Professional Documents

Culture Documents

A Study On Power Factor Correction With

A Study On Power Factor Correction With

Uploaded by

shehboz ershodCopyright:

Available Formats

You might also like

- Electric Power Distribution Project ReportDocument20 pagesElectric Power Distribution Project ReportSaleh Ahmad100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Power Factor ImprovementDocument8 pagesPower Factor ImprovementmshahidshaukatNo ratings yet

- Power System AnalysisDocument4 pagesPower System Analysisahmedfhd1No ratings yet

- Print Head Repair Secrets - William HorDocument137 pagesPrint Head Repair Secrets - William HorJay Ilagan100% (3)

- Energy Management & Conservation: Session Four Instructor - Pramod Daspute BEE Certified Energy AuditorDocument18 pagesEnergy Management & Conservation: Session Four Instructor - Pramod Daspute BEE Certified Energy AuditorUjjwal Kumar SinghNo ratings yet

- Paper #37CDocument6 pagesPaper #37CDrAdel A. ElbasetNo ratings yet

- Smoothing of Grid-Connected Wind-Diesel Power Output Using Energy Capacitor SystemDocument6 pagesSmoothing of Grid-Connected Wind-Diesel Power Output Using Energy Capacitor SystemDrAdel A. ElbasetNo ratings yet

- En TH01!11!2004 Power Factor CorrectionDocument12 pagesEn TH01!11!2004 Power Factor CorrectionSirish SabbellaNo ratings yet

- BidireDocument11 pagesBidiretadivadavamsiNo ratings yet

- Power Factor CorrectionDocument6 pagesPower Factor Correctionmostafa HusseinNo ratings yet

- How Capacitors Improve The Power Factor and How To Calculate Them - EEPDocument4 pagesHow Capacitors Improve The Power Factor and How To Calculate Them - EEPMohamedAhmedFawzy100% (1)

- Convention Centre-E-8.11.2019 - R0Document11 pagesConvention Centre-E-8.11.2019 - R0ManojNo ratings yet

- Capacitor BanksDocument7 pagesCapacitor BanksMilton EspinozaNo ratings yet

- Submission+07+-+copyedited V2+Document13 pagesSubmission+07+-+copyedited V2+Sơn Phạm ThanhNo ratings yet

- DC DC ConvertorDocument11 pagesDC DC ConvertorJyothiNo ratings yet

- Findings and ResearchDocument33 pagesFindings and Researchuaminu422No ratings yet

- Basics of Low Voltage Systems Design-Ver.01Document158 pagesBasics of Low Voltage Systems Design-Ver.01MohamedAhmedFawzy50% (2)

- Scholar Search: A Simplistic Technique For Power Factor Compensation Capacity Calculation in Medium Size IndustryDocument7 pagesScholar Search: A Simplistic Technique For Power Factor Compensation Capacity Calculation in Medium Size IndustryfathieldrassiNo ratings yet

- Renewable Energy Photovoltaic IVDocument77 pagesRenewable Energy Photovoltaic IVcharbel jabbourNo ratings yet

- S NoteDocument116 pagesS NoteankitNo ratings yet

- @@power Factor Correction of Coet - 100605Document63 pages@@power Factor Correction of Coet - 100605Sangiwa SalimNo ratings yet

- How To Apply Capacitors To Low Voltage Power Systems.Document13 pagesHow To Apply Capacitors To Low Voltage Power Systems.Ahmed Reda Abdou MohamedNo ratings yet

- Solar Charging Station For Electric VehiclesDocument5 pagesSolar Charging Station For Electric VehiclesDriss OuladabbouNo ratings yet

- Analysis On Multiple Combinations of Series Parallel Connections of Super Capacitors For Maximum Energy Transferring To Load in Minimum TimeDocument9 pagesAnalysis On Multiple Combinations of Series Parallel Connections of Super Capacitors For Maximum Energy Transferring To Load in Minimum TimeAkhilesh NimjeNo ratings yet

- Capacitor Banks in Power System Part FourDocument4 pagesCapacitor Banks in Power System Part FourTigrillo100% (1)

- Quadratic Boost Converter With Less Input Current Ripple and Rear-End Capacitor Voltage Stress For Renewable Energy ApplicationsDocument11 pagesQuadratic Boost Converter With Less Input Current Ripple and Rear-End Capacitor Voltage Stress For Renewable Energy ApplicationsSureshkumar AlagarsamyNo ratings yet

- A Wide Band Gap Devices Based Switched Capacitor Circuits For Photovoltaic ApplicationsDocument10 pagesA Wide Band Gap Devices Based Switched Capacitor Circuits For Photovoltaic ApplicationsMIKS DARKNo ratings yet

- Electrical SystemDocument75 pagesElectrical SystemS Bharadwaj Reddy75% (4)

- Unit3 - Electrical SystemDocument57 pagesUnit3 - Electrical SystemNethaji BKNo ratings yet

- FUTO SIWES TrainingDocument27 pagesFUTO SIWES Trainingugwuegbuchibuike2003No ratings yet

- Power Factor Management Scheme Is Best Described Here.Document42 pagesPower Factor Management Scheme Is Best Described Here.Sunil SinghNo ratings yet

- Solar IrradiationDocument4 pagesSolar IrradiationL CHNo ratings yet

- Electric Machine Lab3Document19 pagesElectric Machine Lab3NiTrO jOk3RNo ratings yet

- Power FactorDocument28 pagesPower Factoravijeet2828100% (1)

- Challenges and Opportunities of RooftopDocument9 pagesChallenges and Opportunities of RooftopYousup AliNo ratings yet

- Review of Related Literature: 2.1.1 Indoor Light Energy HarvestingDocument14 pagesReview of Related Literature: 2.1.1 Indoor Light Energy HarvestingGillian AmbaNo ratings yet

- Utilization of Electrical Energy: CHAPTER 6: Demand Side Management L-6-2Document17 pagesUtilization of Electrical Energy: CHAPTER 6: Demand Side Management L-6-2Frozen BoyNo ratings yet

- K.G.Harish,: Dy - Manager (Utilities) Glaxo Smithkline Consumer Healthcare Ltd. Sonepat. HaryanaDocument7 pagesK.G.Harish,: Dy - Manager (Utilities) Glaxo Smithkline Consumer Healthcare Ltd. Sonepat. HaryanaSam MillerNo ratings yet

- Diesel Generator SetDocument17 pagesDiesel Generator Setcellr2885No ratings yet

- Wind Powered Mobile Phone ChargerDocument9 pagesWind Powered Mobile Phone ChargerTutor Cad Elec ProgNo ratings yet

- Power FactorDocument48 pagesPower FactortyutyuNo ratings yet

- Design of Power Converters For Renewable Energy Sources and Electric Vehicles ChargingDocument6 pagesDesign of Power Converters For Renewable Energy Sources and Electric Vehicles ChargingRay Aavanged IINo ratings yet

- Analysis of Real and Reactive Power Mode of Operation of Electric Vehicle in A DFIG Based Wind FarmDocument5 pagesAnalysis of Real and Reactive Power Mode of Operation of Electric Vehicle in A DFIG Based Wind FarmbelbymathewNo ratings yet

- 2008 Braun EwecDocument10 pages2008 Braun EwecfarzanesunflowerNo ratings yet

- Abstract - : The Energy Usage IsDocument5 pagesAbstract - : The Energy Usage IsNunna BaskarNo ratings yet

- Electrical Systems: Power Factor Correction: Ps Supplied Power (Kva) PR Reactive Power (Kvar)Document28 pagesElectrical Systems: Power Factor Correction: Ps Supplied Power (Kva) PR Reactive Power (Kvar)Mahendra KumarNo ratings yet

- Tutorial 4 - SolutionDocument3 pagesTutorial 4 - Solutionkant734No ratings yet

- Chapter 2 - 2Document58 pagesChapter 2 - 2Firdaus Khairi100% (1)

- Ee 308Document15 pagesEe 308catdogsunmoon12No ratings yet

- 45 16255 EE543 2015 1 1 1 Week 8 9Document25 pages45 16255 EE543 2015 1 1 1 Week 8 9Kristel Mae Hertz CastilloNo ratings yet

- Assignment No. 6: Energy Conservation and ManagementDocument28 pagesAssignment No. 6: Energy Conservation and ManagementYashashree Gedam100% (1)

- PF Improvement On DG SetsDocument8 pagesPF Improvement On DG SetsAnupam SharmaNo ratings yet

- Solar and Wind Hybrid Power Generation: Abstract-This Paper Reflects An Independent DistributedDocument5 pagesSolar and Wind Hybrid Power Generation: Abstract-This Paper Reflects An Independent DistributedDr. Eddie YadavNo ratings yet

- Reactive Power Supplied by Wind Energy Converters - Cost-Benefit-AnalysisDocument10 pagesReactive Power Supplied by Wind Energy Converters - Cost-Benefit-AnalysisjandazNo ratings yet

- SmartGrid vs MicroGrid; Energy Storage Technology: Energy, #2From EverandSmartGrid vs MicroGrid; Energy Storage Technology: Energy, #2No ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Danaher Trouble Shooting CodesDocument8 pagesDanaher Trouble Shooting CodesHarits PermanaNo ratings yet

- VLSI DesignDocument7 pagesVLSI DesignVarun ThejNo ratings yet

- DE Question BankDocument5 pagesDE Question BankKaree MullahNo ratings yet

- Sensymaster Fmt430, Fmt450: Thermal Mass FlowmeterDocument68 pagesSensymaster Fmt430, Fmt450: Thermal Mass FlowmeterGabriela CastroNo ratings yet

- Are Optical Transistors The Logical Next Step?: CommentaryDocument3 pagesAre Optical Transistors The Logical Next Step?: CommentaryAhmed IbrahimNo ratings yet

- BA-LT2Ex DLT3006-15-aEN-031Document102 pagesBA-LT2Ex DLT3006-15-aEN-031Banu EdoNo ratings yet

- Winter Semester 2021-22 All Course Allocation Report Except LAW (1) - RemovedDocument6 pagesWinter Semester 2021-22 All Course Allocation Report Except LAW (1) - RemovedAbi nashNo ratings yet

- Tannoy Mercury V4iDocument12 pagesTannoy Mercury V4iChris YorkNo ratings yet

- Unit Iii Micro W A VE Solid State DevicesDocument7 pagesUnit Iii Micro W A VE Solid State DevicesRAJASHEKHARNo ratings yet

- Worker'S Assistant Robot Using Myrio and Labview: April 2019Document6 pagesWorker'S Assistant Robot Using Myrio and Labview: April 2019chuyen truongNo ratings yet

- UPS No-Break PoE Switch 2022.3.5 - CompressedDocument38 pagesUPS No-Break PoE Switch 2022.3.5 - CompressedHong Kwok FaiNo ratings yet

- Datasheet SUN2000 100KTL M1 AFCIDocument2 pagesDatasheet SUN2000 100KTL M1 AFCIShin UchihaNo ratings yet

- The Factors Affecting The Performance of Solar Cell: Bhalchandra V. Chikate Y.A. SadawarteDocument5 pagesThe Factors Affecting The Performance of Solar Cell: Bhalchandra V. Chikate Y.A. Sadawartepragya mitaNo ratings yet

- Pcs TCM 2800 - 200Document1 pagePcs TCM 2800 - 200Garrett AinsworthNo ratings yet

- Datasheet HT6P20BDocument9 pagesDatasheet HT6P20BJosihel AndradeNo ratings yet

- PrimeMotion C ENDocument2 pagesPrimeMotion C ENHAPPY KLUBNo ratings yet

- How To Use 24 TFT LCD Shield With Arduino Mega PDFDocument4 pagesHow To Use 24 TFT LCD Shield With Arduino Mega PDFYeiner Smith Polo MercadoNo ratings yet

- Design of Current Mode ComparatorDocument13 pagesDesign of Current Mode ComparatorAbdelRahman MahmoudNo ratings yet

- ATP Hydraulic Owner Install Guide ATP62 r081517 WEBDocument56 pagesATP Hydraulic Owner Install Guide ATP62 r081517 WEBIngo BorchersNo ratings yet

- IC307 Industrial Instrumentation - IDocument2 pagesIC307 Industrial Instrumentation - IAKSHAY KRISHNA K RNo ratings yet

- Power Electronics Circuit Analysis and DesignDocument683 pagesPower Electronics Circuit Analysis and DesignSameerAhmedNo ratings yet

- ALL Service Menu TVDocument23 pagesALL Service Menu TVnenengNo ratings yet

- Penmount 1610 Control Board Data SheetDocument2 pagesPenmount 1610 Control Board Data Sheetnelson david pineda higueraNo ratings yet

- Growatt 17000TL3-S/20000TL3-S/ 25000TL3-S: Leading - Edge TechnologyDocument2 pagesGrowatt 17000TL3-S/20000TL3-S/ 25000TL3-S: Leading - Edge TechnologyMohamed SomaiNo ratings yet

- Texas Instruments HDMI Design GuideDocument12 pagesTexas Instruments HDMI Design GuidenaveenkumarNo ratings yet

- User ManualDocument76 pagesUser ManualRodrigo AlejandroNo ratings yet

- A11229 - MotionPRO - UM-Rev1 (Optred) PDFDocument720 pagesA11229 - MotionPRO - UM-Rev1 (Optred) PDFCarlos RodriguesNo ratings yet

- Evaluation and Calibration of An Inertial Measurement Unit: AIP Conference Proceedings December 2018Document10 pagesEvaluation and Calibration of An Inertial Measurement Unit: AIP Conference Proceedings December 2018Anisa FauziahNo ratings yet

- ADXL317Document38 pagesADXL317LeandroNo ratings yet

A Study On Power Factor Correction With

A Study On Power Factor Correction With

Uploaded by

shehboz ershodOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Study On Power Factor Correction With

A Study On Power Factor Correction With

Uploaded by

shehboz ershodCopyright:

Available Formats

Ahmed Rashad .E. Bakr, et. al.

International Journal of Engineering Research and Applications

www.ijera.com

ISSN: 2248-9622, Vol. 11, Issue 1, (Series-II) January 2021, pp. 47-54

RESEARCH ARTICLE OPEN ACCESS

A study on Power Factor Correction with Capacitor Bank Using

ERACS’ Software

Ahmed Rashad .E. Bakr (1), Fawaz .M. Alsubaie (2)

Electrical Networks Department, High Institute of Energy, Public Authority of Applied Education and Training,

KUWAIT

ABSTRACT

This paper intends to briefly compare the Power Factor Correction with Capacitor Bank & without Capacitor

Bank Using ERACS’ Software.

In this Study, capacitors are used in different locations of the network to get the best choice for correction and

capacitor bank technique are applied for different voltage levels in the network such as 33, 11, 6.6 and 0.415 K

volt.

--------------------------------------------------------------------------------------------------------------------------------------

Date of Submission: 01-01-2021 Date of Acceptance: 12-01-2021

---------------------------------------------------------------------------------------------------------------------------------------

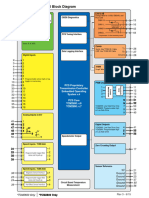

I. INTRODUCTION We will explain the results for using

This Study represents any distributed area capacitor bank to each case and the way for

having both residential and industrial loads, so we calculating the required size of capacitor bank to

invented a network similar to real one. each case.

Figure 1: The Project Network

1.1 Case 1: installing Capacitor bank on bus 1.1.1 Part 1: getting the suitable capacitor

bar 2 rating

The plan is to improve the power factor from 0.75 to The first thing needed is getting the consumed load

0.95 by adding shunt capacitor to bus bar 2, but for the network from eracs simulation, which is done

before that we need to know the value of the after building the network and simulated.

capacitor bank needs.

The consumed power in MVA is 13.518 + j 11.818

and the power factor for the network can be

calculated by

www.ijera.com DOI: 10.9790/9622-1101024754 47 | P a g e

Ahmed Rashad .E. Bakr, et. al. International Journal of Engineering Research and Applications

www.ijera.com

ISSN: 2248-9622, Vol. 11, Issue 1, (Series-II) January 2021, pp. 47-54

This power factor value indicates that the required reactive power to change the power factor

efficiency for the network is 75% and the losses from 0.75 to 0.95. This is done by applying the same

equal 25%, which is huge amount and the network, formula again, which is the new power factor value:

is considered a low quality. Then we need the

Figure 2: this figure show installing capacitor bank on bus bar 2

The amount of reactive power needed by capacitor bank is

We used a simplified constant PQ shunt load to act as shunt capacitor and set the reactive power to 424

MVAR. Then after connecting the capacitor bank we got

The below table summarizes the data for this case:

www.ijera.com DOI: 10.9790/9622-1101024754 48 | P a g e

Ahmed Rashad .E. Bakr, et. al. International Journal of Engineering Research and Applications

www.ijera.com

ISSN: 2248-9622, Vol. 11, Issue 1, (Series-II) January 2021, pp. 47-54

Table 1: Technical data for case 1 before and after correction

Case 1 before correction After correction

Generated Power

13.701 + j 13.637 13.688 + j 6.128

MVA

Consumed power

13.518 + j 11.818 13.518 + j4.394

MVA

Loss power

0.183 + j 1.819 0.17 + j1.734

MVA

Power factor 0.75 0.95

1.1.2 Part 2: Calculation of the cost assumption that in this case the number of hours for

The cost of adding capacitor bank that includes the electricity are supposed to be 18 a day.

fixed price of capacitor bank and the time needed to

cover the cost of capacitor bank should be Total MwH = 13.518Mw x 365 days x 18 hour =

considered. In addition, the variable cost that is 88813.26 MwH

related to the cost of KVA and compared with the According to the majority of electric companies in

original network before the power factor correction the UK, the cost for each KwH is equal to £0.2.

should also be taken into consideration. Then, we can get the total cost for a year as follows:

The total cost for KwH = 88813.26 x 103 x 0.2

without the capacitor bank £/KwH = £17762652

The calculation can be verified by the following The total cost for electric companies includes two

steps: parts, which are a fixed cost represented in

1- The electric provider or company will consumed KVA and the real power consumed:

produce a certain amount of power and a portion The total cost per year = the total cost for power in

will be lost in the system because of the losses from KVA + The total cost for KwH

the electrical equipment. These losses result from = 1795554.087 + 17762652

transformers, cables and over headlines which can = £19558206.09

be reduced if capacitor bank is installed to the

generation side for network and this will reduce the with the capacitor bank

total cost of generation to the electric provider It is seen that the consumed power was 13.518+j

before getting to consumers. From the ERCS 11.818 before using capacitor bank, while it became

simulation the generated power is equal to 13.701 + 13.518+j 4.394 after the compensation which

j 13.637Mvar, whereas the net power supplied the indicate reduction of the amount of reactive power

load is 13.518 + j 11.818Mvar which indicates that by 7.424 MVAR which reduce the cost of consumed

1.819 Mw is the total loss to this network. power to electric provider. This also can help to

reduce the load for the electrical equipment, which

2- It is possible to get the cost of consumed can help for adding more loads in the future with the

power by taking assumption for the cost of each same equipment and extend the duration for the

KVA. Assume that each 1KVA cost £100, the total equipment because the usage is under the maximum

cost for the consumed power can be computed as rate. I will follow the same assumption above and

below: we will get:

The total cost for power in KVA = 17.95 x 103 x 100 The total cost for power in KVA = 14.214 x 103 x

£ /KVA = £1795554.087 100 £ /KVA = £1421420.27

The electric company can charge mainly the

consumers for the real power used during certain This cost is less compared to the network before

time of the day or month. In case of using capacitor using the capacitor bank. It can be approved by

bank, the reactive power will be reduced and that referring to the cost in both cases:

provides extra space in cables, over headlines and

transformers which can be used in the future to The total cost for KVA was £1795554.087, which

provide extra loads using same equipment taking means that £374133.811 is saved.

www.ijera.com DOI: 10.9790/9622-1101024754 49 | P a g e

Ahmed Rashad .E. Bakr, et. al. International Journal of Engineering Research and Applications

www.ijera.com

ISSN: 2248-9622, Vol. 11, Issue 1, (Series-II) January 2021, pp. 47-54

Assuming that the load of the network is working This can help to save money to electric companies

the whole year for 18 hours daily and the cost for and it can be used to extend the network in the

KwH/year is equal to £0.2 then we can get the total future on the long run.

cost for a year as follows: To get the cost for the capacitor bank we need to

assume that the cost for each 1MVAR.

Total MwH = 13.518Mw x 365 days x 18 hour =

88813.26 MwH Assumption: 1MVR costs £16000

Then, capacitor cost = £16000 / MVAR x 8MVAR

This calculation indicates that the total used energy = £128000

is the same before and after using the capacitor bank

because the compensation is done to the reactive It is possible to get the spent money for installing

power only: capacitors by getting the ratio between capacitor

The total cost for KwH = 88813.26 x 103 x 0.2 bank cost and the saved amount form the correction.

£/KwH = £17762652

The total cost per year = the total cost for power in Recovery cost for capacitor =

KVA + The total cost for KwH

= £1421420.27 + 17762652

= £19184072.27

That is a good indicator because the electric

By comparing this to the original network, we found

company can return the spent money for capacitor

Total saving = 19558206.09 – 19184072.27 =

bank in a short period of time.

£374133.82

We can summarize the cost for adding capacitor

bank in the following table:

Table 2: Economical data for case 1 before and after correction

Network after

Case 1 Network before PFC

PFC

Total KVA 17950 14214

Total cost for KVA @100£/KVA 1795554.087 1421420.27

Total Mw H

88813.26 88813.26

@ 18 hours /day in year

Total cost Kw H/year

17762652 17762652

@0.2£/Kw H

Total cost / year 19558206.09 19184072.27

Total saving/year - 374133.82

Capacitor bank cost -

128000

@1MVAR =16000£

Capacitor bank

- 4.13 months

Cost recovery

1.2 Case 2 installing Capacitor bank on bus 1.2.1 Part 1 getting the suitable capacitor

bar 9 The same process is done to calculate the reactive

The plan is to improve the power factor from 0.75 to power needed form the capacitor bank from

0.95 for the network by adding shunt capacitor to bus Eracs simulation. The consumed power in the bus 9

bar 9 which has nominal voltage that is equal to 415 is equal to 1.488 + j 2 and the power factor for the

volt. same bus bar can be calculated by:

www.ijera.com DOI: 10.9790/9622-1101024754 50 | P a g e

Ahmed Rashad .E. Bakr, et. al. International Journal of Engineering Research and Applications

www.ijera.com

ISSN: 2248-9622, Vol. 11, Issue 1, (Series-II) January 2021, pp. 47-54

Then, we need the required reactive power to change 0.6 to 0.95 and this is done by applying the same

the power factor particularly in the bus bar 9 from formula:

Figure 3 :this figure show installing capacitor bank on bus bar

The amount of the reactive power needed there is no ready shunt capacitor in the tools. Then, I

by capacitor bank is entered the value of the reactive power as equal to

which is a smaller amount compared MVAR.

to case 2 because the compensation is done to

individual bus bar only. Then, after connecting the capacitor bank, we

I used the same element to represent the capacitor checked the new power factor for bus bar 9 by

bank which is simplified constant PQ shunt because applying the same formula:

This represents high quality for this bus bar and limited loss.

Then calculating the new power factor to the whole network to check the improvement, it can be seen as below:

This is still not what is recommended for correction and this means that 20% of the power is wasted. The below

table summarizes the data for this case:

www.ijera.com DOI: 10.9790/9622-1101024754 51 | P a g e

Ahmed Rashad .E. Bakr, et. al. International Journal of Engineering Research and Applications

www.ijera.com

ISSN: 2248-9622, Vol. 11, Issue 1, (Series-II) January 2021, pp. 47-54

Table 3: Technical data for case 2 before and after correction

Case 2 before correction After correction

Generated Power

13.701 + j 13.637 13.653+ j 11.945

MVA

Consumed power

13.518 + j 11.818 13.518 + j10.307

MVA

Loss power

0.183 + j 1.819 0.135 + j1.638

MVA

Power factor 0.75 0.79

1.2.2 Part 2 Calculation of the cost The total cost for KwH = 88813.26 x 103 x 0.2

Without the capacitor bank £/KwH = £17762652

The calculation is done in the previous case (case1) There is no effect for the total consumed energy and

After installing the capacitor bank its cost because the compensation does not affect this

From the simulation, the consumed power is equal to part of the network.

13.653Mw + j10.307 Mvar and with comparing it to The total cost per year = the total cost for power in

the power in case 1, it is found that the compensation KVA + The total cost for KwH

at main bus bar can effectively reduce the reactive = £1710668.46+ £17762652 =

power more than the individual compensation. Global £19473320.46

compensation is more economical because it can Compared to case 1, the total cost is higher by

improve the power factor better than individual £289248.19 and that indicates using correction in

compensation. particular bus bar does not reduce the cost compared

to the global compensation done in case1.

The less quantity of reactive power means that loads

to cables and transformers became lower than before Total saving = 19558206.09 – 19473320.46 =

installing the capacitor bank to the system. £84885.63

The consumed reactive power in case 1 was This amount can be used in several ways such as

4.394Mvar, which is less by 5.913Mvar. regular and major maintenance to the network or help

Then, the total MVA = 17.106 MVA partly in the cost for replacing equipment.

Using the same assumption 1KVA = 100 £ /KVA:

The total cost for power in KVA = 17.106 x 103 x Assume that the cost for 1MVAR is equal to £16000

100 £ /KVA = £1710668.46 Capacitor cost = 16000 £ / MVAR x 2MVAR =

It is noticed that the cost in this case is higher than 32000

case 1 by £289248.19 and that represents higher cost The recovery cost for capacitor =

for the compensation which is not recommended to

apply.

Assuming that the load of the network is working the The time needed to get the cost of capacitor bank is

whole year for 18 hours daily and the cost for similar to case 1, which is equal to 4 months. Then,

KwH/year is equal to £0.2, then we can get the total the cost for adding capacitor bank in short shown in

cost for a year as follows: the following table:

Total MwH = 13.518Mw x 365 days x 18 hour =

88813.26 MwH

www.ijera.com DOI: 10.9790/9622-1101024754 52 | P a g e

Ahmed Rashad .E. Bakr, et. al. International Journal of Engineering Research and Applications

www.ijera.com

ISSN: 2248-9622, Vol. 11, Issue 1, (Series-II) January 2021, pp. 47-54

Table 4: Technical data for case 2 before and after correction

Network Network after

Case 2

before PFC PFC

Total KVA 17950 17106

Total cost for KVA @100£/KVA 1795554.087 1710668.46

Total Mw H

88813.26 88813.26

@ 18 hours /day in year

Total cost Kw H/year

17762652 17762652

@0.2£/Kw H

Total cost / year 19558206.09 19473320.46

Total saving/year - 84885.63

Capacitor bank cost -

32000

@1MAVR =16000£

Capacitor bank

- 4.58 months

Cost recovery

II. CONCLUSION can save this amount to additional inductive, loads in

For the simulation results in Eracs and the economic the future.

calculation, we have the following:

In case 1, global compensation is done at REFERENCES:

the 33KV bus bar 2 and the power factor value [1]. B. D., Industrial power systems handbook.

improved from 0.75 to 0.95 which represents an NEWYORK,TORNTO,LONDON:

ideal case. In addition, the consumed reactive power McGRAW-HILL BOOK COMPANY, 1955.

in Mvar was reduced by 7.509. The saving achieved [2]. O. A. Al-Naseem and A. K. Adi, "Impact of

in this case was £374133.82. Case 1 proved that Power Factor Correction on the Electrical

global compensation had many advantages, which Distribution Network of Kuwait–A Case

are reduction of the reactive power, minimizing the Study," The Online Journal on Power and

load to the electrical components and getting lower Energy Engineering, pp. 173-176, 2003.

cost. [3]. S. Basu and M. H. Bollen, "A novel common

The compensation done in case 2 had power factor correction scheme for homes

different technique, which was named individual and offices," Power Delivery, IEEE

compensation. The capacitors was installed to bus Transactions on, vol. 20, pp. 2257-2263,

bar 9. The power factor at the mentioned bus bar 2005.

became equal to 0.95, whereas the power factor to [4]. V. V. Inti, K. Mangamuri, and C. P. Kumar,

the whole network did not improve much and "A New Topology for Power Factor

changed to 0.8 and this was not what designers look Correction using Resonant Converters,"

for. In addition, the resultant amount for reactive International Journal of Soft Computing and

power was 11.945 Mvar, which indicated that only Engineering, vol. 3, pp. 2231-2307, 2013.

slight change happed. At this case, the total cost was [5]. S. Khanchi and V. K. Garg, "Power Factor

£84885.63 and this showed low amount compared to Improvement of Induction Motor by Using

case1. Capacitors," International Journal of

In conclusion, it has become clear how Engineering Trends and Technology (IJETT),

important is the power factor correction for electric vol. 4, 2013.

network either in generation, transmission or [6]. I. Daut, Y. Irwan, M. Irwanto, I. Safwati, N.

distribution level. It proved that there are many Gomesh, M. Ezzani, et al., "Improvement of

merits that can be obtained from the power factor induction machine performance using power

correction, which can be technical or economical. In factor correction," in Electrical, Control and

this project, several aspects for the technical side are Computer Engineering (INECCE), 2011

achieved such as reducing the reactive power, which International Conference on, 2011, pp. 472-

476.

www.ijera.com DOI: 10.9790/9622-1101024754 53 | P a g e

Ahmed Rashad .E. Bakr, et. al. International Journal of Engineering Research and Applications

www.ijera.com

ISSN: 2248-9622, Vol. 11, Issue 1, (Series-II) January 2021, pp. 47-54

[7]. A. Pamela, "Power Factor Correction For

Power System " Colarado sate

University2007.

[8]. H. Azazi, E. El-Kholy, S. Mahmoud, and S.

Shokralla, "Review of passive and active

circuits for power factor correction in single

phase, low power AC-DC converters," in 14th

International Middle East Power system

Conference (MEPCON’10), Egypt, 2010, pp.

217-224.

[9]. (16-9). ERACS [Website]. Available:

http://www.edifgroup.com/services/eracs

[10]. G. S. Akash, Himnay Pratap Singh2, Avinas

Kumar Chauhan, "Importance of Reactive

Power for Distributed Generation,"

International Journal of Emerging

Technology and Advanced Engineering, vol.

4, 2014.

Ahmed Rashad .E. Bakr, et. al. “A study on Power Factor Correction with Capacitor Bank

Using ERACS’ Software.” International Journal of Engineering Research and Applications

(IJERA), vol.11 (1), 2021, pp 47-54.

www.ijera.com DOI: 10.9790/9622-1101024754 54 | P a g e

You might also like

- Electric Power Distribution Project ReportDocument20 pagesElectric Power Distribution Project ReportSaleh Ahmad100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Power Factor ImprovementDocument8 pagesPower Factor ImprovementmshahidshaukatNo ratings yet

- Power System AnalysisDocument4 pagesPower System Analysisahmedfhd1No ratings yet

- Print Head Repair Secrets - William HorDocument137 pagesPrint Head Repair Secrets - William HorJay Ilagan100% (3)

- Energy Management & Conservation: Session Four Instructor - Pramod Daspute BEE Certified Energy AuditorDocument18 pagesEnergy Management & Conservation: Session Four Instructor - Pramod Daspute BEE Certified Energy AuditorUjjwal Kumar SinghNo ratings yet

- Paper #37CDocument6 pagesPaper #37CDrAdel A. ElbasetNo ratings yet

- Smoothing of Grid-Connected Wind-Diesel Power Output Using Energy Capacitor SystemDocument6 pagesSmoothing of Grid-Connected Wind-Diesel Power Output Using Energy Capacitor SystemDrAdel A. ElbasetNo ratings yet

- En TH01!11!2004 Power Factor CorrectionDocument12 pagesEn TH01!11!2004 Power Factor CorrectionSirish SabbellaNo ratings yet

- BidireDocument11 pagesBidiretadivadavamsiNo ratings yet

- Power Factor CorrectionDocument6 pagesPower Factor Correctionmostafa HusseinNo ratings yet

- How Capacitors Improve The Power Factor and How To Calculate Them - EEPDocument4 pagesHow Capacitors Improve The Power Factor and How To Calculate Them - EEPMohamedAhmedFawzy100% (1)

- Convention Centre-E-8.11.2019 - R0Document11 pagesConvention Centre-E-8.11.2019 - R0ManojNo ratings yet

- Capacitor BanksDocument7 pagesCapacitor BanksMilton EspinozaNo ratings yet

- Submission+07+-+copyedited V2+Document13 pagesSubmission+07+-+copyedited V2+Sơn Phạm ThanhNo ratings yet

- DC DC ConvertorDocument11 pagesDC DC ConvertorJyothiNo ratings yet

- Findings and ResearchDocument33 pagesFindings and Researchuaminu422No ratings yet

- Basics of Low Voltage Systems Design-Ver.01Document158 pagesBasics of Low Voltage Systems Design-Ver.01MohamedAhmedFawzy50% (2)

- Scholar Search: A Simplistic Technique For Power Factor Compensation Capacity Calculation in Medium Size IndustryDocument7 pagesScholar Search: A Simplistic Technique For Power Factor Compensation Capacity Calculation in Medium Size IndustryfathieldrassiNo ratings yet

- Renewable Energy Photovoltaic IVDocument77 pagesRenewable Energy Photovoltaic IVcharbel jabbourNo ratings yet

- S NoteDocument116 pagesS NoteankitNo ratings yet

- @@power Factor Correction of Coet - 100605Document63 pages@@power Factor Correction of Coet - 100605Sangiwa SalimNo ratings yet

- How To Apply Capacitors To Low Voltage Power Systems.Document13 pagesHow To Apply Capacitors To Low Voltage Power Systems.Ahmed Reda Abdou MohamedNo ratings yet

- Solar Charging Station For Electric VehiclesDocument5 pagesSolar Charging Station For Electric VehiclesDriss OuladabbouNo ratings yet

- Analysis On Multiple Combinations of Series Parallel Connections of Super Capacitors For Maximum Energy Transferring To Load in Minimum TimeDocument9 pagesAnalysis On Multiple Combinations of Series Parallel Connections of Super Capacitors For Maximum Energy Transferring To Load in Minimum TimeAkhilesh NimjeNo ratings yet

- Capacitor Banks in Power System Part FourDocument4 pagesCapacitor Banks in Power System Part FourTigrillo100% (1)

- Quadratic Boost Converter With Less Input Current Ripple and Rear-End Capacitor Voltage Stress For Renewable Energy ApplicationsDocument11 pagesQuadratic Boost Converter With Less Input Current Ripple and Rear-End Capacitor Voltage Stress For Renewable Energy ApplicationsSureshkumar AlagarsamyNo ratings yet

- A Wide Band Gap Devices Based Switched Capacitor Circuits For Photovoltaic ApplicationsDocument10 pagesA Wide Band Gap Devices Based Switched Capacitor Circuits For Photovoltaic ApplicationsMIKS DARKNo ratings yet

- Electrical SystemDocument75 pagesElectrical SystemS Bharadwaj Reddy75% (4)

- Unit3 - Electrical SystemDocument57 pagesUnit3 - Electrical SystemNethaji BKNo ratings yet

- FUTO SIWES TrainingDocument27 pagesFUTO SIWES Trainingugwuegbuchibuike2003No ratings yet

- Power Factor Management Scheme Is Best Described Here.Document42 pagesPower Factor Management Scheme Is Best Described Here.Sunil SinghNo ratings yet

- Solar IrradiationDocument4 pagesSolar IrradiationL CHNo ratings yet

- Electric Machine Lab3Document19 pagesElectric Machine Lab3NiTrO jOk3RNo ratings yet

- Power FactorDocument28 pagesPower Factoravijeet2828100% (1)

- Challenges and Opportunities of RooftopDocument9 pagesChallenges and Opportunities of RooftopYousup AliNo ratings yet

- Review of Related Literature: 2.1.1 Indoor Light Energy HarvestingDocument14 pagesReview of Related Literature: 2.1.1 Indoor Light Energy HarvestingGillian AmbaNo ratings yet

- Utilization of Electrical Energy: CHAPTER 6: Demand Side Management L-6-2Document17 pagesUtilization of Electrical Energy: CHAPTER 6: Demand Side Management L-6-2Frozen BoyNo ratings yet

- K.G.Harish,: Dy - Manager (Utilities) Glaxo Smithkline Consumer Healthcare Ltd. Sonepat. HaryanaDocument7 pagesK.G.Harish,: Dy - Manager (Utilities) Glaxo Smithkline Consumer Healthcare Ltd. Sonepat. HaryanaSam MillerNo ratings yet

- Diesel Generator SetDocument17 pagesDiesel Generator Setcellr2885No ratings yet

- Wind Powered Mobile Phone ChargerDocument9 pagesWind Powered Mobile Phone ChargerTutor Cad Elec ProgNo ratings yet

- Power FactorDocument48 pagesPower FactortyutyuNo ratings yet

- Design of Power Converters For Renewable Energy Sources and Electric Vehicles ChargingDocument6 pagesDesign of Power Converters For Renewable Energy Sources and Electric Vehicles ChargingRay Aavanged IINo ratings yet

- Analysis of Real and Reactive Power Mode of Operation of Electric Vehicle in A DFIG Based Wind FarmDocument5 pagesAnalysis of Real and Reactive Power Mode of Operation of Electric Vehicle in A DFIG Based Wind FarmbelbymathewNo ratings yet

- 2008 Braun EwecDocument10 pages2008 Braun EwecfarzanesunflowerNo ratings yet

- Abstract - : The Energy Usage IsDocument5 pagesAbstract - : The Energy Usage IsNunna BaskarNo ratings yet

- Electrical Systems: Power Factor Correction: Ps Supplied Power (Kva) PR Reactive Power (Kvar)Document28 pagesElectrical Systems: Power Factor Correction: Ps Supplied Power (Kva) PR Reactive Power (Kvar)Mahendra KumarNo ratings yet

- Tutorial 4 - SolutionDocument3 pagesTutorial 4 - Solutionkant734No ratings yet

- Chapter 2 - 2Document58 pagesChapter 2 - 2Firdaus Khairi100% (1)

- Ee 308Document15 pagesEe 308catdogsunmoon12No ratings yet

- 45 16255 EE543 2015 1 1 1 Week 8 9Document25 pages45 16255 EE543 2015 1 1 1 Week 8 9Kristel Mae Hertz CastilloNo ratings yet

- Assignment No. 6: Energy Conservation and ManagementDocument28 pagesAssignment No. 6: Energy Conservation and ManagementYashashree Gedam100% (1)

- PF Improvement On DG SetsDocument8 pagesPF Improvement On DG SetsAnupam SharmaNo ratings yet

- Solar and Wind Hybrid Power Generation: Abstract-This Paper Reflects An Independent DistributedDocument5 pagesSolar and Wind Hybrid Power Generation: Abstract-This Paper Reflects An Independent DistributedDr. Eddie YadavNo ratings yet

- Reactive Power Supplied by Wind Energy Converters - Cost-Benefit-AnalysisDocument10 pagesReactive Power Supplied by Wind Energy Converters - Cost-Benefit-AnalysisjandazNo ratings yet

- SmartGrid vs MicroGrid; Energy Storage Technology: Energy, #2From EverandSmartGrid vs MicroGrid; Energy Storage Technology: Energy, #2No ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Danaher Trouble Shooting CodesDocument8 pagesDanaher Trouble Shooting CodesHarits PermanaNo ratings yet

- VLSI DesignDocument7 pagesVLSI DesignVarun ThejNo ratings yet

- DE Question BankDocument5 pagesDE Question BankKaree MullahNo ratings yet

- Sensymaster Fmt430, Fmt450: Thermal Mass FlowmeterDocument68 pagesSensymaster Fmt430, Fmt450: Thermal Mass FlowmeterGabriela CastroNo ratings yet

- Are Optical Transistors The Logical Next Step?: CommentaryDocument3 pagesAre Optical Transistors The Logical Next Step?: CommentaryAhmed IbrahimNo ratings yet

- BA-LT2Ex DLT3006-15-aEN-031Document102 pagesBA-LT2Ex DLT3006-15-aEN-031Banu EdoNo ratings yet

- Winter Semester 2021-22 All Course Allocation Report Except LAW (1) - RemovedDocument6 pagesWinter Semester 2021-22 All Course Allocation Report Except LAW (1) - RemovedAbi nashNo ratings yet

- Tannoy Mercury V4iDocument12 pagesTannoy Mercury V4iChris YorkNo ratings yet

- Unit Iii Micro W A VE Solid State DevicesDocument7 pagesUnit Iii Micro W A VE Solid State DevicesRAJASHEKHARNo ratings yet

- Worker'S Assistant Robot Using Myrio and Labview: April 2019Document6 pagesWorker'S Assistant Robot Using Myrio and Labview: April 2019chuyen truongNo ratings yet

- UPS No-Break PoE Switch 2022.3.5 - CompressedDocument38 pagesUPS No-Break PoE Switch 2022.3.5 - CompressedHong Kwok FaiNo ratings yet

- Datasheet SUN2000 100KTL M1 AFCIDocument2 pagesDatasheet SUN2000 100KTL M1 AFCIShin UchihaNo ratings yet

- The Factors Affecting The Performance of Solar Cell: Bhalchandra V. Chikate Y.A. SadawarteDocument5 pagesThe Factors Affecting The Performance of Solar Cell: Bhalchandra V. Chikate Y.A. Sadawartepragya mitaNo ratings yet

- Pcs TCM 2800 - 200Document1 pagePcs TCM 2800 - 200Garrett AinsworthNo ratings yet

- Datasheet HT6P20BDocument9 pagesDatasheet HT6P20BJosihel AndradeNo ratings yet

- PrimeMotion C ENDocument2 pagesPrimeMotion C ENHAPPY KLUBNo ratings yet

- How To Use 24 TFT LCD Shield With Arduino Mega PDFDocument4 pagesHow To Use 24 TFT LCD Shield With Arduino Mega PDFYeiner Smith Polo MercadoNo ratings yet

- Design of Current Mode ComparatorDocument13 pagesDesign of Current Mode ComparatorAbdelRahman MahmoudNo ratings yet

- ATP Hydraulic Owner Install Guide ATP62 r081517 WEBDocument56 pagesATP Hydraulic Owner Install Guide ATP62 r081517 WEBIngo BorchersNo ratings yet

- IC307 Industrial Instrumentation - IDocument2 pagesIC307 Industrial Instrumentation - IAKSHAY KRISHNA K RNo ratings yet

- Power Electronics Circuit Analysis and DesignDocument683 pagesPower Electronics Circuit Analysis and DesignSameerAhmedNo ratings yet

- ALL Service Menu TVDocument23 pagesALL Service Menu TVnenengNo ratings yet

- Penmount 1610 Control Board Data SheetDocument2 pagesPenmount 1610 Control Board Data Sheetnelson david pineda higueraNo ratings yet

- Growatt 17000TL3-S/20000TL3-S/ 25000TL3-S: Leading - Edge TechnologyDocument2 pagesGrowatt 17000TL3-S/20000TL3-S/ 25000TL3-S: Leading - Edge TechnologyMohamed SomaiNo ratings yet

- Texas Instruments HDMI Design GuideDocument12 pagesTexas Instruments HDMI Design GuidenaveenkumarNo ratings yet

- User ManualDocument76 pagesUser ManualRodrigo AlejandroNo ratings yet

- A11229 - MotionPRO - UM-Rev1 (Optred) PDFDocument720 pagesA11229 - MotionPRO - UM-Rev1 (Optred) PDFCarlos RodriguesNo ratings yet

- Evaluation and Calibration of An Inertial Measurement Unit: AIP Conference Proceedings December 2018Document10 pagesEvaluation and Calibration of An Inertial Measurement Unit: AIP Conference Proceedings December 2018Anisa FauziahNo ratings yet

- ADXL317Document38 pagesADXL317LeandroNo ratings yet