Professional Documents

Culture Documents

A Revolution in Pumping Efficiency Part 3

A Revolution in Pumping Efficiency Part 3

Uploaded by

Tasawwur TahirOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Revolution in Pumping Efficiency Part 3

A Revolution in Pumping Efficiency Part 3

Uploaded by

Tasawwur TahirCopyright:

Available Formats

PUMP solutions

A Revolution in Pumping Efficiency

All-Flo’s A200 pump reduces energy costs, improves performance

PART 3 IN A 4-PART SERIES

By Paul McGarry, All-Flo Pump Co.

A

ll air-operated double diaphragm pumps (AODDPs) the right pump for your application will become abundantly

are not created equal. In fact, significant differences clear.

in performance, efficiency, and total cost of ownership

exist from one manufacturer’s pump to another. Sometimes A QUICK RECAP

these differences are so pronounced that they can add up to Before we move on, let’s take a moment to look back at

losses of hundreds of thousands of dollars every year. how we got here. The first two articles in this series covered

If AODDPs were truly the interchangeable commodity how AODDPs work, how to read performance curves, and

products as some believe, would this be the case? The how to calculate pump operating costs. We also delved into

answer is an emphatic no. There is still room for innovation how All-Flo’s new A200 model drastically improved upon

and improvement in the field of AODDPs. One example of its predecessor and has raised the bar for performance and

where these ideas have found a home—as we’ve seen in the efficiency across the entire industry.

first two installments of this series—is All-Flo’s A200 pump. Please reference the prior installments if you need a

The A200 stands apart from other AODDPs on the market. refresher, but for your convenience, here’s a reminder of

As you read this month’s article, the importance of choosing the primary takeaway: All-Flo seriously advanced pump

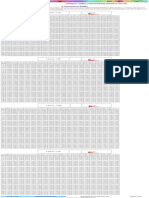

Discharge Flow - Liters/Min.

Pressure Inlet/Outlet PSIG (Bars)

Total Head in Feet (Meters)

Discharge Flow - U.S. Gals./Min.

Figure 7

About The Author

Paul McGarry is the All-Flo sales and marketing manager for North America. To learn more, visit www.all-flo.com, and

www.aoddpumpefficiency.com.

26 | JUNE 2014 www.modernpumpingtoday.com

performance and efficiency with

Redesigned Original

the A200. This was achieved by Pumps Pump Model

Brand A Brand B Brand C Brand D

reducing and optimizing dead

space on the liquid and air Required air pressure (psi) 90 82 81 100 120 97

sides of the diaphragms and by Required SCFM 70 122 108 135 125 175

improving the timing of the main

air valve. $ Per hour $0.91 $1.59 $1.41 $1.76 $1.63 $2.28

$ Per 8-hour day $7.31 $12.71 $11.28 $14.10 $13.06 $18.28

SETTING THE

$ Per five-day week

COMPARISON CRITERIA (8 hours per day)

$36.55 $63.71 $56.40 $70.50 $65.28 $91.39

To get a fair apples-to-apples

comparison underway, we $ Per year (52 weeks) $1,901 $3,313 $2,933 $3,666 $3,394 $4,752

will start with some specific

assumptions. First, the Table 1: The operating requirements of the redesigned A200 AODDP and other pumps.

application scenario. For our

purposes, we are going to

suppose that the AODDP being evaluated needs to transfer All-Flo customers run four hundred pumps or more at any

8000 gallons (30,283.29 liters) of liquid every hour, for eight given time, so imagine extending these savings across an

hours a day, over the course of a year. It will do this with a entire operation! You don’t have to be a mathematician to

liquid discharge pressure of 20 PSI. Second, 8000 gallons understand that those kinds of numbers can dramatically

(30,283.29 liters) per hour is equivalent to a flow rate of 133 impact a company’s bottom line. That’s why it’s so important

gallons (503.46 liters) per minute. This means that the pump to know exactly what you’re getting into—exactly what

in our example operates at 133 gallons (503.46 liters) per you’re getting for your AODDP investment—before you make

minute against a discharge pressure of 20 PSI. a purchasing decision. The numbers don’t lie.

Using the performance curve shown in figure 7, we can

find out how much air is required to run the pump. Simply COMING UP

find 133 gallons (503.46 liters) per minute on the horizontal In our next, and final, article in this series, we will discuss

axis and then look to see where that value intersects with how to make sure you get the ideal AODDP for your needs.

20 PSI on the vertical axis. You can see that they meet We’ll clue you in on what to look for when evaluating

between the two blue lines that represent 80 and 100 PSI. AODDP performance and give you the right questions to ask

This means that the required operating pressure is around 90 pump manufacturers. Q

PSI. The intersection point also lies between the red lines that

represent 60 and 80 SCFM. This tells us that we can estimate

the air consumed by the pump to be 70 SCFM.

WHAT DOES THIS MEAN?

To put it all together to calculate operating costs, we use the

following equations:

70 SCFM x 1 hp/4 SCFM = 17.5 hp

17.5 hp x 0.746 kW/hp = 13.06 kW

13.06 kW x $0.07/kWh = $0.91 per hour

As you can see, in our example, this particular pump can

transfer 8000 gallons (30,283.29 liters) per hour at a cost

of $0.91 per hour. This makes the extended annual cost

somewhere in the neighborhood of $1900.

ONE OF THESE PUMPS IS NOT LIKE THE OTHERS

The impressive pump performance used in the previous

example belongs to All-Flo’s A200. In Table 1, we’ve put

those numbers (found under A200 Redesigned Pumps)

up against the operating costs of the A200’s own All-Flo

predecessor (Legacy Pump Model) as well as AODDPs

currently sold by other manufacturers. As you can see, the

A200 beats the competition in every single category.

Sure, the differences in operating costs demonstrated here

are stark, but remember—this is just for one pump. Some

www.modernpumpingtoday.com JUNE 2014 | 27

You might also like

- Consulting Service Proposal TemplateDocument12 pagesConsulting Service Proposal TemplateAmos Korme50% (2)

- API 692 Seal Gas Filters & SeparatorsDocument4 pagesAPI 692 Seal Gas Filters & SeparatorsTasawwur Tahir100% (1)

- PSM 30 6 Pool Hydraulics 101Document3 pagesPSM 30 6 Pool Hydraulics 101dassagraNo ratings yet

- Odoo HR PDFDocument17 pagesOdoo HR PDFRejoy Radhakrishnan100% (1)

- A Revolution in Pumping Efficiency Part 2Document4 pagesA Revolution in Pumping Efficiency Part 2Tasawwur TahirNo ratings yet

- A Revolution in Pumping Efficiency Part 1Document2 pagesA Revolution in Pumping Efficiency Part 1Tasawwur TahirNo ratings yet

- Centrifugal Pump EfficiencyDocument3 pagesCentrifugal Pump EfficiencyAlfredo GallardoNo ratings yet

- Pump CurvesDocument8 pagesPump CurvesKrishna Chaitanya Kalaga100% (1)

- How Read Pump CurvesDocument5 pagesHow Read Pump CurvesmohamedNo ratings yet

- BBA Pumps North America - Pump Cost Saving TipsDocument5 pagesBBA Pumps North America - Pump Cost Saving TipsMarcosNo ratings yet

- AODD Pumps in Chemical ProcessesDocument7 pagesAODD Pumps in Chemical ProcessesAlexNo ratings yet

- Pumps CurvesDocument14 pagesPumps CurvesAhmedNo ratings yet

- Pool Pump CalculatorDocument6 pagesPool Pump CalculatorEppNo ratings yet

- Kuntz 1600Document5 pagesKuntz 1600karan aggarwalNo ratings yet

- Pumps Vs Agitators For Tank Mixing Classic Case of CAPEX Vs OPEX White PaperDocument5 pagesPumps Vs Agitators For Tank Mixing Classic Case of CAPEX Vs OPEX White PaperJesse Haney IIINo ratings yet

- Pump-Flo Method of SolutionDocument21 pagesPump-Flo Method of SolutionMaría Nieves García MartínezNo ratings yet

- Pumps Vs AgitatorAsd F DsfsDocument5 pagesPumps Vs AgitatorAsd F DsfsMARK LESTER REALNo ratings yet

- Asaddff: Pumps vs. Agitators For Tank Mixing, Classic Case of CAPEX Vs OPEX: White PaperaDocument5 pagesAsaddff: Pumps vs. Agitators For Tank Mixing, Classic Case of CAPEX Vs OPEX: White PaperaMARK LESTER REALNo ratings yet

- Pumps Vs AgitatorAsdds FDSFSDDocument5 pagesPumps Vs AgitatorAsdds FDSFSDMARK LESTER REALNo ratings yet

- Design Pumping StationsDocument5 pagesDesign Pumping Stationsnksuthar5399No ratings yet

- Tips For Correct Pump SelectionDocument2 pagesTips For Correct Pump Selectionfawmer61No ratings yet

- ALL AMN ALL en 1812 ALL Newsletter11 CAGIDatasheetDocument10 pagesALL AMN ALL en 1812 ALL Newsletter11 CAGIDatasheetCursed RonyNo ratings yet

- Pumps Vs AgitatorAsdf DsfdsDocument5 pagesPumps Vs AgitatorAsdf DsfdsMARK LESTER REALNo ratings yet

- Pump ED 101: How Curve Shape Can Influence Pump SelectionDocument5 pagesPump ED 101: How Curve Shape Can Influence Pump Selectionmercedes_rico_5No ratings yet

- Suction Specific Speed (Why Worry)Document8 pagesSuction Specific Speed (Why Worry)Tasawwur TahirNo ratings yet

- Yamada APDD Eng Handbk PDFDocument152 pagesYamada APDD Eng Handbk PDFAnas BENCHIKHNo ratings yet

- How To Read A Pump Curve PDFDocument24 pagesHow To Read A Pump Curve PDFbennylivi100% (5)

- Calculate N.P.S.H.ADocument9 pagesCalculate N.P.S.H.AkichasNo ratings yet

- 1Document28 pages1Enrique MurgiaNo ratings yet

- Industrial Water Supply.: Table of ContentDocument9 pagesIndustrial Water Supply.: Table of ContentDuan YuNo ratings yet

- How To Read Pump CurveDocument4 pagesHow To Read Pump CurvenghiemvhNo ratings yet

- ANSI Vs API Pumps - What's The DifferenceDocument4 pagesANSI Vs API Pumps - What's The Differencearunima04No ratings yet

- Pump Flow - TestDocument4 pagesPump Flow - TestmoammerNo ratings yet

- Visual Pump GlossaryDocument67 pagesVisual Pump GlossaryLorino BaldezamoNo ratings yet

- Tech Brief 2013 - Reading Centrifugal Pump Curves PDFDocument5 pagesTech Brief 2013 - Reading Centrifugal Pump Curves PDFFawaaz KhurwolahNo ratings yet

- Tech Brief Pump Curves PDFDocument5 pagesTech Brief Pump Curves PDFThomas KamongNo ratings yet

- System Curves-Pump CurvesDocument87 pagesSystem Curves-Pump CurvesChandaKunda100% (1)

- Internship Report NestleDocument30 pagesInternship Report NestleAli RazaNo ratings yet

- Pump BasicsDocument72 pagesPump BasicsVineeth Vs100% (1)

- Research Paper On PumpsDocument4 pagesResearch Paper On Pumpsnikuvivakuv3100% (1)

- The Pumps CurvesDocument13 pagesThe Pumps Curvesمعلومة اسلاميةNo ratings yet

- Navigating Pump CurvesDocument7 pagesNavigating Pump Curvescastingforge4875100% (1)

- Efficiencies in PumpsDocument5 pagesEfficiencies in PumpsgulfengsolutionsNo ratings yet

- Katalog MULTISTAGE - ANG MinDocument44 pagesKatalog MULTISTAGE - ANG MinTaimoorNo ratings yet

- Pump Curve UnderstandingDocument7 pagesPump Curve UnderstandingViệt Đặng Xuân100% (1)

- YAMADA AODD Engineering Handbook PDFDocument152 pagesYAMADA AODD Engineering Handbook PDFAnonymous dGzE1FUSTLNo ratings yet

- Pumps Best Practice ToolsDocument9 pagesPumps Best Practice Toolspm2013100% (1)

- Fountain Pump Tutorial PDFDocument7 pagesFountain Pump Tutorial PDFLorino BaldezamoNo ratings yet

- How To Read A Pump CurveDocument3 pagesHow To Read A Pump CurvemetropumpsNo ratings yet

- Eta SeriesDocument16 pagesEta SeriesjoejumbooNo ratings yet

- A Step-by-Step Approach To Pump Selection Pumps & SystemsDocument6 pagesA Step-by-Step Approach To Pump Selection Pumps & SystemsABRAHAM ESTRADANo ratings yet

- How to Read a Pump CurveDocument6 pagesHow to Read a Pump CurvetayeloluNo ratings yet

- Fluid Handling: Identifying The TRUE Cost Savings of Variable Speed Pumping SystemsDocument2 pagesFluid Handling: Identifying The TRUE Cost Savings of Variable Speed Pumping SystemsPallab MukherjeeNo ratings yet

- FlowLabEOC2e CH14Document2 pagesFlowLabEOC2e CH14Nathan100% (1)

- Amarinth Technical Bulletin Guidance For Completing Fluid Properties On An Api 610 Datasheet To Ensure The Most Suitable Pump SelectionDocument5 pagesAmarinth Technical Bulletin Guidance For Completing Fluid Properties On An Api 610 Datasheet To Ensure The Most Suitable Pump Selectionyou kackNo ratings yet

- As D CalculatorsDocument14 pagesAs D CalculatorsPatricio TamayoNo ratings yet

- LUF617 - DW - 8Hx11 - F Gas WellDocument10 pagesLUF617 - DW - 8Hx11 - F Gas WellJosé TimanáNo ratings yet

- Introduction To Plunger Lift: Prepared For: SPE Queensland BrisbaneDocument64 pagesIntroduction To Plunger Lift: Prepared For: SPE Queensland BrisbanePedro Antonio Mejia SuarezNo ratings yet

- Reading The Pump Curve - Intro To PumpsDocument4 pagesReading The Pump Curve - Intro To PumpsVIVANo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowRating: 2 out of 5 stars2/5 (1)

- Cost & Managerial Accounting II EssentialsFrom EverandCost & Managerial Accounting II EssentialsRating: 4 out of 5 stars4/5 (1)

- Catalog For ABB Motors Acc To AU MEPS - 05-2014 - LOWDocument128 pagesCatalog For ABB Motors Acc To AU MEPS - 05-2014 - LOWTasawwur TahirNo ratings yet

- API 682 Seal Selection Process FinalDocument28 pagesAPI 682 Seal Selection Process FinalTasawwur Tahir100% (1)

- Case Study - Petronas Single Mechanical Seal Pump UpgradeDocument2 pagesCase Study - Petronas Single Mechanical Seal Pump UpgradeTasawwur Tahir100% (1)

- Case Study - Sealless Pumps For Schwarz PharmaDocument1 pageCase Study - Sealless Pumps For Schwarz PharmaTasawwur TahirNo ratings yet

- Beyond Reach: HMD KontroDocument1 pageBeyond Reach: HMD KontroTasawwur TahirNo ratings yet

- Case Study - Magnetic Drive Pumps For Scrubbing ServiceDocument1 pageCase Study - Magnetic Drive Pumps For Scrubbing ServiceTasawwur TahirNo ratings yet

- PD Cen TR 13932-2009Document28 pagesPD Cen TR 13932-2009Tasawwur TahirNo ratings yet

- Mediciones CEMS - ZZ-025-0802EDocument4 pagesMediciones CEMS - ZZ-025-0802EdcarunchioNo ratings yet

- Tootekataloog EngDocument8 pagesTootekataloog EngGonçalo FerreiraNo ratings yet

- Training and Development Practices in Bangladesh (HR Report)Document23 pagesTraining and Development Practices in Bangladesh (HR Report)nafisahmednazim44% (9)

- D7G 92VDocument184 pagesD7G 92Valexander100% (3)

- Pinjra 1Document4 pagesPinjra 1azharNo ratings yet

- Case Study 1Document12 pagesCase Study 1Mujtaba Ali100% (2)

- Motor StandardsDocument17 pagesMotor Standardskodandaram100% (4)

- Business Model CanvasDocument1 pageBusiness Model Canvasigosnell7948No ratings yet

- Moodle Basic ThermodynamicsDocument14 pagesMoodle Basic ThermodynamicsArpan BiswasNo ratings yet

- Mmmmmetro Electrical VariationDocument80 pagesMmmmmetro Electrical VariationchristianNo ratings yet

- Synchro Check A216 220KV - D09Document4 pagesSynchro Check A216 220KV - D09m khNo ratings yet

- Dewa Gede Sidan Magna Dinata - 04211840000011 - Latihan SoalDocument4 pagesDewa Gede Sidan Magna Dinata - 04211840000011 - Latihan SoalSidan MagnaNo ratings yet

- F-Distribution TablesDocument1 pageF-Distribution TablesSafira AliNo ratings yet

- Telemanagement Forum (TMF) Ngoss and EtomDocument25 pagesTelemanagement Forum (TMF) Ngoss and EtomkuvvetliNo ratings yet

- Unit 1 Sustainable Development: Concept and Scope: StmctureDocument18 pagesUnit 1 Sustainable Development: Concept and Scope: StmctureAnonymous xvwInTdk7QNo ratings yet

- Service Manual Clamp Cascade PDFDocument28 pagesService Manual Clamp Cascade PDFFelipe Molina DiazNo ratings yet

- Selection Tools: Move Tool Rectangular Marquee Elliptical Marquee Single Column Marquee The Single Row MarqueeDocument10 pagesSelection Tools: Move Tool Rectangular Marquee Elliptical Marquee Single Column Marquee The Single Row MarqueePeralta Marilao Justine BryanNo ratings yet

- Datasheet LA1805 (AM-FM-IF-MPX Tuner System)Document13 pagesDatasheet LA1805 (AM-FM-IF-MPX Tuner System)vanmarteNo ratings yet

- GCV405-RCII-Chapter 12 - Introduction To Seismic Design - Norms and StandardsDocument3 pagesGCV405-RCII-Chapter 12 - Introduction To Seismic Design - Norms and StandardsOec EngNo ratings yet

- 1) SCP-200-460-HA (280kw, 4 Pole) Data SheetDocument6 pages1) SCP-200-460-HA (280kw, 4 Pole) Data Sheetنايفف بن عبداللهNo ratings yet

- Arm Amba AhbDocument18 pagesArm Amba AhbgeethaNo ratings yet

- Voltage References and Biasing: KT/Q, For Example) - Similarly, Any Current We Produce Must Depend On Parameters ThatDocument15 pagesVoltage References and Biasing: KT/Q, For Example) - Similarly, Any Current We Produce Must Depend On Parameters ThatmaheshsamanapallyNo ratings yet

- Catalogo de Consumibles HTADocument13 pagesCatalogo de Consumibles HTAAlexander Nieto VelaNo ratings yet

- Product Name Seeded Paper Packet: DescriptionDocument16 pagesProduct Name Seeded Paper Packet: DescriptionshowmelocalNo ratings yet

- ASME B36.19M-2004 (R2010) - UnlockDocument14 pagesASME B36.19M-2004 (R2010) - UnlockadprimNo ratings yet

- Overfill Training Presentation March 2015 PDFDocument39 pagesOverfill Training Presentation March 2015 PDFLucas CandidoNo ratings yet

- KF-Butterfly Hale & BG SeriesDocument8 pagesKF-Butterfly Hale & BG SeriesKasthuri Rangan KNo ratings yet

- High Altitude Bell 47Document14 pagesHigh Altitude Bell 47Sesquipedaliac100% (1)