Professional Documents

Culture Documents

D From Exp Flitch Plates DeStefano Pac 5-10-071

D From Exp Flitch Plates DeStefano Pac 5-10-071

Uploaded by

Hassan A. GorayaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D From Exp Flitch Plates DeStefano Pac 5-10-071

D From Exp Flitch Plates DeStefano Pac 5-10-071

Uploaded by

Hassan A. GorayaCopyright:

Available Formats

From Experience

“how did you do that ? ”

Flitch Plate Beams

Design Guide ®

By Jim DeStefano, P.E.

E

The wood side pieces provide lateral support beams since these members contain three

Flitch plate beams have been

R

to the slender steel flitch plate and brace the wood pieces.

T

commonly used with wood frame steel against lateral buckling. The shear capacity indicated in Table 1 is

construction for over 75 years. With a flitch plate beam, the structural the shear strength of the wood alone since

U

Despite the popularity of these hybrid

F

load is shared between the steel plate and the full beam reaction must be transferred

structural elements, structural design the wood side pieces proportionally to their through the wood side pieces at end bearing

t©

t

guidance has been conspicuously

irgighInh order to structurally ana-

T

relative stiffness. supports.

y r

A

p p y

absent from engineering literature.

That is, up until now.

CCoo plate beam, transformed section

lyze a flitch The values in Table 1 are based on the steel

properties are used that treat the composite plate being A36 steel. This is a reasonable

R C

section as an equivalent wood member. The assumption since steel plates are not readily

F

litch plate beams are composite mem- section properties indicated in Table 1 are available in Grade 50 steel. Be sure when spec-

bers which combine the strength and based on the wood members being composed ifying flitch plates to indicate that the plate

e

D U

stiffness of structural steel with the ver- of Douglas Fir - Larch #2 as well as laminated is made of steel. Some builders believe that

n

satility of wood. A flitch plate is a steel plate veneer lumber (LVL). flitch plates can be made out of plywood.

i

R

that is sandwiched between pieces of framing The flexural strength of flitch plate beams

Bolting of Flitch Plates

z

lumber and bolted together. They are used in using Douglas Fir side pieces is controlled

by the bending stress in the wood, while the Adequate bolting is crucial to the perfor-

T

a similar manner to built-up wood girders or

headers in residential and light commercial

construction. Flitch plate beams are capable

a

strength of flitch plate beams using LVL side

pieces is controlled by the bending stress in

g

mance of flitch plate beams. Since the load is

applied to this composite beam through the

S

of achieving greater spans and supporting the steel. wood side pieces, the bolts must distribute

a

higher loads than built-up wood members. No load duration factor was applied to the that portion of the load that the steel plates

Unlike engineered wood beams, flitch plate allowable bending stress. The allowable stress will be carrying. At the beam end bearing

m

beams can be flush framed with dimension was adjusted by the appropriate size factor. A supports, only the wood side pieces rest on

lumber joists without causing shrinkage re- repetitive member factor was applied to the the supports. Consequently, bolts at the ends

lated distortions to the structure. allowable bending stress of double flitch plate of the beam must transfer the end reaction

from the plate to the wood.

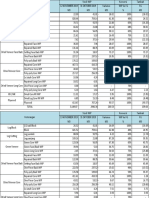

Flitch P

L Section Properties

lTR (in4) STR (in3) M(ft-lb) Msteel/M Vwood (lb) n Wood Steel

(2)–2x8 PL dx7 289 79.7 7,173 67% 2,610

E = 1,600,00 psi Fb = 900 psi

P

(2) –2x8 L 2x7 354 97.7 8,793 73% 2,610

Douglas Fir - Larch #2

(3) –2x8 (2) P

L 2x7 661 182.2 18,851 78% 3,915

(2)–2x10 P

L dx9 611 132.0 10,890 68% 3,330

(2)–2x10 P

L 2x9 748 161.7 13,340 74% 3,330

ASTM A36 Fy = 36 ksi

18.1

(3)–2x10 (2)– P

L 2x9 1,397 302.1 28,649 79% 4,995

(2)–2x12 P

L dx11 1,109 197.2 14,790 68% 4,050

(2)–2x12 P

L 2x11 1,361 241.9 18,142 74% 4,050

(3)–2x12 (2)– P

L2x11 2,543 452.1 38,994 79% 6,075

(2)–LVL 1:x92

715 158.9 20,776 64% 6,320

E=1,900,000 psi

P

Fb = 2,600 psi

L 2x9

(2)–LVL 1: x11f

1,337 243.1 31,784 64% 7,900 15.3

P

L 2x11

(2)–LVL 1:x14

2,549 364.0 47,593 69% 9,310

P

L 2x14

Table 1

STRUCTURE magazine 56 June 2007

Load is transferred between

the steel plate and the wood side

pieces by a combination of shear

through the bolts and friction

between the steel and wood.

The magnitude of the load

transferred through friction is a

function of the tightness of the ®

E

bolts. Washers should always

be used under the nuts. The

nuts should not be tightened

T R

to the extent that the wood

crushes under the bolt head or

washer. As the lumber seasons

F U

and shrinks, the bolt tension

and the friction forces will t©t

irgighh

T

y r

A

diminish. Because of this and pp y

the fact that determining the CCoo

C

magnitude of load transfer due

R

to friction between the wood

and steel cannot be calculated

e

U

with certainty, this bolt friction

D

contribution is usually neglected

in the calculations.

i n

R

Carriage bolts with either ½ or

e-inch diameter are commonly

z

T a

used with flitch plates. Larger

diameter bolts are not readily

g

available through lumber yards

S

or hardware stores. Figure 1: Empirical bolting pattern

The bolt holes should be drilled or

punched in the steel plate. Flame cut bolt

a

Bolts should not be positioned closer than standard bolting pattern for single and double

than the bolt diameter. m

holes do not allow uniform bearing for the 2 inches to the end or edge of the wood

bolt. Bolt holes should be 1/16 inch larger members for ½-inch diameter bolts and not

Where wallboard or wood trim is applied bolts.

closer than 2 ½ inches for e-inch diameter

flitch plate beams. The 16-inch spacing of

bolts insures that the bolt heads and nuts will

not interfere with joists which are also spaced

at 16 inches.

directly to the face of a flitch plate beam, it There are two methods for determining the Rational Method: The required bolt size

is desirable to counterbore the nuts into the required bolt size and spacing, the empirical and spacing is determined from structural

wood side pieces. Since counterboring reduces method and the rational method. calculations. The allowable bolt capacities

the amount of bearing for the bolt, the depth Empirical Method: A standard bolting are calculated based on the National Design

of the counterbore should not exceed the pattern is used which has performed Specification for Wood Construction (NDS).

thickness of the nut and washer. adequately in the past. Figure 1 indicates a The load carried by the steel plate is deter-

mined and uniformly spaced bolts are pro-

vided to transfer this load. The end reaction

Design Example on the steel plate is then calculated and bolts

are provided at the end of the beam to resist

this reaction. This method neglects the con-

(2)-2x10 & plate ½-inch x 9 inches - Douglas Fir - Larch #2 tribution from friction between the steel and

Span = 12 feet Uniform load = 700 plf the wood and, as a result, will yield conser-

Calculate the capacity of a ½-inch diameter bolt, with the load vative results.▪

perpendicular to the grain, per NDS 2005:

NDS Eq. 11.3-8 z = 945 lb Jim DeStefano, P.E., is the senior partner

Calculate the uniform load on the plate: with DeStefano Associates located in

Fairfield, CT. Jim can be reached at

700 plf x 74% (from Table 1) = 518 plf

jimd@destefanoassociates.com.

Calculate the uniform bolt spacing:

(945 / 518) x 12 inches = 21.9 inches >>>> Space bolts at 20 inches o.c.

Calculate the end reaction on the plate:

518 plf x 12 feet/2 = 3108 lb

Calculate the number of end bolts required:

Visit STRUCTURE® on-line

3108 / 945 = 3.29 >>>> Provide 4 bolts at each end of beam

www.STRUCTUREmag.org

STRUCTURE magazine 57 June 2007

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Residential Structural Design Guide REV7!20!12Document434 pagesResidential Structural Design Guide REV7!20!12joel100% (1)

- PGCIL Approved Suppliers PDFDocument9 pagesPGCIL Approved Suppliers PDFverma2100% (2)

- Report for Heston Builders Private Limited, TardeoDocument32 pagesReport for Heston Builders Private Limited, TardeomustafazahmedNo ratings yet

- Assumptions For RCC Structure Quantity CalculationDocument1 pageAssumptions For RCC Structure Quantity CalculationmustafazahmedNo ratings yet

- Institute of Aeronautical Engineering: Dundigal, Hyderabad - 500 043Document8 pagesInstitute of Aeronautical Engineering: Dundigal, Hyderabad - 500 043mustafazahmedNo ratings yet

- 1401 0101 Design Basis Report Ver 1Document22 pages1401 0101 Design Basis Report Ver 1mustafazahmedNo ratings yet

- Certificate For Mr. For - QUIZ COMPETITION ON ENVIRON...Document1 pageCertificate For Mr. For - QUIZ COMPETITION ON ENVIRON...mustafazahmedNo ratings yet

- Due Amount: We're ListeningDocument2 pagesDue Amount: We're ListeningmustafazahmedNo ratings yet

- Marvel ConsultantDocument3 pagesMarvel ConsultantmustafazahmedNo ratings yet

- Generalized Hooke'S Law: 1 - A FigDocument1 pageGeneralized Hooke'S Law: 1 - A FigmustafazahmedNo ratings yet

- Me CivilDocument5 pagesMe CivilmustafazahmedNo ratings yet

- Received With Thanks ' 15,160.68 Through Payment Gateway Over The Internet FromDocument1 pageReceived With Thanks ' 15,160.68 Through Payment Gateway Over The Internet FrommustafazahmedNo ratings yet

- Irjet V5i8206 PDFDocument7 pagesIrjet V5i8206 PDFmustafazahmedNo ratings yet

- List of BMC Schools in MumbaiDocument102 pagesList of BMC Schools in MumbaimustafazahmedNo ratings yet

- Halal Housing Almond Acres PDFDocument9 pagesHalal Housing Almond Acres PDFmustafazahmedNo ratings yet

- MPP Design and Construction GuideDocument28 pagesMPP Design and Construction GuideGisele PaimNo ratings yet

- H815 Design of All-Plywood BeamsDocument29 pagesH815 Design of All-Plywood BeamsbabshuagNo ratings yet

- US Lumber ManufacturerDocument80 pagesUS Lumber ManufacturerGillian ZhangNo ratings yet

- AHE ECO-ZEN Wood Composite Catalog - 09-07-2019Document21 pagesAHE ECO-ZEN Wood Composite Catalog - 09-07-2019Ronald WongNo ratings yet

- TJ 7003Document2 pagesTJ 7003Vidyadhar BommeriNo ratings yet

- Master PlanckDocument2 pagesMaster PlanckhcabanillaspNo ratings yet

- PHRC Research Report Structural Design of CLT HomeDocument53 pagesPHRC Research Report Structural Design of CLT HomeJulian TumielewiczNo ratings yet

- HANYO BIOWOOD Catalog For Online 1 PDFDocument110 pagesHANYO BIOWOOD Catalog For Online 1 PDFHorstNo ratings yet

- TFM - Xueting ZhangDocument208 pagesTFM - Xueting ZhangJavierNo ratings yet

- EJOT WoodscrewsDocument18 pagesEJOT WoodscrewssebkahnNo ratings yet

- Vivre Louvers by Vivre PanelsDocument83 pagesVivre Louvers by Vivre PanelsAnkit JaiswalNo ratings yet

- Veneer, Particle Board, Plywood, Fiber BoardDocument23 pagesVeneer, Particle Board, Plywood, Fiber BoardRatnesh PatelNo ratings yet

- LP Solidstart I-Joists Residential Construction: Canadian (LSD) Technical GuideDocument28 pagesLP Solidstart I-Joists Residential Construction: Canadian (LSD) Technical GuidepghasaeiNo ratings yet

- Measurement Form of An T.W.Partition: Name of Work: FURNITUREDocument4 pagesMeasurement Form of An T.W.Partition: Name of Work: FURNITUREakshay salviNo ratings yet

- List of MillsDocument342 pagesList of MillsKrishan KakkarNo ratings yet

- Listofmills 0Document405 pagesListofmills 0Wilfried P. Hermann KinayaNo ratings yet

- Vitenam Export To USA HSN 94 (Repaired)Document3,016 pagesVitenam Export To USA HSN 94 (Repaired)The Cultural CommitteeNo ratings yet

- Works: All Types ofDocument65 pagesWorks: All Types ofAzahar Uddin MallickNo ratings yet

- Alternatives To Wood Packaging MaterialDocument2 pagesAlternatives To Wood Packaging Materialcole santosNo ratings yet

- APA Engineered Wood Construction Guide Excerpt Cross-Laminated Timber (CLT) Selection and Specification PDFDocument4 pagesAPA Engineered Wood Construction Guide Excerpt Cross-Laminated Timber (CLT) Selection and Specification PDFAbdurrahman CinarNo ratings yet

- Specs - Outline OnlyDocument3 pagesSpecs - Outline OnlyKenneth Ignacio ArcillaNo ratings yet

- Plywood Moe MorDocument1 pagePlywood Moe MorellisblNo ratings yet

- Technical Guide For The Design and Construction of Tall Wood Buildings in CanadaDocument510 pagesTechnical Guide For The Design and Construction of Tall Wood Buildings in CanadaDeniza Kirilova KostadinovaNo ratings yet

- Engineered Wood Flooring VsDocument3 pagesEngineered Wood Flooring VsMathew Joel MathewNo ratings yet

- Particle Wood ManufactureDocument43 pagesParticle Wood ManufactureMicah Juguan Salgado100% (2)

- Wood Technology: Introduction ToDocument4 pagesWood Technology: Introduction ToThe Physics SocietyNo ratings yet

- WIPDocument3 pagesWIPAris SusantoNo ratings yet