in diameter from 1/4 ″to 3/8 ″ .

River gravel: larger aggregates dredged

from river bottoms, banks, and flood plains.

Crushed stone: mined stone that has been

mechanically fractured to a specified size.

Concrete

Concrete: It is a mixture of cement, sand, coarse and

fine aggregates, admixtures, and water .When first

mixed, it is plastic (able to flow and be shaped) and can

be cast to take the shape of the formwork provided.

Hardening of the concrete is caused by a chemical

reaction between the cement and water called

hydration.

Most mixtures of concrete set within 4–12 hours ,

depending on the temperature, the volume of the pour ,

type of cement, and admixtures.

Concrete continues to harden for months after the initial

set, but most placements reach their compressive or

design strength within 28 days .

Types of Cement

Cement binds the concrete mix together. Types

of cement include:

Type I, Normal Cement (most common)

Type II, Moderate Sulfate Resistance (slow-reacting)

Type III, High Early Strength (fast-setting)

Type IV, Low Heat of Hydration (low heat generation)

Type V, High Sulfate Resistance.

One example of the usage is Type IV which is

low heat generation for large construction

building foundation projects, such as dams.

Reinforced Concrete

Concrete has great compressive strength, but

very little tensile (pulling) strength. To overcome

this weakness, concrete is cast around steel

reinforcing bars.

These bars (commonly referred to as “rebar”)

have high tensile strength. As the concrete

hardens, it grips the steel to form a bond.

Reinforcing bars are round in shape, with

projections (called deformations) formed in the

rolling process to strength bonding with the

concrete.

Reinforced Concrete

Sheets of wire mesh also are used for

reinforcement. Welded wire fabric (WWF) is a

prefabricated material used to reinforce

concrete slabs, floors, an pipe.

It consists of a mesh of steel wires welded

together. It is available in sheets and rolls.

There are two types of welded wire fabric:

smooth (plain), designated by a W; and

deformed, designated D.

Welded wire fabric is further designated by

numbers .

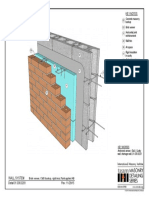

Masonry

Masonry structures are made from a number

of smaller units held together with a bonding

material known as mortar. Masonry units are

manufactured as brick, concrete block,

stone and clay tile. Mortar is a cementitious

material that bonds the individual units

together.

Almost all masonry construction must be

reinforced with metals. Like concrete,

masonry has good compressive strength and

poor tensile strength.

Brick Masonry

It uses units (bricks) that are manufactured,

rather than removed from quarries. There are

many types:

Adobe brick: Natural sun-dried clays or earth

and a binder.

Klin-burned brick: Natural clays or shales

molded to shape, dried, ad fired for hardness.

Sand-lime brick: A mixture of sand and lime,

molded and hardened under steam pressure

and heat.

Brick Masonry

Concrete brick: A mixture of cement and

aggregates, molded into solid or cored units

and hardened chemically.

Building brick: Usually called “common brick”

this is the most-used type. It is used for walls,

backing, and other applications where

appearance is not important.

Face brick: This material is manufactured

under more controlled conditions to produce

bricks of specific dimensions, colors, and

structural qualities .

Brick Masonry

Glazed brick: Finished with a hard,

smooth coating, these bricks are used

for decorative and special service

applications.

Firebrick: Used where masonry units are

subjected to extreme heat, such as

fireplaces, incinerators , and furnaces.

Paving brick: Used in drive ways or

areas where abrasion is a concern.

Stone Masonry

The most common materials used in

stone masonry are granite, limestone,

marble, sandstone, and slate. Due to

the development of new materials and

methods of construction, stones are now

used mainly for their decorative value.

Most stones are removed from a quarry

and sent to a finishing mill for final

dressing. Some stones are used in their

original shapes and surface finishes.

Stone Masonry

Stone masonry can be laid as solid walls of

stone or as composite walls backed with

concrete block or tile. It is also used as a

veneer. Stone walls are classified in the

following ways:

Rubble consists of stones as they come from

the quarry or are gathered from a field or

stream.

Ashlar stones are squared stones that have

been laid in a pattern but not cut to

dimensions.

Stone Masonry

Cut stones, also known as dimensional

stones, are cut and finished at the mill to

meet the specifications of a particular

construction job.

Unlike ashlar masonry, which is laid

largely at the design of the mason, cut

stones are laid according to the design

of the architect.

Metals

Construction jobs make use of metal

windows, doors, studs, beams, joists, wall

facings, roofing, plumbing, and hardware .

Among the different kinds of metals, there are

included the following:

Metals can be divided into two categories,

ferrous and nonferrous. Ferrous metals contain

iron as a principal element, and usually have

magnetic properties. Nonferrous metals

contain no iron and do not have magnetic

properties. They are typically lighter and less

strong than ferrous metals .

Ferrous Metals

Iron is malleable, ductile, magnetic , and silver

white in color. There are many kinds of iron, such

as pig iron, cast iron, and wrought iron. Iron is one

of the principal ingredients of steel.

Steel is an iron-based alloy with a carbon content

ranging from 0.2% to 2.0%. Depending on the

intended use , steel has many chemical

compositions. Carbon steel, alloy steel, mild steel,

medium steel, tool steel, spring steel, and stainless

steel are a few of the varieties available. By

varying the carbon content, steel can be made

harder and stronger , but it also becomes more

brittle.

Nonferrous Metals

Aluminum: Pure aluminum and aluminum alloys

are used in many building applications where

resistance to corrosion is important. Aluminum

that is 99% pure is soft and ductile, but weak.

Aluminum is typically used in such building

applications as flashing, downspouts , some kinds

of roofing, doors and trim, mullions f or windows,

etc.

Copper: Copper and copper alloys have a high

electrical conductivity and are resistant to

corrosion. This metal is typically used in

construction for water distribution, electrical

wiring, and flashing.

Nonferrous Metals

Brass: This metal is widely used f or door and

window hardware, grilles, and railings. Brass is

copper with zinc as its principal alloy element.

Bronze: A copper-tin alloy, bronze also can

contain various other elements, such as

aluminum or silicon. Bronze resists corrosion

and is widely used for ornamental

architectural products .

You might also like

- Brick&Bolt Quality Assessment System - QASCONDocument24 pagesBrick&Bolt Quality Assessment System - QASCONPulkit ChawlaNo ratings yet

- Kuala Lumpur and Selangor Chinese Assembly HallDocument25 pagesKuala Lumpur and Selangor Chinese Assembly HallZacharyTay100% (2)

- B+G+2 Boq - (367-625)Document116 pagesB+G+2 Boq - (367-625)Amy Fitzpatrick100% (3)

- (Art of Woodworking 16) Time-Life Books-Classic American Furniture - Time Life Education (1995)Document148 pages(Art of Woodworking 16) Time-Life Books-Classic American Furniture - Time Life Education (1995)cosmelli100% (2)

- 2-1 Building MaterialsDocument64 pages2-1 Building MaterialsVũ Thị Hà TrangNo ratings yet

- Construction Material and Their ApplicationsDocument17 pagesConstruction Material and Their ApplicationsMay Myat Mon KyawNo ratings yet

- Building Design System: Submitted By: Hafiz Uzair Naeem Ud DinDocument15 pagesBuilding Design System: Submitted By: Hafiz Uzair Naeem Ud DinUzair SiddiqueNo ratings yet

- Types of Building Materials - Be Assignment-Shreya PDFDocument12 pagesTypes of Building Materials - Be Assignment-Shreya PDFShreya SinghNo ratings yet

- Stone MasonryDocument2 pagesStone MasonryPRIYA KUMARINo ratings yet

- MCM Assignment 1Document5 pagesMCM Assignment 1arnabgogoiNo ratings yet

- Unit Ii Construction Practices: MasonryDocument16 pagesUnit Ii Construction Practices: MasonryDarius CardozaNo ratings yet

- Basic Construction MaterialsDocument15 pagesBasic Construction MaterialsMark Angelo SuperalesNo ratings yet

- Masonry For Construction PDFDocument46 pagesMasonry For Construction PDFRando ClintonNo ratings yet

- 1622I - 2nd Semester - Mechanical EngineeringDocument21 pages1622I - 2nd Semester - Mechanical EngineeringReshab DeyNo ratings yet

- Research 4Document3 pagesResearch 4jacobsimon navarroNo ratings yet

- Unit 2Document142 pagesUnit 2srikarryettapu.ai22No ratings yet

- Building MaterialsDocument16 pagesBuilding MaterialsgloryyotlelyNo ratings yet

- BCM ReportDocument24 pagesBCM ReportPiyush ThakurNo ratings yet

- Boq DefinitionsDocument1 pageBoq DefinitionsRita AbdallahNo ratings yet

- Walls: Presented By: Manoj Kader Vengatesh DeekshiDocument24 pagesWalls: Presented By: Manoj Kader Vengatesh DeekshiDEEKSHI MNo ratings yet

- Specification, Estimation and Costing MODULE I (12 Hours)Document2 pagesSpecification, Estimation and Costing MODULE I (12 Hours)NITHIN A V100% (1)

- HW5 Ce100Document12 pagesHW5 Ce100Prince KJNo ratings yet

- Types of Building Materials Used in ConstructionDocument4 pagesTypes of Building Materials Used in ConstructionNurmaizatul HawaNo ratings yet

- Geological Materials Used in Construction:: Metamorphic RocksDocument3 pagesGeological Materials Used in Construction:: Metamorphic RocksMuhammadRohanAfzalNo ratings yet

- Paolo Fabugais Dain Casalta Chelsa Tapis: Construction Materials A. ConcreteDocument9 pagesPaolo Fabugais Dain Casalta Chelsa Tapis: Construction Materials A. ConcretePaolo Miguel FabugaisNo ratings yet

- Metal: Common Metals in The Construction Industry Carbon SteeDocument3 pagesMetal: Common Metals in The Construction Industry Carbon SteeChris Michelle JapinNo ratings yet

- Introduction To Masonry StructuresDocument65 pagesIntroduction To Masonry StructuresPRATIBHA AGRAWALNo ratings yet

- HW1Document2 pagesHW1Cyrille's ThoughtsNo ratings yet

- Ce102-W6-Masonry and Its Types: Engr. Caroline A. Asuncion 1 Semester A.Y. 2021-2022 La Concepcion CollegeDocument46 pagesCe102-W6-Masonry and Its Types: Engr. Caroline A. Asuncion 1 Semester A.Y. 2021-2022 La Concepcion CollegeRomel BernardoNo ratings yet

- ARC 3201 CANTOS LUISE ISABELLE M. BT 4 Research Work No. 1Document12 pagesARC 3201 CANTOS LUISE ISABELLE M. BT 4 Research Work No. 1Ivana Joyce VillalobosNo ratings yet

- Types of Construction Materials in Civil EngineeringDocument2 pagesTypes of Construction Materials in Civil EngineeringAssyifa FitrianiNo ratings yet

- Week 2 Types of Building Materials (Concrete and Masonry) 1Document68 pagesWeek 2 Types of Building Materials (Concrete and Masonry) 1spy0161No ratings yet

- Building MaterialsDocument5 pagesBuilding MaterialsNiranjana Karandikar100% (1)

- BCE 1st ModuleDocument17 pagesBCE 1st ModuleAdii100% (1)

- Installation of LintelsDocument3 pagesInstallation of LintelsJustine Noel De CastroNo ratings yet

- Buildig MaterialsDocument5 pagesBuildig MaterialsJoedel CapillanNo ratings yet

- Classification of Architectural MaterialsDocument33 pagesClassification of Architectural Materialsfernandez arar67% (3)

- Unit 2 Building MaterialsDocument4 pagesUnit 2 Building MaterialsHoàng NamNo ratings yet

- Furniture Production Materials - 2Document9 pagesFurniture Production Materials - 2Pitz Shady ShinNo ratings yet

- Module 1 NotesDocument38 pagesModule 1 Notesakshatanandvs2005No ratings yet

- Construction Materials DescriptionDocument69 pagesConstruction Materials DescriptionAlejandra De LeonNo ratings yet

- Part 1 MetalsDocument14 pagesPart 1 MetalsLenard UsonNo ratings yet

- Faculty of Engineering Tech. & Research.: Name Pen NoDocument70 pagesFaculty of Engineering Tech. & Research.: Name Pen NoBIJAYKUMAR MAJHI( CIVIL-1 2017 )No ratings yet

- BTLE 107 Chapter 1Document13 pagesBTLE 107 Chapter 1Lorenzo RamosNo ratings yet

- CM 01 - IntroductionDocument31 pagesCM 01 - IntroductionVijayNo ratings yet

- Al Tahadi UnivesityDocument19 pagesAl Tahadi UnivesityPadma SundarNo ratings yet

- Faculty of Engineering Tech. & Research.: Name Pen NoDocument70 pagesFaculty of Engineering Tech. & Research.: Name Pen NoKatherineCaayohanNo ratings yet

- Building Materials English For Civil EngDocument17 pagesBuilding Materials English For Civil EngDipendra AwasthiNo ratings yet

- Properties of Ferro-Cement: CopperDocument3 pagesProperties of Ferro-Cement: CopperCh-47JDZNo ratings yet

- 5 - Building MaterialsDocument86 pages5 - Building MaterialsZynb AlhlalNo ratings yet

- Materials Used in Civil EngineeringDocument18 pagesMaterials Used in Civil EngineeringMohsen TennichNo ratings yet

- UNIT-1 Reinforced BrickworkDocument24 pagesUNIT-1 Reinforced BrickworkKarnalPreethNo ratings yet

- Lec-1 - CE 201 - Bricks@CE-22 - 2021Document33 pagesLec-1 - CE 201 - Bricks@CE-22 - 2021Rj 30No ratings yet

- Construction MaterialsDocument4 pagesConstruction MaterialssateeshNo ratings yet

- CE 201 - Bricks@CE-21 - 2020Document54 pagesCE 201 - Bricks@CE-21 - 2020Nahid SultanNo ratings yet

- Pangilinan, Koryne E. Bs-Architecture 2-1Document7 pagesPangilinan, Koryne E. Bs-Architecture 2-1Koryne Escauriaga PangilinanNo ratings yet

- DIFFERENT TYPES OF BUILDING MATERIALSDocument10 pagesDIFFERENT TYPES OF BUILDING MATERIALSmohdmaazkhan025No ratings yet

- Composite Masonry1Document17 pagesComposite Masonry1Bibek Basnet0% (1)

- Stone MasonryDocument2 pagesStone MasonryDavid PascualNo ratings yet

- Assignment 2Document11 pagesAssignment 2Amit ChopraNo ratings yet

- TRAINING REPORT - Rate AnalysisDocument28 pagesTRAINING REPORT - Rate AnalysisvarshaNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Mainpuri Circle S.O.R 2020 PDFDocument101 pagesMainpuri Circle S.O.R 2020 PDFVikas KumarNo ratings yet

- Geotechnical Engineering: Hernandez, Gene Bryant V. Pangdan, Katherine Mae P. Pascual, John Casimir TDocument15 pagesGeotechnical Engineering: Hernandez, Gene Bryant V. Pangdan, Katherine Mae P. Pascual, John Casimir TKenneth RepasNo ratings yet

- DP 1Document1 pageDP 1MridulHasanNo ratings yet

- Dea-Report of Baridhara Dohs Building - 02 July 2019Document66 pagesDea-Report of Baridhara Dohs Building - 02 July 2019CEG BangladeshNo ratings yet

- Foundation Plan Second Floor Framing Plan Roof Framing Plan: C1F1 C1F1 C1F1 RB RBDocument1 pageFoundation Plan Second Floor Framing Plan Roof Framing Plan: C1F1 C1F1 C1F1 RB RBDanica Mae Amicay100% (1)

- Bill of QuantitiesDocument5 pagesBill of QuantitiesUlquiorra Garcia0% (1)

- Boq Schedule A DSR ItemesDocument22 pagesBoq Schedule A DSR ItemeskkodgeNo ratings yet

- Training - Guiding Principles For Design and Construction of Flood, Cyclone and Storm Surge Resilient House A CDMP Approach PDFDocument25 pagesTraining - Guiding Principles For Design and Construction of Flood, Cyclone and Storm Surge Resilient House A CDMP Approach PDFCDMP BangladeshNo ratings yet

- Low Cost Construction TechniquesDocument6 pagesLow Cost Construction TechniquesXahid UsmanNo ratings yet

- Labour Requirement For Various Building WorksDocument4 pagesLabour Requirement For Various Building WorksArun Chandra Babu100% (1)

- Renaissance ArchitectureDocument26 pagesRenaissance ArchitectureMiroslav Šilić100% (1)

- Column Structural Design TemplateDocument10 pagesColumn Structural Design TemplateJelal EdrisNo ratings yet

- Mountain Park Brochure FinalDocument77 pagesMountain Park Brochure FinalMostafa ElghifaryNo ratings yet

- Gothic ArchitectureDocument41 pagesGothic ArchitectureTrisha Marie Bustria MartinezNo ratings yet

- Nordlund HandoutDocument12 pagesNordlund HandoutmybestloveNo ratings yet

- TME522-Chapter 2-ApplicationsDocument33 pagesTME522-Chapter 2-ApplicationsFiras Abu talebNo ratings yet

- Your Energy Audit ChecklistDocument6 pagesYour Energy Audit ChecklistAnthony DavidNo ratings yet

- Punchlist: Area Comments / Remarks Contractor Fig. No. Completion Date ItemsDocument10 pagesPunchlist: Area Comments / Remarks Contractor Fig. No. Completion Date ItemsJan Lawrence AlbertoNo ratings yet

- May2012 - Renovating and Revamping Your Home PDFDocument45 pagesMay2012 - Renovating and Revamping Your Home PDFKapil RampalNo ratings yet

- Lafarge Interior Building Solutions BrochureDocument24 pagesLafarge Interior Building Solutions BrochuretwinpixtwinpixNo ratings yet

- ShaftWall 0Document30 pagesShaftWall 0VictorNo ratings yet

- Steel ExampleDocument177 pagesSteel Examplelomo2002No ratings yet

- History of Architecture (ALE Review 3)Document2 pagesHistory of Architecture (ALE Review 3)Jehan MohamadNo ratings yet

- KPI Precast Reinforced Conc. BlockDocument27 pagesKPI Precast Reinforced Conc. BlockArchie Joseph LlanaNo ratings yet

- Brutalism & Metabolism in ArchitectureDocument10 pagesBrutalism & Metabolism in ArchitectureMaira NoorNo ratings yet

- Key Notes: Wall SystemDocument1 pageKey Notes: Wall SystemMyo Min ThuNo ratings yet