Professional Documents

Culture Documents

MS-E019 Installation of 11KV Switchgear

MS-E019 Installation of 11KV Switchgear

Uploaded by

a wasayCopyright:

Available Formats

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Instant Download Ebook PDF Burns and Groves The Practice of Nursing Research Appraisal Synthesis and Generation of Evidence 8th Edition PDF ScribdDocument48 pagesInstant Download Ebook PDF Burns and Groves The Practice of Nursing Research Appraisal Synthesis and Generation of Evidence 8th Edition PDF Scribdlillie.mitchell825100% (51)

- Itp TransformerDocument2 pagesItp TransformerDwi Mulyanti DwimulyantishopNo ratings yet

- Installation of MV LV Switchgear & Panels - Method StatementDocument3 pagesInstallation of MV LV Switchgear & Panels - Method Statementfathonix100% (2)

- Immunology Lab Worksheet StudentDocument6 pagesImmunology Lab Worksheet StudentBNo ratings yet

- ITP For Communication System InstallationDocument5 pagesITP For Communication System InstallationGanga Daran100% (3)

- Itp-Inspection & Test Plan: Containment InstallationDocument1 pageItp-Inspection & Test Plan: Containment InstallationwagwahkiabatheNo ratings yet

- Method Statement - Polarity TestDocument5 pagesMethod Statement - Polarity TestKhaled Badawy100% (1)

- Method Statement For MV Power Cables & Accessories InstallationDocument9 pagesMethod Statement For MV Power Cables & Accessories InstallationAdil HasanovNo ratings yet

- Method Statment For Earthing InstallationDocument8 pagesMethod Statment For Earthing InstallationJustin AlwarNo ratings yet

- Method Statement For The Installation of TransformerDocument2 pagesMethod Statement For The Installation of Transformeramg007100% (4)

- Testing and Commissioning of Motor Control Center Method StatementDocument3 pagesTesting and Commissioning of Motor Control Center Method StatementHumaid Shaikh75% (4)

- Method Statement Machnical, Electrical PlumbingDocument11 pagesMethod Statement Machnical, Electrical Plumbingmangeshshinde124No ratings yet

- Method Statement For GroundingDocument7 pagesMethod Statement For Groundingkamil100% (1)

- Iwp Cable Tray Installation Checklist: Appendix - 9Document3 pagesIwp Cable Tray Installation Checklist: Appendix - 9dennykvg0% (1)

- Checklist For Earthing & Bonding System InstallationDocument1 pageChecklist For Earthing & Bonding System InstallationPrashant Kadam100% (1)

- Method Statement For 33KV Switchgear Testing and CommissioningDocument7 pagesMethod Statement For 33KV Switchgear Testing and CommissioningBabu50% (2)

- Method Statement LV Distribution Boards Installation PDF FreeDocument9 pagesMethod Statement LV Distribution Boards Installation PDF Freetristan guarinoNo ratings yet

- MS-Installation 11Kv Switch Gear at Lusail-CP1Document6 pagesMS-Installation 11Kv Switch Gear at Lusail-CP1Tayab Ansari100% (2)

- For Information For Review For Approval For Construction As-BuiltDocument35 pagesFor Information For Review For Approval For Construction As-BuiltUtku Can KılıçNo ratings yet

- Installation Checklist For Earthing System & PV Yard LayoutDocument2 pagesInstallation Checklist For Earthing System & PV Yard LayoutCarla VietorNo ratings yet

- Rev.0 - ITP For Cable Pulling & Termination & JointingDocument3 pagesRev.0 - ITP For Cable Pulling & Termination & JointingUtku Can Kılıç100% (1)

- Mos T&C EarthingDocument20 pagesMos T&C EarthingAhanaf TahmidNo ratings yet

- Method Statement For MV Power Cables & Accessories InstallationDocument2 pagesMethod Statement For MV Power Cables & Accessories InstallationAdil Hasanov100% (1)

- p103-Stts-gec-Asi-ms-ele-003 - Method Statement For Installation of LV Distribution Panels (MDB, Capacitor Bank, VFD, SMDB, DB)Document6 pagesp103-Stts-gec-Asi-ms-ele-003 - Method Statement For Installation of LV Distribution Panels (MDB, Capacitor Bank, VFD, SMDB, DB)Anandu AshokanNo ratings yet

- ITP No 703 Fibre Optic Cable InstallationDocument1 pageITP No 703 Fibre Optic Cable InstallationkamilNo ratings yet

- HG Power Transmission Sdn. BHD.: Method StatementDocument6 pagesHG Power Transmission Sdn. BHD.: Method StatementNabil MazelanNo ratings yet

- 00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkDocument12 pages00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkAbdul Mohid SheikhNo ratings yet

- Electrical Acceptance TestingDocument23 pagesElectrical Acceptance TestingMarioNo ratings yet

- Method Statement For CB Replacement Job at MarmulDocument4 pagesMethod Statement For CB Replacement Job at MarmulJohn George100% (2)

- STP-ELECT-DB Distribution Board TestDocument18 pagesSTP-ELECT-DB Distribution Board TestYouwan LeeNo ratings yet

- Ohl TestDocument5 pagesOhl TestAnonymous ExWAN2xjFJNo ratings yet

- Project: Samsun CCPP: Title: ITP of SwitchgearsDocument4 pagesProject: Samsun CCPP: Title: ITP of SwitchgearsUtku Can Kılıç100% (1)

- Right Factorz Projects PVT LTD Checklist For Cable InstallationDocument9 pagesRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanNo ratings yet

- p103-Stts-gec-Asi-ms-ele-004 - Method Statement For Cable Laying On Cable TrayDocument6 pagesp103-Stts-gec-Asi-ms-ele-004 - Method Statement For Cable Laying On Cable TrayAnandu AshokanNo ratings yet

- Inspection and Test Plan (Itp) For ElectricalDocument38 pagesInspection and Test Plan (Itp) For ElectricalJames Pol JumarangNo ratings yet

- ITP For MV Power Cables & Accessories InstallationDocument1 pageITP For MV Power Cables & Accessories InstallationAdil HasanovNo ratings yet

- Inspection & Test Check ListDocument1 pageInspection & Test Check ListPRAKTISINo ratings yet

- Method Statement - Bus BarDocument2 pagesMethod Statement - Bus Barsoubhagya100% (1)

- Megger Testing Method StatementDocument7 pagesMegger Testing Method StatementRay Agacia0% (1)

- Field Work Procedure: 8. 8.1 Pre Hand ChecksDocument7 pagesField Work Procedure: 8. 8.1 Pre Hand Checkselsayed abdemagied100% (1)

- KP-00+++-MQ758-V0018-Rev 0-METHOD OF STATEMENT FOR EARTHING INSTALLATION WORKSDocument22 pagesKP-00+++-MQ758-V0018-Rev 0-METHOD OF STATEMENT FOR EARTHING INSTALLATION WORKSUtku Can KılıçNo ratings yet

- Technical Proposal: BKT Wellhead PlatformDocument43 pagesTechnical Proposal: BKT Wellhead PlatformMaina MathengeNo ratings yet

- Minor Electrical Installation Works - RedDocument2 pagesMinor Electrical Installation Works - RedSeby SebastianNo ratings yet

- Electrical Junction Box ITPDocument1 pageElectrical Junction Box ITPkamilNo ratings yet

- MS For Lighting & Small Power InstallationDocument17 pagesMS For Lighting & Small Power InstallationGanga Daran0% (1)

- Grounding Installation Inspection and Test Plan ITPDocument2 pagesGrounding Installation Inspection and Test Plan ITPtristan guarinoNo ratings yet

- p103-Stts-gec-Asi-ms-ele-008 - Method Statement For Installation of Earthing & Lightning ProtectionDocument7 pagesp103-Stts-gec-Asi-ms-ele-008 - Method Statement For Installation of Earthing & Lightning ProtectionAnandu AshokanNo ratings yet

- Cable Tray Installation Quality Control and Inspection Report FormDocument2 pagesCable Tray Installation Quality Control and Inspection Report FormSyam Chitturi0% (1)

- Itp For Commissioning Procedure For LV Switchgear SystemDocument4 pagesItp For Commissioning Procedure For LV Switchgear SystemSulimanNo ratings yet

- ELECT-TIC-1.4 (Backfilling and Concrete Tile Installation)Document2 pagesELECT-TIC-1.4 (Backfilling and Concrete Tile Installation)Muhammad Irfan100% (1)

- Power and Control Cable Installation ITPDocument1 pagePower and Control Cable Installation ITPkamilNo ratings yet

- Method Statement Installation of 11kv HV Switchgear PanelDocument7 pagesMethod Statement Installation of 11kv HV Switchgear Panelsyed fazluddin67% (3)

- Work Method Statement For Erection in Loc Start D and End CDocument8 pagesWork Method Statement For Erection in Loc Start D and End CTwin Bulls0% (1)

- Method Statement For Electrical ServicesDocument6 pagesMethod Statement For Electrical ServicesUmaira ZainalNo ratings yet

- Method Statement For Replacing of Existing MCCDocument3 pagesMethod Statement For Replacing of Existing MCCNambiappan Manikkam33% (3)

- Condition Assessment Manual: Transformer Inspection Form and ChecklistDocument9 pagesCondition Assessment Manual: Transformer Inspection Form and ChecklistmuhardionoNo ratings yet

- 11.method Statement Electrical WorkDocument25 pages11.method Statement Electrical Workشاز إياس100% (1)

- Method Statement: Al Andalus Trdg. & Elect. Cont. Co. L.L.CDocument32 pagesMethod Statement: Al Andalus Trdg. & Elect. Cont. Co. L.L.CAva GhaziNo ratings yet

- MS-E018 Installation of Fire Alarm SystemDocument8 pagesMS-E018 Installation of Fire Alarm Systema wasayNo ratings yet

- MS-M07 Installation of Duct InsulationDocument7 pagesMS-M07 Installation of Duct Insulationa wasayNo ratings yet

- Cable Entry FormatDocument2 pagesCable Entry Formata wasayNo ratings yet

- MS-E018 Installation of Fire Alarm SystemDocument8 pagesMS-E018 Installation of Fire Alarm Systema wasayNo ratings yet

- DB Enclosures SubmittalDocument90 pagesDB Enclosures Submittala wasayNo ratings yet

- MS-M07 Installation of Duct InsulationDocument7 pagesMS-M07 Installation of Duct Insulationa wasayNo ratings yet

- MS-M09 Installation of Water ChillerDocument8 pagesMS-M09 Installation of Water Chillera wasayNo ratings yet

- Provisional Allotment Report 2Document158 pagesProvisional Allotment Report 2AnkitNo ratings yet

- Renal FunctionsDocument13 pagesRenal FunctionsMohamed AhmedNo ratings yet

- Iso 23529 2016 enDocument8 pagesIso 23529 2016 endilaraNo ratings yet

- 1639 GCS190753 PhamCongMinh Assignment2Document28 pages1639 GCS190753 PhamCongMinh Assignment2Pham Cong Minh (FGW HCM)No ratings yet

- Training Schedule 2021 - SLVDocument4 pagesTraining Schedule 2021 - SLVFerdie OSNo ratings yet

- Detection of Typhoid CarriersDocument6 pagesDetection of Typhoid CarriersClarestaNo ratings yet

- Equipment or Machinery Movement and Commissioning FormDocument2 pagesEquipment or Machinery Movement and Commissioning FormJen SamNo ratings yet

- PERDEV Big Five Personality Inventory ResponseDocument2 pagesPERDEV Big Five Personality Inventory ResponseClyde Kendrick MachanNo ratings yet

- LEEA-059-2 Documentation and Marking - Part 2 Powered Lifting Machines - Version 2Document11 pagesLEEA-059-2 Documentation and Marking - Part 2 Powered Lifting Machines - Version 2john_192775339No ratings yet

- Research MethodologyDocument22 pagesResearch MethodologyZhaineNo ratings yet

- Introducing Objective Structured Practical Examination As A Formative Assessment Tool For Phase I Medical Professionals in PhysiologyDocument6 pagesIntroducing Objective Structured Practical Examination As A Formative Assessment Tool For Phase I Medical Professionals in PhysiologyPramod JaliNo ratings yet

- Template Data PQR SANTA E 100Document124 pagesTemplate Data PQR SANTA E 100Dina FadillaNo ratings yet

- OOSDocument14 pagesOOSqfbfabyholaNo ratings yet

- Afp48-133 - 00JUN01 - Physical Examination TechniquesDocument149 pagesAfp48-133 - 00JUN01 - Physical Examination TechniquesRat-a-tat-tatNo ratings yet

- Kumbhakar 2017 SFA ReviewDocument103 pagesKumbhakar 2017 SFA ReviewzdenkaNo ratings yet

- What's Next Regarding Validation and Verification: Overview of ISO 16140 SeriesDocument61 pagesWhat's Next Regarding Validation and Verification: Overview of ISO 16140 Seriessajid waqasNo ratings yet

- Roger 1993Document8 pagesRoger 1993Simona TintaNo ratings yet

- Laboratory Report: Test Required Result Reference Sars-Cov-2 TestDocument1 pageLaboratory Report: Test Required Result Reference Sars-Cov-2 TestMuhammad Haris AbidinNo ratings yet

- Mythic 60Document2 pagesMythic 60yogesh kumarNo ratings yet

- Hubungan Pola Makan Fast Food Dengan Peningkatan Penderita Kolesterol Pada Orang Dewasa Umur 35 - 40 Di Uptd Puskesmas TanasitoloDocument8 pagesHubungan Pola Makan Fast Food Dengan Peningkatan Penderita Kolesterol Pada Orang Dewasa Umur 35 - 40 Di Uptd Puskesmas TanasitoloratuNo ratings yet

- TP2 501Document4 pagesTP2 501hairiNo ratings yet

- Intro 2 Psychological TestingDocument6 pagesIntro 2 Psychological TestingAnanya NarangNo ratings yet

- NSF 44 (Summary) - Cation Exchange Water SoftenersDocument2 pagesNSF 44 (Summary) - Cation Exchange Water SoftenersJuan LeeNo ratings yet

- 4 Preoperative CareDocument14 pages4 Preoperative CareJay VillasotoNo ratings yet

- Question Bank PrintDocument8 pagesQuestion Bank PrintGayatri MudliyarNo ratings yet

- Lidocaine Spray On An Endoscope Immediately Before Gi-5-067Document5 pagesLidocaine Spray On An Endoscope Immediately Before Gi-5-067Byung ChaNo ratings yet

- Your COVID-19 ResultDocument1 pageYour COVID-19 Resultsebhat lab denekew100% (1)

- JCDR 8 FC05Document4 pagesJCDR 8 FC05Mohammed AdemNo ratings yet

MS-E019 Installation of 11KV Switchgear

MS-E019 Installation of 11KV Switchgear

Uploaded by

a wasayOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS-E019 Installation of 11KV Switchgear

MS-E019 Installation of 11KV Switchgear

Uploaded by

a wasayCopyright:

Available Formats

Method Statement

Installation of 11 KV Switchgear

Rev.00

PREPARED BY DESIGNATION COMPANY NAME

SIGN & DATE

EURASIA

AW PE ELECTROMECHANICAL

WORKS LLC

APPROVED BY DESIGNATION COMPANY NAME

SIGN & DATE

EURASIA

MA PM ELECTROMECHANICAL

WORKS LLC

(225-EUR-MST-MEP-ELE-0019 Rev.00) Page 1/8

Installation of LV Panels

Method Statement

CONTENTS

1) PURPOSE and SCOPE

2) REFERENCES

3) RESPONSIBILITIES

4) TOOLS and EQUIPMENTS

5) MATERIALS

6) WORK PROCEDURE

6.1 STORAGE

6.2 METHOD OF INSTALLATION

7) SAFETY and ENVIRONMENT

8) RECORDS

9) ATTACHMENTS

Inspection Test Plan

Installation Checklist

(225-EUR-MST-MEP-ELE-0019 Rev.00) Page 2/8

Installation of LV Panels

Method Statement

1.0 PURPOSE and SCOPE

The purpose of this document is to lay down the systematic procedures for the various activities required for

Installation of 11 KV Switchgear to ensure that all works are carried out in accordance with the contract

specification. This Method Statement is for installation of Installation of 11 KV Switchgear.

2.0 REFERENCES

Project Specification

IEC International Electro Technical Commission

BS Standard

FEWA Approved Shop Drawings

Approved Shop Drawings

Approved Technical Submittal

Manufacturer Instructions

3.0 RESPONSIBILITIES

TECH EGINEERING LLC is responsible for carrying out the works specified in this method

statement.

Project Manager

Will oversee the whole project ensuring that the necessary information to perform their job rules.

Construction Manager

Will ensure that the relevant department is aware and understand the requirements of this method

statement. He ensures that all relevant safety precautions in the delivery of the job are adhered to

and will implemented the company safety standards and compliances.

Site Engineer

Will ensure that the all works are being carried out as per the latest shop and specification and

coordinates with the QA/QC Departments for inspection and approval and will ensure that all

relevant safety precautions in the execution of the job are adhered to all times and implement

company safety standards and compliances.

QA/QC Engineer

The Quality Department will be a part of all quality inspections testing and control regarding

Installation of 11 KV Switchgear.

Foreman

Will ensure that his crew understands the method statement and works are to be executed safely,

within the time of schedule and specified finishes. All foremen will provide the crew with

appropriate PPE and approved drawings for the works and make sure it is implemented.

Installation Team

Will execute the works safely, within time schedule and under the direct supervision of the Charge

Hands and Foreman and they are also responsible for keeping the work area clean and tidy.

(225-EUR-MST-MEP-ELE-0019 Rev.00) Page 3/8

Installation of LV Panels

Method Statement

4.0 TOOLS and EQUIPMENTS

Drilling Machine

Hammer

Grinder with cutting disk

Sprit Level

Measuring tape

Hydraulic crimping tools

Cranes

Knife

Spanner set

Torque Wrench

Calibrated Insulation Tester

Pork Lift

5.0 MATERIALS

11 KV Switchgear and Accessories

6.0 WORK PROCEDURE

Installation of 11 KV Switchgear works activities shall be as per approved shop drawing and complying with the

contract requirements.

6.1 STORAGE

All material received on site will be inspected, handled and stored upon receipt in accordance with

the project procedures

All inspection/construction will be carried out in compliance with the main contractor and client

safety manual.

Site engineer will inspect the equipment as per manufacturer's recommendation prior to

installation.

Store keeper will inspect for any damage during shipping, handling and storage.

Store keeper will review the documents and verify the items with the packing list.

Store keeper is responsible for proper storage as per the requirement

Safety officer will ensure the appropriate measures to avoid any unexpected events.

All received material will be checked for conformance and approval will be given by the store

keeper or site engineer before offering inspection.

(225-EUR-MST-MEP-ELE-0019 Rev.00) Page 4/8

Installation of LV Panels

Method Statement

Any discrepancies, damages shall be notified and reported for further action.

Materials found not suitable for the project will be remove from the site immediately.

Panel should be protected against moisture, dirt, vermin and unauthorized access.

Panels to be stored away from the dust.

Panels to be stored in covered place separately as per manufacturer recommended with the

original factory packing’s.

Inspection shall be conducted by the site QC inspector and be coordinated with in the main

contractor and Consultant.

Verification, inspection checklists and tests will be verified, recorded on approved forms and

signed by site QC inspector and Consultant

6.2 METHOD OF INSTALLATION

References

Drawing and Specification: Approved shop-drawings FEWA

IEE Regulations and B.S. Standards

Technical Specifications

Manufacturer Instructions

Pre-Installation Checks

All installation will be carried out in accordance with the specifications Contract Specifications:

All materials will be approved and material inspection will completed in advance before installation.

Physical verification of the materials will be carried out for any damages prior to taking from the

stores.

Check and verify the availability of space for the installation as per approved shop drawings.

Ensure that the approved materials are available to carry out the works.

Ensure the installation areas are free from debris and foreign materials.

Ensure that adequate number of technicians and proper tools are present at site.

Thoroughly clean the area prior to the commencement of work. Extreme cleanliness is required

during installation.

The area outside and adjacent to the substation room and electrical rooms shall be free from

obstructions and with enough space barricaded with warning tapes.

A forklift and/or a hydraulic pallet truck will transport the Switchgear. Ensure that the unloading

space is clean and dry.

A safety barrier is to be erected around the area and warning signs will be provided.

Ensure that latest approved shop drawing for the installation is present and all the personnel are

working on the same drawings.

Installation of 11 KV Switchgear

(225-EUR-MST-MEP-ELE-0019 Rev.00) Page 5/8

Installation of LV Panels

Method Statement

Ensure that the Shop drawings are approved.

Supervisor in charge will issue instruction and control the safety and environment performance of

his workers.

11 KV switchgear along with packing will be off loaded from transportation to the mobile hydraulic

trolley placed on platform by using site tower crane.

Ensure the completion of all civil work at the location of installation before shifting 11 KV

switchgear.

Attach wire rope or fiber slings to lifting lugs on the top of the switchgear casing. Wire ropes, slings

to be rated for lifting load.

The slings will be carefully positioned such as to ensure that the switchgear will be balanced in a

lifted position; check assembled components are not chaffed or otherwise damaged.

Trailing ropes may be used for lateral control whilst lifting, and the operation will be closely

supervised, all necessary steps will be taken to ensure the safety of the equipment.

Lower 11 kV switchgear on to the pallet jacks, manually transport it in ground floor. Final

placement will be by "inch-lowering" as per final drawing location/survey.

Remove packing and check for any physical damage on casing as well on interiors.

The same above transportation procedure will be adopted for other pieces of switchgear as

mentioned in the drawing, ensuring connections between sections are matching without bending or

force.

Fix switchgear in position with suitable HILT fixing bolts.

Remove interiors and safely place in store wrapped and identified.

Pre-installation inspection of 11 kV switchgear shall be carried out as per manufacturer instruction.

Before the start of conduit and glancing entry, check the details of approved construction drawing.

Take precautions to cover internal components / terminals from duct / metal filling.

MV cables to be correctly spaced & terminated as per local authority regulation / codes of practice

by specialist MV testing / terminating contractor.

(Note: all cables to be tested prior to installation & after installation prior to connection)

Drill require conduit & gland holes in the top panel of the switchgear for controls / earthing and

power cables in designated low voltage / extra low voltage cubicle.

Terminate Power & earthing cables to 11 kV switchgear as per the approved shop drawings.

Check the connections of 11 kV switchgear with respective equipment and ensure that the circuit is

complete. And conduit / phase rotation / earth fault readings are correct.

Test outgoing circuits in accordance with the requirements of the specifications.

After finishing the installation, apply ID labels and tags as per approved material submittal.

After completion of all electrical installation, remove dirt and construction debris. Clean the work

location and left the installation site in tidy fashion.

(225-EUR-MST-MEP-ELE-0019 Rev.00) Page 6/8

Installation of LV Panels

Method Statement

Inspection shall be offered to QC and the Consultant Engineer for verification and approval.

All installations shall be inspected on completion of works, as per specifications and contract

documents.

7.0 SAFETY and ENVIRONMENT

Control Measures

Working at height requires edge protection (at the correct height) and in most cases harnesses

with the correct length.

Cordon-off work area and post warning signs and or warning tape as required. Access shall be

restricted to authorized persons only.

The erection site will be kept reasonably clean and tidy. Manufacturer's packing material, cable

waste, etc. will be cleaned from the erection site at regular intervals during the erection or

connection process.

Prevention of falling materials from height, this would involve toe boards on scaffolding etc.

All workers to wear appropriate PPE for the task, i.e. goggles, mask, gloves etc. The foreman

should provide all the necessary PPE and implement the wearing of it.

Electrical power tools will be approved, double insulated or grounded to avoid electrical shock.

Fire extinguishers are to be placed within reaching distance any works that is within risk of a fire.

Plant and equipment will have third party inspection certificates and be inspected prior to use.

All personnel entering the site will wear the appropriate PPE.

Personnel Protective Equipment

Safety helmet

Safety shoes

Goggles

Gloves

Mask

Emergency Arrangements

The Health & Safety officer will be responsible for coordinating the emergency procedure.

If there is an emergency the Health & Safety officer will be notified immediately.

The Health & Safety officer will then notify the relevant emergency services if required

997 – Fire

998 – Ambulance

(225-EUR-MST-MEP-ELE-0019 Rev.00) Page 7/8

Installation of LV Panels

Method Statement

999 – Police

The Health & Safety officer will notify the Safety Advisor of the emergency, if the site nurse is

required he will be notified, the Safety Advisor will attend the emergency and take control of the

emergency.

The required notification, investigation and reporting of the incident will be conducted in

accordance with the site HSE Plan.

8.0 RECORDS

1. Inspection request duly signed by the consultant.

9.0 ATTACHMENTS

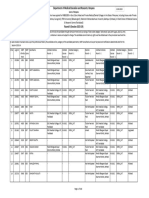

AP-CL-E-019 (Check List)

AP-ITP-E-019 (ITP)

(225-EUR-MST-MEP-ELE-0019 Rev.00) Page 8/8

Installation of LV Panels

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Instant Download Ebook PDF Burns and Groves The Practice of Nursing Research Appraisal Synthesis and Generation of Evidence 8th Edition PDF ScribdDocument48 pagesInstant Download Ebook PDF Burns and Groves The Practice of Nursing Research Appraisal Synthesis and Generation of Evidence 8th Edition PDF Scribdlillie.mitchell825100% (51)

- Itp TransformerDocument2 pagesItp TransformerDwi Mulyanti DwimulyantishopNo ratings yet

- Installation of MV LV Switchgear & Panels - Method StatementDocument3 pagesInstallation of MV LV Switchgear & Panels - Method Statementfathonix100% (2)

- Immunology Lab Worksheet StudentDocument6 pagesImmunology Lab Worksheet StudentBNo ratings yet

- ITP For Communication System InstallationDocument5 pagesITP For Communication System InstallationGanga Daran100% (3)

- Itp-Inspection & Test Plan: Containment InstallationDocument1 pageItp-Inspection & Test Plan: Containment InstallationwagwahkiabatheNo ratings yet

- Method Statement - Polarity TestDocument5 pagesMethod Statement - Polarity TestKhaled Badawy100% (1)

- Method Statement For MV Power Cables & Accessories InstallationDocument9 pagesMethod Statement For MV Power Cables & Accessories InstallationAdil HasanovNo ratings yet

- Method Statment For Earthing InstallationDocument8 pagesMethod Statment For Earthing InstallationJustin AlwarNo ratings yet

- Method Statement For The Installation of TransformerDocument2 pagesMethod Statement For The Installation of Transformeramg007100% (4)

- Testing and Commissioning of Motor Control Center Method StatementDocument3 pagesTesting and Commissioning of Motor Control Center Method StatementHumaid Shaikh75% (4)

- Method Statement Machnical, Electrical PlumbingDocument11 pagesMethod Statement Machnical, Electrical Plumbingmangeshshinde124No ratings yet

- Method Statement For GroundingDocument7 pagesMethod Statement For Groundingkamil100% (1)

- Iwp Cable Tray Installation Checklist: Appendix - 9Document3 pagesIwp Cable Tray Installation Checklist: Appendix - 9dennykvg0% (1)

- Checklist For Earthing & Bonding System InstallationDocument1 pageChecklist For Earthing & Bonding System InstallationPrashant Kadam100% (1)

- Method Statement For 33KV Switchgear Testing and CommissioningDocument7 pagesMethod Statement For 33KV Switchgear Testing and CommissioningBabu50% (2)

- Method Statement LV Distribution Boards Installation PDF FreeDocument9 pagesMethod Statement LV Distribution Boards Installation PDF Freetristan guarinoNo ratings yet

- MS-Installation 11Kv Switch Gear at Lusail-CP1Document6 pagesMS-Installation 11Kv Switch Gear at Lusail-CP1Tayab Ansari100% (2)

- For Information For Review For Approval For Construction As-BuiltDocument35 pagesFor Information For Review For Approval For Construction As-BuiltUtku Can KılıçNo ratings yet

- Installation Checklist For Earthing System & PV Yard LayoutDocument2 pagesInstallation Checklist For Earthing System & PV Yard LayoutCarla VietorNo ratings yet

- Rev.0 - ITP For Cable Pulling & Termination & JointingDocument3 pagesRev.0 - ITP For Cable Pulling & Termination & JointingUtku Can Kılıç100% (1)

- Mos T&C EarthingDocument20 pagesMos T&C EarthingAhanaf TahmidNo ratings yet

- Method Statement For MV Power Cables & Accessories InstallationDocument2 pagesMethod Statement For MV Power Cables & Accessories InstallationAdil Hasanov100% (1)

- p103-Stts-gec-Asi-ms-ele-003 - Method Statement For Installation of LV Distribution Panels (MDB, Capacitor Bank, VFD, SMDB, DB)Document6 pagesp103-Stts-gec-Asi-ms-ele-003 - Method Statement For Installation of LV Distribution Panels (MDB, Capacitor Bank, VFD, SMDB, DB)Anandu AshokanNo ratings yet

- ITP No 703 Fibre Optic Cable InstallationDocument1 pageITP No 703 Fibre Optic Cable InstallationkamilNo ratings yet

- HG Power Transmission Sdn. BHD.: Method StatementDocument6 pagesHG Power Transmission Sdn. BHD.: Method StatementNabil MazelanNo ratings yet

- 00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkDocument12 pages00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkAbdul Mohid SheikhNo ratings yet

- Electrical Acceptance TestingDocument23 pagesElectrical Acceptance TestingMarioNo ratings yet

- Method Statement For CB Replacement Job at MarmulDocument4 pagesMethod Statement For CB Replacement Job at MarmulJohn George100% (2)

- STP-ELECT-DB Distribution Board TestDocument18 pagesSTP-ELECT-DB Distribution Board TestYouwan LeeNo ratings yet

- Ohl TestDocument5 pagesOhl TestAnonymous ExWAN2xjFJNo ratings yet

- Project: Samsun CCPP: Title: ITP of SwitchgearsDocument4 pagesProject: Samsun CCPP: Title: ITP of SwitchgearsUtku Can Kılıç100% (1)

- Right Factorz Projects PVT LTD Checklist For Cable InstallationDocument9 pagesRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanNo ratings yet

- p103-Stts-gec-Asi-ms-ele-004 - Method Statement For Cable Laying On Cable TrayDocument6 pagesp103-Stts-gec-Asi-ms-ele-004 - Method Statement For Cable Laying On Cable TrayAnandu AshokanNo ratings yet

- Inspection and Test Plan (Itp) For ElectricalDocument38 pagesInspection and Test Plan (Itp) For ElectricalJames Pol JumarangNo ratings yet

- ITP For MV Power Cables & Accessories InstallationDocument1 pageITP For MV Power Cables & Accessories InstallationAdil HasanovNo ratings yet

- Inspection & Test Check ListDocument1 pageInspection & Test Check ListPRAKTISINo ratings yet

- Method Statement - Bus BarDocument2 pagesMethod Statement - Bus Barsoubhagya100% (1)

- Megger Testing Method StatementDocument7 pagesMegger Testing Method StatementRay Agacia0% (1)

- Field Work Procedure: 8. 8.1 Pre Hand ChecksDocument7 pagesField Work Procedure: 8. 8.1 Pre Hand Checkselsayed abdemagied100% (1)

- KP-00+++-MQ758-V0018-Rev 0-METHOD OF STATEMENT FOR EARTHING INSTALLATION WORKSDocument22 pagesKP-00+++-MQ758-V0018-Rev 0-METHOD OF STATEMENT FOR EARTHING INSTALLATION WORKSUtku Can KılıçNo ratings yet

- Technical Proposal: BKT Wellhead PlatformDocument43 pagesTechnical Proposal: BKT Wellhead PlatformMaina MathengeNo ratings yet

- Minor Electrical Installation Works - RedDocument2 pagesMinor Electrical Installation Works - RedSeby SebastianNo ratings yet

- Electrical Junction Box ITPDocument1 pageElectrical Junction Box ITPkamilNo ratings yet

- MS For Lighting & Small Power InstallationDocument17 pagesMS For Lighting & Small Power InstallationGanga Daran0% (1)

- Grounding Installation Inspection and Test Plan ITPDocument2 pagesGrounding Installation Inspection and Test Plan ITPtristan guarinoNo ratings yet

- p103-Stts-gec-Asi-ms-ele-008 - Method Statement For Installation of Earthing & Lightning ProtectionDocument7 pagesp103-Stts-gec-Asi-ms-ele-008 - Method Statement For Installation of Earthing & Lightning ProtectionAnandu AshokanNo ratings yet

- Cable Tray Installation Quality Control and Inspection Report FormDocument2 pagesCable Tray Installation Quality Control and Inspection Report FormSyam Chitturi0% (1)

- Itp For Commissioning Procedure For LV Switchgear SystemDocument4 pagesItp For Commissioning Procedure For LV Switchgear SystemSulimanNo ratings yet

- ELECT-TIC-1.4 (Backfilling and Concrete Tile Installation)Document2 pagesELECT-TIC-1.4 (Backfilling and Concrete Tile Installation)Muhammad Irfan100% (1)

- Power and Control Cable Installation ITPDocument1 pagePower and Control Cable Installation ITPkamilNo ratings yet

- Method Statement Installation of 11kv HV Switchgear PanelDocument7 pagesMethod Statement Installation of 11kv HV Switchgear Panelsyed fazluddin67% (3)

- Work Method Statement For Erection in Loc Start D and End CDocument8 pagesWork Method Statement For Erection in Loc Start D and End CTwin Bulls0% (1)

- Method Statement For Electrical ServicesDocument6 pagesMethod Statement For Electrical ServicesUmaira ZainalNo ratings yet

- Method Statement For Replacing of Existing MCCDocument3 pagesMethod Statement For Replacing of Existing MCCNambiappan Manikkam33% (3)

- Condition Assessment Manual: Transformer Inspection Form and ChecklistDocument9 pagesCondition Assessment Manual: Transformer Inspection Form and ChecklistmuhardionoNo ratings yet

- 11.method Statement Electrical WorkDocument25 pages11.method Statement Electrical Workشاز إياس100% (1)

- Method Statement: Al Andalus Trdg. & Elect. Cont. Co. L.L.CDocument32 pagesMethod Statement: Al Andalus Trdg. & Elect. Cont. Co. L.L.CAva GhaziNo ratings yet

- MS-E018 Installation of Fire Alarm SystemDocument8 pagesMS-E018 Installation of Fire Alarm Systema wasayNo ratings yet

- MS-M07 Installation of Duct InsulationDocument7 pagesMS-M07 Installation of Duct Insulationa wasayNo ratings yet

- Cable Entry FormatDocument2 pagesCable Entry Formata wasayNo ratings yet

- MS-E018 Installation of Fire Alarm SystemDocument8 pagesMS-E018 Installation of Fire Alarm Systema wasayNo ratings yet

- DB Enclosures SubmittalDocument90 pagesDB Enclosures Submittala wasayNo ratings yet

- MS-M07 Installation of Duct InsulationDocument7 pagesMS-M07 Installation of Duct Insulationa wasayNo ratings yet

- MS-M09 Installation of Water ChillerDocument8 pagesMS-M09 Installation of Water Chillera wasayNo ratings yet

- Provisional Allotment Report 2Document158 pagesProvisional Allotment Report 2AnkitNo ratings yet

- Renal FunctionsDocument13 pagesRenal FunctionsMohamed AhmedNo ratings yet

- Iso 23529 2016 enDocument8 pagesIso 23529 2016 endilaraNo ratings yet

- 1639 GCS190753 PhamCongMinh Assignment2Document28 pages1639 GCS190753 PhamCongMinh Assignment2Pham Cong Minh (FGW HCM)No ratings yet

- Training Schedule 2021 - SLVDocument4 pagesTraining Schedule 2021 - SLVFerdie OSNo ratings yet

- Detection of Typhoid CarriersDocument6 pagesDetection of Typhoid CarriersClarestaNo ratings yet

- Equipment or Machinery Movement and Commissioning FormDocument2 pagesEquipment or Machinery Movement and Commissioning FormJen SamNo ratings yet

- PERDEV Big Five Personality Inventory ResponseDocument2 pagesPERDEV Big Five Personality Inventory ResponseClyde Kendrick MachanNo ratings yet

- LEEA-059-2 Documentation and Marking - Part 2 Powered Lifting Machines - Version 2Document11 pagesLEEA-059-2 Documentation and Marking - Part 2 Powered Lifting Machines - Version 2john_192775339No ratings yet

- Research MethodologyDocument22 pagesResearch MethodologyZhaineNo ratings yet

- Introducing Objective Structured Practical Examination As A Formative Assessment Tool For Phase I Medical Professionals in PhysiologyDocument6 pagesIntroducing Objective Structured Practical Examination As A Formative Assessment Tool For Phase I Medical Professionals in PhysiologyPramod JaliNo ratings yet

- Template Data PQR SANTA E 100Document124 pagesTemplate Data PQR SANTA E 100Dina FadillaNo ratings yet

- OOSDocument14 pagesOOSqfbfabyholaNo ratings yet

- Afp48-133 - 00JUN01 - Physical Examination TechniquesDocument149 pagesAfp48-133 - 00JUN01 - Physical Examination TechniquesRat-a-tat-tatNo ratings yet

- Kumbhakar 2017 SFA ReviewDocument103 pagesKumbhakar 2017 SFA ReviewzdenkaNo ratings yet

- What's Next Regarding Validation and Verification: Overview of ISO 16140 SeriesDocument61 pagesWhat's Next Regarding Validation and Verification: Overview of ISO 16140 Seriessajid waqasNo ratings yet

- Roger 1993Document8 pagesRoger 1993Simona TintaNo ratings yet

- Laboratory Report: Test Required Result Reference Sars-Cov-2 TestDocument1 pageLaboratory Report: Test Required Result Reference Sars-Cov-2 TestMuhammad Haris AbidinNo ratings yet

- Mythic 60Document2 pagesMythic 60yogesh kumarNo ratings yet

- Hubungan Pola Makan Fast Food Dengan Peningkatan Penderita Kolesterol Pada Orang Dewasa Umur 35 - 40 Di Uptd Puskesmas TanasitoloDocument8 pagesHubungan Pola Makan Fast Food Dengan Peningkatan Penderita Kolesterol Pada Orang Dewasa Umur 35 - 40 Di Uptd Puskesmas TanasitoloratuNo ratings yet

- TP2 501Document4 pagesTP2 501hairiNo ratings yet

- Intro 2 Psychological TestingDocument6 pagesIntro 2 Psychological TestingAnanya NarangNo ratings yet

- NSF 44 (Summary) - Cation Exchange Water SoftenersDocument2 pagesNSF 44 (Summary) - Cation Exchange Water SoftenersJuan LeeNo ratings yet

- 4 Preoperative CareDocument14 pages4 Preoperative CareJay VillasotoNo ratings yet

- Question Bank PrintDocument8 pagesQuestion Bank PrintGayatri MudliyarNo ratings yet

- Lidocaine Spray On An Endoscope Immediately Before Gi-5-067Document5 pagesLidocaine Spray On An Endoscope Immediately Before Gi-5-067Byung ChaNo ratings yet

- Your COVID-19 ResultDocument1 pageYour COVID-19 Resultsebhat lab denekew100% (1)

- JCDR 8 FC05Document4 pagesJCDR 8 FC05Mohammed AdemNo ratings yet