Professional Documents

Culture Documents

Conexion Columna - Pedestal

Conexion Columna - Pedestal

Uploaded by

Alejandro OspinaCopyright:

Available Formats

You might also like

- Games Workshop - Warhammer Townscapes (1988)Document46 pagesGames Workshop - Warhammer Townscapes (1988)Soulpunch97% (29)

- Cavern of The Fear (Deltora Shadowlands, N. 1) by Emily RoddaDocument123 pagesCavern of The Fear (Deltora Shadowlands, N. 1) by Emily Roddamaheshwa100% (3)

- Anchor Chair Design - Version 1Document3 pagesAnchor Chair Design - Version 1Rey Fiedacan100% (3)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Brochure Uffizi WEB ENGLISH-Pubblicazione-3.12Document3 pagesBrochure Uffizi WEB ENGLISH-Pubblicazione-3.12Anonymous PYgnwOWKNo ratings yet

- Determination of Footing Dimensions: Na All FDocument4 pagesDetermination of Footing Dimensions: Na All FLenielle AmatosaNo ratings yet

- Base Plate CircularDocument8 pagesBase Plate Circularmrprabhu16No ratings yet

- Processing - THERM - S-I - FS-I - 2017 (RAICO) PDFDocument174 pagesProcessing - THERM - S-I - FS-I - 2017 (RAICO) PDFAnrStukNo ratings yet

- Connection Design: C1-BP: ETABS 2016 16.2.1 License # 13GKCULR7HUKDLFDocument5 pagesConnection Design: C1-BP: ETABS 2016 16.2.1 License # 13GKCULR7HUKDLFjaicollaNo ratings yet

- EQ2 1st Flooor ColumnDocument17 pagesEQ2 1st Flooor ColumnWilbert Carlo RachoNo ratings yet

- EQ2 2nd Floor ColumnDocument17 pagesEQ2 2nd Floor ColumnWilbert Carlo RachoNo ratings yet

- Placa Base c740-BpDocument3 pagesPlaca Base c740-BpuetingenieriasasNo ratings yet

- Column Design at 3 Floor: Uact U 4 F UactDocument16 pagesColumn Design at 3 Floor: Uact U 4 F UactWilbert Carlo RachoNo ratings yet

- Design of SlabDocument14 pagesDesign of Slabابراهيم المبيضينNo ratings yet

- Conexion Viga - PilarDocument5 pagesConexion Viga - PilarAlejandro OspinaNo ratings yet

- Base Plate Design MS601a - BS - CodeDocument4 pagesBase Plate Design MS601a - BS - CodeRAMSNo ratings yet

- Column 5: Column Design at 3 Floor C. Total Loading Liveload 52.0778 KN Deadload 198.433 KN E 75.087KNDocument6 pagesColumn 5: Column Design at 3 Floor C. Total Loading Liveload 52.0778 KN Deadload 198.433 KN E 75.087KNWilbert Carlo RachoNo ratings yet

- Tank Anchor Bolt DesignDocument9 pagesTank Anchor Bolt Designgon972001100% (1)

- Connection Design: B104-CJ: ETABS 2016 16.0.3 License # 15QT3R6KGWUL9HRDocument4 pagesConnection Design: B104-CJ: ETABS 2016 16.0.3 License # 15QT3R6KGWUL9HReffan f gultomNo ratings yet

- Check Punching For Edge ColumnsDocument5 pagesCheck Punching For Edge ColumnsAli AbdallahNo ratings yet

- Example II.B-4 Four-Bolt Unstiffened Extended End-Plate FR Moment Connection (Beam-To-Column Flange)Document9 pagesExample II.B-4 Four-Bolt Unstiffened Extended End-Plate FR Moment Connection (Beam-To-Column Flange)Luis TorresNo ratings yet

- DesignDocument13 pagesDesignAnshulGuptaNo ratings yet

- Base Plate Design MS601a - BS - CodeDocument4 pagesBase Plate Design MS601a - BS - CodeCivil StructureNo ratings yet

- Isolated Footing (ACI)Document4 pagesIsolated Footing (ACI)Boubakeur FerkousNo ratings yet

- Chapter 2Document13 pagesChapter 2muhamad irvanNo ratings yet

- Combined FootingDocument7 pagesCombined FootingMohammed ElemamNo ratings yet

- Isolated Footing P OnlyDocument14 pagesIsolated Footing P OnlyAhmed AbuoelnagaNo ratings yet

- Determination of Footing Dimensions: Na All FDocument4 pagesDetermination of Footing Dimensions: Na All FMohammed ElemamNo ratings yet

- Isolated Footing (ACI)Document4 pagesIsolated Footing (ACI)engyana engyyyNo ratings yet

- Wall Design ProgramDocument12 pagesWall Design Programaaalcantara3520qcNo ratings yet

- Slab DesignDocument12 pagesSlab DesignPAOLO AGORILLANo ratings yet

- Timber Circular Columns 1Document4 pagesTimber Circular Columns 1John SmithNo ratings yet

- EQ2 3rd Floor ColumnDocument17 pagesEQ2 3rd Floor ColumnWilbert Carlo RachoNo ratings yet

- Design and Analysis For First Floor BeamDocument2 pagesDesign and Analysis For First Floor BeamVergel Pabunan NogadasNo ratings yet

- Anchor Bolt CHKDocument17 pagesAnchor Bolt CHKPriya GNo ratings yet

- Design of Stairs and Landing: Page NoDocument6 pagesDesign of Stairs and Landing: Page NoJun Dela PeñaNo ratings yet

- Connection Design: B19-CI: Units: Kip-In Story: Story1 Design Code: AISC 360-10Document6 pagesConnection Design: B19-CI: Units: Kip-In Story: Story1 Design Code: AISC 360-10surbanoj_79No ratings yet

- Combined Footing DesignDocument1 pageCombined Footing DesignOSCARTAWNNo ratings yet

- Act1 SpecDocument14 pagesAct1 Specabandiola3819qcNo ratings yet

- Etabs 2016 16.2Document6 pagesEtabs 2016 16.2kervinarmasNo ratings yet

- (Reviewed) Auto Update Torsion Design BaldesansoDocument40 pages(Reviewed) Auto Update Torsion Design BaldesansoElmer Leyson BaldesansoNo ratings yet

- Base Plate DesignMS601a Good MahfuzDocument4 pagesBase Plate DesignMS601a Good MahfuzDavid PuenNo ratings yet

- Embedpl v1-4 Demo PDFDocument5 pagesEmbedpl v1-4 Demo PDFMWKELIOLANo ratings yet

- Beam DesignDocument2 pagesBeam DesignJelal EdrisNo ratings yet

- Quality of Materials:: Large Moment Base Plate Design AISC LRFD - MethodeDocument7 pagesQuality of Materials:: Large Moment Base Plate Design AISC LRFD - MethodejunarkoNo ratings yet

- Section 17Document41 pagesSection 17Mark EstepaNo ratings yet

- G4e - G4F (4TH Floor)Document12 pagesG4e - G4F (4TH Floor)Zyril BestoNo ratings yet

- Perhitungan Balok Dua Tumpuan SRPMM SNIDocument5 pagesPerhitungan Balok Dua Tumpuan SRPMM SNIahmadbagusNo ratings yet

- Ground Floor Beam - Gb1: Project Owner DescriptionDocument104 pagesGround Floor Beam - Gb1: Project Owner DescriptionTewodros AbateNo ratings yet

- Torsion DesignDocument45 pagesTorsion DesigngirumNo ratings yet

- Aliran Dalam PipaDocument15 pagesAliran Dalam PipaWidya AndaniNo ratings yet

- 4.4 Base Plate and Anchor Bolt CheckDocument1 page4.4 Base Plate and Anchor Bolt Checksrikanth varmaNo ratings yet

- Semister Assignement: Composite Structure: K, 1 K, 2 K, 1 K, 2Document15 pagesSemister Assignement: Composite Structure: K, 1 K, 2 K, 1 K, 2Belay BayuNo ratings yet

- First Floor Beam - (On Axis B B/N 2&3) : 1 1 1 2 MR 1 1 1 2 MR 1 1 1 2 MR 1 1 1 2 MRDocument1 pageFirst Floor Beam - (On Axis B B/N 2&3) : 1 1 1 2 MR 1 1 1 2 MR 1 1 1 2 MR 1 1 1 2 MRJelal1No ratings yet

- Chapter3 - Analysis Ofwind Loads Acting On StructuresDocument6 pagesChapter3 - Analysis Ofwind Loads Acting On Structuresdagmawi girmaNo ratings yet

- Composite Column DesignDocument3 pagesComposite Column DesignSuraj de SilvaNo ratings yet

- Timber DesignDocument62 pagesTimber DesignLovely Brecio CalixtroNo ratings yet

- Analisa DataDocument39 pagesAnalisa DataUtomo YohanesNo ratings yet

- Anes Proracun VratilaDocument9 pagesAnes Proracun VratilaANES HAJDAREVIĆNo ratings yet

- Example - Trusses Subject To Compression and TensionDocument6 pagesExample - Trusses Subject To Compression and TensionHalina HamidNo ratings yet

- Embedded Plates Calculation - Part 2Document8 pagesEmbedded Plates Calculation - Part 2Mai CNo ratings yet

- End Plate - Bolted ConnectionDocument3 pagesEnd Plate - Bolted ConnectionASKOKONo ratings yet

- Instructor's Manual to Accompany CALCULUS WITH ANALYTIC GEOMETRYFrom EverandInstructor's Manual to Accompany CALCULUS WITH ANALYTIC GEOMETRYNo ratings yet

- Conexion Viga - PilarDocument5 pagesConexion Viga - PilarAlejandro OspinaNo ratings yet

- W Steel Section Tables 080307 PDFDocument5 pagesW Steel Section Tables 080307 PDFAlejandro OspinaNo ratings yet

- Model of Tuned Liquid Damper For Suppressing Pitching Motions of StructuresDocument12 pagesModel of Tuned Liquid Damper For Suppressing Pitching Motions of StructuresAlejandro OspinaNo ratings yet

- Effectiveness of A 2D TLD and Its Numerical Modeling: M. J. Tait, A.M.ASCE N. Isyumov, F.ASCE and A. A. El DamattyDocument13 pagesEffectiveness of A 2D TLD and Its Numerical Modeling: M. J. Tait, A.M.ASCE N. Isyumov, F.ASCE and A. A. El DamattyAlejandro OspinaNo ratings yet

- Mecánica de FLuidos - JAMES FAY PDFDocument312 pagesMecánica de FLuidos - JAMES FAY PDFAlejandro OspinaNo ratings yet

- Architecture, Urbanism and The Good Neighbour - Lauro CavalcantiDocument5 pagesArchitecture, Urbanism and The Good Neighbour - Lauro CavalcantiChristian NoetzlyNo ratings yet

- Drilled Cast-In-Place Pile Design Based On ACI 318-08Document17 pagesDrilled Cast-In-Place Pile Design Based On ACI 318-08Habibur RahmanNo ratings yet

- Full Test Bank For Economics Today The Macro View 5Th Canadian Edition Miller PDF Docx Full Chapter ChapterDocument35 pagesFull Test Bank For Economics Today The Macro View 5Th Canadian Edition Miller PDF Docx Full Chapter Chapterjohnathannealy03w100% (12)

- ID Perhitungan Struktur Beton Bertulang Ged PDFDocument10 pagesID Perhitungan Struktur Beton Bertulang Ged PDFchrisNo ratings yet

- Dental College LDC Post12 02 2020Document118 pagesDental College LDC Post12 02 2020droidNo ratings yet

- Economic Housing-Floor Plans 1Document1 pageEconomic Housing-Floor Plans 1Andrew AmedaNo ratings yet

- Window Sizes HOutDocument11 pagesWindow Sizes HOutAustine MakateNo ratings yet

- Basic Characteristics of Concrete PDFDocument14 pagesBasic Characteristics of Concrete PDFHarold Taylor100% (1)

- London AttractionsDocument3 pagesLondon AttractionswadiwanNo ratings yet

- FM-200 Engineered Nozzles IV.1.03.01Document2 pagesFM-200 Engineered Nozzles IV.1.03.01hdrNo ratings yet

- Elevator DSA OSHPDDocument2 pagesElevator DSA OSHPDjorge01No ratings yet

- Gateleg Table Plan PDFDocument18 pagesGateleg Table Plan PDFraouf menchariNo ratings yet

- EnergyShield Pro-DataSheetDocument2 pagesEnergyShield Pro-DataSheetantonio angaritaNo ratings yet

- Naurang Yatri Niwas, Garli.: Historical Context of The BuildingDocument13 pagesNaurang Yatri Niwas, Garli.: Historical Context of The BuildingRiddhi AggarwalNo ratings yet

- Full Download pdf of (eBook PDF) Managing the Law The Legal Aspects of Doing Business 4th all chapterDocument24 pagesFull Download pdf of (eBook PDF) Managing the Law The Legal Aspects of Doing Business 4th all chaptertujabrhel100% (3)

- A.description - Of.the - East.and - Some.other - Countries.vol1.1743 R.pocockeDocument496 pagesA.description - Of.the - East.and - Some.other - Countries.vol1.1743 R.pocockemiddlekeyNo ratings yet

- My PortfolioDocument9 pagesMy PortfolioJohn Tristan GonzalesNo ratings yet

- Apcotherm Epn 200Document2 pagesApcotherm Epn 200Moin AltafNo ratings yet

- Sump DetailDocument1 pageSump DetailSandeep VarmaNo ratings yet

- Islamic Architecture 1Document56 pagesIslamic Architecture 1Jeff Angelo GalingNo ratings yet

- Stairs: To Afford The Means of Ascent and Descent Between Various Floors of The BuildingDocument26 pagesStairs: To Afford The Means of Ascent and Descent Between Various Floors of The BuildingAnn GertrudeNo ratings yet

- Descriptive Text Is A Text Which Say What A Person or A Thing Is Like. Its Purpose Is To Describe and Reveal A Particular Person, Place, or ThingDocument2 pagesDescriptive Text Is A Text Which Say What A Person or A Thing Is Like. Its Purpose Is To Describe and Reveal A Particular Person, Place, or ThingAnonymous KNnsXtzLDNo ratings yet

- Construction Materials Civil Engineering DepartmentDocument57 pagesConstruction Materials Civil Engineering DepartmentJai Ganesh100% (1)

- Slums and The City - Bhawna Jaimini, Hunnarshala FOundationDocument9 pagesSlums and The City - Bhawna Jaimini, Hunnarshala FOundationdiptilundiaNo ratings yet

- Strip FootingDocument10 pagesStrip FootingKain Pasang Ruby IINo ratings yet

- Schedule BDocument32 pagesSchedule BpanikarickyNo ratings yet

Conexion Columna - Pedestal

Conexion Columna - Pedestal

Uploaded by

Alejandro OspinaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Conexion Columna - Pedestal

Conexion Columna - Pedestal

Uploaded by

Alejandro OspinaCopyright:

Available Formats

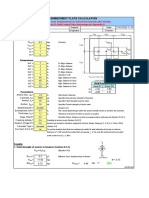

ETABS 2013 13.1.

1 License #

Connection Design: C78-BP

Units: kip-in

Story: Story1

Design Code: AISC 360-10

Column Base Plate Connection

Summary of results

Design Check Type D/C Ratio Result Reference

1 Minimum base plate thickness NaN Passed

2 Anchor rod strength 0.271 Passed Design Guide 1, Secion 3.2.1

3 Weld strength 0.026 Passed J2-2, J2-3

4 Column web stress 0.051 Passed

5 Concrete pullout strength 0.146 Passed

6 Concrete breakout strength 0.05 Passed

7 Side-face blowout strength 0.012 Passed

Material Properties

Column W12X96 A992Fy50 Fy = 50 ksi Fu = 65 ksi

Base Plate A992Fy50 Fy = 50 ksi Fu = 65 ksi

Geometric Properties

Column W12X96 tw = 0.55 in d = 12.7 in tf = 0.9 in bf = 12.2 in

Bolts, Plate & Weld

Anchor rod Diameter = 0.98425 in Head/Nut type = Square Material = ASTM F1554 Grade36

Base Plate Width = 20.57 in Height = 20.07 in Thickness = 0.73819 in

Pedestal

Dimensions Width = 622.58 in Height = 609.88 in

Design Calculations

METALERO METAL.EDB Page 1 of 5 19/03/2021

ETABS 2013 13.1.1 License #

Design calculations of base plate for combined moment and tension

Design Provision = LRFD

Load Combination = DStlS1

Pu = 3.04 kips, Mu = 186.29 kip-in

Base plate area

N = 19 in, d = 12.7 in

N ≥ d + 2x3 inch

B = 12.2 in and bf = 12.2 in

B ≥ bf + 2x3 inch

s1 is less than d, so N is adjusted as

N = max(d + 2(Leh + c), N) N = max(12.7 + 2(2.46 + 1.48),19) N = 20.57 in

S2 is less than bf, so B is adjusted as

B = max(bf + 2(Lev + c), B) B = max(12.2 + 2(2.46 + 1.48),19) B = 20.07 in

A1 = B*N A1 = 19*19 A1 = 361 in2

A2 = (B + 2a)(N + 2b) A2 = (19 + 2*1.97)(19 + 2*1.97) A2 = 526.11 in2

Base plate dimension(N inch x B inch) = 20.5740157480315 x 20.0740157480315

Bearing length, Y and anchor rod tension TU

Mu 186.29

e= e= e = 61.21 in

Pu 3.04

A2

fp (max) = ϕ0.85fc' min(√ , 2)

A1

526.11 fp (max) = 1.83 ksi

fp (max) = 0.65*0.85*4min(√ , 2)

526.11

kips

qmax = fp (max)B qmax = 1.83*20.07 qmax = 36.75

in

N N (2Pu (f-e))

Y1 = (f + ) + √[f + ]2 -

2 2 qmax

20.57 20.57 2 (23.04(7.83-61.21))

Y1 = (7.83 + ) + √[7.83 + ] - Y1 = 36.47 in

2 2 36.75

N N (2Pu (f-e))

Y2 = (f + )-√[f + ]2 -

2 2 qmax

20.57 20.57 2 (23.04(7.83-61.21))

Y2 = (7.83 + )-√[7.83 + ] -

2 2 36.75

Y2 = -0.24246 in

N 20.57

f= -L f= -2.46 f = 7.83 in

2 eh 2

Y = min(Y1 , Y2 ) Y = min(36.47, -0.24246) Y = -0.24246 in

Mu Pu 186.29 3.04

Tu = + Tu = + Tu = 13.42 kips

N-2Leh 2 20.57-22.46 2

Tu 13.42 kips

Pr = Pr = Pr = 6.71

2 2 bolt

METALERO METAL.EDB Page 2 of 5 19/03/2021

ETABS 2013 13.1.1 License #

Minimum base plate thickness

At bearing interface

N-0.95d 20.57-0.95*12.7

m= m= m = 4.25 in

2 2

B-0.8bf 20.07-0.8*12.2

n= n= n = 5.16 in

2 2

Y is less than max(m, n) so

y

fp Y(n- )

tp (min) = 2.11√ 2

Fy

0.24246

√1.83*-0.24246(5.16-- 2

) tp (min) = NaN in

tp (min) = 2.11

50

At tension interface

d tf 12.7 0.9

x = f- + x = 7.83- + x = 1.93 in

2 2 2 2

Tu x

tp2 (min) = 2.11√

BFy

13.42*1.93 tp2 (min) = 0.33867 in

tp2 (min) = 2.11√

20.07*50

tp (min) = max(tp1 (min), tp2 (min)) tp (min) = max(NaN, 0.33867) tp (min) = NaN in

tp (min) NaN

D/C Ratio = D/C Ratio = D/C Ratio = NaN

t 0.73819

The minimum thickness for base plate is NaN inch

Anchor rod strength, Reference(Design Guide 1, Secion 3.2.1)

Force per anchor rod

Tu 13.42 kips

Pr = Pr = Pr = 6.71

2 2 bolt

πdr 2 3.14*0.984252

Ar = Ar = Ar = 0.76047 in2

4 4

Rn = 0.75Fu Ar Rn = 0.75*58*0.76047 Rn = 33.08 kips

ϕRn = ϕRn ϕRn = 0.75*33.08 ϕRn = 24.81 kips

Pr 6.71

D/C Ratio = D/C Ratio = D/C Ratio = 0.27052

ϕRn 24.81

D/C Ratio is less than 1, Design is OK

Weld strength, Reference(J2-2, J2-3)

beff = s2 -tw beff = 11.13-0.55 beff = 10.58 in

Pr 6.71

Ruw = Ruw = Ruw = 0.63461 kips

beff 10.58

0.707D

ϕRn = 2ϕ1.5*0.6FEXX *1*

16

0.707*5.91

ϕRn = 2*0.751.5*0.6*70*1* ϕRn = 24.66 kips

16

Ruw 0.63461

D/C Ratio = D/C Ratio = D/C Ratio = 0.02573

ϕRn 24.66

METALERO METAL.EDB Page 3 of 5 19/03/2021

ETABS 2013 13.1.1 License #

D/C Ratio is less than 1, fillet on each side of the web is ok

Column web stress

beff = s2 -tw beff = 11.13-0.55 beff = 10.58 in

Pr 6.71

Ruw = Ruw = Ruw = 0.63461 kips

beff 10.58

2Ruw 2*0.63461

Ws = Ws = W s = 2.31 ksi

tw 0.55

ws 2.31

D/C Ratio = D/C Ratio = D/C Ratio = 0.05128

0.9Fy 0.950

D/C Ratio is less than 1, Design is OK

Concrete pullout strength

ϕNp = ϕψ4 Abrg 8fc '

ϕNp = 0.7*1.4*1.47*8*4 ϕNp = 45.94 kips

Pr 6.71

D/C Ratio = D/C Ratio = D/C Ratio = 0.14609

ϕNp 45.94

D/C Ratio is less than 1, Design is OK

Concrete breakout strength

ca1 = Leh + b ca1 = 2.46 + 1.97 ca1 = 4.43 in

ca2 = Lev + a ca2 = 2.46 + 1.97 ca2 = 4.43 in

ANo = 9hef 2 ANo = 9*19.692 ANo = 3487.51 in2

An = (2ca2 + min(3hef , s2 )(ca1 + min((s1 + ca1 ), 1.5hef )))

An = (2*4.43 + min(3*19.69, 11.13)(4.43 + min((11.13 + 4.43),1.5*19.69))) An = 231.2 in2

hef is greater than 11 in, soϕNcbg is

5 An

ϕNcbg = ϕψ3 16√fc ' [hef ]3 ( )

ANo

5 231.2

ϕNcbg = 0.7*1.25*16*√4*[19.69]3 ( )

3487.51

ϕNcbg = 266.4 kips

Tu 13.42

DCR = DCR = DCR = 0.05039

ϕNcbg 266.4

D/C Ratio is less than 1, Design is OK

Side-face blowout strength

ca1 = min((Leh + b), (Lev + a)) ca1 = min((2.46 + 1.97), (2.46 + 1.97)) ca1 = 4.43 in

caz = min((Leh + b), (Lev + a)) ca2 = max((2.46 + 1.97), (2.46 + 1.97)) ca2 = 4.43 in

Nsbg = ϕ13ca1 λa √Abrg fc '

Nsbg = 0.75*13*4.43*1 √0.75*4 Nsbg = 181.77 kips

hef > 2.5Ca1

Side-face blow out will control the design

S2 6Ca1

edge anchors work as group

METALERO METAL.EDB Page 4 of 5 19/03/2021

ETABS 2013 13.1.1 License #

s2 11.13

Nsbg = (1 + )N Nsbg = (1 + )*181.77 Nsbg = 257.87 kips

6ca1 sb 6*4.43

Tu 3.04

D/C Ratio = D/C Ratio = D/C Ratio = 0.0118

Nsbg 257.87

D/C Ratio is less than 1, side face blowout is not possible

METALERO METAL.EDB Page 5 of 5 19/03/2021

You might also like

- Games Workshop - Warhammer Townscapes (1988)Document46 pagesGames Workshop - Warhammer Townscapes (1988)Soulpunch97% (29)

- Cavern of The Fear (Deltora Shadowlands, N. 1) by Emily RoddaDocument123 pagesCavern of The Fear (Deltora Shadowlands, N. 1) by Emily Roddamaheshwa100% (3)

- Anchor Chair Design - Version 1Document3 pagesAnchor Chair Design - Version 1Rey Fiedacan100% (3)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Brochure Uffizi WEB ENGLISH-Pubblicazione-3.12Document3 pagesBrochure Uffizi WEB ENGLISH-Pubblicazione-3.12Anonymous PYgnwOWKNo ratings yet

- Determination of Footing Dimensions: Na All FDocument4 pagesDetermination of Footing Dimensions: Na All FLenielle AmatosaNo ratings yet

- Base Plate CircularDocument8 pagesBase Plate Circularmrprabhu16No ratings yet

- Processing - THERM - S-I - FS-I - 2017 (RAICO) PDFDocument174 pagesProcessing - THERM - S-I - FS-I - 2017 (RAICO) PDFAnrStukNo ratings yet

- Connection Design: C1-BP: ETABS 2016 16.2.1 License # 13GKCULR7HUKDLFDocument5 pagesConnection Design: C1-BP: ETABS 2016 16.2.1 License # 13GKCULR7HUKDLFjaicollaNo ratings yet

- EQ2 1st Flooor ColumnDocument17 pagesEQ2 1st Flooor ColumnWilbert Carlo RachoNo ratings yet

- EQ2 2nd Floor ColumnDocument17 pagesEQ2 2nd Floor ColumnWilbert Carlo RachoNo ratings yet

- Placa Base c740-BpDocument3 pagesPlaca Base c740-BpuetingenieriasasNo ratings yet

- Column Design at 3 Floor: Uact U 4 F UactDocument16 pagesColumn Design at 3 Floor: Uact U 4 F UactWilbert Carlo RachoNo ratings yet

- Design of SlabDocument14 pagesDesign of Slabابراهيم المبيضينNo ratings yet

- Conexion Viga - PilarDocument5 pagesConexion Viga - PilarAlejandro OspinaNo ratings yet

- Base Plate Design MS601a - BS - CodeDocument4 pagesBase Plate Design MS601a - BS - CodeRAMSNo ratings yet

- Column 5: Column Design at 3 Floor C. Total Loading Liveload 52.0778 KN Deadload 198.433 KN E 75.087KNDocument6 pagesColumn 5: Column Design at 3 Floor C. Total Loading Liveload 52.0778 KN Deadload 198.433 KN E 75.087KNWilbert Carlo RachoNo ratings yet

- Tank Anchor Bolt DesignDocument9 pagesTank Anchor Bolt Designgon972001100% (1)

- Connection Design: B104-CJ: ETABS 2016 16.0.3 License # 15QT3R6KGWUL9HRDocument4 pagesConnection Design: B104-CJ: ETABS 2016 16.0.3 License # 15QT3R6KGWUL9HReffan f gultomNo ratings yet

- Check Punching For Edge ColumnsDocument5 pagesCheck Punching For Edge ColumnsAli AbdallahNo ratings yet

- Example II.B-4 Four-Bolt Unstiffened Extended End-Plate FR Moment Connection (Beam-To-Column Flange)Document9 pagesExample II.B-4 Four-Bolt Unstiffened Extended End-Plate FR Moment Connection (Beam-To-Column Flange)Luis TorresNo ratings yet

- DesignDocument13 pagesDesignAnshulGuptaNo ratings yet

- Base Plate Design MS601a - BS - CodeDocument4 pagesBase Plate Design MS601a - BS - CodeCivil StructureNo ratings yet

- Isolated Footing (ACI)Document4 pagesIsolated Footing (ACI)Boubakeur FerkousNo ratings yet

- Chapter 2Document13 pagesChapter 2muhamad irvanNo ratings yet

- Combined FootingDocument7 pagesCombined FootingMohammed ElemamNo ratings yet

- Isolated Footing P OnlyDocument14 pagesIsolated Footing P OnlyAhmed AbuoelnagaNo ratings yet

- Determination of Footing Dimensions: Na All FDocument4 pagesDetermination of Footing Dimensions: Na All FMohammed ElemamNo ratings yet

- Isolated Footing (ACI)Document4 pagesIsolated Footing (ACI)engyana engyyyNo ratings yet

- Wall Design ProgramDocument12 pagesWall Design Programaaalcantara3520qcNo ratings yet

- Slab DesignDocument12 pagesSlab DesignPAOLO AGORILLANo ratings yet

- Timber Circular Columns 1Document4 pagesTimber Circular Columns 1John SmithNo ratings yet

- EQ2 3rd Floor ColumnDocument17 pagesEQ2 3rd Floor ColumnWilbert Carlo RachoNo ratings yet

- Design and Analysis For First Floor BeamDocument2 pagesDesign and Analysis For First Floor BeamVergel Pabunan NogadasNo ratings yet

- Anchor Bolt CHKDocument17 pagesAnchor Bolt CHKPriya GNo ratings yet

- Design of Stairs and Landing: Page NoDocument6 pagesDesign of Stairs and Landing: Page NoJun Dela PeñaNo ratings yet

- Connection Design: B19-CI: Units: Kip-In Story: Story1 Design Code: AISC 360-10Document6 pagesConnection Design: B19-CI: Units: Kip-In Story: Story1 Design Code: AISC 360-10surbanoj_79No ratings yet

- Combined Footing DesignDocument1 pageCombined Footing DesignOSCARTAWNNo ratings yet

- Act1 SpecDocument14 pagesAct1 Specabandiola3819qcNo ratings yet

- Etabs 2016 16.2Document6 pagesEtabs 2016 16.2kervinarmasNo ratings yet

- (Reviewed) Auto Update Torsion Design BaldesansoDocument40 pages(Reviewed) Auto Update Torsion Design BaldesansoElmer Leyson BaldesansoNo ratings yet

- Base Plate DesignMS601a Good MahfuzDocument4 pagesBase Plate DesignMS601a Good MahfuzDavid PuenNo ratings yet

- Embedpl v1-4 Demo PDFDocument5 pagesEmbedpl v1-4 Demo PDFMWKELIOLANo ratings yet

- Beam DesignDocument2 pagesBeam DesignJelal EdrisNo ratings yet

- Quality of Materials:: Large Moment Base Plate Design AISC LRFD - MethodeDocument7 pagesQuality of Materials:: Large Moment Base Plate Design AISC LRFD - MethodejunarkoNo ratings yet

- Section 17Document41 pagesSection 17Mark EstepaNo ratings yet

- G4e - G4F (4TH Floor)Document12 pagesG4e - G4F (4TH Floor)Zyril BestoNo ratings yet

- Perhitungan Balok Dua Tumpuan SRPMM SNIDocument5 pagesPerhitungan Balok Dua Tumpuan SRPMM SNIahmadbagusNo ratings yet

- Ground Floor Beam - Gb1: Project Owner DescriptionDocument104 pagesGround Floor Beam - Gb1: Project Owner DescriptionTewodros AbateNo ratings yet

- Torsion DesignDocument45 pagesTorsion DesigngirumNo ratings yet

- Aliran Dalam PipaDocument15 pagesAliran Dalam PipaWidya AndaniNo ratings yet

- 4.4 Base Plate and Anchor Bolt CheckDocument1 page4.4 Base Plate and Anchor Bolt Checksrikanth varmaNo ratings yet

- Semister Assignement: Composite Structure: K, 1 K, 2 K, 1 K, 2Document15 pagesSemister Assignement: Composite Structure: K, 1 K, 2 K, 1 K, 2Belay BayuNo ratings yet

- First Floor Beam - (On Axis B B/N 2&3) : 1 1 1 2 MR 1 1 1 2 MR 1 1 1 2 MR 1 1 1 2 MRDocument1 pageFirst Floor Beam - (On Axis B B/N 2&3) : 1 1 1 2 MR 1 1 1 2 MR 1 1 1 2 MR 1 1 1 2 MRJelal1No ratings yet

- Chapter3 - Analysis Ofwind Loads Acting On StructuresDocument6 pagesChapter3 - Analysis Ofwind Loads Acting On Structuresdagmawi girmaNo ratings yet

- Composite Column DesignDocument3 pagesComposite Column DesignSuraj de SilvaNo ratings yet

- Timber DesignDocument62 pagesTimber DesignLovely Brecio CalixtroNo ratings yet

- Analisa DataDocument39 pagesAnalisa DataUtomo YohanesNo ratings yet

- Anes Proracun VratilaDocument9 pagesAnes Proracun VratilaANES HAJDAREVIĆNo ratings yet

- Example - Trusses Subject To Compression and TensionDocument6 pagesExample - Trusses Subject To Compression and TensionHalina HamidNo ratings yet

- Embedded Plates Calculation - Part 2Document8 pagesEmbedded Plates Calculation - Part 2Mai CNo ratings yet

- End Plate - Bolted ConnectionDocument3 pagesEnd Plate - Bolted ConnectionASKOKONo ratings yet

- Instructor's Manual to Accompany CALCULUS WITH ANALYTIC GEOMETRYFrom EverandInstructor's Manual to Accompany CALCULUS WITH ANALYTIC GEOMETRYNo ratings yet

- Conexion Viga - PilarDocument5 pagesConexion Viga - PilarAlejandro OspinaNo ratings yet

- W Steel Section Tables 080307 PDFDocument5 pagesW Steel Section Tables 080307 PDFAlejandro OspinaNo ratings yet

- Model of Tuned Liquid Damper For Suppressing Pitching Motions of StructuresDocument12 pagesModel of Tuned Liquid Damper For Suppressing Pitching Motions of StructuresAlejandro OspinaNo ratings yet

- Effectiveness of A 2D TLD and Its Numerical Modeling: M. J. Tait, A.M.ASCE N. Isyumov, F.ASCE and A. A. El DamattyDocument13 pagesEffectiveness of A 2D TLD and Its Numerical Modeling: M. J. Tait, A.M.ASCE N. Isyumov, F.ASCE and A. A. El DamattyAlejandro OspinaNo ratings yet

- Mecánica de FLuidos - JAMES FAY PDFDocument312 pagesMecánica de FLuidos - JAMES FAY PDFAlejandro OspinaNo ratings yet

- Architecture, Urbanism and The Good Neighbour - Lauro CavalcantiDocument5 pagesArchitecture, Urbanism and The Good Neighbour - Lauro CavalcantiChristian NoetzlyNo ratings yet

- Drilled Cast-In-Place Pile Design Based On ACI 318-08Document17 pagesDrilled Cast-In-Place Pile Design Based On ACI 318-08Habibur RahmanNo ratings yet

- Full Test Bank For Economics Today The Macro View 5Th Canadian Edition Miller PDF Docx Full Chapter ChapterDocument35 pagesFull Test Bank For Economics Today The Macro View 5Th Canadian Edition Miller PDF Docx Full Chapter Chapterjohnathannealy03w100% (12)

- ID Perhitungan Struktur Beton Bertulang Ged PDFDocument10 pagesID Perhitungan Struktur Beton Bertulang Ged PDFchrisNo ratings yet

- Dental College LDC Post12 02 2020Document118 pagesDental College LDC Post12 02 2020droidNo ratings yet

- Economic Housing-Floor Plans 1Document1 pageEconomic Housing-Floor Plans 1Andrew AmedaNo ratings yet

- Window Sizes HOutDocument11 pagesWindow Sizes HOutAustine MakateNo ratings yet

- Basic Characteristics of Concrete PDFDocument14 pagesBasic Characteristics of Concrete PDFHarold Taylor100% (1)

- London AttractionsDocument3 pagesLondon AttractionswadiwanNo ratings yet

- FM-200 Engineered Nozzles IV.1.03.01Document2 pagesFM-200 Engineered Nozzles IV.1.03.01hdrNo ratings yet

- Elevator DSA OSHPDDocument2 pagesElevator DSA OSHPDjorge01No ratings yet

- Gateleg Table Plan PDFDocument18 pagesGateleg Table Plan PDFraouf menchariNo ratings yet

- EnergyShield Pro-DataSheetDocument2 pagesEnergyShield Pro-DataSheetantonio angaritaNo ratings yet

- Naurang Yatri Niwas, Garli.: Historical Context of The BuildingDocument13 pagesNaurang Yatri Niwas, Garli.: Historical Context of The BuildingRiddhi AggarwalNo ratings yet

- Full Download pdf of (eBook PDF) Managing the Law The Legal Aspects of Doing Business 4th all chapterDocument24 pagesFull Download pdf of (eBook PDF) Managing the Law The Legal Aspects of Doing Business 4th all chaptertujabrhel100% (3)

- A.description - Of.the - East.and - Some.other - Countries.vol1.1743 R.pocockeDocument496 pagesA.description - Of.the - East.and - Some.other - Countries.vol1.1743 R.pocockemiddlekeyNo ratings yet

- My PortfolioDocument9 pagesMy PortfolioJohn Tristan GonzalesNo ratings yet

- Apcotherm Epn 200Document2 pagesApcotherm Epn 200Moin AltafNo ratings yet

- Sump DetailDocument1 pageSump DetailSandeep VarmaNo ratings yet

- Islamic Architecture 1Document56 pagesIslamic Architecture 1Jeff Angelo GalingNo ratings yet

- Stairs: To Afford The Means of Ascent and Descent Between Various Floors of The BuildingDocument26 pagesStairs: To Afford The Means of Ascent and Descent Between Various Floors of The BuildingAnn GertrudeNo ratings yet

- Descriptive Text Is A Text Which Say What A Person or A Thing Is Like. Its Purpose Is To Describe and Reveal A Particular Person, Place, or ThingDocument2 pagesDescriptive Text Is A Text Which Say What A Person or A Thing Is Like. Its Purpose Is To Describe and Reveal A Particular Person, Place, or ThingAnonymous KNnsXtzLDNo ratings yet

- Construction Materials Civil Engineering DepartmentDocument57 pagesConstruction Materials Civil Engineering DepartmentJai Ganesh100% (1)

- Slums and The City - Bhawna Jaimini, Hunnarshala FOundationDocument9 pagesSlums and The City - Bhawna Jaimini, Hunnarshala FOundationdiptilundiaNo ratings yet

- Strip FootingDocument10 pagesStrip FootingKain Pasang Ruby IINo ratings yet

- Schedule BDocument32 pagesSchedule BpanikarickyNo ratings yet