Professional Documents

Culture Documents

Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Properties

Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Properties

Uploaded by

Nibin OdukkathilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Properties

Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Properties

Uploaded by

Nibin OdukkathilCopyright:

Available Formats

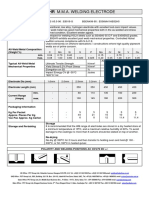

COVERED (STICK) ELECTRODES (SMAW)

LOW ALLOY ELECTRODES

OK 74.46

OK 74.46 is an LMA electrode alloyed with 0.5% Mo for welding steels for pressure vessels. The running characteristics make it suitable for welding joints in inclined

positions. The composition of the coating is adapted for welding with low currents, making OK 74.46 very suitable for the welding of pipes.

Classifications SFA/AWS A5.5 : E7018-A1

EN ISO 3580-A : E Mo B 3 2 H5

Approvals CE EN 13479

DB 10.039.45

VdTÜV 01043

Approvals are based on factory location. Please contact ESAB for more information.

Welding Current AC, DC+

Diffusible Hydrogen < 5ml/100g

Alloy Type Low alloyed (0.5 % Mo)

Coating Type Basic covering

Typical Tensile Properties

Condition Yield Strength Tensile Strength Elongation

ISO

PWHT 460 MPa 560 MPa 27 %

AWS

Typical Charpy V-Notch Properties

Condition Testing Temperature Impact Value

ISO

PWHT 1hr 620°C 20 °C 175 J

Typical Weld Metal Analysis %

C Mn Si Cr Mo

0.05 0.77 0.38 0.04 0.57

Deposition Data

Diameter Current Voltage kg weld metal/kg Number of Fusion time per Deposition Rate

electrodes electrodes/ electrode at 90% I

kg weld metal max

2.0 x 300 mm 55-80 A 22 V 0.59 136.0 40 sec 0.7 kg/h

2.5 x 350 mm 75-110 A 23 V 0.59 73.0 55 sec 0.9 kg/h

3.2 x 350 mm 105-150 A 23 V 0.54 53 66 sec 1 kg/h

3.2 x 450 mm 105-150 A 25 V 0.59 37.0 81 sec 1.2 kg/h

4.0 x 450 mm 140-200 A 26 V 0.65 22.5 90 sec 1.8 kg/h

5.0 x 450 mm 190-270 A 27 V 0.65 14.5 104 sec 2.4 kg/h

410068-en_WW-FactSheet_Main-01 2021-03-18

esab.com/fillermetals

You might also like

- Manual de Bobcat 943Document372 pagesManual de Bobcat 943axel ramirez lopezNo ratings yet

- Steel Grade Equivalents Guide - HillfootDocument5 pagesSteel Grade Equivalents Guide - HillfootNibin OdukkathilNo ratings yet

- 12 Tig WeldingDocument8 pages12 Tig WeldingSampath KumarNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile Propertiescorsini999No ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel Electrodestarun kaushalNo ratings yet

- en GB FactSheet Main 01Document1 pageen GB FactSheet Main 01Chandra YudistiraNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesKrishna VachaNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoNo ratings yet

- Covered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Mild Steel Electrodes: Typical Tensile PropertiesKannan MurugesanNo ratings yet

- ESABDocument1 pageESABXQNo ratings yet

- OK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesDocument1 pageOK Weartrode 30: Covered (Stick) Electrodes (Smaw) Hardfacing Electrodesraghubhaimantra4136No ratings yet

- F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageF For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationTolga UZUNERNo ratings yet

- Pipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pagePipeweld 6010 Plus: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesRys Multiventas SacNo ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesXQNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- WeartrodDocument1 pageWeartrodBhavik PatelNo ratings yet

- Exaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageExaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel Electrodessergio jose morales perazaNo ratings yet

- Ficha Tecnica Esab Electrodos EspecialesDocument1 pageFicha Tecnica Esab Electrodos EspecialesStanley RamirezNo ratings yet

- Ok 74.86 Tensitrode: A Basic Coated Electrode For Steels and Castings With U.T.S. of Min. 690 MpaDocument1 pageOk 74.86 Tensitrode: A Basic Coated Electrode For Steels and Castings With U.T.S. of Min. 690 Mpamitesh prajapatiNo ratings yet

- Glaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiDocument2 pagesGlaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiKiranNo ratings yet

- Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageCovered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesMohammad AdilNo ratings yet

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationDocument1 pageTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More Informationw elhaj abdallaNo ratings yet

- Ok Ni-Ci: Repair and Maintenance Cast Iron AlloysDocument1 pageOk Ni-Ci: Repair and Maintenance Cast Iron AlloysAmR ZakiNo ratings yet

- Esab 28: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pageEsab 28: Covered (Stick) Electrodes (Smaw) Mild Steel Electrodesraghubhaimantra4136No ratings yet

- FICHADocument2 pagesFICHAadmisecoinperuNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesdarmawan listyonoNo ratings yet

- Atom Arc 8018Document2 pagesAtom Arc 8018Jagan TnNo ratings yet

- Covered (Stick) Electrodes (Smaw) Nickel Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Nickel Alloy Electrodes: Typical Tensile PropertiesKaung Sett LynnNo ratings yet

- Tenalloy 125: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 125: LOW ALLOY STEEL (High Strength)satnamNo ratings yet

- Esab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument1 pageEsab Ferroweld 1: Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesraghubhaimantra4136No ratings yet

- EN 14700: E Z Fe1: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesDocument1 pageEN 14700: E Z Fe1: Covered (Stick) Electrodes (Smaw) Hardfacing ElectrodesKARLNo ratings yet

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- Supabase-X-Plus AdorDocument1 pageSupabase-X-Plus AdorJagan TnNo ratings yet

- Wb56S M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb56S M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- Electrode Booklet F Web 23Document1 pageElectrode Booklet F Web 23satnamNo ratings yet

- Wire Wound Fixed Resistors: FeaturesDocument7 pagesWire Wound Fixed Resistors: FeaturesteoilcaNo ratings yet

- Pinnacle Alloys E7018 E7018 1Document2 pagesPinnacle Alloys E7018 E7018 1BerniIrleNo ratings yet

- Sureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesDocument1 pageSureweld 6010: Covered (Stick) Electrodes (Smaw) Mild Steel ElectrodesGibbs PerNo ratings yet

- Electrode Booklet F Web 24Document1 pageElectrode Booklet F Web 24satnamNo ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet

- Aristo Rod 55Document1 pageAristo Rod 55joao guilhermeNo ratings yet

- X Bond: Welding Electrode For Structural Welding ApplicationDocument1 pageX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainNo ratings yet

- Nimoten: LOW ALLOY STEEL (Nimoten Series)Document1 pageNimoten: LOW ALLOY STEEL (Nimoten Series)satnamNo ratings yet

- Wb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.ukDocument1 pageWb88Shr M.M.A. Welding Electrode: Welding@wballoys - Co.uklathasri78No ratings yet

- W Section 1 Mma Welding Saf Fro General Catalogue68475045296859596Document8 pagesW Section 1 Mma Welding Saf Fro General Catalogue68475045296859596sarahrouNo ratings yet

- CM-9CB TG-S9Cb US-9CbDocument3 pagesCM-9CB TG-S9Cb US-9Cbamit singhNo ratings yet

- Tenalloy Z PlusDocument1 pageTenalloy Z Plushemal ChauhanNo ratings yet

- Classifications: Approvals:: Typical Tensile PropertiesDocument1 pageClassifications: Approvals:: Typical Tensile PropertiesAchraf BoudayaNo ratings yet

- Bohler S EMK 6Document1 pageBohler S EMK 6Enaam AtaallahNo ratings yet

- 1SMB5913B - 1SMB5956B: Silicon Zener DiodesDocument3 pages1SMB5913B - 1SMB5956B: Silicon Zener Diodesanurag2006agarwalNo ratings yet

- Electrode Booklet F Web 85Document1 pageElectrode Booklet F Web 85satnamNo ratings yet

- Celwel - 70P (Ador Electrodes)Document1 pageCelwel - 70P (Ador Electrodes)Harish KandollaNo ratings yet

- Ebondm: Mild Steel General Purpose (MSGP)Document1 pageEbondm: Mild Steel General Purpose (MSGP)satnamNo ratings yet

- OK Tigrod 13.32Document1 pageOK Tigrod 13.32Paulo CorreiaNo ratings yet

- Wb2092e E7024Document1 pageWb2092e E7024cwiksjNo ratings yet

- Tenalloy 120G: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 120G: LOW ALLOY STEEL (High Strength)Devender NegiNo ratings yet

- Electrode E8018 DetailsDocument1 pageElectrode E8018 DetailskapsarcNo ratings yet

- Electrode Booklet F Web 20Document1 pageElectrode Booklet F Web 20satnamNo ratings yet

- Electrode Booklet F Web 21Document1 pageElectrode Booklet F Web 21satnamNo ratings yet

- 1 Updated Section E - AxleDocument58 pages1 Updated Section E - AxleNibin Odukkathil100% (2)

- Product Catalogue: Axle ComponentsDocument78 pagesProduct Catalogue: Axle ComponentsNibin Odukkathil100% (1)

- MCB 1P 6ka C-20A 1M: ArchitectureDocument3 pagesMCB 1P 6ka C-20A 1M: ArchitectureNibin OdukkathilNo ratings yet

- IMSB Mechanical Suspensions KPM 002 0310rev11Document17 pagesIMSB Mechanical Suspensions KPM 002 0310rev11Nibin OdukkathilNo ratings yet

- Axle Maintenance KPM 004 0310 Rev12 1Document8 pagesAxle Maintenance KPM 004 0310 Rev12 1Nibin OdukkathilNo ratings yet

- Product Catalogue: Axle ComponentsDocument10 pagesProduct Catalogue: Axle ComponentsNibin OdukkathilNo ratings yet

- Product Data Sheet: MCB 1P 6ka C-32A 1MDocument3 pagesProduct Data Sheet: MCB 1P 6ka C-32A 1MNibin OdukkathilNo ratings yet

- Booking Confirmation - VOX Cinemas UAEDocument3 pagesBooking Confirmation - VOX Cinemas UAENibin OdukkathilNo ratings yet

- Morse Modern Technical LLC: TEL: 00971-2-5541886 FAX: 00971-2-5541813Document1 pageMorse Modern Technical LLC: TEL: 00971-2-5541886 FAX: 00971-2-5541813Nibin OdukkathilNo ratings yet

- Axle Maintenance KPM 004 0310 Rev12 1Document8 pagesAxle Maintenance KPM 004 0310 Rev12 1Nibin OdukkathilNo ratings yet

- Landing Legs KPM 002 0612rev7Document4 pagesLanding Legs KPM 002 0612rev7Nibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Alloy Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Hydraulic Complete Inch GB enDocument338 pagesHydraulic Complete Inch GB enNibin OdukkathilNo ratings yet

- Pure Savings On Your New Mashreq Credit Card!: Offer A DetailsDocument4 pagesPure Savings On Your New Mashreq Credit Card!: Offer A DetailsNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Hydrostatic Test PDFDocument1 pageHydrostatic Test PDFNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Work Completion Certificate: To Whom It May ConcernDocument1 pageWork Completion Certificate: To Whom It May ConcernNibin Odukkathil0% (1)

- Resignation LetterDocument1 pageResignation LetterNibin OdukkathilNo ratings yet

- No Visitors PDFDocument1 pageNo Visitors PDFNibin OdukkathilNo ratings yet

- Resignation LetterDocument1 pageResignation LetterNibin OdukkathilNo ratings yet

- Min. 2 To Max. 4 No'S Coverall at One Time: NoticeDocument1 pageMin. 2 To Max. 4 No'S Coverall at One Time: NoticeNibin OdukkathilNo ratings yet

- Devicenet Communication Manual - 2Nd Edition: Smt-DnetDocument29 pagesDevicenet Communication Manual - 2Nd Edition: Smt-Dnetjroyal692974No ratings yet

- APlus Catalog - A675H-676H-678HDocument1 pageAPlus Catalog - A675H-676H-678HNgọc TrầnNo ratings yet

- Frame Scaffolding: The Leader in Scaffold ServicesDocument16 pagesFrame Scaffolding: The Leader in Scaffold ServicesrisaNo ratings yet

- Prosurge UL CertificateDocument13 pagesProsurge UL CertificateROMEL ENRIQUE LOLI SALCEDONo ratings yet

- Solid Waste Management ProjectDocument12 pagesSolid Waste Management ProjectShahbaz Nasir KhanNo ratings yet

- Manual de Operación y Mantenimiento PDFDocument49 pagesManual de Operación y Mantenimiento PDFJairresistenciagt123No ratings yet

- New York State and Municipal Facilities Program Project NominationDocument1,579 pagesNew York State and Municipal Facilities Program Project NominationNew York SenateNo ratings yet

- TheDynamicConePenetrationTest ModifyDocument17 pagesTheDynamicConePenetrationTest ModifyInfo MilestoneNo ratings yet

- SEG Daniel Santander 05Document24 pagesSEG Daniel Santander 05Daniel Rodriguez santanderNo ratings yet

- 50 - 48 - Uc - Up - 25-90 PSDDocument7 pages50 - 48 - Uc - Up - 25-90 PSDdanielrosas17No ratings yet

- Thermo - First Second LawDocument35 pagesThermo - First Second LawPengintaiNo ratings yet

- Concrete Tech AssignmentDocument7 pagesConcrete Tech AssignmentShehan FernandoNo ratings yet

- 5S Color Chart: Equipment SafetyDocument1 page5S Color Chart: Equipment SafetyOP AryaNo ratings yet

- FSM Testing 1Document45 pagesFSM Testing 1Ragini GuptaNo ratings yet

- Senasa - IcaoDocument13 pagesSenasa - Icaofarellano89No ratings yet

- Toshiba: WLT66 SeriesDocument40 pagesToshiba: WLT66 Seriesdrone001No ratings yet

- Curriculum VitDocument4 pagesCurriculum Vit1dzrbtcom ProfessionalprogramminglanguageNo ratings yet

- Mo (3330502) Final AssignmentDocument8 pagesMo (3330502) Final Assignmentapi-269508649100% (3)

- WD Hearn Tooling Catalogue 2020Document109 pagesWD Hearn Tooling Catalogue 2020Dipal PracaschandraNo ratings yet

- Numerical Derivatives Scilab 2Document59 pagesNumerical Derivatives Scilab 2Alejandro MoncadaNo ratings yet

- SL 264 - PS 835 - Battery ReplacementDocument2 pagesSL 264 - PS 835 - Battery ReplacementIndiomarcio GhelardiNo ratings yet

- Junaid Hassan Muhammad Khalid: Notes byDocument44 pagesJunaid Hassan Muhammad Khalid: Notes byShahid AzizNo ratings yet

- Nano Fiber Reinforcement Polymers Prepared by Fused Deposition ModelingDocument10 pagesNano Fiber Reinforcement Polymers Prepared by Fused Deposition ModelingsandeepNo ratings yet

- E-Catalogue Insulator - Page 43 PDFDocument90 pagesE-Catalogue Insulator - Page 43 PDFparveen115100% (2)

- Smart HELMET: DescriptionDocument4 pagesSmart HELMET: DescriptionMaruthi JacsNo ratings yet

- Loader Crane: PK 53002 SHDocument23 pagesLoader Crane: PK 53002 SHFabian RamirezNo ratings yet

- SlabsOnGrade - Ppthandout ACI 360Document7 pagesSlabsOnGrade - Ppthandout ACI 360Ivan Pacompia Calcina50% (2)

- Hci Unit 3Document18 pagesHci Unit 3Takkallapelly SaitejaNo ratings yet