Professional Documents

Culture Documents

METHOD STATEMENT Sluice Gates Install

METHOD STATEMENT Sluice Gates Install

Uploaded by

jameelCopyright:

Available Formats

You might also like

- Method Statement For FRP Tank Panel ReplacementDocument8 pagesMethod Statement For FRP Tank Panel ReplacementJawNo ratings yet

- Method Statement - Erection, Installation of Above Ground Piping - POXDocument11 pagesMethod Statement - Erection, Installation of Above Ground Piping - POXHabib ur rahmanNo ratings yet

- Method Statement Water Supply Line Tie in Point Re-RoutingDocument17 pagesMethod Statement Water Supply Line Tie in Point Re-RoutingShyju Melepurath83% (6)

- Method Statement For Road Crossing Works For Duct Bank - D2Document1 pageMethod Statement For Road Crossing Works For Duct Bank - D2MidhunRameshThuvassery100% (2)

- Method Statement For Dismantling of Cable TrunkingDocument1 pageMethod Statement For Dismantling of Cable TrunkingBento Box100% (1)

- Method Statement Pressure GroutingDocument2 pagesMethod Statement Pressure GroutingStephen David Gozun100% (7)

- Method Statement For Removing and Installation of Tanks & Pipping WorkDocument7 pagesMethod Statement For Removing and Installation of Tanks & Pipping WorkM Waqas Habib100% (1)

- Method Statement For Site OfficeDocument18 pagesMethod Statement For Site OfficeMuhammad TeguhNo ratings yet

- Method Statement For Chamber Construction of TSE Line Ev ManagerDocument20 pagesMethod Statement For Chamber Construction of TSE Line Ev ManagerBleep News100% (1)

- Method Statement River CrossingDocument2 pagesMethod Statement River CrossingDeny Cahyo N0% (1)

- Method Statement For Clearing and Grubbing (For Review) 12-7-2020Document17 pagesMethod Statement For Clearing and Grubbing (For Review) 12-7-2020Researcher100% (2)

- Method Statement For Leak Rectification WorksDocument7 pagesMethod Statement For Leak Rectification Worksgiri943No ratings yet

- Method Statement For Laying GeomembraneDocument6 pagesMethod Statement For Laying GeomembraneMhando IgnasNo ratings yet

- Method Statement For Ground Improvement (Removal & Replacement) at Approach of VBC Kg. Titi Besi (CH 232.457)Document7 pagesMethod Statement For Ground Improvement (Removal & Replacement) at Approach of VBC Kg. Titi Besi (CH 232.457)MAYMODERN STEELNo ratings yet

- ITP Temporary HoardingDocument1 pageITP Temporary HoardingMohd Azrin100% (1)

- C4M Mivan FormworkDocument3 pagesC4M Mivan Formworkmanohar reddyNo ratings yet

- Method Statement 14728983812691479973057231Document6 pagesMethod Statement 14728983812691479973057231Abhinav SinhaNo ratings yet

- Work Method Statement - Procurement & Installation of FCP at SPDC Locations Rev. ADocument14 pagesWork Method Statement - Procurement & Installation of FCP at SPDC Locations Rev. ATheophilus Orupabo100% (1)

- Form Checklist Machine SHD 160 Butt FusionDocument8 pagesForm Checklist Machine SHD 160 Butt FusionYuwantoniAl100% (1)

- Method Statement For PlasteringDocument14 pagesMethod Statement For Plasteringjameel100% (1)

- Method Statement For PlasteringDocument14 pagesMethod Statement For Plasteringjameel100% (1)

- Ra 57 - Steel Structure Installation 439Document8 pagesRa 57 - Steel Structure Installation 439jameel100% (3)

- MOS For Fabrication and InstallationDocument21 pagesMOS For Fabrication and InstallationDo Van HUNG100% (3)

- ERECTION & INSTALLATION PROCEDURE ClarifierDocument23 pagesERECTION & INSTALLATION PROCEDURE ClarifierMohammad IqbalNo ratings yet

- Method Statement For Temporary Access Road (Towayya) - (Rev.)Document14 pagesMethod Statement For Temporary Access Road (Towayya) - (Rev.)skystar100% (1)

- MS For Pipe Demolation at MT-OffshoreDocument5 pagesMS For Pipe Demolation at MT-OffshoreahmadNo ratings yet

- Water Tightness TesstDocument6 pagesWater Tightness Tesstkarri1963100% (1)

- Method of Statement of HDPE LainingDocument7 pagesMethod of Statement of HDPE Lainingmohammad.a.d94No ratings yet

- Underground HDPEDocument9 pagesUnderground HDPEMamado099No ratings yet

- DSM-xxx-0xxx-xx, Checklist For HDPE Piping InstallationDocument1 pageDSM-xxx-0xxx-xx, Checklist For HDPE Piping Installationkadir tanzaniaNo ratings yet

- Method of Statement For R.C Piling WorkDocument10 pagesMethod of Statement For R.C Piling WorkMacgjoyner SaLauNo ratings yet

- Piping Above Ground Installation Work ProcedureDocument38 pagesPiping Above Ground Installation Work Proceduremanoj thakkar100% (1)

- Method Statement - Excavation & BackfillingDocument3 pagesMethod Statement - Excavation & BackfillingKenn MulingeNo ratings yet

- Method Statement For Earth WorkDocument5 pagesMethod Statement For Earth Workgvs raoNo ratings yet

- Hume Pipe Method StatementDocument2 pagesHume Pipe Method StatementDurgawati Mishra67% (3)

- C8516-CLT-QMT-0001-Inspection Checklist For Pipeline ConstructionDocument2 pagesC8516-CLT-QMT-0001-Inspection Checklist For Pipeline ConstructionJabinNo ratings yet

- Method of Statement For Excavation, Trenching, Backfilling & Compaction WorkDocument9 pagesMethod of Statement For Excavation, Trenching, Backfilling & Compaction WorkAhmed Ibrahim100% (1)

- Commissioning and Decommissioning of Pipelines, District Isolation TestDocument13 pagesCommissioning and Decommissioning of Pipelines, District Isolation TestSevet Gnow DrachirNo ratings yet

- Mos DrainageDocument3 pagesMos DrainageaniesbaekNo ratings yet

- Method Statement For Piping Tie-In Sleeper Jetty 5 Area - POWERTECH PKG SMP#5 - Rev.00CrevisiDocument198 pagesMethod Statement For Piping Tie-In Sleeper Jetty 5 Area - POWERTECH PKG SMP#5 - Rev.00CrevisiJohnNo ratings yet

- Method Statement HoldingDocument4 pagesMethod Statement Holdingqoci5koNo ratings yet

- DI Pipe Handling and Storage ProcedureDocument8 pagesDI Pipe Handling and Storage ProcedureFrancis DhanarajNo ratings yet

- T-242 - Method Statement For Excavation & BackfillDocument9 pagesT-242 - Method Statement For Excavation & Backfillsindalisindi100% (1)

- QCS 2010 Section 3 Part 3 Pits and TrenchesDocument4 pagesQCS 2010 Section 3 Part 3 Pits and Trenchesbryanpastor106No ratings yet

- Method Statement of ExcavationDocument9 pagesMethod Statement of ExcavationAmit kumar thakurNo ratings yet

- CWYC Method Statement For ExcavationDocument9 pagesCWYC Method Statement For Excavation施智捷100% (1)

- Turfing ChecklistDocument1 pageTurfing ChecklistshukriNo ratings yet

- SWMS 1 Loading, Unloading & ShiftingDocument8 pagesSWMS 1 Loading, Unloading & ShiftingJ.j.JijoNo ratings yet

- Method Statement For Installation & Hydrotest of GRP & Upvc PipesDocument19 pagesMethod Statement For Installation & Hydrotest of GRP & Upvc PipesBAVA M.HNo ratings yet

- Logistics Management Plan FormatDocument10 pagesLogistics Management Plan FormatAnna BelleNo ratings yet

- RC Retaining Wall: Method Statement For Concreting Vertical Elements Setting OutDocument3 pagesRC Retaining Wall: Method Statement For Concreting Vertical Elements Setting OutAnonymous ze9ag1No ratings yet

- 2 R-ME-MS-002 Method Statement of Penstock InstallationDocument23 pages2 R-ME-MS-002 Method Statement of Penstock Installationrotimi olalekan fatai100% (1)

- Method of Statement - Construction of Pipe CulvertsDocument18 pagesMethod of Statement - Construction of Pipe Culverts魏秦No ratings yet

- Dewatering Method StatementDocument6 pagesDewatering Method StatementMohsen KeramatiNo ratings yet

- MOS For Underground Pipe Water InstallationDocument2 pagesMOS For Underground Pipe Water InstallationMukhlish AkhatarNo ratings yet

- MMN Bina SDN BHD: Method Statement For Drainage WorksDocument6 pagesMMN Bina SDN BHD: Method Statement For Drainage WorksFosu DicksonNo ratings yet

- Method Statement For CoringDocument12 pagesMethod Statement For CoringjameelNo ratings yet

- Method Statement - Installation of Sewerage Piles in Live LineDocument9 pagesMethod Statement - Installation of Sewerage Piles in Live LineaceNo ratings yet

- Block Work MS (Only Revision Date Pending)Document19 pagesBlock Work MS (Only Revision Date Pending)jonesNo ratings yet

- Cgk063 Rfa Mos M XXX - Cooling Tower InstallationDocument24 pagesCgk063 Rfa Mos M XXX - Cooling Tower Installationdiki anggriawanNo ratings yet

- 014 - G.I Duct, Accessories and FittingsDocument14 pages014 - G.I Duct, Accessories and FittingsJomy JohnyNo ratings yet

- Cgk063-Rfa-mos-m-xxx - Waste Water-Sewerage & Sanitary Fixture Underground Pipe InstallationDocument35 pagesCgk063-Rfa-mos-m-xxx - Waste Water-Sewerage & Sanitary Fixture Underground Pipe Installationdiki anggriawanNo ratings yet

- Method Statement For CoringDocument12 pagesMethod Statement For CoringjameelNo ratings yet

- HSE Report-Plastering-439Document5 pagesHSE Report-Plastering-439jameelNo ratings yet

- New Sop InsulationDocument4 pagesNew Sop InsulationBALAL AKRAM100% (2)

- Telehealth: Health Care Is Only A Website AwayDocument3 pagesTelehealth: Health Care Is Only A Website AwayDonna MarburyNo ratings yet

- Fresh Rally Notfn of Aro BelgaumDocument14 pagesFresh Rally Notfn of Aro BelgaumManjunathNo ratings yet

- 9870 20072021Document2 pages9870 20072021priya swathiNo ratings yet

- Biodata Peserta Orientasi Komunikasi Perubahan PerilakuDocument9 pagesBiodata Peserta Orientasi Komunikasi Perubahan PerilakuPuskesmas CipanasNo ratings yet

- Komunikasi Terapeutik Bidan Dan Pasien Pasca Melahirkan Operasi Pada Rumah Sakit Muhammadiyah Palangka RayaDocument13 pagesKomunikasi Terapeutik Bidan Dan Pasien Pasca Melahirkan Operasi Pada Rumah Sakit Muhammadiyah Palangka RayaSelvyra Eka MasturinaNo ratings yet

- GROW VP NB Combined Zs Boys enDocument2 pagesGROW VP NB Combined Zs Boys enHazel GaringoNo ratings yet

- COA of Prune Extract (Xian)Document1 pageCOA of Prune Extract (Xian)iloveit52252No ratings yet

- Key Operator Study Guide: Thank You For Using The Eogas 4 Sterilization SystemDocument10 pagesKey Operator Study Guide: Thank You For Using The Eogas 4 Sterilization SystemAlejandroCárdenasNo ratings yet

- The Waits That MatterDocument3 pagesThe Waits That MattercarlodapNo ratings yet

- Briefly Describe The Reasons For Your Interest in Tulane University School of MedicineDocument2 pagesBriefly Describe The Reasons For Your Interest in Tulane University School of MedicineCarolyn FanNo ratings yet

- MO Application Form June 2019Document6 pagesMO Application Form June 2019abdul wakeelNo ratings yet

- Henderson CombinedDocument28 pagesHenderson CombinedjonsokolowNo ratings yet

- Nursing Care Delivery SystemsDocument19 pagesNursing Care Delivery SystemsyetroNo ratings yet

- NQ Education: I. Read The Text and Decide Which Answer A, B, C or D Best Fits Each SpaceDocument3 pagesNQ Education: I. Read The Text and Decide Which Answer A, B, C or D Best Fits Each SpaceNGUYỄN THẾ VIỆT QUANGNo ratings yet

- National Safety Council: To All Members and Patrons of NSCDocument1 pageNational Safety Council: To All Members and Patrons of NSCkartik kumarNo ratings yet

- Daily Lesson Plan REFLECTION - DatzDocument10 pagesDaily Lesson Plan REFLECTION - DatzCharlene BorladoNo ratings yet

- Hotel-Dieu Sunshine List 2014Document2 pagesHotel-Dieu Sunshine List 2014windsorstarNo ratings yet

- Leslie Marie M. Artezuela: OBJECTIVE: To Obtain Employment of The Company That Offers A Positive Atmosphere To Learn andDocument3 pagesLeslie Marie M. Artezuela: OBJECTIVE: To Obtain Employment of The Company That Offers A Positive Atmosphere To Learn andKenneth PugnariaNo ratings yet

- HV Cable Duct: Cable Duct To Electrical Building Cable Duct To Electrical BuildingDocument1 pageHV Cable Duct: Cable Duct To Electrical Building Cable Duct To Electrical BuildingsartajNo ratings yet

- The Iso-Toggle Technique: For Extra-Articular Stabilisation of The Cruciate Deficient Stifle Using LigafibaDocument3 pagesThe Iso-Toggle Technique: For Extra-Articular Stabilisation of The Cruciate Deficient Stifle Using LigafibaRuben FBNo ratings yet

- Air Winch OperationDocument1 pageAir Winch OperationReda BoualiNo ratings yet

- Primary Care Nursing and Differentiated Practice NotesDocument4 pagesPrimary Care Nursing and Differentiated Practice NotesJohn Paolo OrioNo ratings yet

- Participants List DDO's and Their Staff 25Document3 pagesParticipants List DDO's and Their Staff 25Manoj Digi LoansNo ratings yet

- Project ReportDocument10 pagesProject ReportPranoti nagesh SolapureNo ratings yet

- Housekeeping Audit Check Sheet For Production ServicesDocument2 pagesHousekeeping Audit Check Sheet For Production ServicesAliben85No ratings yet

- Services Declared EssentialDocument2 pagesServices Declared EssentialAdaderana OnlineNo ratings yet

- The Effects of Body Shaming in Every AdolescentDocument6 pagesThe Effects of Body Shaming in Every AdolescentNicole PagulayanNo ratings yet

- Rubric For Lab OutputDocument1 pageRubric For Lab OutputErika Joille PatayonNo ratings yet

- 44.the Utilization of Snap-On Provisionals For Dental Veneers - From An Analog To A Digital Approach. Esquivel - 2020. J Esthet Restor DentDocument10 pages44.the Utilization of Snap-On Provisionals For Dental Veneers - From An Analog To A Digital Approach. Esquivel - 2020. J Esthet Restor DentValeria CrespoNo ratings yet

METHOD STATEMENT Sluice Gates Install

METHOD STATEMENT Sluice Gates Install

Uploaded by

jameelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

METHOD STATEMENT Sluice Gates Install

METHOD STATEMENT Sluice Gates Install

Uploaded by

jameelCopyright:

Available Formats

SDHO Increment II, Initial Site Development

Pk1 (6600041347) & Pk2 (6600042398)

METHOD STATEMENT FOR SLUICE & BASKET

SCREEN INSTALLATION

Package 01/02 Doc. No. Rev. No.

METHOD STATEMENT

FOR

SLUICE GATE & BASKET SCREEN INSTALLATION

Checked By Checked By Approved By Approved By

Engineering Manager Construction Manager Project Manager Project Manager

Ayhan Umarogullari Mesut Tasar Mehmet Kasaboglu Salih Kasaboglu

METHOD STATEMENT FOR SLUICE GATE & BASKET SCREEN INSTALLATION 1

SDHO Increment II, Initial Site Development

Pk1 (6600041347) & Pk2 (6600042398)

METHOD STATEMENT FOR SLUICE & BASKET

SCREEN INSTALLATION

Package 01/02 Doc. No. Rev. No.

INDEX

1. SCOPE

2. PURPOSE

3. REFERENCES DOCUIMENTS

4. DEFINITIONS / ABBREVIATIONS

5. RESPONSIBILITY

6. RESOURCES

7. WORK EXECUTION PROCEDURE

8. QUALITY ASSURANCE / QUALITY CONTROL

9. HSE REQUIREMENTS

10. DRAWINGS - ATTACHMENTS

METHOD STATEMENT FOR SLUICE GATE & BASKET SCREEN INSTALLATION 2

SDHO Increment II, Initial Site Development

Pk1 (6600041347) & Pk2 (6600042398)

METHOD STATEMENT FOR SLUICE & BASKET

SCREEN INSTALLATION

Package 01/02 Doc. No. Rev. No.

1. SCOPE:

This method statement covers the activities and procedures to be implemented for

installation of sluice gates & basket screens with the Contract Specification and without

any safety violations within our project.

2. PURPOSE:

The purpose of this method statement is to outline the general requirements and

precautionary measures, which should be taken into consideration for installation of

sluice gates & basket screen. Furthermore, to ensure that significant health and safety

risk have been identified and what further control measures must be taken to reduce risk

to an acceptable level.

3. REFERENCE DOCUMENTS:

Relevant approved IFC Drawings, Basic Drawings and Shop Drawings.

ITP & Checklist

ARAMCO Standards and Project Specifications

Project Quality Plan

Construction Safety Manual

* Any conflicts between the following references contractor shall be brought to the

attention of the company for a final decision.

4. DEFINITIONS / ABBREVIATIONS:

PQP Project Quality Plan

HSE Health, Safety and Environment

PPE Personal Protective Equipment

Company Saudi Aramco

Contractor Kolin Company

ITL Independent Testing Lab

5. RESPONSIBILITIES:

Construction Manager

Responsible to perform the activity according to the progress targets, project

specifications and typical drawings.

Ensure that all preparation and works are carried out according to project

specifications, method statement and Aramco Standard.

Ensure that the progressing of work is carried out according to the planned program

and as per the approved Method Statement.

Finding solution in order to eliminate bottlenecks during execution of the activity

METHOD STATEMENT FOR SLUICE GATE & BASKET SCREEN INSTALLATION 3

SDHO Increment II, Initial Site Development

Pk1 (6600041347) & Pk2 (6600042398)

METHOD STATEMENT FOR SLUICE & BASKET

SCREEN INSTALLATION

Package 01/02 Doc. No. Rev. No.

Ensure that all the manpower, equipment and materials required executing the

work are available.

Ensure that all related quality procedures are practiced and implemented.

Ensure that all safety matters related to this procedure are being observed.

Surveyor

Responsible to provide correct line, level and alignment as per IFC, documents

and services before, during and after execution of the activity. The main activities

to be done by surveying engineer are as follows:

Checking the application done by survey crew according to specifications and

drawings.

Joining daily meetings with construction crew to share and report situation

regarding to the activity.

Site Engineer

Responsible to perform the activity according to quality requirements, the

specifications and typical drawings.

Inspecting site, crew and machinery conditions daily prior to commencement of

work.

Instructing the crew according to safety rules.

Assuring the quality during performing the work according to specification and

drawings.

Health and Safety Engineer

Responsible for monitoring and checking the activities according to safety

requirements. All safety issues will be governed by the Construction Safety Manual

and must be strictly followed.

Ensure all personal work having appropriate PPE's

Giving proper training & instructions regarding safety.

Toolbox meeting shall be conducted before starting the work.

Inspecting activity daily for possible cave-ins, hazardous atmospheres or other

hazardous conditions. Inspection shall also be done after rains and any other

outside effects. lf there is an unsafe condition, workers shall not be allowed to enter

the work area.

Ensure all work activities shall be carried out as per HSE plan

Carryout daily HSE site inspections and take corrective actions.

Do not allow workers stay under any load and train them to stay clear of the back

of vehicles.

METHOD STATEMENT FOR SLUICE GATE & BASKET SCREEN INSTALLATION 4

SDHO Increment II, Initial Site Development

Pk1 (6600041347) & Pk2 (6600042398)

METHOD STATEMENT FOR SLUICE & BASKET

SCREEN INSTALLATION

Package 01/02 Doc. No. Rev. No.

Civil Foreman

Responsible for performing the work according to instructions given by responsible

engineer.

Checking the situation of all personnel, machinery & equipment and material

before, during and after execution of the work.

Fulfilling the instructions given by responsible site engineer.

Reporting major problems during execution of the work at once to responsible Site

Engineer.

Assuring and monitoring safety requirements for crew.

Following the maintenance issues for machinery and equipment.

Reporting progress and issues to responsible Site engineer in daily basis.

QC inspector

Perform surveillance and ensure that work performed meet the project

requirements and method statement.

Shall be responsible to carry out inspections by signing various inspections and

test plan as proof record of inspection conforming to MOS.

ITL lab technician

Shall be responsible for inspection and field testing, material sampling and related

laboratory works as required by MOS.

6. RESOURCES:

6.1 EQUIPMENTS:

Mobile Crane/ lifting equipment

Hammers

Web sling

Drilling machine

Grouting mixing equipment.

6.2 MANPOWER:

Construction Manager

Site Engineer

Safety Officer

Dispatcher

Flagman

Labors

METHOD STATEMENT FOR SLUICE GATE & BASKET SCREEN INSTALLATION 5

SDHO Increment II, Initial Site Development

Pk1 (6600041347) & Pk2 (6600042398)

METHOD STATEMENT FOR SLUICE & BASKET

SCREEN INSTALLATION

Package 01/02 Doc. No. Rev. No.

6.3 SAFETY EQUIPMENT:

Personal Protective Equipment (PPE)

Fire Extinguisher

First Aid Kit

7. WORK EXECUTION PROCEDURE:

7.1 Sluice Gate Installation Procedure

For installation of sluice gates inside wastewater pump

stations, following steps shall be followed:

Step No. 01- Position the Gate

Measure inside diameter of pipe or concrete opening

width and height. Record dimension and compare

penstocks opening size. The gate openings should not

be smaller than the mating inside diameter of the pipe or

the concrete opening.

Carefully lower gate adjacent to the mating surface

using suitable lifting equipment and following all

necessary safety precautions.

Fig. 01: Pre Position the Gates

Step No. 02- Position Anchors

Align invert of the gate opening with invert of pipe or concrete opening. Place

temporary support blocks under frame to maintain position.

With a level, ensure that the invert of the gate is level.

To pre- position, the gate where it will be mounted to

mark holes for anchors. If pre-positioning the gate is not

possible, carefully measure and mark the mounting

surface for holes.

Step No. 03 –Place Anchors

After Drilling the hole and fixing the anchor bolts with

epoxy chemical, allow 12 hours to set.

Anchors of any type must be sufficiently long to account

for a grout seal, see #6 below. Fill all mounting holes

with anchors.

Fig. 02: Anchors

METHOD STATEMENT FOR SLUICE GATE & BASKET SCREEN INSTALLATION 6

SDHO Increment II, Initial Site Development

Pk1 (6600041347) & Pk2 (6600042398)

METHOD STATEMENT FOR SLUICE & BASKET

SCREEN INSTALLATION

Package 01/02 Doc. No. Rev. No.

Step No. 04- Jam Nut/ Thrust Nut

After fixation of anchors with chemical, install thrust

nuts on every anchor. Thrust nuts ate meant to

provide an adjustable surface against which the gate

will rest once it is plumb.

Adjust the nuts at each corner of the gate so the gate

is plumb leaving a minimum 1 inch (25mm) space for

grout between mounting surface and gate.

Then bring the remaining nuts up snug to the back of

the gate. Re-check for plumb.

Step No. 05- Secure the Gate.

Place Jam nuts on each anchor and hand tighten to

secure the gate.

Re-check plumb then firmly tighten jam nuts to Fig. 03: Nut Fixation

permanently secure the gate.

Step No. 06- Install Grout

Mix a non- shrinking grout and fill the space

between the mounting surface and back of the gate

and all gate surfaces that make a seal, for example

an upper wiper seal across the top of the opening

as shown in Fig 4. It may be necessary to place a

removable form around the grout locations to hold

the grout in place until dry. Make sure there are no

voids in the grout.

Step No. 06- Install Top cover Plate / Pedestals

Fix the top plate cover on Top slab for support of Fig. 04: Secure Gate with Grout

pedestal using anchor bolts.

After fixation of rising stem & pedestals, wall bracket shall be installed to support

the alignment of rising stem pipe.

7.2 Basket Screen Installation Procedure

For installation of Basket screen inside wastewater pump stations, following steps shall

be followed:

Step No. 01- Position the Wall Brakets

All wall brackets should be install at equal spacing to support the guide rail.

METHOD STATEMENT FOR SLUICE GATE & BASKET SCREEN INSTALLATION 7

SDHO Increment II, Initial Site Development

Pk1 (6600041347) & Pk2 (6600042398)

METHOD STATEMENT FOR SLUICE & BASKET

SCREEN INSTALLATION

Package 01/02 Doc. No. Rev. No.

Before make the drill for anchor in wall brackets, re-check the

horizontal distance shall be as per requirement of guide rail.

Step No. 02- Position the Guide Rail

Minimum two guide rails required for each basket screen.

Before fixation of guide rail, mark all the position of anchor bolts

locations on base and on top slab.

Re-check the distance between sluice gate & basket screen to

avoid the clash, before fixation of anchors

Install the chain Sling hanger at top slab

Fix the chain sling in basket screen to sling hanger.

Fig. 05: Basket screen

8. QUALITY ASSURANCE / QUALITY CONTROL :

The field inspection notice of excavation/backfill works will be given to SAPMT in

advance.

Site QA/QC Inspector/Site Engineer will be responsible for completing inspection

Reports for these activities.

Kolin shall ensure that the area is ready for visual inspection before submitting

WIR’s.

Kolin shall submit WIR’s for the area ready and at least 24 hours during weekdays

and 48 hours during Fridays and holidays.

Kolin shall attach photos to each WIR’s.

All the materials to be used should be approved by the company.

9. HSE REQUIREMENTS

Protection and safety shall be in accordance with SA Construction Safety manual.

All works shall comply with the safety procedure or instruction as set out in project

safety plan and municipality rules and regulations.

All equipment will be visually inspected prior to use.

Basic Personal Protective Equipment (PPE) shall be worn by all staff or laborers.

Toolbox talk shall be conducted before the activity.

Know the safe working load of the hoisting equipment and hardware before use. Never

exceed the Safe Working Load (SWL).

Know the height and size of the precast element before rigging for lifting

METHOD STATEMENT FOR SLUICE GATE & BASKET SCREEN INSTALLATION 8

SDHO Increment II, Initial Site Development

Pk1 (6600041347) & Pk2 (6600042398)

METHOD STATEMENT FOR SLUICE & BASKET

SCREEN INSTALLATION

Package 01/02 Doc. No. Rev. No.

Always inspect the rigging element prior to every use.

Always use taglines with the precast element while lifting to keep the load steady.

Always check the stability of the load before lifting.

Check for any over head power lines.

Never use damaged slings, blocks, hooks for lifting, all damaged lifting gears to be

returned to the store for repair or replacement

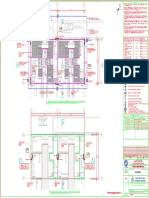

10. DRAWINGS - ATTACHMENTS:

1- INSTALLATION MANNUAL FROM VENDOR

2- SHOP DRAWINGS FOR SLUICE GATES & BASKET SCREENS

METHOD STATEMENT FOR SLUICE GATE & BASKET SCREEN INSTALLATION 9

You might also like

- Method Statement For FRP Tank Panel ReplacementDocument8 pagesMethod Statement For FRP Tank Panel ReplacementJawNo ratings yet

- Method Statement - Erection, Installation of Above Ground Piping - POXDocument11 pagesMethod Statement - Erection, Installation of Above Ground Piping - POXHabib ur rahmanNo ratings yet

- Method Statement Water Supply Line Tie in Point Re-RoutingDocument17 pagesMethod Statement Water Supply Line Tie in Point Re-RoutingShyju Melepurath83% (6)

- Method Statement For Road Crossing Works For Duct Bank - D2Document1 pageMethod Statement For Road Crossing Works For Duct Bank - D2MidhunRameshThuvassery100% (2)

- Method Statement For Dismantling of Cable TrunkingDocument1 pageMethod Statement For Dismantling of Cable TrunkingBento Box100% (1)

- Method Statement Pressure GroutingDocument2 pagesMethod Statement Pressure GroutingStephen David Gozun100% (7)

- Method Statement For Removing and Installation of Tanks & Pipping WorkDocument7 pagesMethod Statement For Removing and Installation of Tanks & Pipping WorkM Waqas Habib100% (1)

- Method Statement For Site OfficeDocument18 pagesMethod Statement For Site OfficeMuhammad TeguhNo ratings yet

- Method Statement For Chamber Construction of TSE Line Ev ManagerDocument20 pagesMethod Statement For Chamber Construction of TSE Line Ev ManagerBleep News100% (1)

- Method Statement River CrossingDocument2 pagesMethod Statement River CrossingDeny Cahyo N0% (1)

- Method Statement For Clearing and Grubbing (For Review) 12-7-2020Document17 pagesMethod Statement For Clearing and Grubbing (For Review) 12-7-2020Researcher100% (2)

- Method Statement For Leak Rectification WorksDocument7 pagesMethod Statement For Leak Rectification Worksgiri943No ratings yet

- Method Statement For Laying GeomembraneDocument6 pagesMethod Statement For Laying GeomembraneMhando IgnasNo ratings yet

- Method Statement For Ground Improvement (Removal & Replacement) at Approach of VBC Kg. Titi Besi (CH 232.457)Document7 pagesMethod Statement For Ground Improvement (Removal & Replacement) at Approach of VBC Kg. Titi Besi (CH 232.457)MAYMODERN STEELNo ratings yet

- ITP Temporary HoardingDocument1 pageITP Temporary HoardingMohd Azrin100% (1)

- C4M Mivan FormworkDocument3 pagesC4M Mivan Formworkmanohar reddyNo ratings yet

- Method Statement 14728983812691479973057231Document6 pagesMethod Statement 14728983812691479973057231Abhinav SinhaNo ratings yet

- Work Method Statement - Procurement & Installation of FCP at SPDC Locations Rev. ADocument14 pagesWork Method Statement - Procurement & Installation of FCP at SPDC Locations Rev. ATheophilus Orupabo100% (1)

- Form Checklist Machine SHD 160 Butt FusionDocument8 pagesForm Checklist Machine SHD 160 Butt FusionYuwantoniAl100% (1)

- Method Statement For PlasteringDocument14 pagesMethod Statement For Plasteringjameel100% (1)

- Method Statement For PlasteringDocument14 pagesMethod Statement For Plasteringjameel100% (1)

- Ra 57 - Steel Structure Installation 439Document8 pagesRa 57 - Steel Structure Installation 439jameel100% (3)

- MOS For Fabrication and InstallationDocument21 pagesMOS For Fabrication and InstallationDo Van HUNG100% (3)

- ERECTION & INSTALLATION PROCEDURE ClarifierDocument23 pagesERECTION & INSTALLATION PROCEDURE ClarifierMohammad IqbalNo ratings yet

- Method Statement For Temporary Access Road (Towayya) - (Rev.)Document14 pagesMethod Statement For Temporary Access Road (Towayya) - (Rev.)skystar100% (1)

- MS For Pipe Demolation at MT-OffshoreDocument5 pagesMS For Pipe Demolation at MT-OffshoreahmadNo ratings yet

- Water Tightness TesstDocument6 pagesWater Tightness Tesstkarri1963100% (1)

- Method of Statement of HDPE LainingDocument7 pagesMethod of Statement of HDPE Lainingmohammad.a.d94No ratings yet

- Underground HDPEDocument9 pagesUnderground HDPEMamado099No ratings yet

- DSM-xxx-0xxx-xx, Checklist For HDPE Piping InstallationDocument1 pageDSM-xxx-0xxx-xx, Checklist For HDPE Piping Installationkadir tanzaniaNo ratings yet

- Method of Statement For R.C Piling WorkDocument10 pagesMethod of Statement For R.C Piling WorkMacgjoyner SaLauNo ratings yet

- Piping Above Ground Installation Work ProcedureDocument38 pagesPiping Above Ground Installation Work Proceduremanoj thakkar100% (1)

- Method Statement - Excavation & BackfillingDocument3 pagesMethod Statement - Excavation & BackfillingKenn MulingeNo ratings yet

- Method Statement For Earth WorkDocument5 pagesMethod Statement For Earth Workgvs raoNo ratings yet

- Hume Pipe Method StatementDocument2 pagesHume Pipe Method StatementDurgawati Mishra67% (3)

- C8516-CLT-QMT-0001-Inspection Checklist For Pipeline ConstructionDocument2 pagesC8516-CLT-QMT-0001-Inspection Checklist For Pipeline ConstructionJabinNo ratings yet

- Method of Statement For Excavation, Trenching, Backfilling & Compaction WorkDocument9 pagesMethod of Statement For Excavation, Trenching, Backfilling & Compaction WorkAhmed Ibrahim100% (1)

- Commissioning and Decommissioning of Pipelines, District Isolation TestDocument13 pagesCommissioning and Decommissioning of Pipelines, District Isolation TestSevet Gnow DrachirNo ratings yet

- Mos DrainageDocument3 pagesMos DrainageaniesbaekNo ratings yet

- Method Statement For Piping Tie-In Sleeper Jetty 5 Area - POWERTECH PKG SMP#5 - Rev.00CrevisiDocument198 pagesMethod Statement For Piping Tie-In Sleeper Jetty 5 Area - POWERTECH PKG SMP#5 - Rev.00CrevisiJohnNo ratings yet

- Method Statement HoldingDocument4 pagesMethod Statement Holdingqoci5koNo ratings yet

- DI Pipe Handling and Storage ProcedureDocument8 pagesDI Pipe Handling and Storage ProcedureFrancis DhanarajNo ratings yet

- T-242 - Method Statement For Excavation & BackfillDocument9 pagesT-242 - Method Statement For Excavation & Backfillsindalisindi100% (1)

- QCS 2010 Section 3 Part 3 Pits and TrenchesDocument4 pagesQCS 2010 Section 3 Part 3 Pits and Trenchesbryanpastor106No ratings yet

- Method Statement of ExcavationDocument9 pagesMethod Statement of ExcavationAmit kumar thakurNo ratings yet

- CWYC Method Statement For ExcavationDocument9 pagesCWYC Method Statement For Excavation施智捷100% (1)

- Turfing ChecklistDocument1 pageTurfing ChecklistshukriNo ratings yet

- SWMS 1 Loading, Unloading & ShiftingDocument8 pagesSWMS 1 Loading, Unloading & ShiftingJ.j.JijoNo ratings yet

- Method Statement For Installation & Hydrotest of GRP & Upvc PipesDocument19 pagesMethod Statement For Installation & Hydrotest of GRP & Upvc PipesBAVA M.HNo ratings yet

- Logistics Management Plan FormatDocument10 pagesLogistics Management Plan FormatAnna BelleNo ratings yet

- RC Retaining Wall: Method Statement For Concreting Vertical Elements Setting OutDocument3 pagesRC Retaining Wall: Method Statement For Concreting Vertical Elements Setting OutAnonymous ze9ag1No ratings yet

- 2 R-ME-MS-002 Method Statement of Penstock InstallationDocument23 pages2 R-ME-MS-002 Method Statement of Penstock Installationrotimi olalekan fatai100% (1)

- Method of Statement - Construction of Pipe CulvertsDocument18 pagesMethod of Statement - Construction of Pipe Culverts魏秦No ratings yet

- Dewatering Method StatementDocument6 pagesDewatering Method StatementMohsen KeramatiNo ratings yet

- MOS For Underground Pipe Water InstallationDocument2 pagesMOS For Underground Pipe Water InstallationMukhlish AkhatarNo ratings yet

- MMN Bina SDN BHD: Method Statement For Drainage WorksDocument6 pagesMMN Bina SDN BHD: Method Statement For Drainage WorksFosu DicksonNo ratings yet

- Method Statement For CoringDocument12 pagesMethod Statement For CoringjameelNo ratings yet

- Method Statement - Installation of Sewerage Piles in Live LineDocument9 pagesMethod Statement - Installation of Sewerage Piles in Live LineaceNo ratings yet

- Block Work MS (Only Revision Date Pending)Document19 pagesBlock Work MS (Only Revision Date Pending)jonesNo ratings yet

- Cgk063 Rfa Mos M XXX - Cooling Tower InstallationDocument24 pagesCgk063 Rfa Mos M XXX - Cooling Tower Installationdiki anggriawanNo ratings yet

- 014 - G.I Duct, Accessories and FittingsDocument14 pages014 - G.I Duct, Accessories and FittingsJomy JohnyNo ratings yet

- Cgk063-Rfa-mos-m-xxx - Waste Water-Sewerage & Sanitary Fixture Underground Pipe InstallationDocument35 pagesCgk063-Rfa-mos-m-xxx - Waste Water-Sewerage & Sanitary Fixture Underground Pipe Installationdiki anggriawanNo ratings yet

- Method Statement For CoringDocument12 pagesMethod Statement For CoringjameelNo ratings yet

- HSE Report-Plastering-439Document5 pagesHSE Report-Plastering-439jameelNo ratings yet

- New Sop InsulationDocument4 pagesNew Sop InsulationBALAL AKRAM100% (2)

- Telehealth: Health Care Is Only A Website AwayDocument3 pagesTelehealth: Health Care Is Only A Website AwayDonna MarburyNo ratings yet

- Fresh Rally Notfn of Aro BelgaumDocument14 pagesFresh Rally Notfn of Aro BelgaumManjunathNo ratings yet

- 9870 20072021Document2 pages9870 20072021priya swathiNo ratings yet

- Biodata Peserta Orientasi Komunikasi Perubahan PerilakuDocument9 pagesBiodata Peserta Orientasi Komunikasi Perubahan PerilakuPuskesmas CipanasNo ratings yet

- Komunikasi Terapeutik Bidan Dan Pasien Pasca Melahirkan Operasi Pada Rumah Sakit Muhammadiyah Palangka RayaDocument13 pagesKomunikasi Terapeutik Bidan Dan Pasien Pasca Melahirkan Operasi Pada Rumah Sakit Muhammadiyah Palangka RayaSelvyra Eka MasturinaNo ratings yet

- GROW VP NB Combined Zs Boys enDocument2 pagesGROW VP NB Combined Zs Boys enHazel GaringoNo ratings yet

- COA of Prune Extract (Xian)Document1 pageCOA of Prune Extract (Xian)iloveit52252No ratings yet

- Key Operator Study Guide: Thank You For Using The Eogas 4 Sterilization SystemDocument10 pagesKey Operator Study Guide: Thank You For Using The Eogas 4 Sterilization SystemAlejandroCárdenasNo ratings yet

- The Waits That MatterDocument3 pagesThe Waits That MattercarlodapNo ratings yet

- Briefly Describe The Reasons For Your Interest in Tulane University School of MedicineDocument2 pagesBriefly Describe The Reasons For Your Interest in Tulane University School of MedicineCarolyn FanNo ratings yet

- MO Application Form June 2019Document6 pagesMO Application Form June 2019abdul wakeelNo ratings yet

- Henderson CombinedDocument28 pagesHenderson CombinedjonsokolowNo ratings yet

- Nursing Care Delivery SystemsDocument19 pagesNursing Care Delivery SystemsyetroNo ratings yet

- NQ Education: I. Read The Text and Decide Which Answer A, B, C or D Best Fits Each SpaceDocument3 pagesNQ Education: I. Read The Text and Decide Which Answer A, B, C or D Best Fits Each SpaceNGUYỄN THẾ VIỆT QUANGNo ratings yet

- National Safety Council: To All Members and Patrons of NSCDocument1 pageNational Safety Council: To All Members and Patrons of NSCkartik kumarNo ratings yet

- Daily Lesson Plan REFLECTION - DatzDocument10 pagesDaily Lesson Plan REFLECTION - DatzCharlene BorladoNo ratings yet

- Hotel-Dieu Sunshine List 2014Document2 pagesHotel-Dieu Sunshine List 2014windsorstarNo ratings yet

- Leslie Marie M. Artezuela: OBJECTIVE: To Obtain Employment of The Company That Offers A Positive Atmosphere To Learn andDocument3 pagesLeslie Marie M. Artezuela: OBJECTIVE: To Obtain Employment of The Company That Offers A Positive Atmosphere To Learn andKenneth PugnariaNo ratings yet

- HV Cable Duct: Cable Duct To Electrical Building Cable Duct To Electrical BuildingDocument1 pageHV Cable Duct: Cable Duct To Electrical Building Cable Duct To Electrical BuildingsartajNo ratings yet

- The Iso-Toggle Technique: For Extra-Articular Stabilisation of The Cruciate Deficient Stifle Using LigafibaDocument3 pagesThe Iso-Toggle Technique: For Extra-Articular Stabilisation of The Cruciate Deficient Stifle Using LigafibaRuben FBNo ratings yet

- Air Winch OperationDocument1 pageAir Winch OperationReda BoualiNo ratings yet

- Primary Care Nursing and Differentiated Practice NotesDocument4 pagesPrimary Care Nursing and Differentiated Practice NotesJohn Paolo OrioNo ratings yet

- Participants List DDO's and Their Staff 25Document3 pagesParticipants List DDO's and Their Staff 25Manoj Digi LoansNo ratings yet

- Project ReportDocument10 pagesProject ReportPranoti nagesh SolapureNo ratings yet

- Housekeeping Audit Check Sheet For Production ServicesDocument2 pagesHousekeeping Audit Check Sheet For Production ServicesAliben85No ratings yet

- Services Declared EssentialDocument2 pagesServices Declared EssentialAdaderana OnlineNo ratings yet

- The Effects of Body Shaming in Every AdolescentDocument6 pagesThe Effects of Body Shaming in Every AdolescentNicole PagulayanNo ratings yet

- Rubric For Lab OutputDocument1 pageRubric For Lab OutputErika Joille PatayonNo ratings yet

- 44.the Utilization of Snap-On Provisionals For Dental Veneers - From An Analog To A Digital Approach. Esquivel - 2020. J Esthet Restor DentDocument10 pages44.the Utilization of Snap-On Provisionals For Dental Veneers - From An Analog To A Digital Approach. Esquivel - 2020. J Esthet Restor DentValeria CrespoNo ratings yet