Professional Documents

Culture Documents

FIR No. JSL-KAN-OGC-92091-FIR-150 Insp. Date. 11.01.2021

FIR No. JSL-KAN-OGC-92091-FIR-150 Insp. Date. 11.01.2021

Uploaded by

kbpatel123Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FIR No. JSL-KAN-OGC-92091-FIR-150 Insp. Date. 11.01.2021

FIR No. JSL-KAN-OGC-92091-FIR-150 Insp. Date. 11.01.2021

Uploaded by

kbpatel123Copyright:

Available Formats

FIR No:

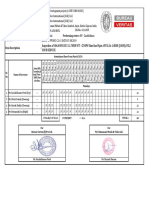

Bureau Veritas FIELD INSPECTION REPORT JSL/KAN/OGC/92091/FIR/150

(India) Private Limited

BVIL REF: IND.A.4.20.0177 R1 BVIL Date: 12/01/2021

Project: South Grid Debottlenecking Phase II Project Manufacturer: M/s. Jindal Saw Ltd.

Supply Intended For: OQ Gas Network (OGC) Order No/ LOA No: OGC-21-2019-LOA-92091

Inspection Ordered By: M/s. Jindal Saw Ltd. Place with: OQ Gas Network (OGC) to Jindal Saw Ltd.

Supplier: M/s. Jindal Saw Ltd. Supply / Item: Bare LSAW Pipes

Performing Office (PO): BV – Gandhidham Contracting Office (CO): BV – Ahmedabad

Drawing No: -N.A.- Rev.: -N.A.- ITP No. : Q-OGC-2020S Rev. : C Dated : 03/07/2020

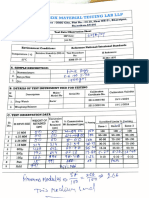

A] Measuring Instruments Used (including satisfactory verification of suitability)

Please refer Plant Calibration Record Report No. JSLM/ICR/J1/21/0002 Rev.0 Dated 03.01.2021

Please refer Lab Calibration Record Report No. JSLM/LAB/CALIBRATION LIST/2021/02 Rev.0 Dated 08.01.2021

Quantity Offered: Quantity Accepted: Quantity Rejected:

As per “Today’s Qty” of Table – 1 As per “Today’s Qty” of Table – 1 Nil

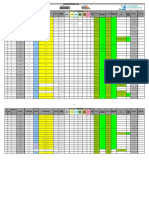

TABLE – 1: LOA Status (Cumulative Qty is accepted qty from Final Visual & Dimensional Inspection)

Ordered

Ordered Previous Today’s Cumulative Balance

Qty

Qty Qty Qty Qty Qty

combined

Sr. %

Item Description In

No. In Meters In Meters Completed

In In Meters

(No's of (No's of In Meters

Meters Meters (No's of

Pipe) Pipe)

Pipe)

PART 36" Pipe, 22.23mm WT, API 5L

24 24 0.000 24.860 24.860 NIL 100.00%*

A/014 Gr. X65MS / L450MS, PSL2, SAWL

PART 32" Pipe, 22.23mm WT, API 5L

48 48 0.000 0.000 0.000 48.000 0.00%

A/016 Gr. X65MS / L450MS, PSL2, SAWL

* - Completed % finalize after satisfactory test result of lab testing.

TABLE – 2: Production Status of Item mentioned in Table – 1 (36” OD X 22.23 MM WT)

Inspection Stage Previous Qty Today’s Qty Cumulative Qty

Plates Received at Plant 10 8 18

Plate Auto UT 8 0 16

Pipe Forming 6 5 11

Tack Welding 6 5 11

ID Welding 6 5 11

OD Welding 6 5 11

Cold Expansion 6 5 11

Hydro Test 6 5 11

Magnetic Particle Inspection 6 5 11

Final Auto Weld UT 6 5 11

End X-Ray 6 5 11

Repair Required 0 0 0

Repair Pipe Accepted 0 0 0

Pipes Accepted from Final Visual & Dimensional Inspection (No’s of Pipe) 3 2 5

Pipes Accepted from Final Visual & Dimensional Inspection (Meters) 37.395 24.860 62.255

Pipes Released (No’s of Pipe) 0 0 0

Pipes Released (Meters) 0.000 0.000 0.000

Pipe Rejected (No's of Pipe) 0 0 0

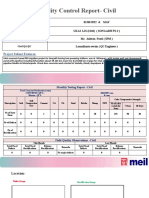

TABLE – 2: Production Status of Item mentioned in Table – 1 (32” OD X 19.05 MM WT)

Inspection Stage Previous Qty Today’s Qty Cumulative Qty

Plates Received at Plant 2717 15 2732

Plate Auto UT 2715 1 2716

Pipe Forming 2715 0 2715

Tack Welding 2715 0 2715

ID Welding 2715 0 2715

OD Welding 2715 0 2715

Cold Expansion 2715 0 2715

Hydro Test 2715 0 2715

Format FIR r5 – 19th Aug 2015 Page 1 of 3

FIR No:

Bureau Veritas FIELD INSPECTION REPORT JSL/KAN/OGC/92091/FIR/150

(India) Private Limited

BVIL REF: IND.A.4.20.0177 R1 BVIL Date: 12/01/2021

TABLE – 2: Production Status of Item mentioned in Table – 1 (32” OD X 19.05 MM WT)

Inspection Stage Previous Qty Today’s Qty Cumulative Qty

Magnetic Particle Inspection 2714 0 2714

Final Auto Weld UT 2714 0 2714

End X-Ray 2713 0 2713

Repair Required 27 0 27

Repair Pipe Accepted 27 0 27

Pipes Accepted from Final Visual & Dimensional Inspection (No’s of Pipe) 2710 0 2710

Pipes Accepted from Final Visual & Dimensional Inspection (Meters) 33621.950 0.000 33621.950

Pipes Released (No’s of Pipe) 0 0 0

Pipes Released (Meters) 0.000 0.000 0.000

Pipe Rejected (No's of Pipe) 0 0 0

B] Details of Inspection Carried out :

For MPQT & Regular production of Pipes (Size: 36” OD X 22.23 MM WT). :-

Reviewed x -ray film (MPQT Pipe 100% RT Film review and RP both end RT film review) and reports as per ITP Sr.No.

9.3- Found satisfactory.

Witnessed visual inspection of inside for excessive area and outside pipes as per ITP Sr.No. 10.1- No injures surface

defect observed.

Witnessed pipe inspection for the dents as per ITP Sr.No. 10.2- Found satisfactory.

Witnessed radial offset of plate edges as per ITP Sr.No. 10.3- Found satisfactory.

Witnessed misalignment of weld bead as per ITP Sr.No. 10.4- Found within acceptable limit.

Witnessed height of weld bead (inside for excessive area & outside) as per ITP Sr.No. 10.5- Found within acceptable

limit.

Witnessed pipe inspection for the hard spot as per ITP Sr.No. 10.6- No hard spot observed.

Witnessed visual inspection free from cracks, sweats and leaks as per ITP Sr.No. 10.7- pipe found free from cracks and

leaks.

Witnessed visual inspection for lamination as per ITP Sr.No. 10.8- Found satisfactory.

Witnessed weld inspection for undercuts as per ITP Sr.No. 10. 9- Found satisfactory.

Witnessed other surface imperfections as per ITP Sr.No. 10. 10- Found satisfactory.

Witnessed visual inspection for arc burns as per ITP Sr.No. 10. 11- Found satisfactory.

Witnessed wall thickness pipe as per ITP Sr.No. 11.1- Found within acceptable limit.

Witnessed pipe length as per ITP Sr.No. 11.2- Found within acceptable limit.

Witnessed straightness of pipe as per ITP Sr.No. 11.3- Found within acceptable limit.

Witnessed visual pipe inspection for no jointers as per ITP Sr.No. 11.4- Found satisfactory.

Witnessed inside diameter at pipe ends as per ITP Sr.No. 11.5- Found within acceptable limit.

Witnessed outside diameter at pipe body as per ITP Sr.No. 11.6- Found within acceptable limit.

Witnessed out of roundness at pipe end inside diameter as per ITP Sr.No. 11.7- Found within acceptable limit.

Witnessed out of roundness at pipe body outside diameter as per ITP Sr.No. 11.8- Found within acceptable limit.

Witnessed peaking and flat sports at end at pipe ends in the vicinity of weld as per ITP Sr.No. 11.9- Found acceptable

limit.

Witnessed weight of pipes as per ITP Sr.No. 11.10- Found Satisfactory.

Witnessed bevel angle and root face as per ITP Sr.No. 12.1- Found within acceptable limit.

Witnessed end Squareness as per ITP Sr.No. 12.2- Found within acceptable limit.

Witnessed inside and outside weld bead grinding as per ITP Sr.No. 12.3- Found within acceptable limit.

Selected MPQT pipes L121A01935, L121A01936 and L121A01938.

For Regular Production of Pipe Size: 32” OD X 19.05 MM WT.:-

Reviewed raw material test certificates for plates – Found meeting the requirements except below point incorporate in

RMTC. (Continuous casting method not specified)

Witnessed visual & dimensional inspection of incoming plats as per ITP Sr. No. 2.1 – Found within tolerance.

Witnessed visual & dimensional inspection of incoming plats before plate ultrasonic testing as per ITP Sr. No. 2.3 –

Found within tolerance.

Witnessed plate auto UT calibration as per ITP Sr.No. 2.4 – Found satisfactory.

Random Witnessed Automatic Ultrasonic testing of Plate as per ITP Sr. No. 2.4 – No significant indications were

observed during test.

Format FIR r5 – 19th Aug 2015 Page 2 of 3

FIR No:

Bureau Veritas FIELD INSPECTION REPORT JSL/KAN/OGC/92091/FIR/150

(India) Private Limited

BVIL REF: IND.A.4.20.0177 R1 BVIL Date: 12/01/2021

B] Details of Inspection Carried out :

Identification: Nil

Remark: Photographs not attached due to USB access not permitted to JSL premises.

RMTC review for 22.23mm WT – Inclusion report Thickness Wrong and Continuous cast method not specified

RMTC review for 19.05mm WT – Continuous cast method not specified

RMTC review for 14.27mm WT – Continuous cast method not specified, HIC Control sample Heat No. are wrong in Main MTC

and HIC report.

Attending Inspectors: Nimesh Patel - Day Shift & Mohit Solanki – Night Shift

Category: (1) Accepted, (2) Conditionally Accepted, (3) Re-Inspection Required, (4) Rejected, (5) Advice / Instruction from Client Required.

Inspection Date(s):

ANY NON Yes

11/01/2021

CONFORMITY

FOUND? No

Complete

Inspection Place(s):

ORDER

JCO – I, Jindal Saw Ltd, Kaushikkumar Patel

STATUS

Nanakapaya, Mundra Balance Supplier’s Signature & Date Date: 12.01.2021

Telephone No. Mobile No. +91-9687000073

`

Format FIR r5 – 19th Aug 2015 Page 3 of 3

You might also like

- TRANSFORMER Inspection ChecklistDocument3 pagesTRANSFORMER Inspection ChecklistWisnu Hartono94% (16)

- CMAS Training Manual P3Eng PDFDocument104 pagesCMAS Training Manual P3Eng PDFdigibillNo ratings yet

- PRC Memorandum Circular No. 03 (Hazard Pay Clarifiation On Risk Factor)Document1 pagePRC Memorandum Circular No. 03 (Hazard Pay Clarifiation On Risk Factor)ABI Alco QANo ratings yet

- Brain SyncDocument1 pageBrain SyncvickimabelliNo ratings yet

- Final Wellhead ReportDocument53 pagesFinal Wellhead ReportAli BoubeniaNo ratings yet

- Procedure For Handling, Storage & Transportations of Bare & Coated PipesDocument6 pagesProcedure For Handling, Storage & Transportations of Bare & Coated Pipeskbpatel123No ratings yet

- Fba Report BlankDocument3 pagesFba Report Blankapi-308475283No ratings yet

- Energy Audit of KCC Traction Substation, VijaywadaDocument2 pagesEnergy Audit of KCC Traction Substation, Vijaywadathailamuthu100% (1)

- 30 Traits of An EmpathDocument5 pages30 Traits of An EmpathFangedNimphNo ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-149 Insp. Date. 10.01.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-149 Insp. Date. 10.01.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-148 Insp. Date. 09.01.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-148 Insp. Date. 09.01.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-151 Insp. Date. 12.01.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-151 Insp. Date. 12.01.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-152 Insp. Date. 13.01.2021Document4 pagesFIR No. JSL-KAN-OGC-92091-FIR-152 Insp. Date. 13.01.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-102 Insp. Date. 13.09.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-102 Insp. Date. 13.09.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-129 Insp. Date. 10.10.2020Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-129 Insp. Date. 10.10.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-144 Insp. Date. 25.10.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-144 Insp. Date. 25.10.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-008 Date. 05.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-008 Date. 05.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-179 Insp. Date. 09.02.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-179 Insp. Date. 09.02.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-104 Insp. Date. 15.09.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-104 Insp. Date. 15.09.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-147 Insp. Date. 28.10.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-147 Insp. Date. 28.10.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-015 Date. 26.06.2021Document5 pagesFIR No. JSL-KAN-OGC-92091-FIR-015 Date. 26.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-006 Date. 28.04.2021Document7 pagesFIR No. JSL-KAN-OGC-92091-FIR-006 Date. 28.04.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-010 Date. 17.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-010 Date. 17.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-013 Date. 05.06.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-013 Date. 05.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-114 Insp. Date. 25.09.2020Document4 pagesFIR No. JSL-KAN-OGC-92091-FIR-114 Insp. Date. 25.09.2020kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-007 Date. 30.04.2021Document4 pagesFIR No. JSL-KAN-OGC-92091-FIR-007 Date. 30.04.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-014 Date. 17.06.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-014 Date. 17.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-012 Date. 28.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-012 Date. 28.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-015 Date. 20.06.2021Document5 pagesFIR No. JSL-KAN-OGC-92091-FIR-015 Date. 20.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-189 Insp. Date. 19.02.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-189 Insp. Date. 19.02.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-175 Insp. Date. 05.02.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-175 Insp. Date. 05.02.2021kbpatel123No ratings yet

- Daily Progress Report: SR No Activity Unit ProgressDocument1 pageDaily Progress Report: SR No Activity Unit ProgressLokabhiram DikshitNo ratings yet

- PR Bolt-2Document3 pagesPR Bolt-2rupesh417No ratings yet

- QHM 2017-18Document16 pagesQHM 2017-18Ravi Kiran MNo ratings yet

- 1 - OM061-Weekly report-W11-SGWDocument30 pages1 - OM061-Weekly report-W11-SGWAhmed NagiebNo ratings yet

- Vernier CalibDocument1 pageVernier CalibOmkar PrindavankarNo ratings yet

- StatementDocument2 pagesStatementamit singhNo ratings yet

- TRDR 300204825BDocument2 pagesTRDR 300204825BVidya SheeshNo ratings yet

- EN455-vinyl&nitrile Blend GlovesDocument8 pagesEN455-vinyl&nitrile Blend GlovesBenny Jaime Toshio ZhaoNo ratings yet

- Statement 23Document4 pagesStatement 23amit singhNo ratings yet

- Name of The CBO and A/C No: SB A/C NO 32316962577 SBI KUDERUDocument45 pagesName of The CBO and A/C No: SB A/C NO 32316962577 SBI KUDERUTuara sangmaNo ratings yet

- Adobe Scan Feb 29, 2024Document1 pageAdobe Scan Feb 29, 2024vishnuprasad0041No ratings yet

- CIVIL/Mech. Work Scope of RCC Unit Rate Value Remarks Rs. Rs. (Lac)Document8 pagesCIVIL/Mech. Work Scope of RCC Unit Rate Value Remarks Rs. Rs. (Lac)Utkarsh TiwariNo ratings yet

- 1.internal Concrete Pour Register Updated On 25-01-2023Document9 pages1.internal Concrete Pour Register Updated On 25-01-2023721917114 47No ratings yet

- Project Inventory - MODELAMIENTO 2 DE MAYO - WTGDocument2 pagesProject Inventory - MODELAMIENTO 2 DE MAYO - WTGRobert Lopez OsorioNo ratings yet

- Project Status As at 26.08.20Document4 pagesProject Status As at 26.08.20Anilduth BaldanNo ratings yet

- Inspection Report No. 73Document3 pagesInspection Report No. 73Rahul MoottolikandyNo ratings yet

- DPR Oq Pipemill 19 May 2021Document125 pagesDPR Oq Pipemill 19 May 2021kbpatel123No ratings yet

- 18 03 2024 10 RicDocument1 page18 03 2024 10 RicPrabhakaran CHNQualityNo ratings yet

- IPIC Catalogue 2019 PDFDocument40 pagesIPIC Catalogue 2019 PDFMohamed YassinNo ratings yet

- Daily Progress Report: Mtr. 4690 Mtr. Mtr. 4690Document3 pagesDaily Progress Report: Mtr. 4690 Mtr. Mtr. 4690Manoranjan sharmaNo ratings yet

- API 682 Accumulator Data SheetDocument1 pageAPI 682 Accumulator Data SheetBhyrappaNo ratings yet

- Monthly Report HK-JAWA910-January 2022Document2 pagesMonthly Report HK-JAWA910-January 2022Biguri JunnataNo ratings yet

- MRM (Civil) REPORT MAY 2022 MonthDocument4 pagesMRM (Civil) REPORT MAY 2022 MonthLaxmikanta swainNo ratings yet

- Quotation For Geotechnical Investigation For Eight Story Hostel Construction Project, in Insein Township, YangonDocument2 pagesQuotation For Geotechnical Investigation For Eight Story Hostel Construction Project, in Insein Township, YangonMin KhantNo ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- 18 Document of Part Wise Inspection ProcessDocument111 pages18 Document of Part Wise Inspection ProcessQAD LotusNo ratings yet

- Pump HeadDocument15 pagesPump HeadNghiaNo ratings yet

- 2mva TR-2 For 2 PT MillDocument2 pages2mva TR-2 For 2 PT MillVishal Kumar SinghNo ratings yet

- 1.1 1.2 Mechanical Items 1.3 Seal Tanks 1.4 Mechnical Equipments (Pumps +pipe Line + Fittings Etc)Document14 pages1.1 1.2 Mechanical Items 1.3 Seal Tanks 1.4 Mechnical Equipments (Pumps +pipe Line + Fittings Etc)yv singlaNo ratings yet

- Xxxx-Spe-Xxx - Mto FormatDocument10 pagesXxxx-Spe-Xxx - Mto FormatVijay GaikwadNo ratings yet

- ATA ReportDocument10 pagesATA Reportshaker MahmoudNo ratings yet

- Experimental Investigation of Cyclic Vibration Morton Effect in The Bearing of A Double Overhung Compressor by Jim McGinley and Bill MarscherDocument28 pagesExperimental Investigation of Cyclic Vibration Morton Effect in The Bearing of A Double Overhung Compressor by Jim McGinley and Bill MarscherGang HANNo ratings yet

- Project Inventory - MODELAMIENTO LINEA DE CONDUCCION - WTGDocument2 pagesProject Inventory - MODELAMIENTO LINEA DE CONDUCCION - WTGRobert Lopez OsorioNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- FIR No. JSL-KAN-OGC-92091-FIR-013 Date. 05.06.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-013 Date. 05.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-012 Date. 28.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-012 Date. 28.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-015 Date. 20.06.2021Document5 pagesFIR No. JSL-KAN-OGC-92091-FIR-015 Date. 20.06.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-010 Date. 17.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-010 Date. 17.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-014 Date. 17.06.2021Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-014 Date. 17.06.2021kbpatel123No ratings yet

- Curriculum Vitae: Total Experience 18.1 YearsDocument7 pagesCurriculum Vitae: Total Experience 18.1 Yearskbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-015 Date. 26.06.2021Document5 pagesFIR No. JSL-KAN-OGC-92091-FIR-015 Date. 26.06.2021kbpatel123No ratings yet

- Steelbird - Faceshield BillDocument1 pageSteelbird - Faceshield Billkbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-011 Date. 23.05.2021kbpatel123No ratings yet

- Procurement Services: Industry & Facilities DivisionDocument10 pagesProcurement Services: Industry & Facilities Divisionkbpatel123No ratings yet

- Foa Jindal SawDocument2 pagesFoa Jindal Sawkbpatel123No ratings yet

- Chandan Nath Gosewami SR - Qa/Qc Inspector (Welding, Coating) +91-7017386979Document13 pagesChandan Nath Gosewami SR - Qa/Qc Inspector (Welding, Coating) +91-7017386979kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-008 Date. 05.05.2021Document3 pagesFIR No. JSL-KAN-OGC-92091-FIR-008 Date. 05.05.2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-007 Date. 30.04.2021Document4 pagesFIR No. JSL-KAN-OGC-92091-FIR-007 Date. 30.04.2021kbpatel123No ratings yet

- Inspection of 406.4 MM OD X 11.78MM WT - CS HFW Bare Line Pipes API 5L Gr. L450M (X65M), PSL2 Sour ServiceDocument1 pageInspection of 406.4 MM OD X 11.78MM WT - CS HFW Bare Line Pipes API 5L Gr. L450M (X65M), PSL2 Sour Servicekbpatel123No ratings yet

- DPR Oq Pipemill 19 May 2021Document125 pagesDPR Oq Pipemill 19 May 2021kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-006 Date. 28.04.2021Document7 pagesFIR No. JSL-KAN-OGC-92091-FIR-006 Date. 28.04.2021kbpatel123No ratings yet

- Curriculum Vitae: Discipline Material Forms Material Types Pressure Equipment Rotating Equipment Lifting EquipmentDocument4 pagesCurriculum Vitae: Discipline Material Forms Material Types Pressure Equipment Rotating Equipment Lifting Equipmentkbpatel123No ratings yet

- Ts Scope of Work and SupplyDocument12 pagesTs Scope of Work and Supplykbpatel123No ratings yet

- Ts LSAW SpecificationDocument40 pagesTs LSAW Specificationkbpatel123No ratings yet

- Inspection Certificate: IC No.: Date: Page 1 of 3Document3 pagesInspection Certificate: IC No.: Date: Page 1 of 3kbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-102 Insp. Date. 13.09.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-102 Insp. Date. 13.09.2020kbpatel123No ratings yet

- Inspection and Test Paln For LSAWDocument4 pagesInspection and Test Paln For LSAWkbpatel123No ratings yet

- FIR No. JSL-KAN-OGC-92091-FIR-104 Insp. Date. 15.09.2020Document2 pagesFIR No. JSL-KAN-OGC-92091-FIR-104 Insp. Date. 15.09.2020kbpatel123No ratings yet

- Universiti Teknologi Mara Final Examination: Confidential AS/MAR2012/PHY310Document9 pagesUniversiti Teknologi Mara Final Examination: Confidential AS/MAR2012/PHY310luminousspaceNo ratings yet

- (WWW - Asianovel.com) - Isekai Tensei Harem Chapter 1 - Chapter 50Document291 pages(WWW - Asianovel.com) - Isekai Tensei Harem Chapter 1 - Chapter 50Jairo Custodio JurupeNo ratings yet

- Surgery KGMU Proff Chapterwise by Arif Naseem 2009-2021Document4 pagesSurgery KGMU Proff Chapterwise by Arif Naseem 2009-2021DR. PARDEEP SHARMANo ratings yet

- Masterglenium Sky 8765: High-Performance Super Plasticiser Based On Pce (Polycarboxylic Ether) For ConcreteDocument3 pagesMasterglenium Sky 8765: High-Performance Super Plasticiser Based On Pce (Polycarboxylic Ether) For ConcreteVYASNo ratings yet

- Extract Pages From 373422607-1-Print-Microsystems-AcupunctureDocument11 pagesExtract Pages From 373422607-1-Print-Microsystems-AcupunctureHenrique CaldasNo ratings yet

- Sps 2Document24 pagesSps 2Sai Sireesha GajulaNo ratings yet

- 1adulteration and Evaluation of Crude DrugsDocument23 pages1adulteration and Evaluation of Crude DrugsRamling PatrakarNo ratings yet

- Explosives Used in QuarryingDocument11 pagesExplosives Used in Quarryingjohn mwangiNo ratings yet

- N-Channel Enhancement Mode MOSFET: Product SummaryDocument5 pagesN-Channel Enhancement Mode MOSFET: Product Summaryserrano.flia.coNo ratings yet

- Hazardous Chemical Risk Assessment Checklist 2014Document8 pagesHazardous Chemical Risk Assessment Checklist 2014NavinNo ratings yet

- FirmwareUpgradeInstructionsRx3iCPEs v1Document4 pagesFirmwareUpgradeInstructionsRx3iCPEs v1Wilson KnuppNo ratings yet

- Cable Entry Seals: We Seal Your WorldDocument56 pagesCable Entry Seals: We Seal Your WorldErick Josue Mart100% (1)

- Swine ProductionDocument73 pagesSwine ProductionDUGONG PHNo ratings yet

- Annex 1 Case StudyDocument6 pagesAnnex 1 Case StudyJohn WeakNo ratings yet

- Chapter 4.material Planning and SuppliesDocument41 pagesChapter 4.material Planning and SuppliesChng TianNo ratings yet

- Essay - Nuclear EnergyDocument4 pagesEssay - Nuclear EnergyPARUL DIWANNo ratings yet

- FDQ Level 2 Diploma For Proficiency in Brewing Industry Skills 501.1054.8 12.12.2019Document11 pagesFDQ Level 2 Diploma For Proficiency in Brewing Industry Skills 501.1054.8 12.12.2019AnshulNo ratings yet

- The Periodic Table CDocument177 pagesThe Periodic Table Cmarius1966No ratings yet

- Fuel CellDocument51 pagesFuel CellAbrar MominNo ratings yet

- Grading Structure GesDocument7 pagesGrading Structure Ges3944/95100% (1)

- Musculoskeletal System - 4th EdDocument33 pagesMusculoskeletal System - 4th EdpadialmichelleNo ratings yet

- Reproductive and Lactation Performances of Dairy Cows in Chacha Town and Nearby Selected Kebeles, North Shoa Zone, Amhara Region, EthiopiaDocument10 pagesReproductive and Lactation Performances of Dairy Cows in Chacha Town and Nearby Selected Kebeles, North Shoa Zone, Amhara Region, EthiopiaChern YuanNo ratings yet

- Riyadus Saliheen - Hadeeth No. 35 (Woman of Paradise)Document13 pagesRiyadus Saliheen - Hadeeth No. 35 (Woman of Paradise)Abdul Qadir QadriNo ratings yet