Professional Documents

Culture Documents

BA-BMS-Burner For Rotary Kiln

BA-BMS-Burner For Rotary Kiln

Uploaded by

DIAGNEOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BA-BMS-Burner For Rotary Kiln

BA-BMS-Burner For Rotary Kiln

Uploaded by

DIAGNECopyright:

Available Formats

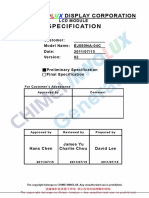

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

Kommissions-Nr.:

Commission-No.:

MAIN BURNER

OPERATION MANUAL

BURNER MANAGEMENT SYSTEM

IM151-8F PN/DP CPU

with

HMI KTP1000

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 1 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

Kommissions-Nr.:

Commission-No.:

CONTENT

Orientation HMI (Human Machine Interface) ...................................................................... 3

Used symbols .................................................................................................................... 4

Inside screens ................................................................................................................ 4

Status of group ............................................................................................................... 5

Description of functions...................................................................................................... 6

Screen selection with “F” function key ............................................................................ 6

Select screen with softkey .............................................................................................. 7

Basics of operation ............................................................................................................ 8

Password - level ................................................................................................................ 8

Change parameter values .................................................................................................. 8

Set time and date............................................................................................................... 8

ACKNOWLEGE / RESET .................................................................................................. 9

Change LOCAL – REMOTE .............................................................................................. 9

Change set point in LOCAL mode...................................................................................... 9

START and STOP fuel’s .................................................................................................... 9

Screen START..................................................................................................................10

Screen MAIN BURNER ....................................................................................................11

Screens Interlocking MAIN BURNER ............................................................................11

Screen IGNITOR ..............................................................................................................13

Screens Interlocking IGNITOR ......................................................................................14

Screen Parameter IGNITOR .........................................................................................16

Screen HFO VALVE TRAIN ..............................................................................................17

Screens Interlocking HFO .............................................................................................18

Screens Parameter HFO ...............................................................................................20

Screen COAL....................................................................................................................22

Screen MESSAGES .........................................................................................................23

Screen SYSTEM...............................................................................................................24

Screen FAILSAFE MODULS .........................................................................................25

LOGIC ..............................................................................................................................26

PROFIBUS DP – COMMUNICATION...............................................................................26

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 2 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

Kommissions-Nr.:

Commission-No.:

Orientation HMI (Human Machine Interface)

F1 – F8 the function keys are for screen selection – see “description of function”

Other functions or selection of screens have to be done for each screen inside the screen

with touch keys.

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 3 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Used symbols

Inside screens

ERROR / STATUS Error is present

Signal is present – good condition

Signal not present

Signal is present but not acknowled

ACTORS No limit is present

Closed/off position

Open/on position

Both limits are present

Actor is faulty

ANALOG VALUES 12345 Analog value ok

12345 Analog value faulty

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 4 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Status of group

Operation interlock

starting interlock

Operation

Actual step no.

OI SI OP STEP

Operation and starting interlock not OK – no operation

0 possible

OI SI OP STEP

Operation interlock OK but starting interlock not OK – no start

0 possible

OI SI OP STEP

0 Operation and starting interlock OK – start possible

OI SI OP STEP

1-16 Group is in start sequence

OI SI OP STEP

16 Group is started sucessfull and in operation

OI SI OP STEP

51-66 Group is in stop sequence

OI SI OP STEP

66 Group is stopped sucessfull – ready to start

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 5 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Description of functions

Screen selection with “F” function key

START Go to screen „START“ (always screen after start HMI)

IGN Go to screen „IGNITOR“

HFO Go to screen „HFO VALVE TRAIN“

COAL Go to screen „COAL“

INT Go to screen „INTERLOCKS“

PARA Go to screen „PARAMETERS“

à Go to next screen

ß Go to previous screen

MES Go to screen „MESSAGES“

SYS Go to screen „SYSTEM“

FS-MOD Go to screen „FAILSAFE MODULS“

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 6 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Select screen with softkey

START Start push button

STOP Stop push button

INT Go to screens of interlocking

PARA Go to screens for parameter

à Go to next screen

ß Go to previous screen

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 7 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Basics of operation

The controller watches and controls the ignition and operation of fuels on a safe way.

In REMOTE mode the commands start and stop and the set points will give from central control room

(CCR). In LOCAL mode the commands start and stop and the set points will control from the local

HMI (human machine interface).

Additional for the regulating of fuel flow a possibility to switch between automatic control and manual

control is given.

Password - level

To change any settings or parameter a password with the right user is necessary. The default setting

of password is :

password user purpose

555 5 change settings, parameter and configuration

Change parameter values

If it is necessary to write a new value in the desired parameter field user have to touch the parameter

field à a key board and the login screen is automatically open and the user can write by touching the

soft keys the user name and password and after the new value.

If the value is right press ENTER à new set point will transferred to the controller and the screen

switch back to origin screen. Is the value wrong press ESC à old value is shown in the field.

Set time and date

Normally if the data interchange to CCR is ok the time and data will synchronised all the time to the

time and date of CCR.

If the communication is disturbed you can set time and/or date manually via HMI.

To set time and date you have to go to screen SYSTEM.

If you have written in the actual time and date you have to press CLOCK .

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 8 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

ACKNOWLEGE / RESET

If a fault is present in the controller a fault memory is activated and the group goes in safe position

(closed valves).

By each new fault a signal – new fault - is activated. To reset the signal you have to press the ACK

button.

For acknowledging of 1 or more faults you have to press ACK button.

Is the reason of the fault solved you have to reset the fault memory by pressing again ACK button.

Otherwise the starting interlock of the group give not the enable signal for starting.

Change LOCAL – REMOTE

If the communication to remote system run successful you can switch the operation mode from

LOCAL to REMOTE by using the KEY SWITCH.

If the communication is disturbed (the feedback of LIVE signal does not come back in adjusted time)

automatically the controller goes in LOCAL mode – so the operator can react immediately.

Change set point in LOCAL mode

If the controller is in LOCAL mode the operator can write a new value in the desired set point field.

Operator have to touch the set point field à a key board is automatically open and the operator can

write by touching the soft keys the new value.

If the value is right press ENTER à new set point will transferred to the controller and the screen

switch back to origin screen. Is the value wrong press ESC à old value is shown in the field.

If the controller is in REMOTE mode the set point from remote system is shown in the field. Any

change of set point is not possible.

START and STOP fuel’s

All fuel’s and the ignitor are able to start and stop from the relevant screen if the controller is in

LOCAL mode. In REMOTE mode the commands are given from central control room (CCR).

Before you start any fuel or Ignitor call the relevant picture.

A stopping of any fuel or ignitor is always possible. To start a fuel or ignitor the starting interlock has to

be fulfilled.

The starting interlock is fulfilled if operation and starting interlock is green (see “Status of group”)

For start you have to press in same time START (see “Select screen with softkey”).

For stop you have to press in same time STOP (see “Select screen with softkey”).

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 9 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Screen START

After a successful start of controller this screen will shown automatically.

LOCAL REMOTE Indication of actual operation mode

FS MODUL it means 1 or more failsafe module are passivated

ACK it means a new fault is present

KILN T > 750°C it means kiln temperature is greater as MIN

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 10 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Screen MAIN BURNER

Screens Interlocking MAIN BURNER

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 11 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 12 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Screen IGNITOR

The starting interlock is fulfilled if operation and starting interlock is green (see “Status of group”)

For start you have to press in same time START (see “Select screen with softkey”).

For stop you have to press in same time STOP (see “Select screen with softkey”).

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 13 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Screens Interlocking IGNITOR

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 14 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 15 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Screen Parameter IGNITOR

Safety time XXXX failsafe parameters – not possible to change

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 16 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Screen HFO VALVE TRAIN

The starting interlock is fulfilled if operation and starting interlock is green (see “Status of group”)

For start you have to press in same time START (see “Select screen with softkey”).

For stop you have to press in same time STOP (see “Select screen with softkey”).

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 17 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Screens Interlocking HFO

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 18 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 19 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Screens Parameter HFO

Setting of regulator parameter:

dead band – DEAD inside of dead band the regulator does not react to any changes of actual

value

dimension: same as set point and actual value

proportional factor – GAIN with proportional factor you make regulator slower or faster

increase factor à regulator is faster

decrease factor à regulator is slower

dimension: less

integral time – TI with integral time you make the regulator more or less sensitive

dimension: seconds

max output – LMN_H limit of max output signal

dimension: %

min output – LMN_L limit of min output signal

dimension: %

IGN-POS position for start HFO firing

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 20 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Safety time XXXX failsafe parameters – not possible to change

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 21 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Screen COAL

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 22 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Screen MESSAGES

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 23 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Screen SYSTEM

THE FOLLOWING SCREENS AND POSSIBILITIES ARE

FOR WELL TRAINED PERSONAL!

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 24 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

Screen FAILSAFE MODULS

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 25 of 26

Kunde:

customer: BENIN

Anlage:

plant:

MAIN BURNER

KommissionsNr.:

Commission-No.:

LOGIC

The start and Stop of fuel is realised by sequences. For trouble shooting the indication of the steps

is very important.

STEP = 0 operation interlock is not ok

STEP 1 - 49 starting steps

STEP 51 - 99 stopping steps

Definition of operation and start interlock:

- OPERATION INTERLOCK the operation interlock have to be always 1 (OK – green

indication); by loosing operation interlock all valves goes in

safe position (closed valves)

- START INTERLOCK the start interlock has to be 1 in time of activating start; a

change to 0 after has no influence

PROFIBUS DP – COMMUNICATION

For the data interchange between GRECO controller and DCS-system (scada system) there is a

communication device installed.

1 DP-DP Koppelung Ord.No. 6ES7-158-0AD01-0XA0

Baud rate max 12 Mbit/s

To DCS system

Start address Q 100.0 (outputs)

Length 64 bytes consistent

From DCS system

Start address I 100.0 (inputs)

Length 32 Byte consistent

Bearbeitet/designed Datum/date Seite/page

V0.1 Swarat 2012-11-22 26 of 26

You might also like

- Kiln Process and Operation Training - TRR - NEWDocument97 pagesKiln Process and Operation Training - TRR - NEWDIAGNE100% (5)

- Manual Operation C264Document20 pagesManual Operation C264uriep keanNo ratings yet

- Grease Spray System User ManualDocument78 pagesGrease Spray System User ManualDIAGNENo ratings yet

- Engineering Systems LTD.: PROJECT: 90KLPD Distillery Plant Section: Fermentation ClientDocument7 pagesEngineering Systems LTD.: PROJECT: 90KLPD Distillery Plant Section: Fermentation ClientS B DubalNo ratings yet

- Ej080na 04C CmimeiDocument24 pagesEj080na 04C CmimeiИгорь ПлэчинтэNo ratings yet

- Re-Setting of Inverter: Novatex Limited SOP / E&I / 20Document2 pagesRe-Setting of Inverter: Novatex Limited SOP / E&I / 20OSAMANo ratings yet

- Guide Lines: Field Component ManualDocument22 pagesGuide Lines: Field Component Manualmohammed ahmedNo ratings yet

- CI 42 040 NL enDocument4 pagesCI 42 040 NL enHafsa BoudguigNo ratings yet

- Operator Manual - Level 1Document36 pagesOperator Manual - Level 1taghdirimNo ratings yet

- Specification: Inno Display CorporationDocument23 pagesSpecification: Inno Display CorporationThanh Nguyen NgocNo ratings yet

- NB 215 - 1) N2 Plan ManualDocument30 pagesNB 215 - 1) N2 Plan Manualionut nicolaeNo ratings yet

- Ej070na-01c CmimeiDocument24 pagesEj070na-01c CmimeiИгорь ПлэчинтэNo ratings yet

- Intervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Document1 pageIntervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Ramy Hassan EmaraNo ratings yet

- Blohm + Voss Industries GMBH: Operating Manual For 15 PPM Alarm Type:Bilgmon488 - 115/230vacDocument24 pagesBlohm + Voss Industries GMBH: Operating Manual For 15 PPM Alarm Type:Bilgmon488 - 115/230vacerolNo ratings yet

- Ej070na 01J CmimeiDocument24 pagesEj070na 01J CmimeiИгорь ПлэчинтэNo ratings yet

- Foreign Material Presence Chefsen 10142344-108KLF V3Document13 pagesForeign Material Presence Chefsen 10142344-108KLF V3g.cuachaNo ratings yet

- Service ReportDocument3 pagesService ReportDiana Putri SofyanNo ratings yet

- Inspection: AIR Winch Ingersoll RandDocument19 pagesInspection: AIR Winch Ingersoll RandAbdou BoucheritNo ratings yet

- PM Check SheetDocument7 pagesPM Check Sheetcharul2298No ratings yet

- AE3100 Series User ManualV1.06-deviserDocument35 pagesAE3100 Series User ManualV1.06-deviserGerardo AbregoNo ratings yet

- P21-0161 Final Report Acm 315 Kw-LoherDocument19 pagesP21-0161 Final Report Acm 315 Kw-Loherdindin6666No ratings yet

- Operation and Maintenance ManualDocument17 pagesOperation and Maintenance Manualpepenapao1217No ratings yet

- Sdmo Telys 1 Control Panel ManualDocument40 pagesSdmo Telys 1 Control Panel ManualGONZALO100% (1)

- Sony Trinitron CPD G420 W0002510MDocument70 pagesSony Trinitron CPD G420 W0002510MSaigon8n8No ratings yet

- Work - PM - AAH PM 202209 01155 PDFDocument1 pageWork - PM - AAH PM 202209 01155 PDFmaruthaiNo ratings yet

- Digital Video Camera Recorder: DCR-TRV120/TRV320Document132 pagesDigital Video Camera Recorder: DCR-TRV120/TRV320Marcelo Canepa GuerraNo ratings yet

- en Da deDocument86 pagesen Da deGabriel SetnicNo ratings yet

- Reconnect AC Error Codes - B80 SeriesDocument5 pagesReconnect AC Error Codes - B80 SeriesINSTA SERVICENo ratings yet

- LG Cm6520-ApDocument94 pagesLG Cm6520-ApMike DavidNo ratings yet

- Kum Be0106 3 1Document17 pagesKum Be0106 3 1nika.tsertsvadze.1No ratings yet

- 7026 - Preventive Maintenance - 20210906039 - 20210906039Document1 page7026 - Preventive Maintenance - 20210906039 - 20210906039Tulus EriksonNo ratings yet

- 10-In-1 Remote Control: Home TechDocument109 pages10-In-1 Remote Control: Home Techleo van houtenNo ratings yet

- DialogP SW9.Xx STD Trouble Shooting Rev. 1.01 2011-09-02.Pps-1Document35 pagesDialogP SW9.Xx STD Trouble Shooting Rev. 1.01 2011-09-02.Pps-1Younis AlsmadiNo ratings yet

- StandardEcuReprogramming Part2 EcuToolProgrammingInterfacesDescriptionDocument15 pagesStandardEcuReprogramming Part2 EcuToolProgrammingInterfacesDescriptionMarshall Tichaona ChikonoNo ratings yet

- 10-In-1 Remote ControlDocument58 pages10-In-1 Remote ControlNick KatrivesisNo ratings yet

- Engine and Peripherals: Diesel InjectionDocument269 pagesEngine and Peripherals: Diesel InjectionArchivo 0546No ratings yet

- Mesotech Final ResultDocument8 pagesMesotech Final ResultBudhi 'Ipank' PangestuNo ratings yet

- 5117 CM 15052024Document2 pages5117 CM 15052024intikomrajaNo ratings yet

- G90 Repair Manual-V1.0-ENDocument48 pagesG90 Repair Manual-V1.0-ENgeraldo medeirosNo ratings yet

- SM 4Document269 pagesSM 4Ilhami DemirNo ratings yet

- Data SheetDocument23 pagesData SheetJoel LopezNo ratings yet

- Pilot Lot InspectionDocument4 pagesPilot Lot Inspectiongocohov660No ratings yet

- GRP Drainage Piping System FabricationDocument5 pagesGRP Drainage Piping System FabricationkahootNo ratings yet

- Document 2 Wpmz-5,6 WatanabeDocument35 pagesDocument 2 Wpmz-5,6 WatanabeHendrik BastiwNo ratings yet

- 0186 MOM DSP 025 040 0010 Inversor de Giro TVDocument120 pages0186 MOM DSP 025 040 0010 Inversor de Giro TVLukas Ramírez SchiaffinoNo ratings yet

- Sop-40-Start Up of Loss in Weight Type Schenck UnitDocument2 pagesSop-40-Start Up of Loss in Weight Type Schenck UnitOSAMANo ratings yet

- QAS - Shutdown Maint - Test Case - 05Document4 pagesQAS - Shutdown Maint - Test Case - 05Harshvardhan RajawatNo ratings yet

- Eoc China 2014 - AmsDocument28 pagesEoc China 2014 - AmsmarioNo ratings yet

- Operating Panel Integral PIP: User ManualDocument4 pagesOperating Panel Integral PIP: User ManualcarmenbutnareanuNo ratings yet

- P32469 Acessorios AlarmeC2 Unificado REV0Document2 pagesP32469 Acessorios AlarmeC2 Unificado REV0geovane cardosoNo ratings yet

- Adjustment ManualDocument23 pagesAdjustment ManualViệt Thảo Trần100% (2)

- CNC-Tutorial 2 Ver0.4Document41 pagesCNC-Tutorial 2 Ver0.4balaji817150No ratings yet

- DSC-P71/P51/P31 Sony Digital Still CameraDocument108 pagesDSC-P71/P51/P31 Sony Digital Still CameraguilleamodeoNo ratings yet

- The Netherlands: (Nederland)Document22 pagesThe Netherlands: (Nederland)luke MaNo ratings yet

- W0007438M PDFDocument208 pagesW0007438M PDFPeterNo ratings yet

- Digital Video Cassette Recorder: Operating InstructionsDocument76 pagesDigital Video Cassette Recorder: Operating InstructionsDerlis Walter HodgeNo ratings yet

- Servicebulletin 663 Iolmaster Keyboarderror BootproblemsDocument2 pagesServicebulletin 663 Iolmaster Keyboarderror BootproblemsjtorresNo ratings yet

- Engine and Peripherals: Diesel Injection Petrol InjectionDocument500 pagesEngine and Peripherals: Diesel Injection Petrol InjectionAli ALiNo ratings yet

- Lenovo D1960WDocument51 pagesLenovo D1960WSalatiel FirminoNo ratings yet

- Main Burner: OperationDocument8 pagesMain Burner: OperationDIAGNENo ratings yet

- Burner Start-Up Quick Guide: Appendix ADocument3 pagesBurner Start-Up Quick Guide: Appendix ADIAGNENo ratings yet

- Air Adjustment ValuesDocument1 pageAir Adjustment ValuesDIAGNENo ratings yet

- Rotary Kiln Hydraulic Oil Station User ManualDocument44 pagesRotary Kiln Hydraulic Oil Station User ManualDIAGNE100% (1)

- Clinker Cooler Mechanical TrainingDocument51 pagesClinker Cooler Mechanical TrainingDIAGNE100% (1)

- Kiln OperationDocument98 pagesKiln OperationMarvin Garcia Catungal84% (25)

- Lab 5,6Document11 pagesLab 5,6ik227374728No ratings yet

- GTmetrix Report Addera - Pe 20230706T075633 UDnNDYSUDocument8 pagesGTmetrix Report Addera - Pe 20230706T075633 UDnNDYSUJavier J. LópezNo ratings yet

- 003 TSOP DN Series Non CDM SimulatorDocument107 pages003 TSOP DN Series Non CDM SimulatorengzoheryNo ratings yet

- Infra 3 - ATS2023 Shared Purpose - Collaborating To Transform The Datacenter and Beyond - Imran YusufDocument18 pagesInfra 3 - ATS2023 Shared Purpose - Collaborating To Transform The Datacenter and Beyond - Imran YusufAndy WuNo ratings yet

- GSM Single Site VerificationDocument26 pagesGSM Single Site Verificationgagan_555100% (8)

- Power Bi FundamentalsDocument379 pagesPower Bi FundamentalsShailja Sheetal100% (2)

- A Novel Approach of Women Safety Assistant Device With Biometric Verification in Real ScenarioDocument6 pagesA Novel Approach of Women Safety Assistant Device With Biometric Verification in Real ScenarioGeetha Priyanka GuggullaNo ratings yet

- Lab Manual of Computer Graphics For 3D ObjectDocument3 pagesLab Manual of Computer Graphics For 3D ObjectSatish PathakNo ratings yet

- Textbook Embedded System Design Embedded Systems Foundations of Cyber Physical Systems and The Internet of Things Marwedel Ebook All Chapter PDFDocument54 pagesTextbook Embedded System Design Embedded Systems Foundations of Cyber Physical Systems and The Internet of Things Marwedel Ebook All Chapter PDFmelissa.mcmillan964100% (15)

- PCM 1781Document37 pagesPCM 1781isaiasvaNo ratings yet

- Az Storage NotesDocument13 pagesAz Storage NotesmaheshNo ratings yet

- PP Ds On s4 HanaDocument10 pagesPP Ds On s4 HanaDipak BanerjeeNo ratings yet

- Qianli Thermal Camera User Guide v3Document4 pagesQianli Thermal Camera User Guide v3Abdulrahman AlabdanNo ratings yet

- tk207 User ManualDocument15 pagestk207 User ManualHernan EtchegarayNo ratings yet

- HUAWEI Nova 3i Secret CodesDocument2 pagesHUAWEI Nova 3i Secret CodesSyls. G.BandaNo ratings yet

- 04 Laboratory Exercise 142Document2 pages04 Laboratory Exercise 142andres tabaldoNo ratings yet

- Computer Graphics Lab CSP-305 Practical-1Document7 pagesComputer Graphics Lab CSP-305 Practical-1Samridh GargNo ratings yet

- CV Ashfaq Salehin Academic EmploymentDocument5 pagesCV Ashfaq Salehin Academic EmploymentaytrrddeNo ratings yet

- DOCKER and KUBERNETES TrainingDocument25 pagesDOCKER and KUBERNETES TrainingAhteshInamdarNo ratings yet

- Compute S Programming The Commodore 64 The Definitive GuideDocument628 pagesCompute S Programming The Commodore 64 The Definitive GuideGastón colNo ratings yet

- Designing A Complete Vehicle Safety and Alert System Integrated IotDocument70 pagesDesigning A Complete Vehicle Safety and Alert System Integrated IotJohn WickNo ratings yet

- Wireshark Notes-OSI and TCP-IPDocument34 pagesWireshark Notes-OSI and TCP-IPanzieriNo ratings yet

- Abu Huraira Khalid F21RINFT1M01071Document4 pagesAbu Huraira Khalid F21RINFT1M01071Harry ChoudharyNo ratings yet

- Electronics - Kantrak 2700and 2710Document2 pagesElectronics - Kantrak 2700and 2710FernandoNo ratings yet

- Digital Signal LabDocument13 pagesDigital Signal LabHermain Fayyaz KarimNo ratings yet

- Assignment 4Document2 pagesAssignment 4Cristina CarlosNo ratings yet

- Unit 2 - 1 Computer Application-IiiDocument10 pagesUnit 2 - 1 Computer Application-Iiirahuldodiyat001No ratings yet

- Mạng Máy Tính Thầy VinhDocument500 pagesMạng Máy Tính Thầy VinhLong Nguyễn HoàngNo ratings yet

- EC Council Career Path 2015 PDFDocument1 pageEC Council Career Path 2015 PDFadyanganefiNo ratings yet

- C048ps01a1 Ra-02 Product Specification v1.1Document2 pagesC048ps01a1 Ra-02 Product Specification v1.1Bogie GunturNo ratings yet