Professional Documents

Culture Documents

Operator'S Manual: 1" Diaphragm Pump (Ba25Xx-Xxxx-X)

Operator'S Manual: 1" Diaphragm Pump (Ba25Xx-Xxxx-X)

Uploaded by

janwilsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operator'S Manual: 1" Diaphragm Pump (Ba25Xx-Xxxx-X)

Operator'S Manual: 1" Diaphragm Pump (Ba25Xx-Xxxx-X)

Uploaded by

janwilsonCopyright:

Available Formats

OPERATOR’S MANUAL

1” DIAPHRAGM PUMP (BA25XX-XXXX-X)

PN 6461-9

Revised: 2017-4-18

Model Description Chart

Rev: B

BA25XX-XXXX-X

Porting Options

A-BSP B-NPT C- Flange

O-ring materials

1-NBR 2-EPDM 3-PTFE(Full) 4-PTFE(Cover)5 – FKM

Diaphragm Materials

9 - Santoprene® B –Nitrile H – Hytrel® T - PTFE/Santoprene®

Ball Materials

9 - Santoprene® H - Hytre® T - PTFE S –Stainless steel 7 –Nylon

P - UPE

Seat Material

P – PP T –PVDF S –Stainless steel C - Carbon steel 0 –Aluminum 7 –Nylon

9 – Santoprene®

Wetted Material

AL –Aluminum SS –Stainless steel CS- Carbon steel

PP –Polypropylene PV – PVDF

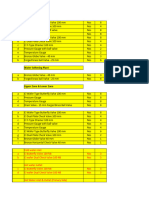

Pump Data Max. Temperature Limits (Diaphragm/ball/sealed material)

Description Data Material Application temperature range

Porting size (inch) 1” POM 10°-180°F (-12°- 82°C)

Center body material Aluminum Santoprene® -40°- 225°F (-40°- 107.2°C)

Max. air inlet pressure (Mpa) 0.83 PTFE 40°- 220°F (4.4°- 104°C)

Max. flow rate (lpm) 192 Nitrile 10°- 180°F (-12°- 82°C)

Max. dry suction (m) 6.7 FKM -0°- 392°F (-18°-200°C)

Displacement / cycle (L) 0.87 PVDF -20°-150°F (-12°- 93°C)

Max. Particle size (mm) 3.0 Hytrel® 10°-200°F (-28.9°- 65.5°C)

Noise level @70psi (dB) 75 Polypropylene 32°- 175°F (0 -79.4°C)

Weight (kg) Nylon -40°- 248°F (-40°- 120°C)

Aluminum 9.5 EPDM -60°-280°F (-51°- 138°C)

Stainless steel 14.5

Carbon steel 14.5

Polypropylene 9.5

PVDF 12.5

BSK Fluid Technology LLC

Add: 3625 Aqua Spring Drive Plano, Tx75025 U.S.A

E-mail: sales@bskfluid.com

http://www.bskfluid.com

SAFETY AND MAINTANANCE INFORMATION

Operating and safety prevention

Read, understand and follow this information to avoid injury and property damage.

Do not exceed the maximum inlet air pressure as stated on the pump model plate.

The air inlet of the pump is connected to the air supply that has sufficient capacity and of which pressure conforms to the design

requirements.

The clean compressed air makes for the extension of the service life of the pump.

If the air supply line is a hard pipe, the short hose connecting the pump and the pipe can reduce vibration and twisting. (It is

recommended to reduce the pulse in the fluid with a use a surge tank or fluid buffers.)

The air intake pipe of the pump must be installed with the pressure regulating valve to ensure the air supply pressure doesn’t exceed the

specified range.,

Pumps’ air inlet should be installed a pressure regulating valve to make sure the supplied air pressure doesn’t exceed the limits.

Do not make your pumps working in the EXCESSIVE AIR PRESSURE in a long time. Can cause pump damage, personal injury or

property damage.

Make sure the hoses and other components can endure the fluid pressure of the pumps. Check all hoses for are not damage or worn. To

ensure that the distribution device is clean and reliable.

STATIC SPARK. Can cause explosion resulting in severe injury or death. Ground pump and pumping system.

Sparks can ignite flammable material and vapors.

Secure pump, connections and all contact points to avoid vibration and generation of contact or static spark.

To use the correct ventilation equipment..

To make flammable items away from heat, open flames and sparks.

When not in use, please close the container.

Pump exhaust may contain contaminants. Can cause severe injury. Pipe exhaust away from work area and personnel.

In the event of a diaphragm rupture material can be forced out of the air exhaust muffler.

Pipe the exhaust to a safe remote location when pumping hazardous or inflammable materials.

Use a grounded3/8”minimum i.d. hose between the pump and the muffler.

HAZARDOUS PRESSURE. Can result in serious injury or property damage. Do not service or clean pump, hoses or dispensing valve

while the system is pressurized. Disconnect air supply line and relieve pressure from the system by opening dispensing valve or device

and / or carefully and slowly loosening and removing outlet hose or piping from pump.

HAZARDOUSMATERIALS. Can cause serious injury or property damage. Do not attempt to return a pump to the factory or service

center that contains hazardous material. Safe handling practices must comply with local and national laws and safety code

requirements.

Obtain Material Safety Data Sheets on all materials from the supplier for proper handling instructions.

EXPLOSION HAZARD.Models containing aluminum wetted parts cannot be used with 1,1,1-trichloroethane, methylene chloride

or other halogenated hydrocarbon solvents which may react and explode.

Check pump motor section, fluid caps, manifolds and all wetted parts to assure compatibility before using with solvents of this type.

The pump should be placed close to the product as possible to shorten t the suction pipe and reduce the number of parts to the

greatest extent.

To extend the service life to diaphragm, we must to place the pump close to the pumped fluid as much as possible. When the inlet

pressure exceeds 10 feet (3 meters) of the fluid column, it is necessary to install a set of pressure relief and regulation devices to extend

the service life of diaphragm.

We must ensure the sealing of each adapter for the inlet and outlet pipes.

All the fasteners must be tightened once again prior to the use of the product to avoid the looseness that may arise out of the creep of

the seal components and effectively prevent the leakage of fluid or air.

Verify the chemical compatibility of the pump wetted parts and the substance being pumped, flushed or re-circulated. Chemical

6461-3 2 BSK Fluid Technology LLC

compatibility may change with temperature and concentration of the chemical(s) within the substances being pumped, flushed or

circulated. For specific fluid compatibility, consult the chemical manufacturer.

Maximum temperatures are based on mechanical stress only. Certain chemicals will significantly reduce maximum safe operating

temperature. Consult the chemical manufacturer for chemical compatibility and temperature limits.

Be certain all operators of this equipment have been trained for safe working practices, understand its limitations, and wear safety

goggles / equipment when required.

Do not use the pump for the structural support of the piping system. Be certain the system components are properly supported to

prevent stress on the pump parts.

Suction and discharge connections should be flexible connections (such as hose), not rigid piped, and should be compatible with the

substance being pumped.

Prevent unnecessary damage to the pump. Do not allow pump to operate when out of material for long periods of time.

It is a must to prevent unnecessary damage to the pump. If it has to lie idle for a long time, please clean it thoroughly after each use.

The product left in the pump will become dry or sticky on the pump, which will give rise to the diaphragm and valve problems prior to

the next start. At the freezing temperature, it is must to empty the pump completely under any circumstances after use.

General Description

The BSK diaphragm pump offers high volume delivery even at low air pressure and a broad range of material compatibility options

available. BSK pumps feature stall resistant design, modular air motor / fluid sections.

Air operated double diaphragm pumps utilize a pressure differential in the air chambers to alternately create suction and positive fluid

pressure in the fluid chambers, ball checks insure a positive flow of fluid.

Pump cycling will begin as air pressure is applied and it will continue to pump and keep up with the demand. It will build and maintain

line pressure and will stop cycling once maximum line pressure is reached (dispensing

device closed) and will resume pumping as needed.

Air and Lube Requirements

EXCESSIVE AIR PRESSURE. Can cause pump damage, personal injury or property damage.

A filter capable of filtering out particles larger than 50 microns should be used on the air supply. There is no lubrication required other

than the “O” ring lubricant which is applied during assembly or repair.

If lubricated air is present, make sure that it is compatible with the“O”rings and seals in the air motor section of the pump.

Operating Instructions

Always flush the pump with a solvent compatible with the material being pumped if the material being pumped is subject to “setting

up” when not in use for a period of time.

Disconnect the air supply from the pump if it is to be inactive for a few hours.

The outlet material volume is governed not only by the air supply but also by the material supply available at the inlet. The material

supply tubing should not be too small or restrictive. Be sure not to use hose which might collapse.

When the diaphragm pump is used in a forced-feed (flooded inlet) situation, it is recommended that a “Check Valve” be installed at the

air inlet.

Maintenance

Refer to the part views in the assembly chart for the parts’ number and name to understand the information of the part and service

kits.

Parts which marked with “△”, to prepare these parts in hand will help you save time for fast maintenance and reduce downtime.

Service kits are divided to service two separate diaphragm pump functions: Air section and fluid section. The fluid section is further

divided to match the material options for typical parts.

Provide a clean work surface to protect sensitive internal moving parts from contamination from dirt and foreign matter during service

disassembly and reassembly.

BSK Fluid Technology LLC 3 6461-3

Keep good records of service activity and include pump in preventive maintenance program.

Before disassembling, empty captured material in the outlet manifold by turning the pump upside down to drain material from the

pump.

Reassembly

All sealed parts and the connected positions need to be coated with grease.

All re-use sealed parts need to be checked if there has damage. If there has damage on the surface, please to use a new one.

The lip direction of the lip shape seal ring need to install to the directed direction on the chart.

Bolts on the fluid cap need to be fastened alternating to ensure the better sealing effect..

Trouble Shooting

1. Air exhaust has pumping product

Check if the diaphragm (B-07)(B-08) be damaged

Check if the diaphragm bolts (B-10) loosening

2. The pumping product has air bubble

Check the suction pipe joints are well sealed

Check the suction pipe and fluid inlet manifold (B-02) are well sealed

Check the O-ring (B-06) between inlet manifold (B-02) and fluid cap (B-03) are well sealed

Check the tightness of diaphragm bolts (B-10)

3. Low output volume

Check the air supply

Check whether the inlet and outlet hose is blocked

Check the joint to the fluid inlet manifold (B-02) is sealed and not leakage

Check if the ball (B-04) stick to the ball seat (B-05) or ball seat (B-05) is not suitable

4. Air exhaust in the case of reciprocating motion stopping

Check the sealed ring (A-05) at the main air valve

Check the sealed ring (A-18) at the pilot rod valve

Check the sealed ring (A-29) on the diaphragm rod

AIR MOTOR SECTION (BA25-P1)

PART LIST

Item Desc P/N Mtl Qty Item Desc P/N Mtl Qty Item Desc P/N Mtl Qty

A-01 Retainer 6232-1 SS 2 A-13 Gasket 6216 B 1 A-25 O-ring 6222-2 B 4

A-02 Plug 6219 PP 2 A-14 Plate 6206 Ce 1 A-26 Gasket 6217 B 2

A-03 O-ring 6222-1 B 4 A-15 Insert 6207 Ce 1 A-29 O-ring 6474-3 U 1

A-04 Sleeve 6220 Br 2 A-16 Center body 6213 AL 1 A-30 Rod 6465 CS 1

A-05 Y-ring 6221-3 B 2 A-17 Rod 6471 D 1 A-31 O-ring 6222-10 B 2

A-06 Spool 6218 D 1 A-18 O-ring 6474-2 U 4 A-32 Sleeve 6468 D 1

A-07 Housing 6214 AL 1 A-19 Actuator 6472 D 2 A-33 Air cap 6209-2 AL 1

A-08 Screw 6236-2 SS 4 A-20 Sleeve

pin 6470 Br 2

Material Code: SS= Stainless Steel

A-09 Insert 6205 Ce 1 A-21 Backup 6226-1 CS 2

PP= Polypropylene B=NBR Br=Brass

A-10 Plate 6204 Ce 1 A-22 Screw

washer 6236-1 CS 4

AL= Aluminum Alloy Ce=Ceramic D=POM

A-11 Gasket 6257 B 1 A-23 Air cap 6208-2 AL 1

CS=Carbon steel U=Urethane

A-12 Plate 6215-1 AL 1 A-24 Muffler 6283 PP 1

6461-3 4 BSK Fluid Technology LLC

Torque Requirements:

A-08:4.5-6.0 Nm

A-22:14-16 Nm

Item with “△” is spare

part. Keep them on

hand in addition for

fast repair and

reduction of down

time. Those items are

included in service kit

6395-BA25-P1

Air Motor service

Distribution Valve Disassembly

Remove screw (A-08). Remove housing assembly (A-07).Remove gasket (A-11),plate(A-12),gasket(A-13).Remove plate(A-10) and insert(A-09)

from housing(A-07).Remove plate(A-14) and insert(A-15) from center body (A-16)

Distribution Valve Reassembly

Inspect and replace old parts with new parts as necessary.

Install insert (A-15) into center body (A-16). Which end side with fit face to housing (A-07).Install plate (A-14), which smooth side face to

center body (A-16). Install insert (A-09) into housing (A-07). Which end side with fit face to center body (A-16).Install plate (A-10), which

smooth side face to housing (A-07).

Install gasket (A-11)(A-13),plate (A-12) and housing assembly (A-07) to center body (A-16).

Major Valve Disassembly

Remove retainer (A-01).Remove plug (A-02), O-ring (A-03), spool (A-06) and Y-ring (A-05).Remove sleeve (A-04),O-ring (A-03)

Major Valve reassembly

Inspect and replace old parts with new parts as necessary. Lubricate O-ring, Y-ring and moving surface.

Install O-ring (A-03) onto sleeve (A-04). Then push them together into housing (A-07).

Install Y-ring (A-05) onto spool (A-06). Which lip face to middle of spool. Then push them into housing (A-07)

Install O-ring (A-03) onto plug (A-02). Press them into housing (A-07). Install retainer (A-01)

Pilot Valve Disassembly

Remove bolt (A-22). Remove air cap (A-23) (A-33),O-ring (A-25),gasket (A-26),actuator (A-19), rod (A-17). Remove O-ring (A-18) from

actuator (A-19) and rod (A-17)

Remove sleeve (A-32), O-ring (A-31)

Pilot Valve Reassembly

Inspect and replace old parts with new parts as necessary. Lubricate O-ring and moving surface.

Install O-ring (A-31) onto sleeve (A-32). Then push them into air cap (A-23)

Install O-ring (A-18) onto actuator (A-19) and rod (A-17).Press a actuator (A-19) and rod (A-17) into sleeve (A-20). Then push them into

center body (A-16).Install another actuator (A-19) into another sleeve (A-20) and push them into center body (A-16).

Install O-ring (A-25) and gasket (A-26) onto center body (A-16).Cover center body assembly onto air cap (A-23). Cover air cap (A-33) onto

center body assembly. Clamp them by bolt (A-16).

BSK Fluid Technology LLC 5 6461-3

FLUID SECTION

BA25AL-XXXX-X Torque Requirements:

B-10: 34-41 Nm

B-11, B-12: 27-32 Nm

B-15: 14-16 Nm

Item with “△” is spare part. Keep

them on hand in addition for fast

repair and reduction of down time.

Those items are included in service

kit 6396-X (X-pump model, for

example: BA25AL-0TT3-A)

Wet Section Service

BA25SS-XXXX-X

Disassembly

BA25CS-XXXX-X

Remove manifold (B-02),O-ring (B-06),seat

(B-05),ball (B-04).

Remove manifold (B-01),O-ring (B-06),seat

(B-05),ball (B-04).

Remove fluid cap (B-03)

Remove screw (B-10), washer (B-09),

diaphragm (B-08)(B-07),washer (A-21), rod

(A-30), O-ring (A-29).

Reassembly

Reassemble in reverse order.

Inspect and replace old parts with new parts

as necessary.

Lubricate O-ring (A-29) and rod (A-30)

Apply Loctite 243 to threads of screw (B-10)

BA25PP-XXXX-X

BA25PV-XXXX-X

6461-3 6 BSK Fluid Technology LLC

Fluid cap/Manifold/Hardware

“B-05” Seat Options

BA25PV-XXXX-C

BA25AL-XXXX-A

BA25PP-XXXX-C

BA25CS-XXXX-A

BA25SS-XXXX-A

Part Number

Description

Material

quantity

BA25XX-PXXX-X

BA25XX-CXXX-X

BA25XX-TXXX-X

BA25XX-9XXX-X

BA25XX-7XXX-X

BA25XX-0XXX-X

BA25XX-SXXX-X

Item

Part Number

Material

quantity

B-01 Manifold 6211-2 1 AL Y

B-01 Manifold 6278 1 PP Y 6237 4 PP Y

B-01 Manifold 6278-1 1 PV Y 6237-1 4 PV Y

B-01 Manifold 6272 1 SS Y 6237-2 4 Sp Y

B-01 Manifold 6407 1 CS Y 6237-3 4 Ny Y

B-02 Manifold 6212-2 1 AL Y 6225-1 4 AL Y

B-02 Manifold 6279 1 PP Y 6225-2 4 SS Y

B-02 Manifold 6279-1 1 PV Y 6225-4 4 CS Y

B-02 Manifold 6273 1 SS Y

B-02 Manifold 6408 1 CS Y “B-04” Ball Options

B-03 Fluid cap 6210 2 AL Y

BA25XX-XHXX-X

BA25XX-X9XX-X

BA25XX-X7XX-X

BA25XX-XPXX-X

BA25XX-XTXX-X

BA25XX-XSXX-X

Part Number

Material

quantity

B-03 Fluid cap 6277 2 PP Y

B-03 Fluid cap 6277-1 2 PV Y

B-03 Fluid cap 6271 2 SS Y

B-03 Fluid cap 6406 2 CS Y 6254 4 T Y

B-09 Washer 6226-1 2 CS Y Y 6203-1 4 Sp Y

B-09 Washer 6226-2 2 SS Y 6203-2 4 Hy Y

B-10 Screw 6228 2 SS Y Y Y 6203-6 4 Ny Y

B-10 Screw 6280 2 PP Y 6203-7 4 P Y

B-10 Screw 6280-1 2 PV Y 6409 4 SS Y

B-12 Nut 6262-1 16 CS Y Y

B-12 Nut 6328-3 16 SS Y Y Diaphragm Options

B-12 Nut 6231-1 16 SS Y

BA25XX-XXHX-X

BA25XX-XXBX-X

BA25XX-XXTX-X

BA25XX-XX9X-X

Part Number

Material

quantity

B-15 Nut 6328-3 8 SS Y Y

Item

B-13 Bolt 6235-2 16 CS Y Y

B-13 Bolt 6230-5 16 SS Y Y

B-13 Bolt 6230-1 16 SS Y B-07 6239 2 Sp Y

B-11 Bolt 6235-3 8 CS Y Y B-07 6201-1 2 Sp Y

B-11 Bolt 6230-9 8 SS Y Y B-07 6201-2 2 Hy Y

B-11 Bolt 6230-2 8 SS Y B-07 6201-4 2 B Y

B-14 Washer 6329-3 8 SS Y Y B-08 6202 2 T Y

“B-06” O-ring Options

BA25XX-XXX3-X

BA25XX-XXX1-X

BA25XX-XXX4-X

BA25XX-XXX2-X

Part Number

Material

quantity

Material Code

AL= Aluminum Alloy SS= Stainless Steel CS=carbon steel

Sp=Santoprene® PV=PVDF T=PTFE T/c= PTFE(Cover) B= Nitrile

EP=EPDM Hy=Hytrel® PP=Polypropylene Ny=Nylon 6238-1 4 T Y

6222-1 4 B Y

6282 4 T/c Y

6284-1 4 EP Y

BSK Fluid Technology LLC 7 6461-3

Dimensional Data

BA25AL-XXXX-X BA25SS-XXXX-X & BA25CS-XXXX-X

A AIR INLET 1/4 NPT

B AIR EXHAUST 3/8 NPT

C INLET 1-11 BSP R p

D OUTLET 1-11 BSP R p

E INLET 1" ANSI/DIN FLANGE

F OUTLET 1" ANSI/DIN FLANGE

BA25PP-XXXX-C

TYPICAL PUMP CONNECTION TYPICAL PUMP APPLICATION

SUCTION INJECTION

air exhaust

air

inlet

SUBMARINE

6461-3 8 BSK Fluid Technology LLC

You might also like

- Hino 700 Easy StartDocument16 pagesHino 700 Easy Startjoki marzuki100% (1)

- Copia de Manual JUMAO Concentrador PDFDocument16 pagesCopia de Manual JUMAO Concentrador PDFTeran Teran100% (2)

- G. GUN II Manual V2 November08 PDFDocument76 pagesG. GUN II Manual V2 November08 PDFNguyen Thanh Quang100% (2)

- Manual Bomba Versa MaticDocument18 pagesManual Bomba Versa Maticregue_g_801719926100% (1)

- Manual EHDB1200-12000 - May 1996 PDFDocument42 pagesManual EHDB1200-12000 - May 1996 PDFLAURA VANESA HERREROS QUISPE100% (1)

- Beacon Ep 2Document9 pagesBeacon Ep 2David Lie0% (1)

- Es Compleat Coolant Eg Premix - MSDS - Lt16587aDocument6 pagesEs Compleat Coolant Eg Premix - MSDS - Lt16587aCesar G.No ratings yet

- C20 Kubota DC042AA Sep2004Document42 pagesC20 Kubota DC042AA Sep2004gorso19630% (1)

- Alatas S51394 (W) Inspection Report MV Sveti Vlaho Feb 08Document15 pagesAlatas S51394 (W) Inspection Report MV Sveti Vlaho Feb 08Faraz AhmedNo ratings yet

- ScrollDocument8 pagesScrolltrung2iNo ratings yet

- Installation Manual t5350 enDocument36 pagesInstallation Manual t5350 enmayNo ratings yet

- Copeland ZR125KC-TF5-950 Scroll Compressor - Carrier HVACDocument3 pagesCopeland ZR125KC-TF5-950 Scroll Compressor - Carrier HVACjacc42No ratings yet

- FiltersDocument28 pagesFiltersErica Lindsey100% (1)

- Robatherm Medical EngDocument11 pagesRobatherm Medical EngSamiYousifNo ratings yet

- Screw Pumps KRAL Double Station DKC DMC 01Document16 pagesScrew Pumps KRAL Double Station DKC DMC 01Eduardo MartinezNo ratings yet

- 9W 03 Weishaupt Gaasip6letid Kombip6letid - G GL RGL 5-11 ENG PDFDocument24 pages9W 03 Weishaupt Gaasip6letid Kombip6letid - G GL RGL 5-11 ENG PDFpatitay036817No ratings yet

- Masterpact NT: User ManualDocument56 pagesMasterpact NT: User ManualkubikNo ratings yet

- Aalborg TfoDocument1 pageAalborg TfoBoogi Andika TamamiNo ratings yet

- Ebarra Pump SpecsDocument13 pagesEbarra Pump SpecsLiz BargolaNo ratings yet

- Installation LCC1 Low Cement Castables - StandardDocument2 pagesInstallation LCC1 Low Cement Castables - StandardirwansuwainiNo ratings yet

- Mogas Msds 2014-2Document39 pagesMogas Msds 2014-2KalkiHereNo ratings yet

- Engine Troubleshooting VespaDocument67 pagesEngine Troubleshooting VespaMuch Abdulah NurhidayatNo ratings yet

- Sxda/Sxwa/Syda/Sywa: Metering PumpsDocument56 pagesSxda/Sxwa/Syda/Sywa: Metering PumpsZelminha StNo ratings yet

- 12 Air Starting of Diesel EnginesDocument26 pages12 Air Starting of Diesel EnginesCurtler PaquibotNo ratings yet

- AC Systems TroubleshootingDocument39 pagesAC Systems Troubleshootingkesavaganesan58No ratings yet

- Back Pressure ValveDocument3 pagesBack Pressure ValveAnkur SharmaNo ratings yet

- PIM130B1 - Daihatsu DT Series Archived JUN PDFDocument5 pagesPIM130B1 - Daihatsu DT Series Archived JUN PDFAnonymous XGsiY6rNo ratings yet

- Triplex Reciprocating Plunger Pumps Acc - API-674 (ISO-13710) : The Power of Proven TechnologyDocument4 pagesTriplex Reciprocating Plunger Pumps Acc - API-674 (ISO-13710) : The Power of Proven Technologytahera aqeelNo ratings yet

- Alfa Laval AalborgDocument8 pagesAlfa Laval AalborgZairus Fadzli DzulkifliNo ratings yet

- Samson PRV Mounting and Operating InstructionDocument20 pagesSamson PRV Mounting and Operating InstructionRick CalaguiNo ratings yet

- How To Read A Load Chart - CraneDocument6 pagesHow To Read A Load Chart - CraneDanny A SandhyNo ratings yet

- Wilden T15 Metal Diaphragm Pump EnglishDocument27 pagesWilden T15 Metal Diaphragm Pump EnglishArdi 4791No ratings yet

- Operating Manual 2006 - 10Document16 pagesOperating Manual 2006 - 10mrmonzonmNo ratings yet

- Catalog Pneumatic Marine Products For Propulsion Control Aventics Americas en 7536470Document56 pagesCatalog Pneumatic Marine Products For Propulsion Control Aventics Americas en 7536470Elshan jalilzadehNo ratings yet

- Operating & Instructions: ManualDocument20 pagesOperating & Instructions: ManualjujuroyaleNo ratings yet

- Steam Boiler Training CourseDocument8 pagesSteam Boiler Training CoursejohnNo ratings yet

- Instruction Manual: Nash Type Vacuum PumpsDocument16 pagesInstruction Manual: Nash Type Vacuum Pumpsdiscovery channelNo ratings yet

- COMPACTORDocument15 pagesCOMPACTORenrico jordan100% (1)

- Gefico Brochure +UFDocument40 pagesGefico Brochure +UF1zorro10% (1)

- Oil Cube PresentationDocument38 pagesOil Cube PresentationKASHIF NAWAZNo ratings yet

- D9 MG GensetDocument4 pagesD9 MG GensetAji HandokoNo ratings yet

- Function of Thermostatic Expansion Valve in Refrigeration SystemDocument5 pagesFunction of Thermostatic Expansion Valve in Refrigeration SystemSumit SinhaNo ratings yet

- Alternator ExplanationDocument14 pagesAlternator ExplanationjakagastrusNo ratings yet

- Operation Manual For Oxygen CompressorDocument18 pagesOperation Manual For Oxygen CompressorAshutosh SinghNo ratings yet

- CWF - 60 30 Main Air CompressorDocument28 pagesCWF - 60 30 Main Air CompressorkelvinNo ratings yet

- 1LA7Document16 pages1LA7Samuel ValbuenaNo ratings yet

- Manual FM160 CompressorDocument61 pagesManual FM160 CompressorSeekPTNo ratings yet

- Weidmuller Analog Signal ConditionersDocument65 pagesWeidmuller Analog Signal ConditionersCem AlpaslanNo ratings yet

- Air Compressor For Scba - Type LW 100 e & LW 100 BDocument55 pagesAir Compressor For Scba - Type LW 100 e & LW 100 BEserNo ratings yet

- Differential Pressure TransmitterDocument14 pagesDifferential Pressure TransmitterZainab KadhemNo ratings yet

- Milton Roy Dosing PumpDocument52 pagesMilton Roy Dosing Pumpantonyfernandof100% (1)

- Thermostatic Expansion Valves,: Type TE 5 - TE 55Document20 pagesThermostatic Expansion Valves,: Type TE 5 - TE 55dinoestarkxdNo ratings yet

- Steering SystemsDocument48 pagesSteering SystemsOscar Coaquira FelicianoNo ratings yet

- Air Compressor Room ReportDocument7 pagesAir Compressor Room Reportnatee8632No ratings yet

- Basics of HydraulicsDocument17 pagesBasics of HydraulicsMihir Lakshmi KashyapNo ratings yet

- SWCM Marine Sewage Treatment Plant MANUALDocument29 pagesSWCM Marine Sewage Treatment Plant MANUALisaacednNo ratings yet

- SC 360apr-Th-M 04 28-40Document13 pagesSC 360apr-Th-M 04 28-40Ivaylo IvanovNo ratings yet

- Service Contract Visit Overview: Air ConditioningDocument2 pagesService Contract Visit Overview: Air ConditioningWea FareezNo ratings yet

- Troubleshooting Boiler OperationDocument5 pagesTroubleshooting Boiler OperationRahul ChandrawarNo ratings yet

- MNK928-Operation & Maintenance ManualDocument75 pagesMNK928-Operation & Maintenance ManualYe' NaingNo ratings yet

- DC Motor ControllerDocument7 pagesDC Motor ControllerJan MicahNo ratings yet

- UL - General Fact Sheet - November 2005Document2 pagesUL - General Fact Sheet - November 2005RICROD71100% (1)

- Thuy Luc Dce80-100e GBDocument6 pagesThuy Luc Dce80-100e GBANH LÊNo ratings yet

- Back Pressure Control On An Alternator Based System1Document3 pagesBack Pressure Control On An Alternator Based System1Anonymous xKEjITvij2No ratings yet

- Crane Ball ValveDocument20 pagesCrane Ball ValveRicardo de Jesus Rondon GamboaNo ratings yet

- Manual de Partes Cat 3507Document4 pagesManual de Partes Cat 3507Julito Santa CruzNo ratings yet

- Single Acting Cylinder: Manual-SA PN CylinderDocument3 pagesSingle Acting Cylinder: Manual-SA PN CylindermehtahemalNo ratings yet

- Newport Serv Man E150Document69 pagesNewport Serv Man E150quezon100% (1)

- Gep26sp3 RPLDocument2 pagesGep26sp3 RPLJorge Gustavo GoyecheaNo ratings yet

- Aerospace Parts 2 Quick Disconnect CouplingsDocument104 pagesAerospace Parts 2 Quick Disconnect CouplingsSohail100% (1)

- Introduction To Vessels and Vessel OrientationDocument15 pagesIntroduction To Vessels and Vessel OrientationSanjay PatelNo ratings yet

- Gold Sludge Vacuum Filter: Operations and Maintenance ManualDocument28 pagesGold Sludge Vacuum Filter: Operations and Maintenance ManualpilanichisekoNo ratings yet

- Manual Ilp ABCDocument51 pagesManual Ilp ABCGustavo Alejandro Flores GarriNo ratings yet

- Chapter 4 Standards 2021Document19 pagesChapter 4 Standards 2021Bamrung SungnoenNo ratings yet

- Api 594 PDFDocument52 pagesApi 594 PDFGheorghe Calota100% (3)

- Catalog Biocraft Electrical ApparatusDocument9 pagesCatalog Biocraft Electrical ApparatusHmmNo ratings yet

- Introduction To Modelica: Michael Wetter and Thierry S. Nouidui Simulation Research GroupDocument58 pagesIntroduction To Modelica: Michael Wetter and Thierry S. Nouidui Simulation Research GroupAkın ÇağlayanNo ratings yet

- Partsbook Lube Truck LT - R61206Document79 pagesPartsbook Lube Truck LT - R61206Muh tiadiNo ratings yet

- Book 4 Module 11A: Licence by PostDocument56 pagesBook 4 Module 11A: Licence by Postumesh dongolNo ratings yet

- Sta-Rite Jet PumpDocument40 pagesSta-Rite Jet Pumpaaronsmokes1100% (1)

- Sancassiano Mixer Df300 Operation ManualDocument55 pagesSancassiano Mixer Df300 Operation Manualexpert19700% (1)

- V 085 Fluid o Tech PO 500 1000 ModelsDocument9 pagesV 085 Fluid o Tech PO 500 1000 ModelsPaul ThillNo ratings yet

- Chilled Water Fittings - CoDocument209 pagesChilled Water Fittings - CoHarish MenonNo ratings yet

- Enquiry - Valve PlumbingDocument5 pagesEnquiry - Valve PlumbingKiran patelNo ratings yet

- DO - 005 - s2018 - Preventive Maintenance Manual For DPWH Equipment and Service VehiclesDocument231 pagesDO - 005 - s2018 - Preventive Maintenance Manual For DPWH Equipment and Service Vehiclesalterego1225100% (3)

- Bucket Hydraulic System: Operación de SistemasDocument4 pagesBucket Hydraulic System: Operación de SistemasvidalNo ratings yet

- 073686Document432 pages073686Хелфор УкраинаNo ratings yet

- Argus FK75Document2 pagesArgus FK75Felipe Gamboa GálvezNo ratings yet

- Valve Lubrication Pumps LubriAlloys PDFDocument16 pagesValve Lubrication Pumps LubriAlloys PDFPEDRONo ratings yet