Professional Documents

Culture Documents

Asme Sec Viii D1 Ma App 12

Asme Sec Viii D1 Ma App 12

Uploaded by

MarcoCopyright:

Available Formats

You might also like

- Asme V Article 4Document91 pagesAsme V Article 4Cherise D Curtis100% (4)

- ASME B31 3 Acceptance Criteria Tab 341-3-2ADocument2 pagesASME B31 3 Acceptance Criteria Tab 341-3-2Aadel100% (2)

- Profile RadiographyDocument7 pagesProfile Radiographydebduttamallik100% (1)

- Aws d1.1 Ut Inspection ProcedureDocument17 pagesAws d1.1 Ut Inspection ProcedureMohanadNo ratings yet

- ASME V Art 4 UT PDFDocument44 pagesASME V Art 4 UT PDFNavanitheeshwaran SivasubramaniyamNo ratings yet

- Astm A609Document9 pagesAstm A609Marcos Fernandes100% (1)

- Automated Ultrasonic Report Sample PHASE ARRAYDocument2 pagesAutomated Ultrasonic Report Sample PHASE ARRAYAzrul Hanif100% (2)

- Advanced Mathematical Methods With Maple: Derek RichardsDocument30 pagesAdvanced Mathematical Methods With Maple: Derek RichardsAurangZaib LaghariNo ratings yet

- ASME V Article 5 Ultrasonic Examination Methods For MaterialsDocument2 pagesASME V Article 5 Ultrasonic Examination Methods For MaterialsAmanda Ariesta Aprilia100% (1)

- Asme Sec V Article 9 Visual ExaminationDocument11 pagesAsme Sec V Article 9 Visual ExaminationRamesh R100% (1)

- Acceptable Criteria API RP 2X Level C Acceptable Criteria API RP 2X Level CDocument1 pageAcceptable Criteria API RP 2X Level C Acceptable Criteria API RP 2X Level CRamakrishnan AmbiSubbiah100% (5)

- ASME B 31.1 Acceptance Criteria PDFDocument13 pagesASME B 31.1 Acceptance Criteria PDFasim alok swain100% (3)

- ASME SECTION V, Article 8 Mandatory Appendices PDFDocument24 pagesASME SECTION V, Article 8 Mandatory Appendices PDFguaropelaoNo ratings yet

- Standard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodDocument7 pagesStandard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodRenzo BellotaNo ratings yet

- AWS Associate Solutions Architect Study - ACloud - GuruDocument70 pagesAWS Associate Solutions Architect Study - ACloud - Guruzinedine boubakerNo ratings yet

- ASME SB-444 (2013) - В-444-06 (R11) - eng.Document4 pagesASME SB-444 (2013) - В-444-06 (R11) - eng.TetianaNo ratings yet

- Mandatory Appendix 6 MTDocument2 pagesMandatory Appendix 6 MTTahar DabbarNo ratings yet

- ASME Sec V - 2019 - Article 5Document9 pagesASME Sec V - 2019 - Article 5Mohsin IamNo ratings yet

- 7.5.5.2asme Sec Viii Div 2 2017Document3 pages7.5.5.2asme Sec Viii Div 2 2017James100% (2)

- Asme Acc Criteria MT PTDocument3 pagesAsme Acc Criteria MT PTGowrisanthosh Palika100% (1)

- Asme Section II A Sa-435 Sa-435mDocument4 pagesAsme Section II A Sa-435 Sa-435mAnonymous GhPzn1xNo ratings yet

- E213-Ultrasonic Examination of Metal Pipe and TubingDocument5 pagesE213-Ultrasonic Examination of Metal Pipe and Tubingsolrac4371No ratings yet

- Asme Viii d1 Ma Appendix 4Document8 pagesAsme Viii d1 Ma Appendix 4Chihiya Fitria Nurhayati100% (1)

- E1254-98 Film StorageDocument3 pagesE1254-98 Film Storageaakash100% (3)

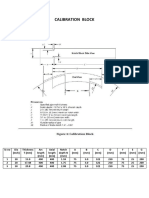

- Calibration Block As Per API 1104Document2 pagesCalibration Block As Per API 1104Chandrashekhar Thiramdasu100% (1)

- Astm e 797 2015 PDFDocument7 pagesAstm e 797 2015 PDFTauseef Patel100% (1)

- 11 Ut ProcedureDocument11 pages11 Ut ProcedureSajeesh KrishnanNo ratings yet

- SA 578 Vs EN 10160Document1 pageSA 578 Vs EN 10160Santanu Saha60% (5)

- Forensic Entomology in Criminal Investigations - Catts & Goff, 1992Document22 pagesForensic Entomology in Criminal Investigations - Catts & Goff, 1992_Myhr_No ratings yet

- Fitment - Ugc 6th Pay CommissionDocument10 pagesFitment - Ugc 6th Pay CommissionJoseph Anbarasu100% (3)

- Prayer Service For The DeadDocument16 pagesPrayer Service For The DeadRodel Ramos DaquioagNo ratings yet

- Asme Sec Viii d1 Ma App 12Document1 pageAsme Sec Viii d1 Ma App 12Gwynnbleid100% (2)

- Difference Between ASTM A435 and ASTM A578Document1 pageDifference Between ASTM A435 and ASTM A578Vijay BedakihaleNo ratings yet

- RT Acceptance Criteria: Asme Sec Viii Div-1 API-650 Ansi/ Asme B 31.3 ASME B 31.1 Asme Sec Ix CodesDocument1 pageRT Acceptance Criteria: Asme Sec Viii Div-1 API-650 Ansi/ Asme B 31.3 ASME B 31.1 Asme Sec Ix CodesEr Md AamirNo ratings yet

- Art 23 AsmeDocument10 pagesArt 23 AsmeKirvi16No ratings yet

- Section II A SA-435 - SA-435MDocument3 pagesSection II A SA-435 - SA-435MSocrates MoralesNo ratings yet

- Uw-51 RT Acceptance CriteriaDocument12 pagesUw-51 RT Acceptance CriteriaSameer RajuNo ratings yet

- AMS2632Document24 pagesAMS2632engineNo ratings yet

- v1 Block Calibration in UtDocument1 pagev1 Block Calibration in Utjaimin100100% (4)

- API 1104 - UT Acceptance StandardsDocument5 pagesAPI 1104 - UT Acceptance StandardsABDIELNo ratings yet

- Acceptance Criteria For NDT (UT, RT, DPT, Visual, MPT)Document5 pagesAcceptance Criteria For NDT (UT, RT, DPT, Visual, MPT)Naveen Kumar75% (4)

- ASMe Sec2 PartcDocument53 pagesASMe Sec2 PartcSARSAN NDTNo ratings yet

- ASME IX QW (Welding General Requirements)Document12 pagesASME IX QW (Welding General Requirements)Ariq Fauzan100% (1)

- ASTM E213-02 UT-Pipes & Tubing PDFDocument11 pagesASTM E213-02 UT-Pipes & Tubing PDFZeeshan HasanNo ratings yet

- Ultrasonic Testing Interview QuesionsDocument2 pagesUltrasonic Testing Interview Quesionsmohammed imran sharief100% (5)

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (2)

- Se 273Document4 pagesSe 273solrac4371No ratings yet

- Asme Sec I PWHT RequirementDocument6 pagesAsme Sec I PWHT RequirementSajin ChandranNo ratings yet

- Astm E3024-2019Document19 pagesAstm E3024-2019RICARDO REY100% (2)

- Planer Vs Non Planer DefectsDocument2 pagesPlaner Vs Non Planer DefectsSavad Alwye75% (8)

- B Sa-435Document2 pagesB Sa-435Antonio GutierrezNo ratings yet

- E 2033 - 99 (2013)Document11 pagesE 2033 - 99 (2013)Enrique Antonio100% (2)

- ASTM E746-07 (2014) Standard Practice For Determining Relative Image Quality Response of Industrial Radiographic Imaging SystemsDocument7 pagesASTM E746-07 (2014) Standard Practice For Determining Relative Image Quality Response of Industrial Radiographic Imaging SystemsnationalfoxNo ratings yet

- Astm Se-273Document5 pagesAstm Se-273Deyci Yamile Peña SantosNo ratings yet

- Acceptance Criteria-Asme Section 5Document18 pagesAcceptance Criteria-Asme Section 5HAKAN67% (3)

- Ut Format AwsDocument2 pagesUt Format Awsmanjeev111No ratings yet

- DPT Acceptance Code ReferenceDocument5 pagesDPT Acceptance Code ReferenceMidhun K Chandrabose100% (2)

- Pentathane 4510 - F2 EIL PDFDocument3 pagesPentathane 4510 - F2 EIL PDFsantosh0% (1)

- Mandatory Appendix 12 Ultrasonic Examination of Welds (Ut) : 12-1 SCOPEDocument1 pageMandatory Appendix 12 Ultrasonic Examination of Welds (Ut) : 12-1 SCOPESefa yıldızNo ratings yet

- Asme Viii - Mandatoryappendix 12 - UtDocument1 pageAsme Viii - Mandatoryappendix 12 - UtDjamelNo ratings yet

- ASME SECTION VIII Ultrasonido CriteriosDocument1 pageASME SECTION VIII Ultrasonido CriteriosLorena Jimenez100% (1)

- Páginas Desde ASME VIII - DIV.1Document2 pagesPáginas Desde ASME VIII - DIV.1daniel_break_1No ratings yet

- RESSUAGEDocument2 pagesRESSUAGELNCI MEHDI EL MIRNo ratings yet

- ASME Sec VIII d1 Ma App 8Document2 pagesASME Sec VIII d1 Ma App 8fuihiufhNo ratings yet

- Section V - Asme 2015 Article 1Document26 pagesSection V - Asme 2015 Article 1HassanSoboh50% (4)

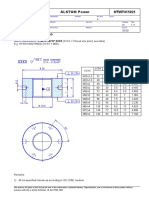

- ALSTOM Power NB00129: 1 GeneralDocument1 pageALSTOM Power NB00129: 1 GeneralMarcoNo ratings yet

- P8AHEM4800Document14 pagesP8AHEM4800MarcoNo ratings yet

- HGGD442030 A en 001Document1 pageHGGD442030 A en 001MarcoNo ratings yet

- HGGD223001 A en 001Document1 pageHGGD223001 A en 001MarcoNo ratings yet

- H 623500meu71 Sa00pb 01 - CDocument9 pagesH 623500meu71 Sa00pb 01 - CMarcoNo ratings yet

- H1006400MKF51 Sa12qt 01Document4 pagesH1006400MKF51 Sa12qt 01MarcoNo ratings yet

- HS Cal01 000000000ecDocument4 pagesHS Cal01 000000000ecMarcoNo ratings yet

- HTWT415073 DDocument3 pagesHTWT415073 DMarcoNo ratings yet

- HTWT417350 BDocument2 pagesHTWT417350 BMarcoNo ratings yet

- HTWT415259 - en 01Document1 pageHTWT415259 - en 01MarcoNo ratings yet

- HTWT415575 A en 01Document1 pageHTWT415575 A en 01MarcoNo ratings yet

- HTWT415021P0036Document1 pageHTWT415021P0036MarcoNo ratings yet

- HS FWR01 000000staec - CDocument4 pagesHS FWR01 000000staec - CMarcoNo ratings yet

- H1006300MKD11 Sa00qw 02Document8 pagesH1006300MKD11 Sa00qw 02MarcoNo ratings yet

- HTWT415021 - enDocument1 pageHTWT415021 - enMarcoNo ratings yet

- HS FSW01 00000088aec - CDocument5 pagesHS FSW01 00000088aec - CMarcoNo ratings yet

- HTWT410375 QDocument4 pagesHTWT410375 QMarcoNo ratings yet

- HS FPN02 000000stlec - BDocument5 pagesHS FPN02 000000stlec - BMarcoNo ratings yet

- H1006300MKD11 Sa00qw 03Document3 pagesH1006300MKD11 Sa00qw 03MarcoNo ratings yet

- H1006300mkd11-Sa00 004 - BomDocument1 pageH1006300mkd11-Sa00 004 - BomMarcoNo ratings yet

- H1006300MKD11 Sa00qw 01 - ADocument3 pagesH1006300MKD11 Sa00qw 01 - AMarcoNo ratings yet

- B50HES1111-08Document2 pagesB50HES1111-08MarcoNo ratings yet

- 01 QWP Template - Step by Step TransferDocument9 pages01 QWP Template - Step by Step TransferMarcoNo ratings yet

- E38102247g01 - Corps Joint Huile CT - Itp - enDocument3 pagesE38102247g01 - Corps Joint Huile CT - Itp - enMarcoNo ratings yet

- Nervatura 5mm: 1:4 CH-6805 MezzovicoDocument1 pageNervatura 5mm: 1:4 CH-6805 MezzovicoMarcoNo ratings yet

- 153GC013Document1 page153GC013MarcoNo ratings yet

- C - 2885 2 10Document1 pageC - 2885 2 10MarcoNo ratings yet

- E38102247g01 - Corps Joint Huile CT - KSL STR - 85Document2 pagesE38102247g01 - Corps Joint Huile CT - KSL STR - 85MarcoNo ratings yet

- STDGF005Document1 pageSTDGF005MarcoNo ratings yet

- +english Test Prac Poison Tree-AnswersDocument5 pages+english Test Prac Poison Tree-AnswersLouise Francis100% (1)

- (EE-335) - Electric Power Generation, Transmission, and Distribution-Fall2021Document8 pages(EE-335) - Electric Power Generation, Transmission, and Distribution-Fall2021Abeer SohailNo ratings yet

- A REVIEW OF SOIL ERODIBILITY Case Study of UGBOJU Settlement of OTURKPO Local Government Area of Benue State NigeriaDocument9 pagesA REVIEW OF SOIL ERODIBILITY Case Study of UGBOJU Settlement of OTURKPO Local Government Area of Benue State NigeriaTIZA MICHAEL B.Engr., BBS, MBA, Aff. M. ASCE, ASS.M. UACSE, M. IAENG. M.ITE.No ratings yet

- Evaluation Rating Sheet For Charts Poster Drill Flash Card and ManipulativesDocument3 pagesEvaluation Rating Sheet For Charts Poster Drill Flash Card and ManipulativesMaricris Bagnes SaludNo ratings yet

- Appendix G Elastic and Inelastic Response SpectraDocument11 pagesAppendix G Elastic and Inelastic Response SpectracedaserdnaNo ratings yet

- ITL - Project Report TemplateDocument5 pagesITL - Project Report Templatemossaengginoli0% (1)

- Ngo Assignment Meryem Barhdadi MSC IbDocument9 pagesNgo Assignment Meryem Barhdadi MSC IbMeryem BarhdadiNo ratings yet

- Conclusion ParagraphDocument7 pagesConclusion Paragraphapi-334926654No ratings yet

- Promote Solutions On SAP App CenterDocument18 pagesPromote Solutions On SAP App CenterdamljanovicNo ratings yet

- 03 - Information PackagesDocument13 pages03 - Information Packagesyusi cantikNo ratings yet

- Current Status, Research Trends, and ChallengesDocument23 pagesCurrent Status, Research Trends, and Challengesqgi-tanyaNo ratings yet

- English Chapter 5Document20 pagesEnglish Chapter 5Kumar sankar SNo ratings yet

- MNS University of Agriculture Multan: Project Assigned ToDocument13 pagesMNS University of Agriculture Multan: Project Assigned ToRana DilawarNo ratings yet

- Grade /: NO. 209 ofDocument3 pagesGrade /: NO. 209 ofrahad60882No ratings yet

- 2PGW Lessons Learned 01Document135 pages2PGW Lessons Learned 01Jonathan WeygandtNo ratings yet

- Pensamento Do Design Urbano Contemporâneo - Roggema RobDocument340 pagesPensamento Do Design Urbano Contemporâneo - Roggema RobLuana LuNo ratings yet

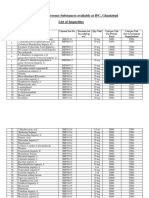

- List of IP Reference Substances Available at IPC, Ghaziabad List of ImpuritiesDocument4 pagesList of IP Reference Substances Available at IPC, Ghaziabad List of ImpuritiesUrva VasavadaNo ratings yet

- MobilityDocument46 pagesMobilityDipen SoniNo ratings yet

- Planes of SymmetryDocument38 pagesPlanes of SymmetryRuchika Chandna83% (6)

- Pointers, Virtual Functions and PolymorphismDocument9 pagesPointers, Virtual Functions and PolymorphismSANJAY MAKWANANo ratings yet

- Youth Mental Health First Aid One PagerDocument1 pageYouth Mental Health First Aid One Pagerapi-298889118No ratings yet

- Worksheet (2023-24) Grade: 10 Subject: Information TechnologyDocument49 pagesWorksheet (2023-24) Grade: 10 Subject: Information TechnologyINFWHATNo ratings yet

- FOI 20210117 1 Data SetDocument82 pagesFOI 20210117 1 Data Setabrar mahir SahilNo ratings yet

- Engineering Physics Lecture Notes Module 1Document36 pagesEngineering Physics Lecture Notes Module 1Damodhar reddy GarlapatiNo ratings yet

- Short Story ElementsDocument8 pagesShort Story Elementsaaliakhan05No ratings yet

Asme Sec Viii D1 Ma App 12

Asme Sec Viii D1 Ma App 12

Uploaded by

MarcoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme Sec Viii D1 Ma App 12

Asme Sec Viii D1 Ma App 12

Uploaded by

MarcoCopyright:

Available Formats

MANDATORY APPENDIX 12

ULTRASONIC EXAMINATION OF WELDS (UT)

12-1 SCOPE Imperfections which produce a response greater than

20% of the reference level shall be investigated to the

(a) This Appendix describes methods which shall be

extent that the operator can determine the shape, identity,

employed when ultrasonic examination of welds is speci-

and location of all such imperfections and evaluate them

fied in this Division.

in terms of the acceptance standards given in (a) and (b)

(b) Article 4 of Section V shall be applied for detail

below.

requirements in methods, procedures and qualifications,

unless otherwise specified in this Appendix. (a) Indications characterized as cracks, lack of fusion,

(c) Ultrasonic examination shall be performed in or incomplete penetration are unacceptable regardless of

accordance with a written procedure, certified by the length.

Manufacturer to be in accordance with the requirements (b) Other imperfections are unacceptable if the indica-

of T-150 of Section V. tions exceed the reference level amplitude and have

lengths which exceed:

(1) 1⁄4 in. (6 mm) for t up to 3⁄4 in. (19 mm);

12-2 CERTIFICATION OF COMPETENCE

(2) 1⁄3t for t from 3⁄4 in. to 21⁄4 in. (19 mm to 57 mm);

OF NONDESTRUCTIVE EXAMINER

(3) 3⁄4 in. (19 mm) for t over 21⁄4 in. (57 mm).

The Manufacturer shall certify that personnel per-

forming and evaluating ultrasonic examinations required

by this Division have been qualified and certified in accor- where t is the thickness of the weld excluding any allow-

dance with their employer’s written practice. SNT-TC- able reinforcement. For a butt weld joining two members

1A1 shall be used as a guideline for employers to establish having different thicknesses at the weld, t is the thinner of

their written practice for qualification and certification of these two thicknesses. If a full penetration weld includes a

their personnel. Alternatively, the ASNT Central Certifi- fillet weld, the thickness of the throat of the fillet shall

cation Program (ACCP)1 or CP-1891 may be used to be included in t.

fulfill the examination and demonstration requirements

of SNT-TC-1A and the employer’s written practice. Pro-

visions for training, experience, qualification, and certifi-

cation of NDE personnel shall be described in the 12-4 REPORT OF EXAMINATION

Manufacturer’s Quality Control System (see Appendix

10). The Manufacturer shall prepare a report of the ultra-

sonic examination and a copy of this report shall be

retained by the Manufacturer until the Manufacturer’s

12-3 ACCEPTANCE–REJECTION Data Report has been signed by the Inspector. The report

STANDARDS shall contain the information required by Section V. In

These Standards shall apply unless other standards are addition, a record of repaired areas shall be noted as well

specified for specific applications within this Division. as the results of the reexamination of the repaired areas.

The Manufacturer shall also maintain a record of all

--``,``,`,```,,,```,`,,,`,`,`-`-`,,`,,`,`,,`---

1

Recommended Practice No. SNT-TC-1A, “Personnel Qualification reflections from uncorrected areas having responses that

and Certification in Nondestructive Testing,” ACCP, ASNT Central exceed 50% of the reference level. This record shall locate

Certification Program, and CP-189 are published by the American Soci-

ety for Nondestructive Testing, Inc., 4153 Arlingate Plaza, Caller each area, the response level, the dimensions, the depth

#28518, Columbus, Ohio 43228-0518. below the surface, and the classification.

403

Copyright ASME International Document provided by IHS Licensee=Bureau Veritas/5959906001, 11/05/2004

Provided by IHS under license with ASME 04:21:40 MST Questions or comments about this message: please call the Document

Policy Group at 303-397-2295.

You might also like

- Asme V Article 4Document91 pagesAsme V Article 4Cherise D Curtis100% (4)

- ASME B31 3 Acceptance Criteria Tab 341-3-2ADocument2 pagesASME B31 3 Acceptance Criteria Tab 341-3-2Aadel100% (2)

- Profile RadiographyDocument7 pagesProfile Radiographydebduttamallik100% (1)

- Aws d1.1 Ut Inspection ProcedureDocument17 pagesAws d1.1 Ut Inspection ProcedureMohanadNo ratings yet

- ASME V Art 4 UT PDFDocument44 pagesASME V Art 4 UT PDFNavanitheeshwaran SivasubramaniyamNo ratings yet

- Astm A609Document9 pagesAstm A609Marcos Fernandes100% (1)

- Automated Ultrasonic Report Sample PHASE ARRAYDocument2 pagesAutomated Ultrasonic Report Sample PHASE ARRAYAzrul Hanif100% (2)

- Advanced Mathematical Methods With Maple: Derek RichardsDocument30 pagesAdvanced Mathematical Methods With Maple: Derek RichardsAurangZaib LaghariNo ratings yet

- ASME V Article 5 Ultrasonic Examination Methods For MaterialsDocument2 pagesASME V Article 5 Ultrasonic Examination Methods For MaterialsAmanda Ariesta Aprilia100% (1)

- Asme Sec V Article 9 Visual ExaminationDocument11 pagesAsme Sec V Article 9 Visual ExaminationRamesh R100% (1)

- Acceptable Criteria API RP 2X Level C Acceptable Criteria API RP 2X Level CDocument1 pageAcceptable Criteria API RP 2X Level C Acceptable Criteria API RP 2X Level CRamakrishnan AmbiSubbiah100% (5)

- ASME B 31.1 Acceptance Criteria PDFDocument13 pagesASME B 31.1 Acceptance Criteria PDFasim alok swain100% (3)

- ASME SECTION V, Article 8 Mandatory Appendices PDFDocument24 pagesASME SECTION V, Article 8 Mandatory Appendices PDFguaropelaoNo ratings yet

- Standard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodDocument7 pagesStandard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodRenzo BellotaNo ratings yet

- AWS Associate Solutions Architect Study - ACloud - GuruDocument70 pagesAWS Associate Solutions Architect Study - ACloud - Guruzinedine boubakerNo ratings yet

- ASME SB-444 (2013) - В-444-06 (R11) - eng.Document4 pagesASME SB-444 (2013) - В-444-06 (R11) - eng.TetianaNo ratings yet

- Mandatory Appendix 6 MTDocument2 pagesMandatory Appendix 6 MTTahar DabbarNo ratings yet

- ASME Sec V - 2019 - Article 5Document9 pagesASME Sec V - 2019 - Article 5Mohsin IamNo ratings yet

- 7.5.5.2asme Sec Viii Div 2 2017Document3 pages7.5.5.2asme Sec Viii Div 2 2017James100% (2)

- Asme Acc Criteria MT PTDocument3 pagesAsme Acc Criteria MT PTGowrisanthosh Palika100% (1)

- Asme Section II A Sa-435 Sa-435mDocument4 pagesAsme Section II A Sa-435 Sa-435mAnonymous GhPzn1xNo ratings yet

- E213-Ultrasonic Examination of Metal Pipe and TubingDocument5 pagesE213-Ultrasonic Examination of Metal Pipe and Tubingsolrac4371No ratings yet

- Asme Viii d1 Ma Appendix 4Document8 pagesAsme Viii d1 Ma Appendix 4Chihiya Fitria Nurhayati100% (1)

- E1254-98 Film StorageDocument3 pagesE1254-98 Film Storageaakash100% (3)

- Calibration Block As Per API 1104Document2 pagesCalibration Block As Per API 1104Chandrashekhar Thiramdasu100% (1)

- Astm e 797 2015 PDFDocument7 pagesAstm e 797 2015 PDFTauseef Patel100% (1)

- 11 Ut ProcedureDocument11 pages11 Ut ProcedureSajeesh KrishnanNo ratings yet

- SA 578 Vs EN 10160Document1 pageSA 578 Vs EN 10160Santanu Saha60% (5)

- Forensic Entomology in Criminal Investigations - Catts & Goff, 1992Document22 pagesForensic Entomology in Criminal Investigations - Catts & Goff, 1992_Myhr_No ratings yet

- Fitment - Ugc 6th Pay CommissionDocument10 pagesFitment - Ugc 6th Pay CommissionJoseph Anbarasu100% (3)

- Prayer Service For The DeadDocument16 pagesPrayer Service For The DeadRodel Ramos DaquioagNo ratings yet

- Asme Sec Viii d1 Ma App 12Document1 pageAsme Sec Viii d1 Ma App 12Gwynnbleid100% (2)

- Difference Between ASTM A435 and ASTM A578Document1 pageDifference Between ASTM A435 and ASTM A578Vijay BedakihaleNo ratings yet

- RT Acceptance Criteria: Asme Sec Viii Div-1 API-650 Ansi/ Asme B 31.3 ASME B 31.1 Asme Sec Ix CodesDocument1 pageRT Acceptance Criteria: Asme Sec Viii Div-1 API-650 Ansi/ Asme B 31.3 ASME B 31.1 Asme Sec Ix CodesEr Md AamirNo ratings yet

- Art 23 AsmeDocument10 pagesArt 23 AsmeKirvi16No ratings yet

- Section II A SA-435 - SA-435MDocument3 pagesSection II A SA-435 - SA-435MSocrates MoralesNo ratings yet

- Uw-51 RT Acceptance CriteriaDocument12 pagesUw-51 RT Acceptance CriteriaSameer RajuNo ratings yet

- AMS2632Document24 pagesAMS2632engineNo ratings yet

- v1 Block Calibration in UtDocument1 pagev1 Block Calibration in Utjaimin100100% (4)

- API 1104 - UT Acceptance StandardsDocument5 pagesAPI 1104 - UT Acceptance StandardsABDIELNo ratings yet

- Acceptance Criteria For NDT (UT, RT, DPT, Visual, MPT)Document5 pagesAcceptance Criteria For NDT (UT, RT, DPT, Visual, MPT)Naveen Kumar75% (4)

- ASMe Sec2 PartcDocument53 pagesASMe Sec2 PartcSARSAN NDTNo ratings yet

- ASME IX QW (Welding General Requirements)Document12 pagesASME IX QW (Welding General Requirements)Ariq Fauzan100% (1)

- ASTM E213-02 UT-Pipes & Tubing PDFDocument11 pagesASTM E213-02 UT-Pipes & Tubing PDFZeeshan HasanNo ratings yet

- Ultrasonic Testing Interview QuesionsDocument2 pagesUltrasonic Testing Interview Quesionsmohammed imran sharief100% (5)

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (2)

- Se 273Document4 pagesSe 273solrac4371No ratings yet

- Asme Sec I PWHT RequirementDocument6 pagesAsme Sec I PWHT RequirementSajin ChandranNo ratings yet

- Astm E3024-2019Document19 pagesAstm E3024-2019RICARDO REY100% (2)

- Planer Vs Non Planer DefectsDocument2 pagesPlaner Vs Non Planer DefectsSavad Alwye75% (8)

- B Sa-435Document2 pagesB Sa-435Antonio GutierrezNo ratings yet

- E 2033 - 99 (2013)Document11 pagesE 2033 - 99 (2013)Enrique Antonio100% (2)

- ASTM E746-07 (2014) Standard Practice For Determining Relative Image Quality Response of Industrial Radiographic Imaging SystemsDocument7 pagesASTM E746-07 (2014) Standard Practice For Determining Relative Image Quality Response of Industrial Radiographic Imaging SystemsnationalfoxNo ratings yet

- Astm Se-273Document5 pagesAstm Se-273Deyci Yamile Peña SantosNo ratings yet

- Acceptance Criteria-Asme Section 5Document18 pagesAcceptance Criteria-Asme Section 5HAKAN67% (3)

- Ut Format AwsDocument2 pagesUt Format Awsmanjeev111No ratings yet

- DPT Acceptance Code ReferenceDocument5 pagesDPT Acceptance Code ReferenceMidhun K Chandrabose100% (2)

- Pentathane 4510 - F2 EIL PDFDocument3 pagesPentathane 4510 - F2 EIL PDFsantosh0% (1)

- Mandatory Appendix 12 Ultrasonic Examination of Welds (Ut) : 12-1 SCOPEDocument1 pageMandatory Appendix 12 Ultrasonic Examination of Welds (Ut) : 12-1 SCOPESefa yıldızNo ratings yet

- Asme Viii - Mandatoryappendix 12 - UtDocument1 pageAsme Viii - Mandatoryappendix 12 - UtDjamelNo ratings yet

- ASME SECTION VIII Ultrasonido CriteriosDocument1 pageASME SECTION VIII Ultrasonido CriteriosLorena Jimenez100% (1)

- Páginas Desde ASME VIII - DIV.1Document2 pagesPáginas Desde ASME VIII - DIV.1daniel_break_1No ratings yet

- RESSUAGEDocument2 pagesRESSUAGELNCI MEHDI EL MIRNo ratings yet

- ASME Sec VIII d1 Ma App 8Document2 pagesASME Sec VIII d1 Ma App 8fuihiufhNo ratings yet

- Section V - Asme 2015 Article 1Document26 pagesSection V - Asme 2015 Article 1HassanSoboh50% (4)

- ALSTOM Power NB00129: 1 GeneralDocument1 pageALSTOM Power NB00129: 1 GeneralMarcoNo ratings yet

- P8AHEM4800Document14 pagesP8AHEM4800MarcoNo ratings yet

- HGGD442030 A en 001Document1 pageHGGD442030 A en 001MarcoNo ratings yet

- HGGD223001 A en 001Document1 pageHGGD223001 A en 001MarcoNo ratings yet

- H 623500meu71 Sa00pb 01 - CDocument9 pagesH 623500meu71 Sa00pb 01 - CMarcoNo ratings yet

- H1006400MKF51 Sa12qt 01Document4 pagesH1006400MKF51 Sa12qt 01MarcoNo ratings yet

- HS Cal01 000000000ecDocument4 pagesHS Cal01 000000000ecMarcoNo ratings yet

- HTWT415073 DDocument3 pagesHTWT415073 DMarcoNo ratings yet

- HTWT417350 BDocument2 pagesHTWT417350 BMarcoNo ratings yet

- HTWT415259 - en 01Document1 pageHTWT415259 - en 01MarcoNo ratings yet

- HTWT415575 A en 01Document1 pageHTWT415575 A en 01MarcoNo ratings yet

- HTWT415021P0036Document1 pageHTWT415021P0036MarcoNo ratings yet

- HS FWR01 000000staec - CDocument4 pagesHS FWR01 000000staec - CMarcoNo ratings yet

- H1006300MKD11 Sa00qw 02Document8 pagesH1006300MKD11 Sa00qw 02MarcoNo ratings yet

- HTWT415021 - enDocument1 pageHTWT415021 - enMarcoNo ratings yet

- HS FSW01 00000088aec - CDocument5 pagesHS FSW01 00000088aec - CMarcoNo ratings yet

- HTWT410375 QDocument4 pagesHTWT410375 QMarcoNo ratings yet

- HS FPN02 000000stlec - BDocument5 pagesHS FPN02 000000stlec - BMarcoNo ratings yet

- H1006300MKD11 Sa00qw 03Document3 pagesH1006300MKD11 Sa00qw 03MarcoNo ratings yet

- H1006300mkd11-Sa00 004 - BomDocument1 pageH1006300mkd11-Sa00 004 - BomMarcoNo ratings yet

- H1006300MKD11 Sa00qw 01 - ADocument3 pagesH1006300MKD11 Sa00qw 01 - AMarcoNo ratings yet

- B50HES1111-08Document2 pagesB50HES1111-08MarcoNo ratings yet

- 01 QWP Template - Step by Step TransferDocument9 pages01 QWP Template - Step by Step TransferMarcoNo ratings yet

- E38102247g01 - Corps Joint Huile CT - Itp - enDocument3 pagesE38102247g01 - Corps Joint Huile CT - Itp - enMarcoNo ratings yet

- Nervatura 5mm: 1:4 CH-6805 MezzovicoDocument1 pageNervatura 5mm: 1:4 CH-6805 MezzovicoMarcoNo ratings yet

- 153GC013Document1 page153GC013MarcoNo ratings yet

- C - 2885 2 10Document1 pageC - 2885 2 10MarcoNo ratings yet

- E38102247g01 - Corps Joint Huile CT - KSL STR - 85Document2 pagesE38102247g01 - Corps Joint Huile CT - KSL STR - 85MarcoNo ratings yet

- STDGF005Document1 pageSTDGF005MarcoNo ratings yet

- +english Test Prac Poison Tree-AnswersDocument5 pages+english Test Prac Poison Tree-AnswersLouise Francis100% (1)

- (EE-335) - Electric Power Generation, Transmission, and Distribution-Fall2021Document8 pages(EE-335) - Electric Power Generation, Transmission, and Distribution-Fall2021Abeer SohailNo ratings yet

- A REVIEW OF SOIL ERODIBILITY Case Study of UGBOJU Settlement of OTURKPO Local Government Area of Benue State NigeriaDocument9 pagesA REVIEW OF SOIL ERODIBILITY Case Study of UGBOJU Settlement of OTURKPO Local Government Area of Benue State NigeriaTIZA MICHAEL B.Engr., BBS, MBA, Aff. M. ASCE, ASS.M. UACSE, M. IAENG. M.ITE.No ratings yet

- Evaluation Rating Sheet For Charts Poster Drill Flash Card and ManipulativesDocument3 pagesEvaluation Rating Sheet For Charts Poster Drill Flash Card and ManipulativesMaricris Bagnes SaludNo ratings yet

- Appendix G Elastic and Inelastic Response SpectraDocument11 pagesAppendix G Elastic and Inelastic Response SpectracedaserdnaNo ratings yet

- ITL - Project Report TemplateDocument5 pagesITL - Project Report Templatemossaengginoli0% (1)

- Ngo Assignment Meryem Barhdadi MSC IbDocument9 pagesNgo Assignment Meryem Barhdadi MSC IbMeryem BarhdadiNo ratings yet

- Conclusion ParagraphDocument7 pagesConclusion Paragraphapi-334926654No ratings yet

- Promote Solutions On SAP App CenterDocument18 pagesPromote Solutions On SAP App CenterdamljanovicNo ratings yet

- 03 - Information PackagesDocument13 pages03 - Information Packagesyusi cantikNo ratings yet

- Current Status, Research Trends, and ChallengesDocument23 pagesCurrent Status, Research Trends, and Challengesqgi-tanyaNo ratings yet

- English Chapter 5Document20 pagesEnglish Chapter 5Kumar sankar SNo ratings yet

- MNS University of Agriculture Multan: Project Assigned ToDocument13 pagesMNS University of Agriculture Multan: Project Assigned ToRana DilawarNo ratings yet

- Grade /: NO. 209 ofDocument3 pagesGrade /: NO. 209 ofrahad60882No ratings yet

- 2PGW Lessons Learned 01Document135 pages2PGW Lessons Learned 01Jonathan WeygandtNo ratings yet

- Pensamento Do Design Urbano Contemporâneo - Roggema RobDocument340 pagesPensamento Do Design Urbano Contemporâneo - Roggema RobLuana LuNo ratings yet

- List of IP Reference Substances Available at IPC, Ghaziabad List of ImpuritiesDocument4 pagesList of IP Reference Substances Available at IPC, Ghaziabad List of ImpuritiesUrva VasavadaNo ratings yet

- MobilityDocument46 pagesMobilityDipen SoniNo ratings yet

- Planes of SymmetryDocument38 pagesPlanes of SymmetryRuchika Chandna83% (6)

- Pointers, Virtual Functions and PolymorphismDocument9 pagesPointers, Virtual Functions and PolymorphismSANJAY MAKWANANo ratings yet

- Youth Mental Health First Aid One PagerDocument1 pageYouth Mental Health First Aid One Pagerapi-298889118No ratings yet

- Worksheet (2023-24) Grade: 10 Subject: Information TechnologyDocument49 pagesWorksheet (2023-24) Grade: 10 Subject: Information TechnologyINFWHATNo ratings yet

- FOI 20210117 1 Data SetDocument82 pagesFOI 20210117 1 Data Setabrar mahir SahilNo ratings yet

- Engineering Physics Lecture Notes Module 1Document36 pagesEngineering Physics Lecture Notes Module 1Damodhar reddy GarlapatiNo ratings yet

- Short Story ElementsDocument8 pagesShort Story Elementsaaliakhan05No ratings yet