Professional Documents

Culture Documents

MS-E018 Installation of Fire Alarm System

MS-E018 Installation of Fire Alarm System

Uploaded by

a wasayOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS-E018 Installation of Fire Alarm System

MS-E018 Installation of Fire Alarm System

Uploaded by

a wasayCopyright:

Available Formats

Method Statement

Installation of Fire Alarm System

Rev.00

PREPARED BY DESIGNATION COMPANY NAME

SIGN & DATE

EURASIA

AW PE ELECTROMECHANICAL

WORKS LLC

APPROVED BY DESIGNATION COMPANY NAME

SIGN & DATE

EURASIA

MA PM ELECTROMECHANICAL

WORKS LLC

(225-EUR-MST-MEP-ELE-0018 Rev.00) Page 1/8

Installation of Fire Alarm System

Method Statement

CONTENTS

1) PURPOSE and SCOPE

2) REFERENCES

3) RESPONSIBILITIES

4) TOOLS and EQUIPMENTS

5) MATERIALS

6) WORK PROCEDURE

6.1 STORAGE

6.2 METHOD OF INSTALLATION

7) SAFETY and ENVIRONMENT

8) RECORDS

9) ATTACHMENTS

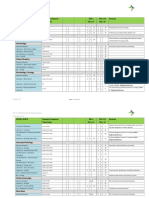

Inspection Test Plan

Installation Checklist

(225-EUR-MST-MEP-ELE-0018 Rev.00) Page 2/8

Installation of Fire Alarm System

Method Statement

1.0 PURPOSE and SCOPE

The purpose of this document is to lay down the systematic procedures for the various activities required for

Installation of Fire Alarm System to ensure that all works are carried out in accordance with the contract

specification. This Method Statement is for installation of Installation of Fire Alarm System.

2.0 REFERENCES

Project Specification

IEC International Electro Technical Commission

NFPA Standard

Ajman Civil Defense Approved Shop Drawings

Approved Shop Drawings

Approved Technical Submittal

Manufacturer Instructions

3.0 RESPONSIBILITIES

TECH EGINEERING LLC is responsible for carrying out the works specified in this method

statement.

Project Manager

Will oversee the whole project ensuring that the necessary information to perform their job rules.

Construction Manager

Will ensure that the relevant department is aware and understand the requirements of this method

statement. He ensures that all relevant safety precautions in the delivery of the job are adhered to

and will implemented the company safety standards and compliances.

Site Engineer

Will ensure that the all works are being carried out as per the latest shop and specification and

coordinates with the QA/QC Departments for inspection and approval and will ensure that all

relevant safety precautions in the execution of the job are adhered to all times and implement

company safety standards and compliances.

QA/QC Engineer

The Quality Department will be a part of all quality inspections testing and control regarding

Installation of Fire Alarm System. Will ensure that any discrepancies are highlighted, recorded

systematically convey to relative and responsible construction manager/site engineer and QA/QC

Manager for correction and action.

Foreman

(225-EUR-MST-MEP-ELE-0018 Rev.00) Page 3/8

Installation of Fire Alarm System

Method Statement

Will ensure that his crew understands the method statement and works are to be executed safely,

within the time of schedule and specified finishes. All foremen will provide the crew with

appropriate PPE and approved drawings for the works and make sure it is implemented.

Installation Team

Will execute the works safely, within time schedule and under the direct supervision of the Charge

Hands and Foreman and they are also responsible for keeping the work area clean and tidy.

4.0 TOOLS and EQUIPMENTS

Drilling Machine

Electrical Tool Box with the Tools

Hammer

Grinder with cutting disk

Sprit Level

Measuring tape

Ladder/Scaffolding

Spanner set

Water level pipe

White chalk/marker

Calibrated continuity tester

5.0 MATERIALS

Fire Alarm Cables

FACP Panel and Accessories

Fire Alarm Devices

6.0 WORK PROCEDURE

Installation of Fire Alarm System works activities shall be as per approved shop drawing and complying with the

contract requirements.

6.1 STORAGE

All material received on site will be inspected, handled and stored upon receipt in accordance with

the project procedures

All inspection/construction will be carried out in compliance with the main contractor and client

safety manual.

All received material will be checked for conformance and approval will be given by the store

keeper or site engineer before offering inspection.

(225-EUR-MST-MEP-ELE-0018 Rev.00) Page 4/8

Installation of Fire Alarm System

Method Statement

Any discrepancies, damages shall be notified and reported for further action.

Materials found not suitable for the project will be remove from the site immediately.

Panel should be protected against moisture, dirt, vermin and unauthorized access.

Panels to be stored away from the dust.

Panels to be stored in covered place separately as per manufacturer recommended with the

original factory packing’s.

Inspection shall be conducted by the site QC inspector and be coordinated with in the main

contractor and Consultant.

Verification, inspection checklists and tests will be verified, recorded on approved forms and

signed by site QC inspector and Consultant

6.2 METHOD OF INSTALLATION

References

Project Specification

Civil Defense Approved Shop Drawings

IEE Regulations and B.S. Standards

Technical Specifications

Manufacturer Instructions

Pre-Installation Checks

All installation will be carried out in accordance with the specifications Contract Specifications:

All materials will be approved and material inspection will completed in advance before installation.

Physical verification of the materials will be carried out for any damages prior to taking from the

stores.

Check and verify the availability of space for the installation as per approved shop drawings.

Ensure that the approved materials are available to carry out the works.

Ensure the installation areas are free from debris and foreign materials.

Ensure that adequate number of technicians and proper tools are present at site.

Ensure that all materials are ready during installation.

Thoroughly clean the area prior to the commencement of work. Extreme cleanliness is required

during installation.

A safety barrier is to be erected around the area and warning signs will be provided.

Before installation of Panel, a visual inspection will be carried out. Where defective parts of the

equipment are found, it will be returned to the store and segregate in a separate storage area for

replacement of the items. Minor defects which can be rectified on site will be recorded for

resolution by the vendors.

Ensure the presence of manufacturer's standard information on the equipment for the type,

capacity, size, color, factory serial no., operating voltage and current (where ever applicable) etc.

(225-EUR-MST-MEP-ELE-0018 Rev.00) Page 5/8

Installation of Fire Alarm System

Method Statement

Check the type and size of wires and cables and their accessories as per approved material

submittal and engineering specifications.

Ensure that latest approved shop drawing for the installation is present and all the personnel are

working on the same drawings.

Installation of Fire Alarm System

A. Installation of Smoke and Heat Detector

Ensure that the Shop drawings are approved.

Supervisor in charge will issue instruction and control the safety and environment

performance of his workers.

Ensure that approved material required to carry out the work is available at site.

Prior to commencement of work, areas and access will be inspected to confirm that site is

ready to commence the work.

Before taking the materials from stores, pre-inspection will be carried out for materials.

Prepare all the materials and approved shop drawings before the installation.

Mark out the Route of Fire alarm cable and position of other equipment as per the

construction drawing of current revision. Multiple cable runs shall be laid in proper

containment system.

Drill the holes of required dia. by using electric drill machine at the marked location to

install Fire alarm cable and other equipment.

Insert a plastic plug in the drilled hole by twisting.

Fix the plastic clip over the installed plug with the help of brass screw; insert approved

Fire Alarm cable in the clip prior to fix it with the plug.

Mark and drill the location of the smoke detector as per the construction drawing.

Make electrical connection of smoke detector to fire alarm system cables in accordance

with manufacturer's connection diagram.

Install the base of smoke and heat detector at marked positions loosely, plumb and level

the base at correct angles with ceiling and walls.

Tighten the base of smoke detector with screws. Care is taken to avoid the over tighten.

Note address, record on schedule and plug in head.

Fit temporary protection cover.

Specialist to authorized supervisor will super supervise the installation.

B. Manual Pull Station

Ensure that the Shop drawings are approved.

Supervisor in charge will issue instruction and control the safety and environment

performance of his workers.

Ensure that approved material required to carry out the work is available at site.

Prior to commencement of work, areas and access will be inspected to confirm that site is

ready to commence the work.

Before taking the materials from stores, pre-inspection will be carried out for materials.

Prepare all the materials and approved shop drawings before the installation.

(225-EUR-MST-MEP-ELE-0018 Rev.00) Page 6/8

Installation of Fire Alarm System

Method Statement

Mark out the Route of Fire alarm cable and position of other equipment as per the

construction drawing of current revision. Multiple cable runs shall be laid in proper

containment system.

Drill the holes of required dia. by using electric drill machine at the marked location to

install Fire alarm cable and other equipment.

Insert a plastic plug in the drilled hole by twisting.

Mark and drill at the location of Pull Station as per the construction drawing.

Install the Pull Station at marked positions loosely, plumb and level it at correct angles

with ceiling and walls.

Make the electrical connection of Pull Station to the Alarm system in accordance with

manufacturer's connection diagram. Note address, record on schedule and plug in head.

C. Fire Alarm Control Panel

Ensure that the Shop drawings are approved.

Supervisor in charge will issue instruction and control the safety and environment

performance of his workers.

Ensure that approved material required to carry out the work is available at site.

Prior to commencement of work, areas and access will be inspected to confirm that site is

ready to commence the work.

Before taking the materials from stores, pre-inspection will be carried out for materials.

Prepare all the materials and approved shop drawings before the installation.

Mark out the Route of Fire alarm cable and position of other equipment as per the

construction drawing of current revision. Multiple cable runs shall be laid in proper

containment system.

Drill the holes of required dia. by using electric drill machine at the marked location to

install Fire alarm cable and other equipment.

Insert a plastic plug in the drilled hole by twisting.

Mark and drill the location of FACP as per the construction drawing.

Install the panel box at marked and drilled positions loosely, plumb at correct angles with

ceiling and walls.

Fit the protection cover of panel box.

Make the connection of all related fire detection equipment and Alarm and level the box

Circuit cables in Accordance with the construction drawing and Manufacturer's connection

diagrams.

After installation and connection of the panel with all related equipment, the control panel

will be programmed by the manufacturer's certified engineer as per the pre-defined fire

zone distribution.

7.0 SAFETY and ENVIRONMENT

Control Measures

Working at height requires edge protection (at the correct height) and in most cases harnesses

with the correct length for the height of work and attached correctly.

Slab openings are to be well protected.

(225-EUR-MST-MEP-ELE-0018 Rev.00) Page 7/8

Installation of Fire Alarm System

Method Statement

Prevention of falling materials from height, this would involve toe boards on scaffolding etc.

All workers to wear appropriate PPE for the task, i.e. goggles, mask, gloves etc. The foreman

should provide all the necessary PPE and implement the wearing of it.

Electrical power tools will be approved, double insulated or grounded to avoid electrical shock.

Fire extinguishers are to be placed within reaching distance any works that is within risk of a fire.

Plant and equipment will have third party inspection certificates and be inspected prior to use.

All personnel entering the site will wear the appropriate PPE.

Personnel Protective Equipment

Safety helmet

Safety shoes

Goggles

Gloves

Mask

Emergency Arrangements

The Health & Safety officer will be responsible for coordinating the emergency procedure.

If there is an emergency the Health & Safety officer will be notified immediately.

The Health & Safety officer will then notify the relevant emergency services if required

997 – Fire

998 – Ambulance

999 – Police

The Health & Safety officer will notify the Safety Advisor of the emergency, if the site nurse is

required he will be notified, the Safety Advisor will attend the emergency and take control of the

emergency.

The required notification, investigation and reporting of the incident will be conducted in

accordance with the site HSE Plan.

8.0 RECORDS

1. Inspection request duly signed by the consultant.

9.0 ATTACHMENTS

AP-CL-E-018 (Check List)

AP-ITP-E-018 (ITP)

(225-EUR-MST-MEP-ELE-0018 Rev.00) Page 8/8

Installation of Fire Alarm System

You might also like

- CAPA Form ExampleDocument1 pageCAPA Form ExampleBharath78% (9)

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- Method Statement of Fire Alarm SystemDocument10 pagesMethod Statement of Fire Alarm Systemmidhun murali100% (6)

- Method of Statement For Testing & Commissioning of Fire Alarm SystemDocument7 pagesMethod of Statement For Testing & Commissioning of Fire Alarm SystemKarim Amer100% (1)

- Verification and Validation WorksheetDocument6 pagesVerification and Validation WorksheetOnline Nina100% (8)

- 16-Itp CCTV SystemDocument2 pages16-Itp CCTV Systemkash30100% (4)

- FM 200 System Installations, Testing and Commissioning. Contract NameDocument16 pagesFM 200 System Installations, Testing and Commissioning. Contract NameAslam Ansari100% (1)

- BS 4962 (Specification For Plastic Pipes and Fittings For Use As Subsoil Field Drains)Document28 pagesBS 4962 (Specification For Plastic Pipes and Fittings For Use As Subsoil Field Drains)minsara madtNo ratings yet

- Vesda System Method StatementDocument6 pagesVesda System Method Statementsanthilal100% (2)

- Method Statement v.1Document3 pagesMethod Statement v.1Senthil Kumar Varadarajan33% (3)

- Method Statement For CCTV Installation r1Document16 pagesMethod Statement For CCTV Installation r1Anindito Wicaksono100% (4)

- MS-E019 Installation of 11KV SwitchgearDocument8 pagesMS-E019 Installation of 11KV Switchgeara wasayNo ratings yet

- MS-E019 Installation of 11KV SwitchgearDocument8 pagesMS-E019 Installation of 11KV Switchgeara wasayNo ratings yet

- Method of Statement For Conduit InstallationDocument15 pagesMethod of Statement For Conduit InstallationMohd MuksinNo ratings yet

- Method Statement For FA SystemDocument6 pagesMethod Statement For FA SystemsanthilalNo ratings yet

- Method Statement For Fire Alarm and Emergency System InstallationDocument9 pagesMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- Method of Statement For Testing & Commissioning of Fire Alarm SystemDocument4 pagesMethod of Statement For Testing & Commissioning of Fire Alarm Systemvin ssNo ratings yet

- MSRA Installation of Firefighting SystemDocument28 pagesMSRA Installation of Firefighting Systemadnan hanif100% (1)

- Method Statement For Fire Alarm System InstallationDocument4 pagesMethod Statement For Fire Alarm System Installationamg00780% (5)

- Method Statement For Fire Suppression System Installation Testing & Commissioning PDFDocument3 pagesMethod Statement For Fire Suppression System Installation Testing & Commissioning PDFReza Akbar80% (5)

- PRECOMMISSIONING and COMMISSIONING METHOD STATEMENT PROCEDURE FOR CCTV SYSTEMDocument2 pagesPRECOMMISSIONING and COMMISSIONING METHOD STATEMENT PROCEDURE FOR CCTV SYSTEMHumaid ShaikhNo ratings yet

- Method Statement For Hydrant As Per PVN CommentsDocument23 pagesMethod Statement For Hydrant As Per PVN CommentsAbcd efgh100% (1)

- Fire Protection Method StatementDocument17 pagesFire Protection Method StatementNawarathna Engineering Dept.100% (1)

- Cable Pulling and Termination of Power CablesDocument4 pagesCable Pulling and Termination of Power Cablessardarmkhan100% (1)

- Method Statement For MV Power Cables & Accessories InstallationDocument9 pagesMethod Statement For MV Power Cables & Accessories InstallationAdil HasanovNo ratings yet

- PRECOMMISSIONING and COMMISSIONING METHOD STATEMENT FOR FIRE HOSE RACKS and FIRE HOSE REELDocument2 pagesPRECOMMISSIONING and COMMISSIONING METHOD STATEMENT FOR FIRE HOSE RACKS and FIRE HOSE REELHumaid Shaikh100% (1)

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDocument11 pagesMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan67% (3)

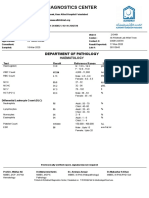

- Al-Khidmat Diagnostics Center: Department of PathologyDocument1 pageAl-Khidmat Diagnostics Center: Department of PathologyKiran HassanNo ratings yet

- Material Receivig SOPDocument3 pagesMaterial Receivig SOParunNo ratings yet

- Method of Statement For Fire AlarmDocument10 pagesMethod of Statement For Fire AlarmShah MuzzamilNo ratings yet

- Fire Alarm System Installation & TestingDocument11 pagesFire Alarm System Installation & TestingMahesh Kumar MNo ratings yet

- Method Statement For Testing and Commissioning of Fire Alarm SystemDocument9 pagesMethod Statement For Testing and Commissioning of Fire Alarm Systemfidgety100% (1)

- 00 - MS - Telephone or Data System InstallationDocument9 pages00 - MS - Telephone or Data System Installationsudeep karunNo ratings yet

- MS - Audio Visual System InstallationDocument9 pagesMS - Audio Visual System InstallationDuel TimeNo ratings yet

- LBS-RC-EO001-MS-MEP-ELE-0015 Method Statement For Testing and Commissioning of Emergency Lighting SystemDocument9 pagesLBS-RC-EO001-MS-MEP-ELE-0015 Method Statement For Testing and Commissioning of Emergency Lighting SystemfidgetyNo ratings yet

- FACP MethodologyDocument6 pagesFACP MethodologyNobita NobiNo ratings yet

- Method of Statement For Fire AlarmDocument9 pagesMethod of Statement For Fire AlarmUmair BaBerNo ratings yet

- Method Statement - Fire AlarmDocument9 pagesMethod Statement - Fire AlarmiamajumalNo ratings yet

- Method Statement For Installation of Light Fixtures and FittingsDocument6 pagesMethod Statement For Installation of Light Fixtures and Fittingsadeniyi abiolaNo ratings yet

- Method Statement For Installation of Electrical DBDocument6 pagesMethod Statement For Installation of Electrical DBsamsungloverNo ratings yet

- MS For Installation of FF Pipes FittingsDocument23 pagesMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- p103-Stts-gec-Asi-ms-ele-013 - Method Statement For Installation of Access Control SystemDocument5 pagesp103-Stts-gec-Asi-ms-ele-013 - Method Statement For Installation of Access Control SystemAnandu AshokanNo ratings yet

- Method Statement For Electrical ServicesDocument6 pagesMethod Statement For Electrical ServicesUmaira ZainalNo ratings yet

- HVAC Split Unit Installation Procedure - Method Statement HQDocument7 pagesHVAC Split Unit Installation Procedure - Method Statement HQEngineer ZiaNo ratings yet

- Method Statement For Firefighting Piping Equipment and Accessories InstallationDocument12 pagesMethod Statement For Firefighting Piping Equipment and Accessories InstallationMohamedNo ratings yet

- Painting Procedure For Firefighting Piping NetworkDocument6 pagesPainting Procedure For Firefighting Piping NetworkWahid HusainNo ratings yet

- Method of Statement (GPON& PABX)Document8 pagesMethod of Statement (GPON& PABX)Muhammad IqbalNo ratings yet

- Method Statement For Cable Conduit & Tray Installation PDFDocument5 pagesMethod Statement For Cable Conduit & Tray Installation PDFUtku Can Kılıç100% (2)

- Method of Statement For Bus Duct InstallationDocument11 pagesMethod of Statement For Bus Duct InstallationMohd MuksinNo ratings yet

- Fire Protection Pipes Method StatementDocument16 pagesFire Protection Pipes Method StatementAbdul Hakkim80% (5)

- Method of Statement For Testing & CommissioningDocument26 pagesMethod of Statement For Testing & CommissioningmirzamuddassirbaigNo ratings yet

- Precommissioning & Commissioning Method Statement For Fire Hose Racks & Fire Hose ReelDocument3 pagesPrecommissioning & Commissioning Method Statement For Fire Hose Racks & Fire Hose Reelvin ss0% (1)

- Method Statement For Installation of Cable TraysDocument6 pagesMethod Statement For Installation of Cable Traysjokanov100% (1)

- 00 - MS - Lighting Control Panels InstallationDocument9 pages00 - MS - Lighting Control Panels InstallationDuel TimeNo ratings yet

- Table of Contents: Method Statement FOR Cable Tray and Trunking System InstallationDocument8 pagesTable of Contents: Method Statement FOR Cable Tray and Trunking System InstallationHassen Lazhar100% (1)

- METHODOLOGY EE-Embedded Conduits (IMC) InstallationDocument5 pagesMETHODOLOGY EE-Embedded Conduits (IMC) Installationjerrick raulNo ratings yet

- Method Statement of Diesel Generator-Rev 00Document8 pagesMethod Statement of Diesel Generator-Rev 00midhun muraliNo ratings yet

- Method Statement - CCTVDocument7 pagesMethod Statement - CCTVamenmohd100% (1)

- Method Statement For Fire Safety Requirements For Under-Construction BuildingDocument20 pagesMethod Statement For Fire Safety Requirements For Under-Construction Buildingmohdrashid100% (1)

- Work Method Statement For Fire ProtectionDocument52 pagesWork Method Statement For Fire ProtectionSugumar Guna20% (5)

- DB, SMDB Method StatementDocument6 pagesDB, SMDB Method StatementNidhin MohanNo ratings yet

- Electrical & Wiring METHOD STATEMENTDocument4 pagesElectrical & Wiring METHOD STATEMENTAfiq JamalNo ratings yet

- Method Statement For Installation of MATV Distribution SystemDocument7 pagesMethod Statement For Installation of MATV Distribution SystemDong VanraNo ratings yet

- Method Statement For Cable Tray InstallationDocument6 pagesMethod Statement For Cable Tray Installationprashant100% (1)

- MS-M07 Installation of Duct InsulationDocument7 pagesMS-M07 Installation of Duct Insulationa wasayNo ratings yet

- Wire and Cable InstallationDocument9 pagesWire and Cable InstallationqaqcmepteamNo ratings yet

- Cable Entry FormatDocument2 pagesCable Entry Formata wasayNo ratings yet

- DB Enclosures SubmittalDocument90 pagesDB Enclosures Submittala wasayNo ratings yet

- MS-M07 Installation of Duct InsulationDocument7 pagesMS-M07 Installation of Duct Insulationa wasayNo ratings yet

- MS-M09 Installation of Water ChillerDocument8 pagesMS-M09 Installation of Water Chillera wasayNo ratings yet

- 18th Meeting of WHO VCAGDocument28 pages18th Meeting of WHO VCAGBAyonly DioufyNo ratings yet

- STROBE Checklist Cross-Sectional Gustian Satria Pratama 20231030052Document3 pagesSTROBE Checklist Cross-Sectional Gustian Satria Pratama 20231030052Gustian07No ratings yet

- UnknownDocument1 pageUnknowngordillodyanaNo ratings yet

- 2 (B) Food SafetyDocument4 pages2 (B) Food SafetyDanial IqhwanNo ratings yet

- Research MethodologyDocument22 pagesResearch MethodologyZhaineNo ratings yet

- Sensitivity and SpecificityDocument12 pagesSensitivity and Specificitymia farrowNo ratings yet

- Yashika RajDocument1 pageYashika RajNitin RajeevNo ratings yet

- Michigan Neuropathy Screening InstrumentDocument15 pagesMichigan Neuropathy Screening Instrumentjinsi georgeNo ratings yet

- Detection of Typhoid CarriersDocument6 pagesDetection of Typhoid CarriersClarestaNo ratings yet

- Research Methodology Sample For Social RDocument5 pagesResearch Methodology Sample For Social RWendimagen Meshesha FantaNo ratings yet

- Analyzing and Interpreting Data From Likert-Type Scales - SullivanDocument3 pagesAnalyzing and Interpreting Data From Likert-Type Scales - SullivanP. Pradnyaparamita (Anya)No ratings yet

- Toxics: Pattern of Paracetamol Poisoning: Influence On Outcome and ComplicationsDocument11 pagesToxics: Pattern of Paracetamol Poisoning: Influence On Outcome and Complicationsinfinity ooNo ratings yet

- Study Guide STH Edition: Clinical LaboratoryDocument30 pagesStudy Guide STH Edition: Clinical LaboratoryMendoza, Richelle A.No ratings yet

- Manual Advantage Mal CardDocument2 pagesManual Advantage Mal CardshanmicroNo ratings yet

- Teknik Pemeriksaan Molekuler TBCDocument28 pagesTeknik Pemeriksaan Molekuler TBCHani Hibatullah Konversi Semester 1 SKMNo ratings yet

- DHA Lab Guidlines 2019-717-720Document4 pagesDHA Lab Guidlines 2019-717-720abinradhNo ratings yet

- Kumbhakar 2017 SFA ReviewDocument103 pagesKumbhakar 2017 SFA ReviewzdenkaNo ratings yet

- Questionnaire Échelle Subjective Lysholm GilquistDocument5 pagesQuestionnaire Échelle Subjective Lysholm GilquistHoudhaifa KlaiNo ratings yet

- Mental Disorders in Self-CuttingDocument4 pagesMental Disorders in Self-CuttingWilson Javier Dominguez PerezNo ratings yet

- in Your Own Words What Is The Difference Between Hospital-Based Laboratory and Non-Hospital-Based Laboratory Based On The Tests They Perform?Document2 pagesin Your Own Words What Is The Difference Between Hospital-Based Laboratory and Non-Hospital-Based Laboratory Based On The Tests They Perform?Ellah MaeNo ratings yet

- Emirates Aluminium Smelter Complex QA PlanDocument32 pagesEmirates Aluminium Smelter Complex QA PlanSagar AliasjackeyNo ratings yet

- Hypothesis Testing Smith-SatterthwaiteDocument1 pageHypothesis Testing Smith-SatterthwaiteLixia D.No ratings yet

- Sure Vue ASO Pi PDFDocument4 pagesSure Vue ASO Pi PDFArifani CahyaniNo ratings yet

- Onsite APE 2022 GuidelinesDocument6 pagesOnsite APE 2022 GuidelinesAXIS CORPORATIONNo ratings yet

- D DimerDocument2 pagesD DimerRaji Creations - தமிழன்No ratings yet