Professional Documents

Culture Documents

Part II: Platinum Group Metals: JOM World Nonferrous Smelter Survey

Part II: Platinum Group Metals: JOM World Nonferrous Smelter Survey

Uploaded by

Chris BothaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Part II: Platinum Group Metals: JOM World Nonferrous Smelter Survey

Part II: Platinum Group Metals: JOM World Nonferrous Smelter Survey

Uploaded by

Chris BothaCopyright:

Available Formats

Feature Industrial Survey

JOM World Nonferrous Smelter Survey,

Part II: Platinum Group Metals

Rodney T. Jones

Editor’s Note: JOM electronic subscribers and TMS members

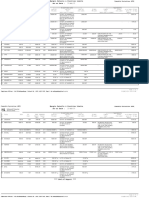

may acquire the raw spread sheets on which these tables are based Table I. PGM Production in 2003

by downloading this article from the TMS Document Center.

Pt Supply Pd Supply Rh Supply

The platinum group metals (PGMs) Moz.* Tonnes Moz.* Tonnes Moz.* Tonnes

are a family of six grayish to silver- South Africa 4.670 145.2 2.310 71.8 0.545 17.0

white metals with close chemical and Russia 1.050 32.7 2.950 91.8 0.140 4.4

physical affinities. The three heavier North America 0.295 9.2 0.940 29.2 0.020 0.6

Other 0.225 7.0 0.250 7.8 0.015 0.5

metals, platinum (Pt), iridium (Ir), and Total 6.240 194 6.450 201 0.720 22.4

osmium (Os), have densities of about Plus recycled material 0.645 20.1 0.410 12.8 0.123 3.8

22 g/cm3. The three somewhat lighter * Units in millions of troy ounces per annum (1 troy ounce = 31.1035 g; 1 million troy ounces = 31.1035 tonnes).

metals, palladium (Pd), rhodium (Rh),

and ruthenium (Ru), have densities of

Table II. Percentage Demand by Market Sector for 2003*

about 12 g/cm3. The PGMs belong to

the transition metals of Group VIII in Pt Pd Rh

the periodic table, as do iron (Fe), nickel Automobile–39 Automobile–58 Automobile–86

(Ni), and cobalt (Co). These metals have Jewelry–37 Electronics–17 Chemical–6

Industrial–23 Dental–14 Glass–5

similar geochemical behavior and tend Investment–0.2 Other–11 Other–3

to be concentrated together geologi-

* The figures for automobiles reflect the demand for new material only (i.e., recycled materials are excluded).

cally. The PGMs, along with gold (Au)

and silver (Ag), are classified as noble

metals because of their high resistance Table III. Smelter Production Figures for 2003*

to oxidation and corrosion. Pt Pd Rh Pt + Pd + Rh

Their great scarcity classifies them

Primary producers of PGMs

as precious metals. Only about 1/13 as Anglo Platinum, South Africa 2.31 1.19 0.23 3.73

much platinum is produced as gold, itself Impala Platinum, South Africa 1.96 1.05 0.25 3.26

a very rare metal. (By contrast, about 5 Lonmin Platinum, South Africa 0.93 0.42 0.14 1.49

Stillwater, United States 0.13 0.45 0.005 0.58

million times as much iron as platinum Northam Platinum, South Africa 0.21 0.10 0.02 0.33

is produced in the world.) As precious Zimplats, Zimbabwe 0.09 0.07 0.01 0.17

and noble metals, PGMs are chemically Producers of PGMs as by-products

Norilsk Nickel, Russia 0.65 2.70 0.06 3.41

more versatile than gold, and have found Falconbridge, Canada 0.11 0.33 0.002 0.44

numerous industrial applications. They Inco, Canada — — — 0.21

are also the only competitors for gold * All units are in millions of troy ounces per annum.

Table IV. Platinum Group Metal Producers

Company Abbreviation Location Web Address

Anglo Platinum–Rustenburg (Waterval) Anglo 1 Rustenburg, South Africa www.angloplatinum.com

Anglo Platinum–Mortimer Anglo 2 Swartklip, South Africa www.angloplatinum.com

Anglo Platinum–Polokwane Anglo 3 Polokwane, South Africa www.angloplatinum.com

Impala Platinum Impala Rustenburg, South Africa www.implats.co.za

Lonmin Platinum Lonmin Marikana, South Africa www.lonmin.com

Northam Platinum Northam Northam, South Africa www.northam.co.za

Zimplats–Makwiro Platinum Zimplats Selous, Zimbabwe www.zimplats.com

Stillwater Stillwater Columbus, Montana, United States www.stillwatermining.com

Norilsk Nickel, Nickel Smelter Norilsk 1 Taimyr Peninsula, Siberia, Russia www.nornik.ru/en/

Norilsk Nickel, Nadezhda Smelter Norilsk 2 Taimyr Peninsula, Siberia, Russia www.nornik.ru/en/

Norilsk Nickel, Copper Smelter Norilsk 3 Taimyr Peninsula, Siberia, Russia www.nornik.ru/en/

2004 December • JOM 59

are produced either as the primary prod-

Table V. PGM Converter Data

ucts or as by-products of the nickel and

Year of copper. The primary PGM-rich deposits

First Type of No. of Converter No. of Tuyeres

Producer Production Converter Converters Dimensions (m) per Converter include the Bushveld Complex in South

Africa (the largest known layered igne-

Anglo 1 2002 Ausmelt (ACP) 1 — 1

Peirce-Smith 6 3.0 × 7.6 — ous complex of its type in the world,

Anglo 2 — None — — — extending some 350 km from west to east

Anglo 3 — None — — — and some 250 km from north to south,

Impala — Peirce-Smith 2 3.6 × 7.3 32

Peirce-Smith 4 3.0 × 4.6 16 containing more than two-thirds of the

Lonmin 1971, Peirce-Smith 3 3.0 × 4.6 18 world’s reserves of PGMs), the Great

2002–2003 Dyke in Zimbabwe (the second largest

Northam 1992 Peirce-Smith 2 3.0 × 6.1 22

Zimplats 1998 Peirce-Smith 2 3.0 × 4.6 16 known deposit of PGMs in the world),

Stillwater 1999 Kaldo (TBRC) 2 2.0 × 3.32 — the Stillwater deposit of the United

Norilsk 1 Early 1940s Russian 6 100 t capacity — States, and the Lac des Isles deposit

Norilsk 2 — Peirce-Smith 6 — —

Norilsk 3 — Peirce-Smith 9 4×9 — of Canada. Platinum group metals are

produced in significant quantities as

by-products from the Norilsk-Talnakh

as investment metals and for jewelry that have made them indispensable to the area of Russia and the Sudbury deposit

purposes. modern industrial world. The PGMs have of Canada. Other deposits occur in Fin-

Platinum was formally discovered high melting points and are chemically land, the Jinchuan deposits of northwest

only in 1751, although it (possibly inert to a wide variety of substances China, the Duluth complex of the United

mistaken for silver at that time) was (even at high temperatures), and thus States, and in numerous smaller deposits.

used as far back as the 7th century B.C. resist corrosion. They also have excel- Platinum group metals are also produced

in Egypt, when the Thebes casket was lent catalytic properties and are widely in small quantities as by-products from

produced. (This was made for Shepenu- used in the chemical industry and in the nickel-copper industry in Australia

pet, the daughter of the king of Thebes, automobile catalytic converters. Com- and Japan.1

and has gold hieroglyphics on one side mercial substitution by cheaper metals The most economically important of

and platinum on the other.) The catalytic has rarely been successful, although an the PGMs are platinum, palladium, and

properties of PGMs were described in individual PGM may readily be replaced rhodium, with ruthenium, iridium, and

the period of 1823–1838. Interestingly, by another. osmium being less prevalent and less in

jewelry and catalysis remain the most Platinum group elements are generally demand. Gold, though it is a precious

important applications of these metals associated with nickel-copper sulfides in metal, is not one of the PGMs although

today. magmatic rocks. Depending on the rela- it is often lumped together with the PGM

Platinum group metals have extraor- tive concentrations (and market prices) of content when talking about the valuable

dinary physical and chemical properties the precious and base metals, the PGMs products from PGM smelting. The base

Table VI. PGM Smelter System Information

Annual Production

Millions of Ounces Thousands of Tonnes

Year of

First Total

Smelter Production PGMs Pt Pd Rh Au Ni Cu

Anglo 1 1926 4.162 2.308 1.191 0.233 0.116 22.1 12.9

Anglo 2 1973 (0.754) (0.46) (0.22) (0.06) (0.014) (2.6) (1.5)

Anglo 3 2003 — — — — — — —

Impala 1969 3.725 1.961 1.046 0.251 0.069 16.4 8.7

Lonmin 1971 1.758 0.933 0.417 0.141 0.018 3.18 2.12

Northam 1992 0.385 0.212 0.103 0.018 0.007 1.51 0.86

Zimplats 1997 0.187 0.085 0.073 0.008 0.011 1.63 1.0

Stillwater 1990 0.599 0.134 0.450 <0.005 <0.010 0.75 0.5

Norilsk 1 Early 1940s 3.410 0.650 2.700 0.060 0.136 239 451

Norilsk 2 Early 1980s — — — — — — —

Norilsk 3 — — — — — — — —

60 2004 December • JOM

metals nickel, copper, and cobalt com- as part of the nickel smelter survey.) ore is processed has a major influence

monly occur together with the PGMs Most company production figures are on the smelting behavior, as traditional

and are produced as co-products in the taken from their current annual reports six-in-line furnaces are susceptible to

smelters and refineries. The PGM market (for 2003 in most cases) that are mostly build-ups of high-melting chromite

is fundamentally strong, particularly in available from their company websites. spinels if the Cr2O3 content of the feed

platinum, where demand has outstripped Note that Russia does not as yet allow is too high.

supply for the past five years. Platinum the release of official production figures The chromite problem is seen as

saw a price increase of almost 30% in the for PGMs and cobalt, although new laws increasingly important as the amount of

past year, reaching the highest point in have been enacted recently to allow for UG2 ore being mined continues to grow

more than 20 years. However, palladium the release of much of this information faster than the amount of Merensky ore.

and rhodium dropped by almost 40% in the year ahead. However, estimated A recent trend is to break the tradition of

in the same period, following periods production figures produced by Johnson recycling converter slag to the primary

of very high prices. Over recent years, Matthey2 for the Polar Division (which smelting furnace. The converter slag

there has been good growth in jewelry produces the bulk of Norilsk’s PGMs) can be treated either in a slag-cleaning

demand and in autocatalysts, especially are believed to be fairly reliable. Table furnace (as practiced at Anglo Platinum)

for diesel vehicles. III shows the Pt, Pd, and Rh production or by subsequent milling and flotation.

Table I shows the geographical distri- figures for the various PGM smelters. There is an increasing move to higher-

bution of the most important PGMs, and South Africa has the greatest con- intensity furnaces fitted with copper

Table II shows the demand by market centration of primary PGM-producing cooling, both for rectangular furnaces

sector for Pt, Pd, and Rh, courtesy of companies,3,4 each of which has its own (at Anglo Platinum’s Polokwane smelter)

Johnson Matthey.2 approach to smelting. (See Table IV for a and circular furnaces (such as those at

The comparative tables presented list of PGM-producing companies.) The Lonmin Platinum and Zimplats). Con-

here include all known primary PGM historical background to these smelters tainment issues are important, especially

smelters around the world, as well as up to 1999 has been provided elsewhere3 at the higher operating temperatures used

Norilsk Nickel. Although not strictly a and will not be repeated here. Production to cope with increasing chromite contents

primary PGM smelter, Norilsk Nickel takes place in differing amounts of the in the furnace feed.

is the world’s largest producer of nickel three currently exploited strata of the A variety of techniques have been used

and palladium and also one of the leading Bushveld Complex. The Merensky Reef in the attempt to reduce SO2 emissions

producers of copper, platinum, and gold. has the PGMs occurring in conjunction from smelters, with different degrees

Leaving out Norilsk would result in an with base metal sulfides; the Platreef has of success. Continuous converting was

incomplete picture of PGM smelting, an even greater quantity of base metal introduced recently by Anglo Platinum

so it is included here even though other sulfides present; and the UG2 chromitite as a way of ensuring a steady stream of

nickel smelters such as Inco and Falcon- layer has a high chromite content together SO2 that can be fed to a sulfuric acid

bridge are not. (Further details on those with relatively low quantities of base plant. Anglo Platinum chose to have

smelters will be presented in due course metal sulfides. The extent to which UG2 one central facility where all convert-

Table VI. PGM Smelter System Information

Converter

Granulation Slag

Furnace Converter Stack Sulfuric Gas Recycl.

Dryer Height Acid Cleaning to

Type Slag Matte Slag Matte (m) Plant Equip. Furnace

Flash (4) Yes Yes Yes Noa 183 Yes Ceramic No

Filters

Flash Yes Nob — — 100 No ESP N/A

Flash (2) Yes Nob — — 165 No Baghouse N/A

Spray (4) Yes No Yes Yes 77 (91) Yesc ESP No

Flashd Yes No Yes Yes 120 No Baghouse for drier; No

ESP and dual-alkali

wet scrubber

Flash Yes No No Yes 200 No ESP and wet scrubber Yes

Flash (1) Yes No No Yes 105 No ESP Yes

Fluid bed No Yes Yes Yes 26 No Baghouse and SO2 wet scrubber Yese

Sinter plant — — — — — — — Yesf

Niro spray (6) — — — — — No 6 x ESPS and —

elemental sulfur production

Rotary (3) — — — — 180 Yes Wet gas cleaning and Yesg

elemental sulfur production

a – slow cooling; b – cast and crushed; c– and sulfacid; d–also 2 old spray towers; e–in granulated form; f–from copper smelter; g–to reverb furnace

2004 December • JOM 61

Table VII. PGM Furnace Data*

Year of Power Electrode

First Furnace Flux, Dimensions Diameter

Producer Production Type Power kW/m2 (m) (mm) Cooling System

Anglo 1 1990s Six-in-line rectangular 34 MW 165 25.8 × 8.0 1,100 Copper finger/

(Hatch) (39 MVA) plate coolers

1990s Six-in-line rectangular 34 MW 165 25.8 × 8.0 1,100 Copper finger/

(Hatch) (39 MVA) plate coolers

2003 Three-electrode AC 28 MVA — — 1,200 Copper coolers

circular slag cleaning

Anglo 2 1973 Six-in-line rectangular 19.5 MVA 110 25.3 × 7.0 1,250 Forced-air cooled

Anglo 3 2003 Six-in-line rectangular 68 MW 250 28.7 × 9.6 1,600 Copper waffle coolers

(168 MVA)

Impala 2001 (No. 3) Six-in-line rectangular 38 MW 180 25.9 × 8.2 1,140 Copper plate coolers

1992 (No. 5) Six-in-line rectangular 35 MW 180 25.9 × 8.2 1,140 Copper plate coolers

1974 (No. 4)–dormant Six-in-line rectangular 15 MW — — — —

1972 (No. 2)–mothballed Six-in-line rectangular 7.5 MW — — — —

Lonmin 2002 Three-electrode AC 28 MW 320 11 (dia.) 1,400 Copper waffle coolers

circular (Hatch) (60 MVA)

1991–mothballed Three-electrode AC 5 MVA 235 5.2 (I.D.) 500 Falling film

circular (Pyromet) (three)

1991–mothballed Six-in-line rectangular 12.5 MVA 120 18.2 × 5.3 900 —

(Barnes-Birlec, Merensky)

Northam 1992 Six-in-line rectangular 15 MW 90 25.9 × 8.7 × 5.6 1,000 None

(Davy) (16.5 MVA)

Zimplats 1997 (2002) Three-electrode AC circular 12.5 MW 90 12 (O.D.) 1,200 Copper plate coolers

(Elkem/Hatch) (9–10 MW,

13.5 MVA)

Stillwater 1999 Three-in-line rectangular 5.0 MW (5.3 MVA) 150 9×5 305 Copper plate coolers

(Hatch)

1990–mothballed Three-in-line rectangular 1.5 MW (1.68 MVA) 150 7.5 × 2.6 305 Copper finger coolers

(Lectromelt)

Norilsk 1 Early 1940s 5 × six-in-line furnaces 75 MW

(3 working; 1 standby, (normal operation — — — —

1 repair) 45 MW)

2 × slag-cleaning electric 20 MW — — — —

furnaces (for converter

slag) (1 working,

1 standby)

6 × electric anode furnaces — — 20 t capacity 1,500 —

(3 graphite electrodes)

using coal for reduction

Norilsk 2 Early 1980s 2 × Outokumpu flash — — 245 m2 hearth area — —

1 × Vanyukov — — — — —

4 × 3-electrode slag- 18 MW each — — — —

cleaning furnaces (normally 8–11 MW)

1 × slag-cleaning — — — — —

rotating vessel

4 × rotating anode furnaces — — — — —

Norilsk 3 — 2 × Vanyukov — — 15.6 × 2.3 hearth — —

1 × Vanyukov — — 20 m hearth area

2

— —

reverb — — 250 m2 hearth area — —

reverb — — 92 m2 hearth area — —

4 × reverb anode — — — — —

furnaces (green poles

for reduction)

* All furnaces are electric except those of Norilsk.

ing and subsequent treatment by slow their furnaces and converting operations direct current arc furnace.5,6 This process

cooling and magnetic separation prior provides operational flexibility as well has been implemented on a large-scale

to refining can take place. (Converter as offering a range of siting possibilities continuous demonstration basis.6 The

and smelter data by PGM producer are for future expansions. ConRoast process eliminates many

shown in Tables V and VI, respectively.) Matte smelting has been in use for the of the traditional constraints on feed

Furnace matte from all three of its smelt- production of PGMs for many decades, composition and also has environmental

ers is treated in the Anglo Platinum but new processes continue to emerge. advantages in the control of SO2 emis-

Converting Process (ACP) that uses (Furnace information by PGM producer sions.

Sirosmelt submerged lance technology is shown in Table VII.) An alternative Tables IV through VII provide further

from Ausmelt with copper waffle coolers PGM smelting process has recently details about PGM producers, including

from Hatch. This strategy of decoupling been developed using alloy smelting in a furnace and converter data.

62 2004 December • JOM

Table VII. PGM Furnace Data

Concentrate Energy Consumption, Slag Tapping Matte Tapping PGM

Smelting kWh/t of Temperature Temperature Matte Fall** Concentrate

Rate (t/h) Concentrate (°C) (°C) (%) Grade (g/t)

71 (total for both furnaces) 700 1,550 — 22 150

Combined with above total 700 1,550 — 22 150

— — — — — —

20 820–850 1,650 1,550 15 145

87 capacity 800–850 1,600 1,550 15 150–200

92 (total for both furnaces) 720 1,460 1,300 12 130

combined with above total 720 1,460 1,300 12 130

— — — — — —

— — — — — —

30 850 1,600–1,650 1,500–1,550 14 300–350

— 880 — — — —

— 1,270 — — — —

10 1,044 1,485 1,385 18 130

10 750–850 1,580 1,420 12 75

5.0 850–950 1,500–1,550 1,150–1,250 14–25 600–1,200

1.3 900–1,000 — — — —

— — — — — —

— — — — — —

— — — — — —

135–180 (each) — — — — —

— — — — — —

— — — — — —

— — — — — —

— — — — — —

— — — — — —

— — — — — —

— — — — — —

— — — — — —

— — — — — —

** Matte fall is the mass of matte relative to the mass of the original concentrate feed.

ACKNOWLEDGEMENTS 3. R.T. Jones, “Platinum Smelting in South Africa,” of the International Platinum Conference, ‘Platinum

South African Journal of Science, 95 (November/ Adding Value’ (Johannesburg, South Africa: The

This paper is published by permission December 1999), pp. 525–534; www.mintek.co.za/ South African Institute of Mining and Metallurgy,

Pyromet/Files/Platinum.pdf. 2004), pp. 33–36; www.mintek.co.za/Pyromet/Files/

of Mintek. The assistance of many friends 4. A.M. Edwards and M.H. Silk, Platinum in South 2004JonesConSmelt.pdf.

and colleagues in the platinum industry Africa, Special Publication No. 12 (Randburg, South

is gratefully acknowledged. Africa: Mintek, 1987).

5. R.T. Jones, “ConRoast: DC Arc Smelting of Dead- Rodney T. Jones is a specialist consultant with

Roasted Sulphide Concentrates,” Sulfide Smelting Mintek in Randburg, South Africa.

References

2002, ed. R.L. Stephens and H.Y. Sohn (Warrendale,

1. C.F. Vermaak, The Platinum-Group Metals: A Global PA: TMS, 2002), pp. 435–456; www.mintek.co.za/ For more information, contact R.T. Jones, Mintek,

Perspective (Randburg, South Africa: Mintek, 1995). Pyromet/Files/ConRoast.pdf. Private Bag X3015, Randburg, 2125, South Africa;

2. T. Kendall, Platinum 2004 (London, England: 6. R.T. Jones and I.J. Kotzé, “DC Arc Smelting of +27-11-709-4602; fax +27-11-793-6241; e-mail

Johnson Matthey, 2004), www.platinum.matthey.com. Difficult PGM-Containing Feed Materials,” Proceedings rtjones@global.co.za.

2004 December • JOM 63

You might also like

- British Hallmarks For Gold, Platinum and Silver.Document20 pagesBritish Hallmarks For Gold, Platinum and Silver.AFLAC ............100% (5)

- Chapter 17Document13 pagesChapter 17Amit WadhelNo ratings yet

- Theory of Non-Ferrous Metals and Alloys ProcessingDocument83 pagesTheory of Non-Ferrous Metals and Alloys ProcessingHimanshuDeepNo ratings yet

- Waterglass - and PhosphatesDocument4 pagesWaterglass - and PhosphatesChris BothaNo ratings yet

- AfriSam Cement ManualDocument3 pagesAfriSam Cement ManualChris BothaNo ratings yet

- SANS 241: 2006 (Ed. 6) Drinking Water Quality RequirementsDocument3 pagesSANS 241: 2006 (Ed. 6) Drinking Water Quality RequirementsChris BothaNo ratings yet

- Gold Bar ManufacturersDocument8 pagesGold Bar ManufacturersedwardianirfanNo ratings yet

- An Overview of Southern African PGM Smelting: Mintek Private Bag X3015, Randburg, 2125, South AfricaDocument32 pagesAn Overview of Southern African PGM Smelting: Mintek Private Bag X3015, Randburg, 2125, South AfricaKyle AprilNo ratings yet

- Production of Fe-Cr-Ni-Mn Alloy by Direct Smelting of Mixed Low-Grade Chromite, Nickel Laterite and Manganese Ores With Low - Grade Coal As ReductantDocument12 pagesProduction of Fe-Cr-Ni-Mn Alloy by Direct Smelting of Mixed Low-Grade Chromite, Nickel Laterite and Manganese Ores With Low - Grade Coal As ReductantTJPRC PublicationsNo ratings yet

- Business of Rare Earth ElementsDocument6 pagesBusiness of Rare Earth ElementsAnanthNo ratings yet

- Metals From Ores: An Introduction: CRI SONDocument8 pagesMetals From Ores: An Introduction: CRI SONSaumya Subhra NandiNo ratings yet

- Lead & Zinc - 2013Document25 pagesLead & Zinc - 201320JE0112 Amar SinghNo ratings yet

- Metal Ores 2Document21 pagesMetal Ores 2Chemistry DepartmentNo ratings yet

- Characterizing and Recovering The Platinum Group Minerals - A ReviewDocument19 pagesCharacterizing and Recovering The Platinum Group Minerals - A ReviewSlim Kat NkosiNo ratings yet

- Metals & Non-Metals Class VIIIDocument30 pagesMetals & Non-Metals Class VIIIAnil KumarNo ratings yet

- Iron and Ferro-Aloy Metals: Chromium CobaltDocument3 pagesIron and Ferro-Aloy Metals: Chromium CobaltAmgalanbaatarJargalsaikhanNo ratings yet

- Exploitation and Development of Non MetaDocument53 pagesExploitation and Development of Non MetaVavania MNo ratings yet

- 300 000 064 529 PDFDocument9 pages300 000 064 529 PDFBlanca GonzalezNo ratings yet

- Minerals in A Smartphone Poster PDFDocument1 pageMinerals in A Smartphone Poster PDFMauricio MmlNo ratings yet

- Metal Recovery From Waste SludgesDocument7 pagesMetal Recovery From Waste SludgesHugo WizenbergNo ratings yet

- Paper - 653Document12 pagesPaper - 653Levent ErgunNo ratings yet

- MDSW Orissa04Document1 pageMDSW Orissa04miningnova1No ratings yet

- Afghanistan MineralsDocument101 pagesAfghanistan MineralsKhan MohammadNo ratings yet

- Processing of Indium A ReviewDocument8 pagesProcessing of Indium A Reviewpmanquera89No ratings yet

- Unit-13 Metallic MineralDocument30 pagesUnit-13 Metallic MineralANIMESHNo ratings yet

- Lectures Up To 6-FebDocument125 pagesLectures Up To 6-Febaryan.cognizanceNo ratings yet

- Chapter 3 PGM GuideDocument10 pagesChapter 3 PGM Guidetanaka nyamandiNo ratings yet

- Zircon 4Document7 pagesZircon 4Lorie BankaNo ratings yet

- Sulfuric Acid Leaching of Kab Amiri Niobium-Tantalum Bearing Minerals, Central Eastern Desert, EgyptDocument11 pagesSulfuric Acid Leaching of Kab Amiri Niobium-Tantalum Bearing Minerals, Central Eastern Desert, EgyptAline FerreiraNo ratings yet

- StatisticalSummary1952 1957 PDFDocument388 pagesStatisticalSummary1952 1957 PDFTHE FORUMNo ratings yet

- Chemistry: Metall RgyDocument136 pagesChemistry: Metall Rgymukesh kannaNo ratings yet

- Origin of Iron OresDocument22 pagesOrigin of Iron OresdeshmukhgeolNo ratings yet

- Antimony PDFDocument6 pagesAntimony PDFRinaOktapianiNo ratings yet

- Mineralogi Lateritic NickelDocument56 pagesMineralogi Lateritic NickelMilky LalisaNo ratings yet

- Control of Radioactivity at The Luxembourg Steel - Making FacilitiesDocument12 pagesControl of Radioactivity at The Luxembourg Steel - Making FacilitiesBoujemaa DrifNo ratings yet

- Lithium and Lithium CompoundsDocument38 pagesLithium and Lithium CompoundsNancy ParvinaNo ratings yet

- Carbon, 2. Diamond: TTO Ohler Abriele Utsch Erdinand Von Turm Rhard EGEDocument17 pagesCarbon, 2. Diamond: TTO Ohler Abriele Utsch Erdinand Von Turm Rhard EGEMujtaba AbbasNo ratings yet

- The Mineral Sands Industry Factbook (Feb 2014)Document25 pagesThe Mineral Sands Industry Factbook (Feb 2014)Victor ChanNo ratings yet

- Aluminium Recovery Process and It's EfficiencyDocument30 pagesAluminium Recovery Process and It's EfficiencyThambidurai KNo ratings yet

- Platinum Group Element Development: Retrospective Analysis ofDocument5 pagesPlatinum Group Element Development: Retrospective Analysis ofTony GaryNo ratings yet

- Replacement of Copper Slag With Fine AggDocument4 pagesReplacement of Copper Slag With Fine Aggmathewmthomas97No ratings yet

- Unit 1Document28 pagesUnit 1ryushinigami49No ratings yet

- ICSE Geography ProjectDocument28 pagesICSE Geography ProjectAditya KasaudhanNo ratings yet

- Alloys Used in ProsthodonticsDocument93 pagesAlloys Used in ProsthodonticsAiswarya MishraNo ratings yet

- Sensor-Based Ore Sorting Technology in MiningDocument25 pagesSensor-Based Ore Sorting Technology in MiningW ZuoNo ratings yet

- Basics in Mineral Processing-IntroductionDocument5 pagesBasics in Mineral Processing-Introductionmakedo33No ratings yet

- A01 481Document47 pagesA01 481jaimeNo ratings yet

- Materials Platinum Part 1 - TeachersnotesDocument3 pagesMaterials Platinum Part 1 - TeachersnotesGagandeep KaurNo ratings yet

- Assignment 1Document35 pagesAssignment 1NitinSrivastavaNo ratings yet

- Pbl1 Transition ElementDocument13 pagesPbl1 Transition ElementVincent Tie Wei WenNo ratings yet

- Upgrading of MN / Fe Ratio of Low-Grade Manganese Ore For Ferromanganese ProductionDocument10 pagesUpgrading of MN / Fe Ratio of Low-Grade Manganese Ore For Ferromanganese ProductionKarin AndersonNo ratings yet

- HKDSE Chemistry Bridging Programe 1CDocument76 pagesHKDSE Chemistry Bridging Programe 1Cthe222No ratings yet

- Rhodium Recovery and Recycling From Spent MaterialsDocument9 pagesRhodium Recovery and Recycling From Spent MaterialsLựuLiềuLìNo ratings yet

- The Metallurgy of Ni-Cr Alloys For Fixed ProsthodonticsDocument12 pagesThe Metallurgy of Ni-Cr Alloys For Fixed ProsthodonticsArushi AgarwalNo ratings yet

- REE - Rare Earth Elements: Home MetalsDocument10 pagesREE - Rare Earth Elements: Home MetalsMorkizgaNo ratings yet

- GBM907 12Document1 pageGBM907 12handriharyadiNo ratings yet

- Metals and Metallurgical PrinciplesDocument13 pagesMetals and Metallurgical PrinciplesManoj KhanalNo ratings yet

- Allotropes of CarbonDocument8 pagesAllotropes of CarbonBhimasen PradhanNo ratings yet

- Structure, Properties, Process, and Aplications of GoldDocument10 pagesStructure, Properties, Process, and Aplications of GoldMahfud EffendiNo ratings yet

- Secondary Sources of Non-Ferrous MetalsDocument35 pagesSecondary Sources of Non-Ferrous MetalsNitinSrivastava100% (1)

- Dolomite PDFDocument15 pagesDolomite PDFsantoshNo ratings yet

- DOLOMITEDocument15 pagesDOLOMITEsantoshNo ratings yet

- 92 Practice Questions From 2 Chapters of Inorganic Chemistry MetallurgyDocument14 pages92 Practice Questions From 2 Chapters of Inorganic Chemistry MetallurgyAyush KullarkarNo ratings yet

- Dri 121117215636 Phpapp02 PDFDocument45 pagesDri 121117215636 Phpapp02 PDFSumit ModakNo ratings yet

- Mullite PropertiesDocument8 pagesMullite PropertiesChris BothaNo ratings yet

- Cromarty R.E - 1985Document43 pagesCromarty R.E - 1985Chris BothaNo ratings yet

- Dekro Painting GuideDocument115 pagesDekro Painting GuideChris BothaNo ratings yet

- Glass Bubbles Condensation White Paper-V1-CelumDocument5 pagesGlass Bubbles Condensation White Paper-V1-CelumChris BothaNo ratings yet

- 4092MCC Decorative BrochureDocument6 pages4092MCC Decorative BrochureChris BothaNo ratings yet

- Zircon DissosiationDocument2 pagesZircon DissosiationChris BothaNo ratings yet

- Deming 1Document38 pagesDeming 1Chris BothaNo ratings yet

- Expancel Microspheres BoudDocument14 pagesExpancel Microspheres BoudChris BothaNo ratings yet

- Review On Current Geopolymer As A Coating MaterialDocument12 pagesReview On Current Geopolymer As A Coating MaterialChris BothaNo ratings yet

- Characteristics of Sorel Cement Prepared From ImpuDocument5 pagesCharacteristics of Sorel Cement Prepared From ImpuChris BothaNo ratings yet

- Coatings With Solar Reflective Properties: - Nouryon Chemicals International B.VDocument41 pagesCoatings With Solar Reflective Properties: - Nouryon Chemicals International B.VChris BothaNo ratings yet

- Ratliperl: The Modern Solution For Energy Efficient BuildingDocument20 pagesRatliperl: The Modern Solution For Energy Efficient BuildingChris BothaNo ratings yet

- A Literature Review On Fiber Reinforced Geopolymer ConcreteDocument5 pagesA Literature Review On Fiber Reinforced Geopolymer ConcreteChris BothaNo ratings yet

- Subject: Furnace Refractory ReplacementDocument2 pagesSubject: Furnace Refractory ReplacementChris BothaNo ratings yet

- 1991 - Hinchliffe - Refactory Linings For BoilersDocument3 pages1991 - Hinchliffe - Refactory Linings For BoilersChris BothaNo ratings yet

- Lead-Acid Battery Recycling and The New Isasmelt ProcessDocument11 pagesLead-Acid Battery Recycling and The New Isasmelt ProcessChris BothaNo ratings yet

- 5586b6 PDFDocument2 pages5586b6 PDFChris BothaNo ratings yet

- Concrete, Plaster & Mortar Mixes: For BuildersDocument5 pagesConcrete, Plaster & Mortar Mixes: For BuildersChris BothaNo ratings yet

- Andalusite Based Raw Materials For Refractory Castable Properties and Application by F. Ahouanto D. Van Den Heever D. FrulliDocument6 pagesAndalusite Based Raw Materials For Refractory Castable Properties and Application by F. Ahouanto D. Van Den Heever D. FrulliChris Botha100% (1)

- Eaton Begerow Product Line LEVASIL en SDBDocument12 pagesEaton Begerow Product Line LEVASIL en SDBChris BothaNo ratings yet

- Micro Silica and Placement PropertiesDocument11 pagesMicro Silica and Placement PropertiesChris BothaNo ratings yet

- The Meaning of CaratDocument4 pagesThe Meaning of CaratprofnileshmrunalNo ratings yet

- Gold Price Per Tola in United Kingdom in British Pound (GBP)Document1 pageGold Price Per Tola in United Kingdom in British Pound (GBP)6jqgrycygsNo ratings yet

- Commodities Span MarginDocument3 pagesCommodities Span MarginVikasNo ratings yet

- Commodity DIS - July 2011Document34 pagesCommodity DIS - July 2011ronak2484bhavsarNo ratings yet

- Platinum Deposit in Jharkhand Sate of India.Document3 pagesPlatinum Deposit in Jharkhand Sate of India.Dr. Nitish Priyadarshi100% (1)

- Binary Phase Diagrams For Selected Platinum Alloys: Supplementary DatasheetDocument2 pagesBinary Phase Diagrams For Selected Platinum Alloys: Supplementary DatasheetJulio GonzalezNo ratings yet

- Agree Not PaidDocument121 pagesAgree Not PaidIndah DestianiNo ratings yet

- Cabal - Red Droptables - Last Updated: 14/05/2019Document8 pagesCabal - Red Droptables - Last Updated: 14/05/2019JonathanTaclindoNo ratings yet

- What Are The Different Types of Gold in Jewelry?Document4 pagesWhat Are The Different Types of Gold in Jewelry?Abdul Rashid100% (2)

- GoldsmithDocument7 pagesGoldsmithKamala VermaNo ratings yet

- Bis Hallmarking SchemeDocument34 pagesBis Hallmarking SchemeAMBROSE ROYSONNo ratings yet

- Platinum Palladium Printing Edward Stapel Drop ChartDocument1 pagePlatinum Palladium Printing Edward Stapel Drop ChartEdward StapelNo ratings yet

- Gold Bullion Coins BookDocument386 pagesGold Bullion Coins BookpetiopetioNo ratings yet

- Data 1Document3,440 pagesData 1Amitash DeganNo ratings yet

- Entrepeneur'S Performance Level (E-P-L) : Volten Asiaemall SDN BHDDocument19 pagesEntrepeneur'S Performance Level (E-P-L) : Volten Asiaemall SDN BHDRikwan RikwanNo ratings yet

- Buy Gold Sharjah - Mint JewelsDocument1 pageBuy Gold Sharjah - Mint Jewelstubalmadina21.aeNo ratings yet

- Website Bar List 2012-06-11Document1,153 pagesWebsite Bar List 2012-06-11Silver DoctorsNo ratings yet

- The Guide: An Introduction To The Global Precious Metals OTC MarketDocument95 pagesThe Guide: An Introduction To The Global Precious Metals OTC MarketThiti Vanich100% (1)

- Brochure EngDocument2 pagesBrochure EngGustavo LafritolaNo ratings yet

- Historical Gold PricesDocument4 pagesHistorical Gold PricesshelterbNo ratings yet

- Jewelcraft Super Fast For GW2Document11 pagesJewelcraft Super Fast For GW2Jeremy SengNo ratings yet

- SANS29Document15 pagesSANS29Amenaw MulunehNo ratings yet

- Jrwheelspreseasonexport2019 PDFDocument3 pagesJrwheelspreseasonexport2019 PDFAnonymous sVHKQMzNo ratings yet

- Welcome To Tantaline - Chemical CompositionDocument5 pagesWelcome To Tantaline - Chemical CompositiontamorenoNo ratings yet

- Top Boarders On MoneycontrolDocument5 pagesTop Boarders On MoneycontrolYatrikNo ratings yet

- Bullion Price Sheet: Spot Gold: Spot SilverDocument3 pagesBullion Price Sheet: Spot Gold: Spot SilverKeithNo ratings yet

- Daftar Harga Power Supplay 2015Document26 pagesDaftar Harga Power Supplay 2015Syah J-RyanNo ratings yet

- Rosicrucian Supply Bureau, Revised Price List (1980)Document6 pagesRosicrucian Supply Bureau, Revised Price List (1980)Sauron386100% (1)